Electronics design

Things that went wrong:

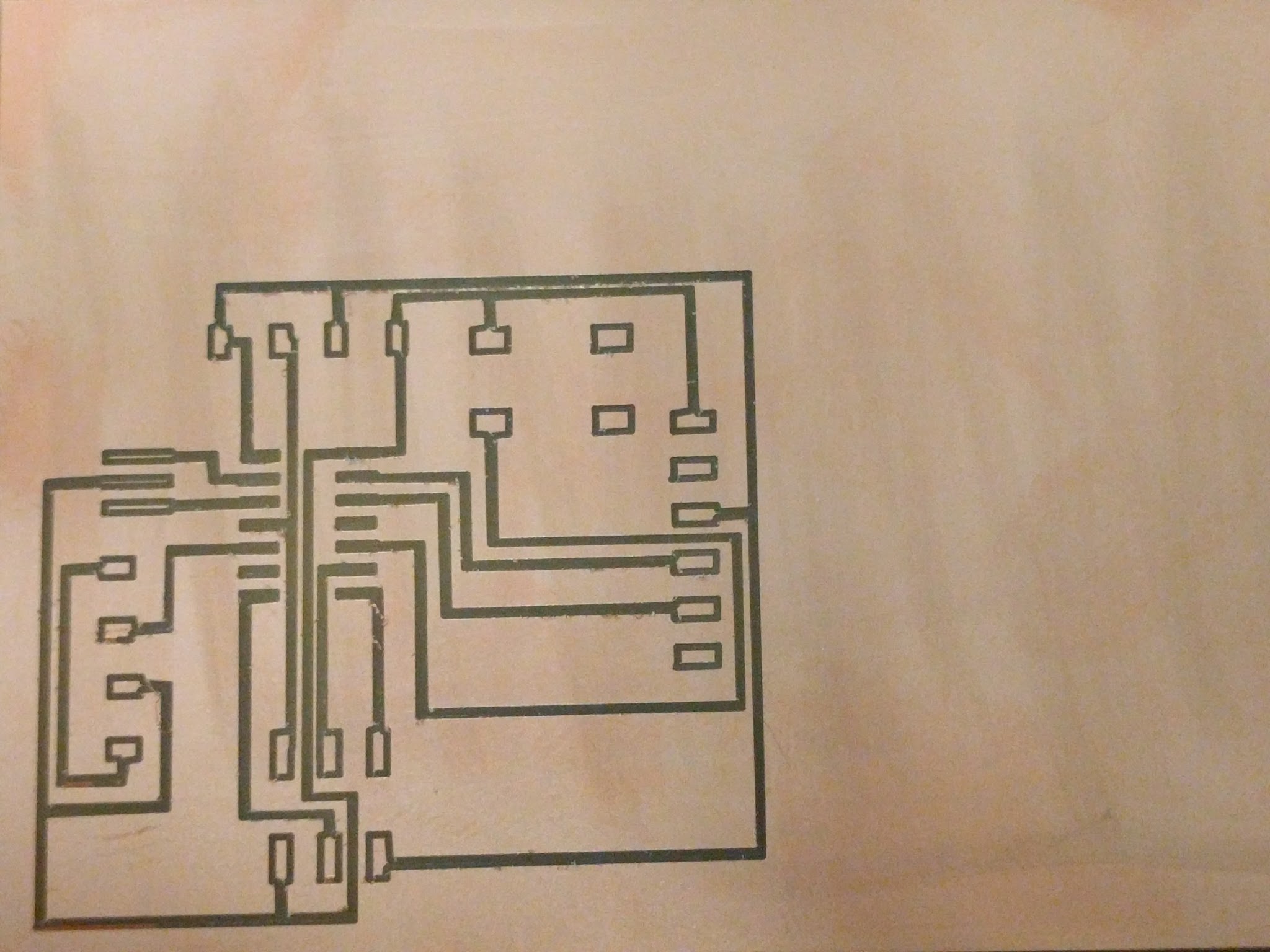

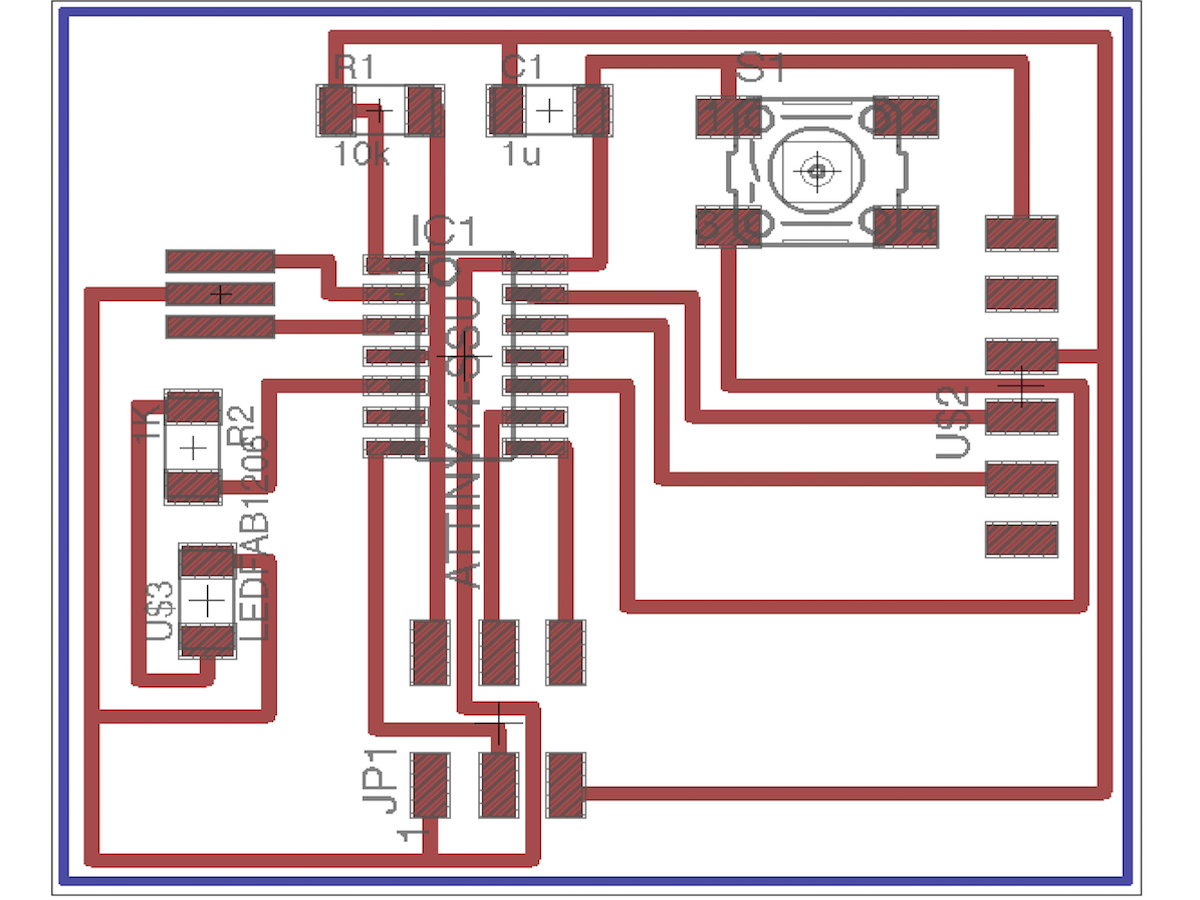

- We forgot to invert the images as we were printing on the modela, so our traces were super thin and we couldn't figure out why. Fortunately, Grace saw one of my boards and noticed that we were cutting the traces, instead of avoiding to cut the traces. This is because our traces were black, which represents a lower height. Once we inverted the colors, the milling worked well! I was almost about to give up on the machine as we had spent more than 4 hours milling the boards. I have a bad history withthe machine.

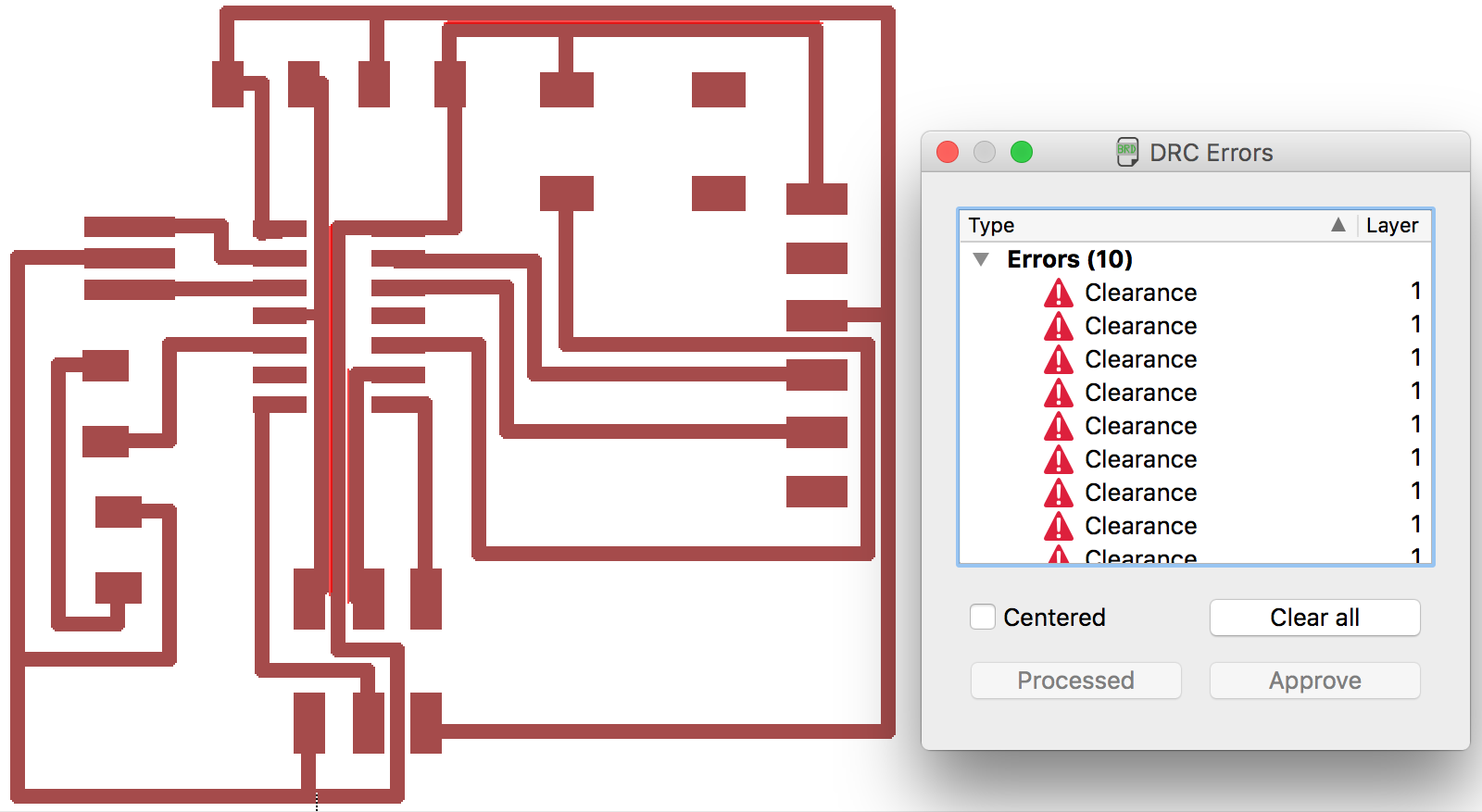

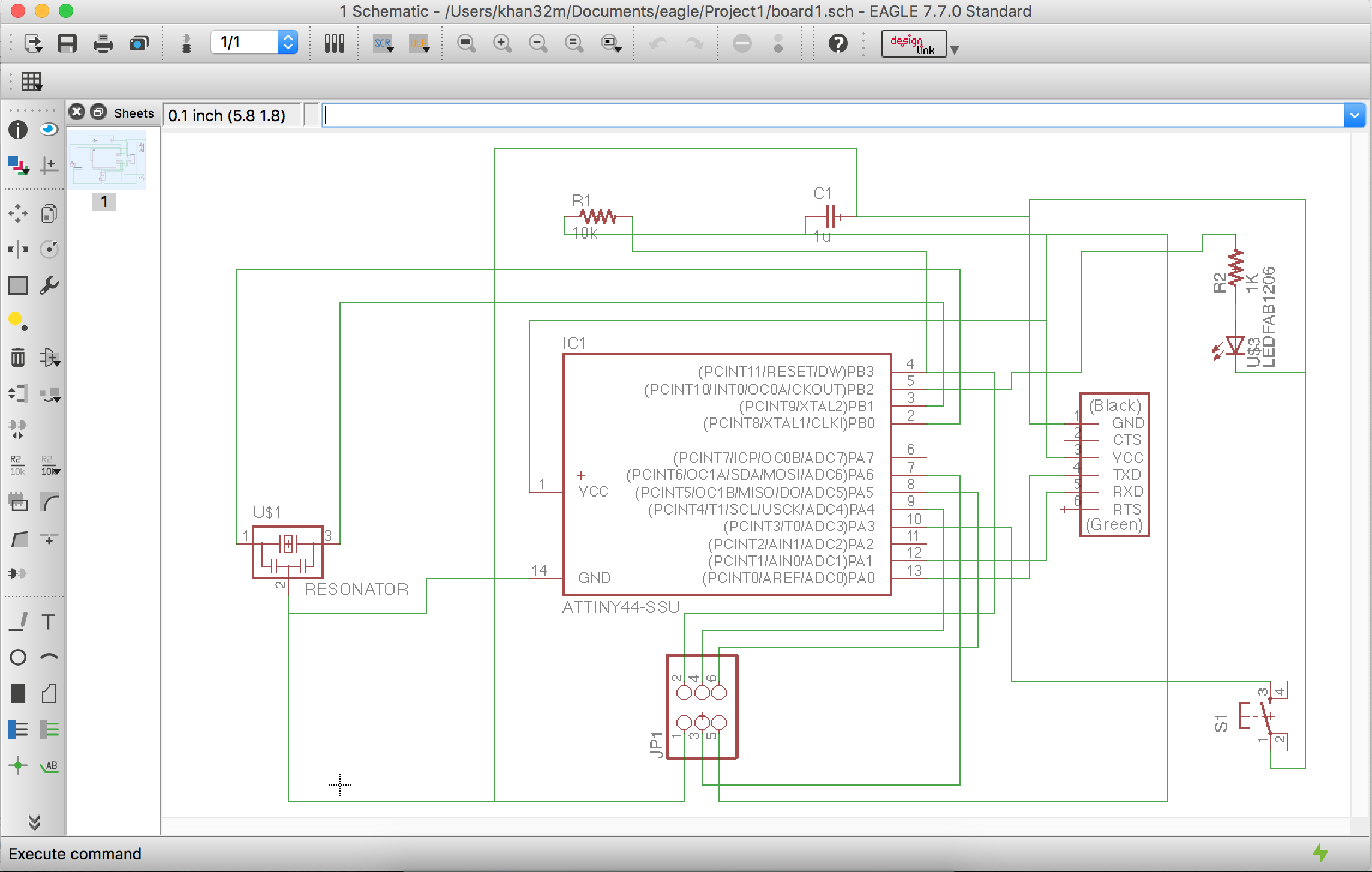

- We tried to make the wires thicker in the circuit design because the traces were too thin from the first problem where we forgot to invert the image. But then there wasn't enough space between the wires when the wires were thicker and I had errors in Eagle.

- We tried auto-routing after trying to route our boards manually and finding out that they were difficult to route. But then Grace told us that auto routing isn't recommended for simpler boards and it was possible to route our boards manually.

Things that went great:

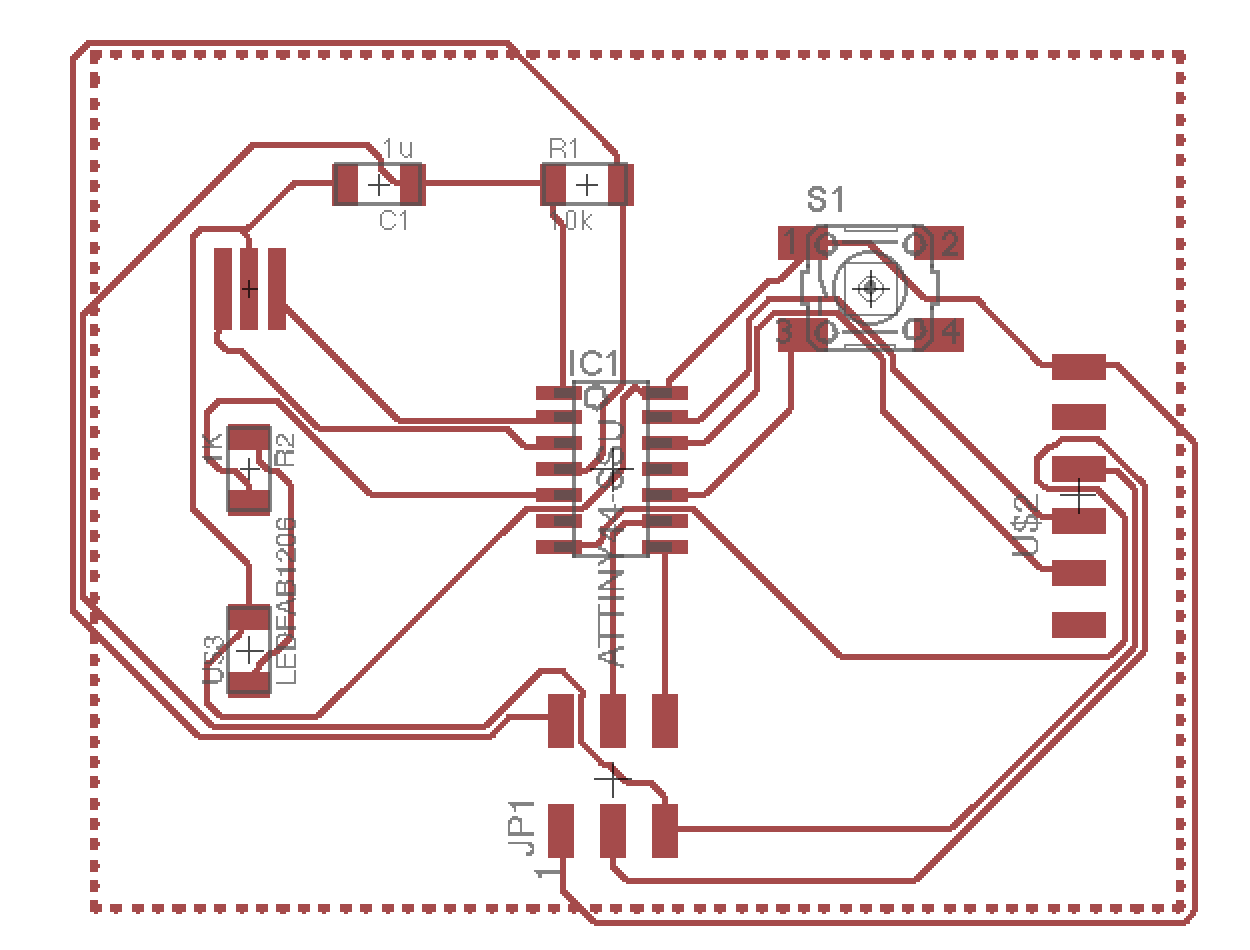

- We designed the schema correctly pretty fast

- We did manual routing correctly.

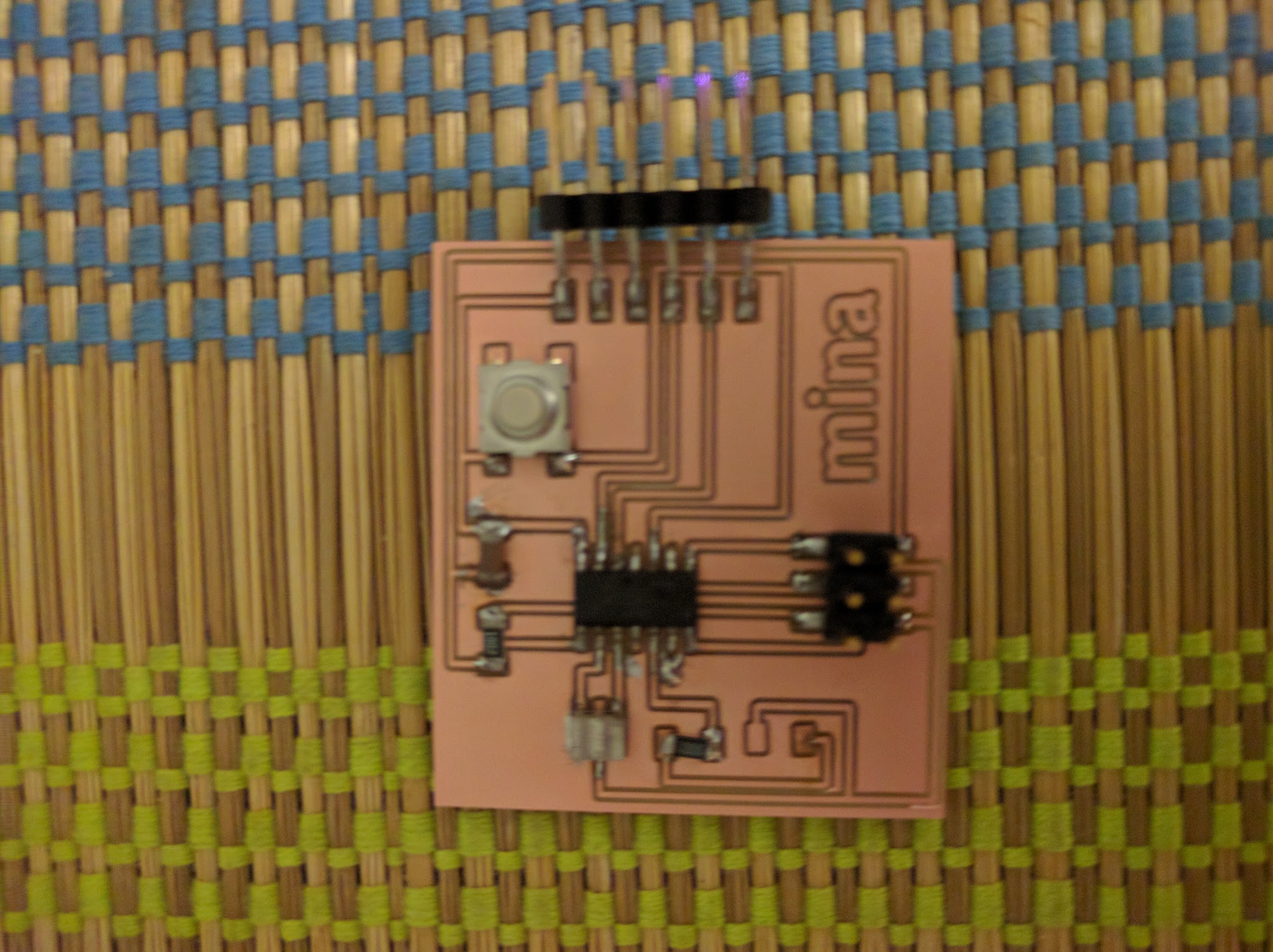

- We inverted the image and got the board to mill correctly