Final Project

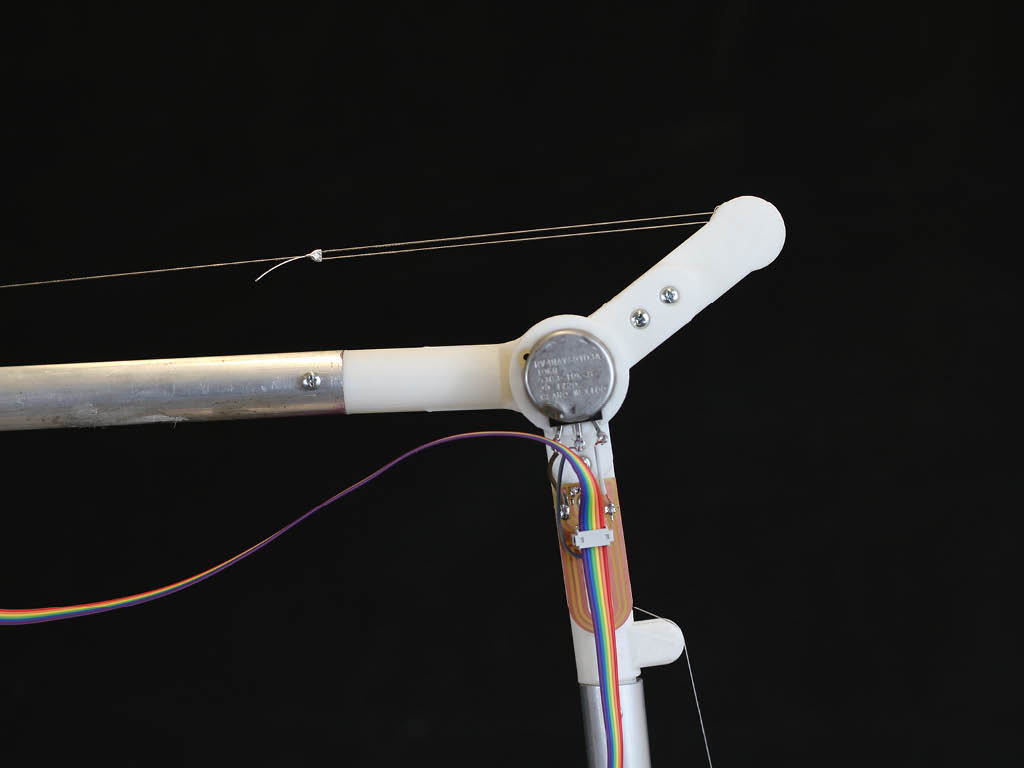

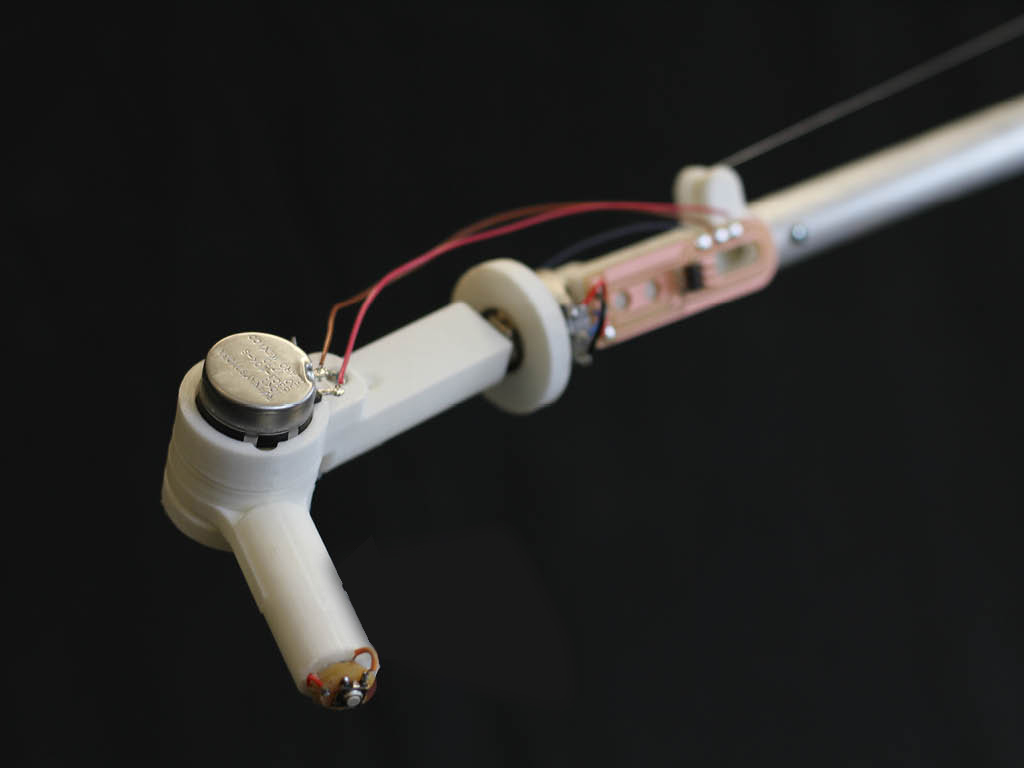

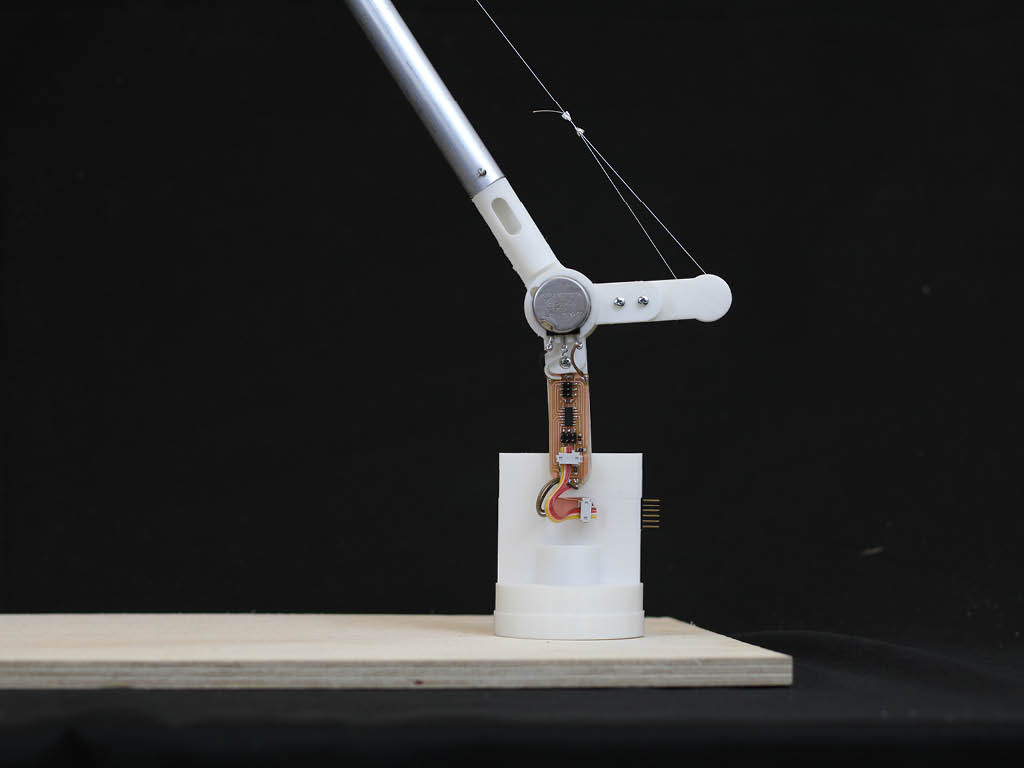

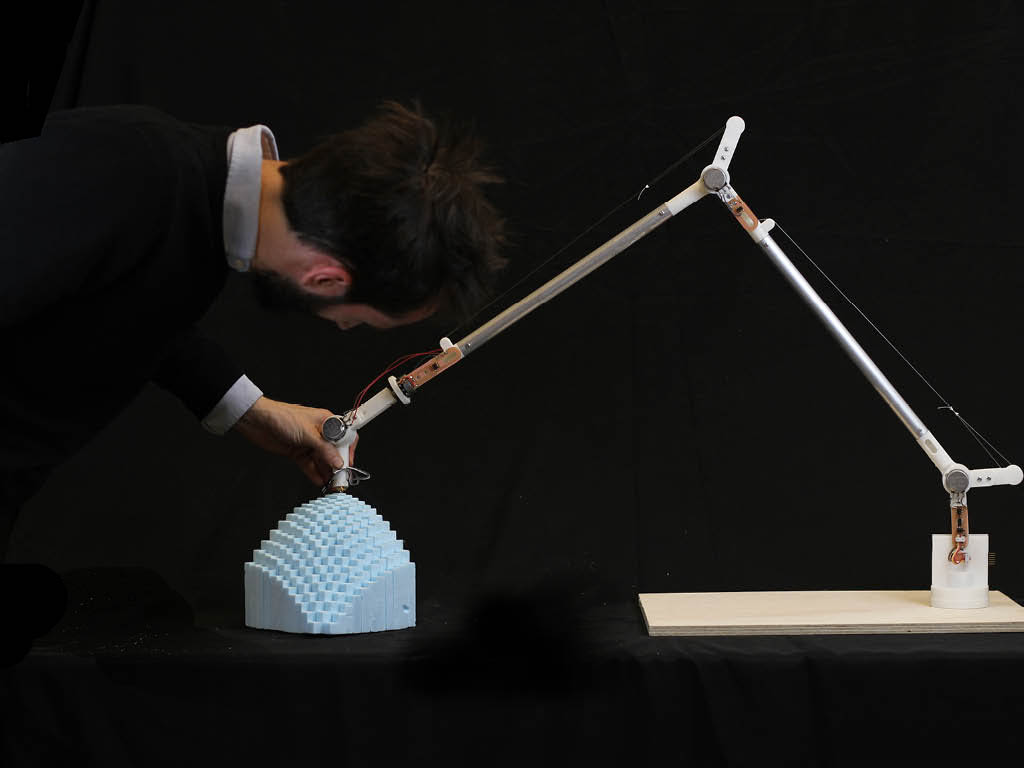

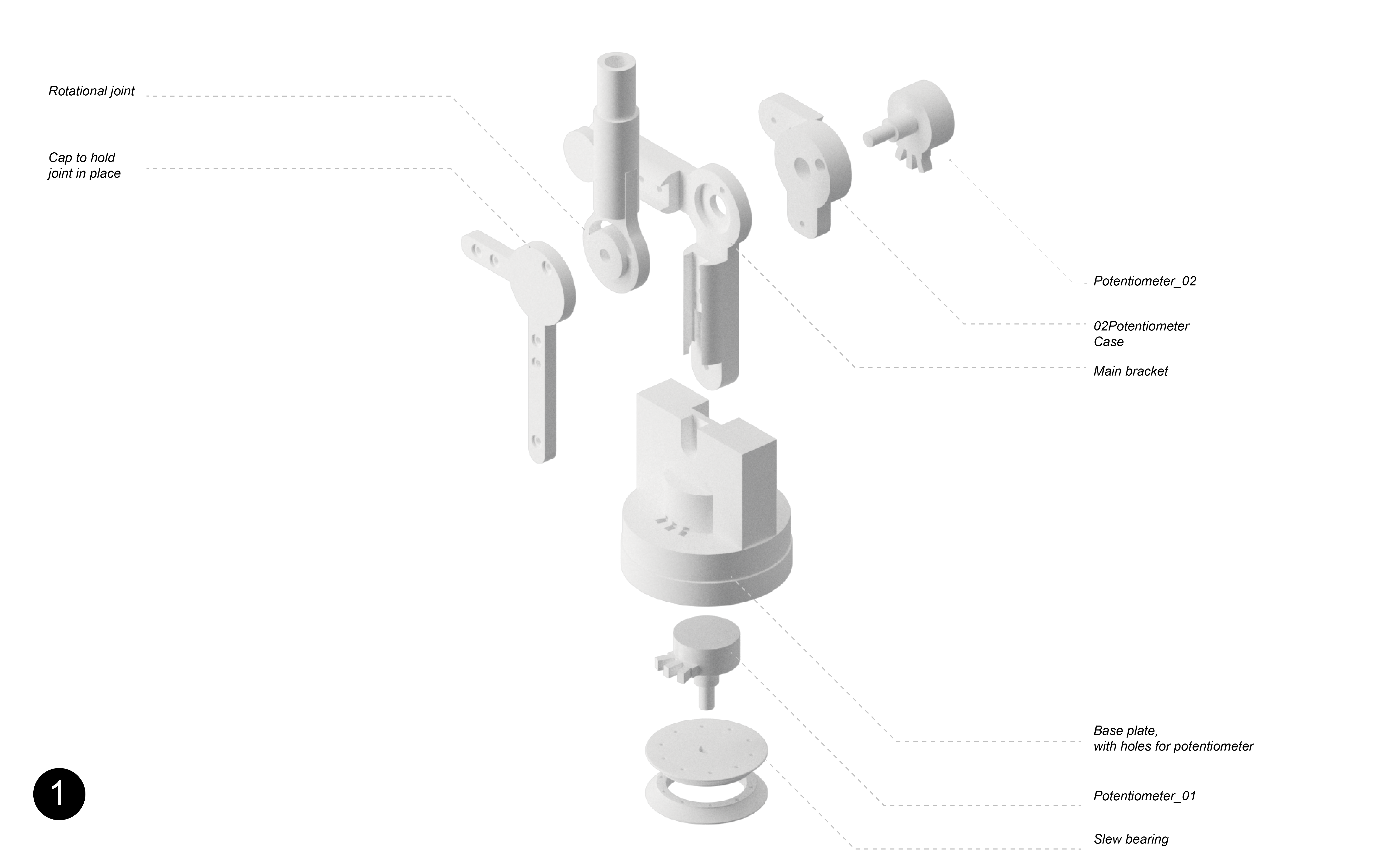

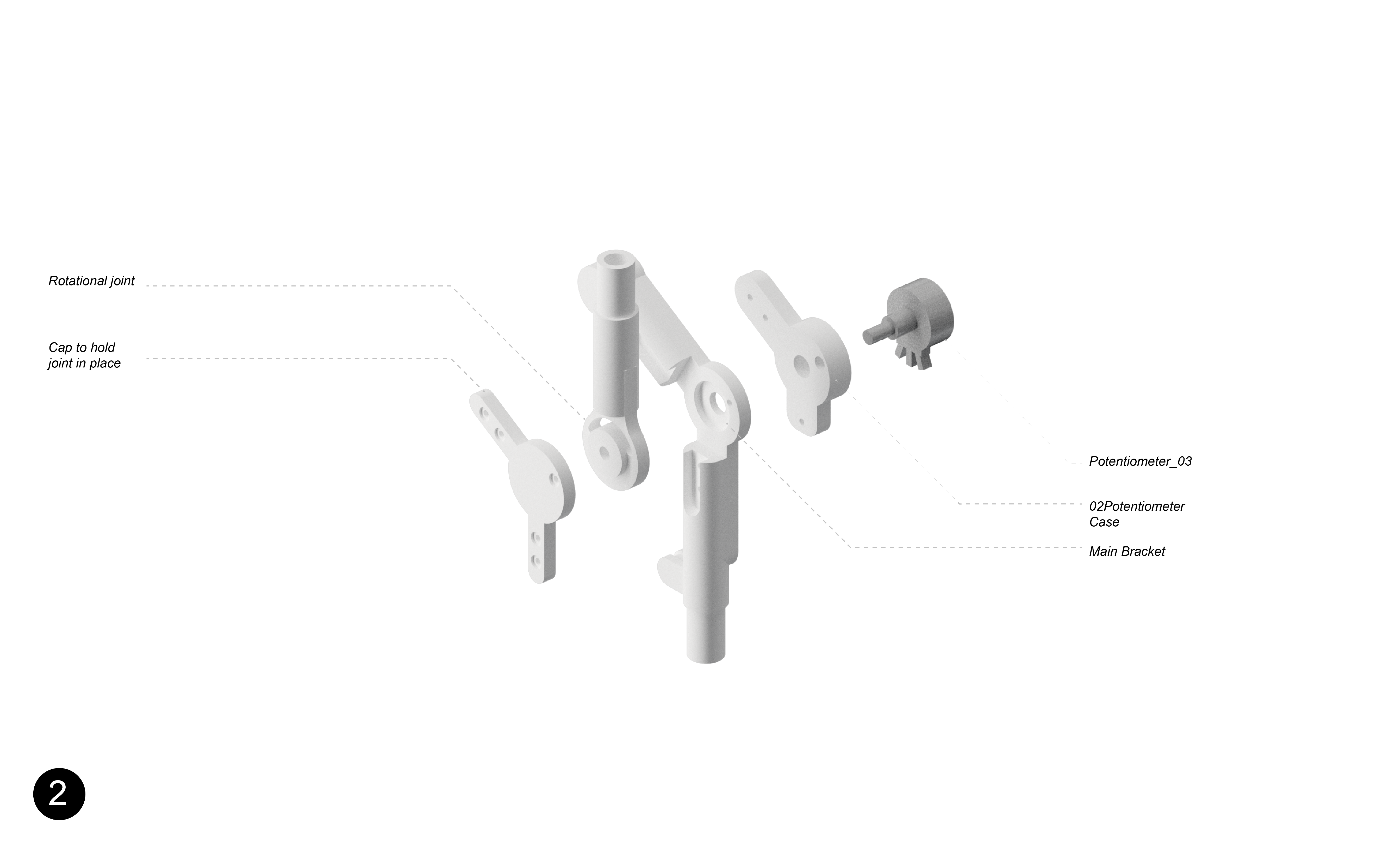

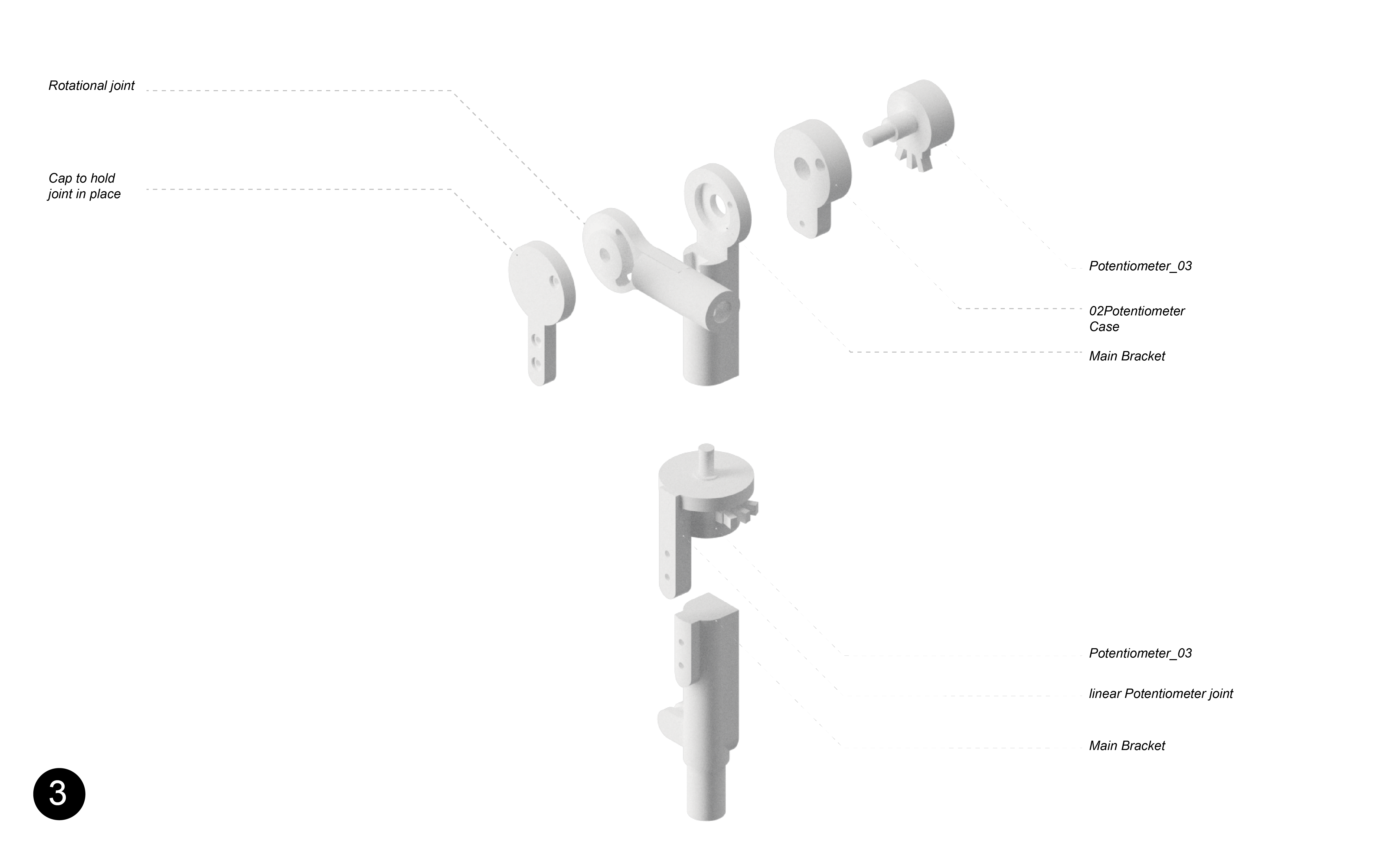

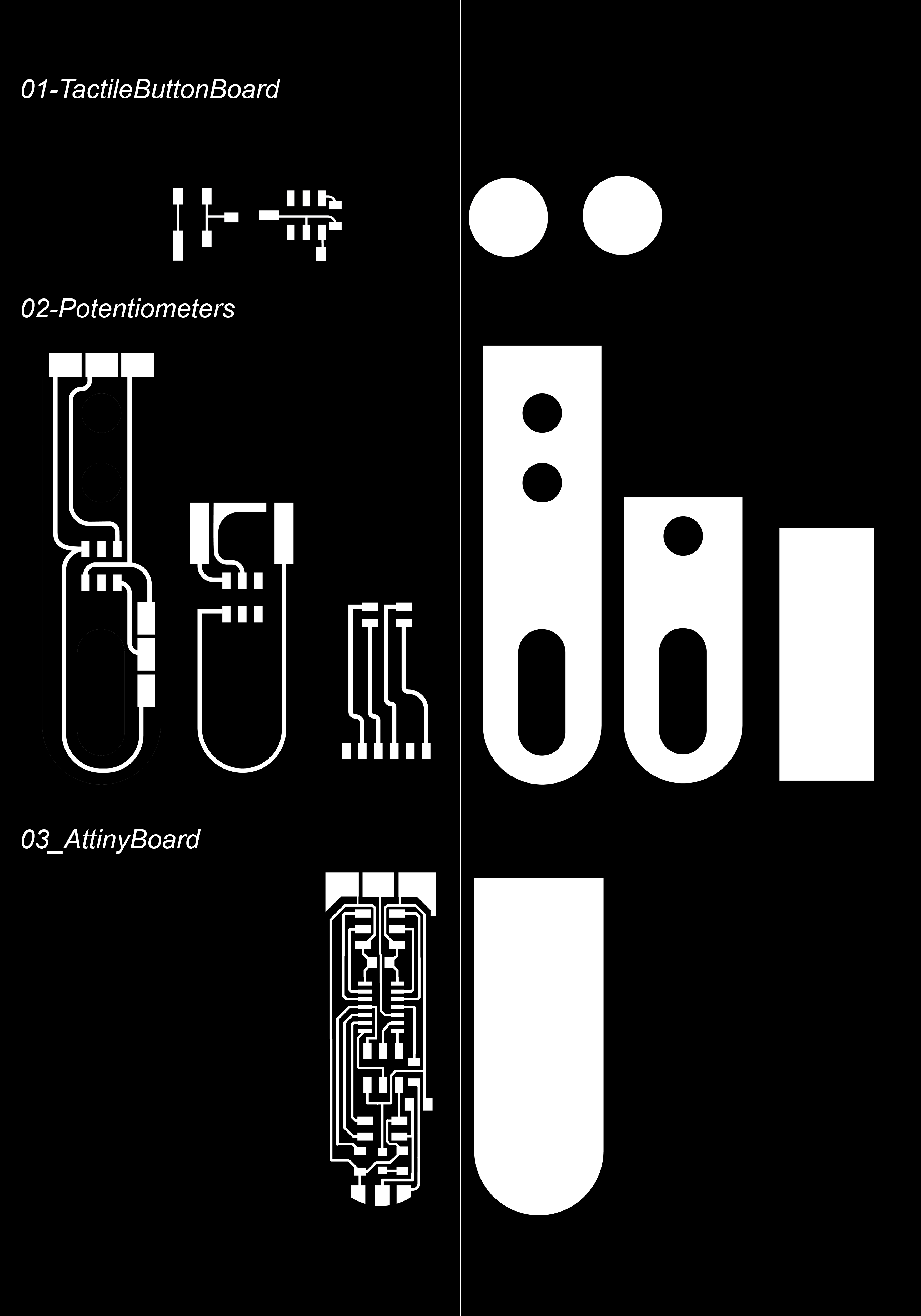

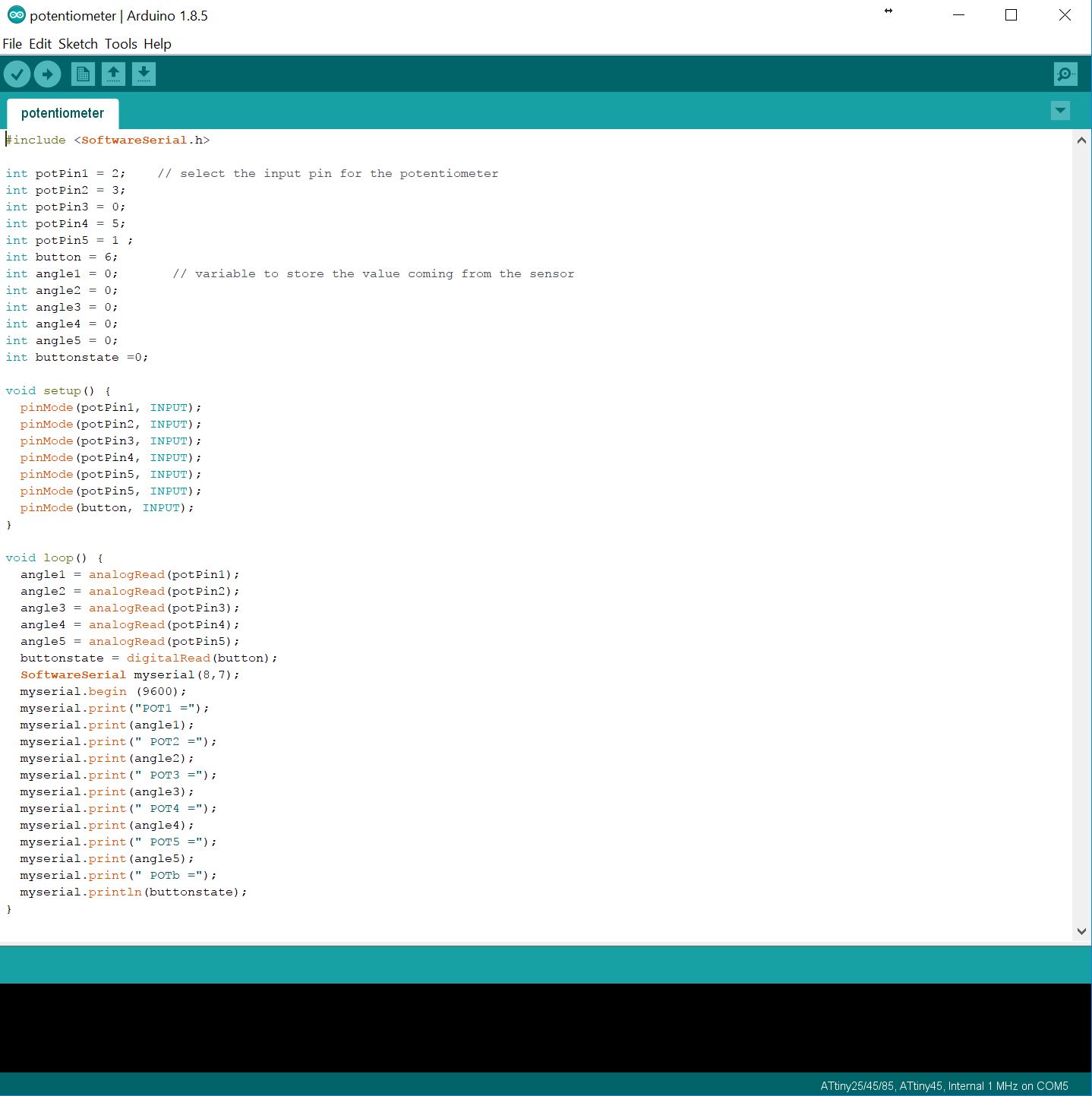

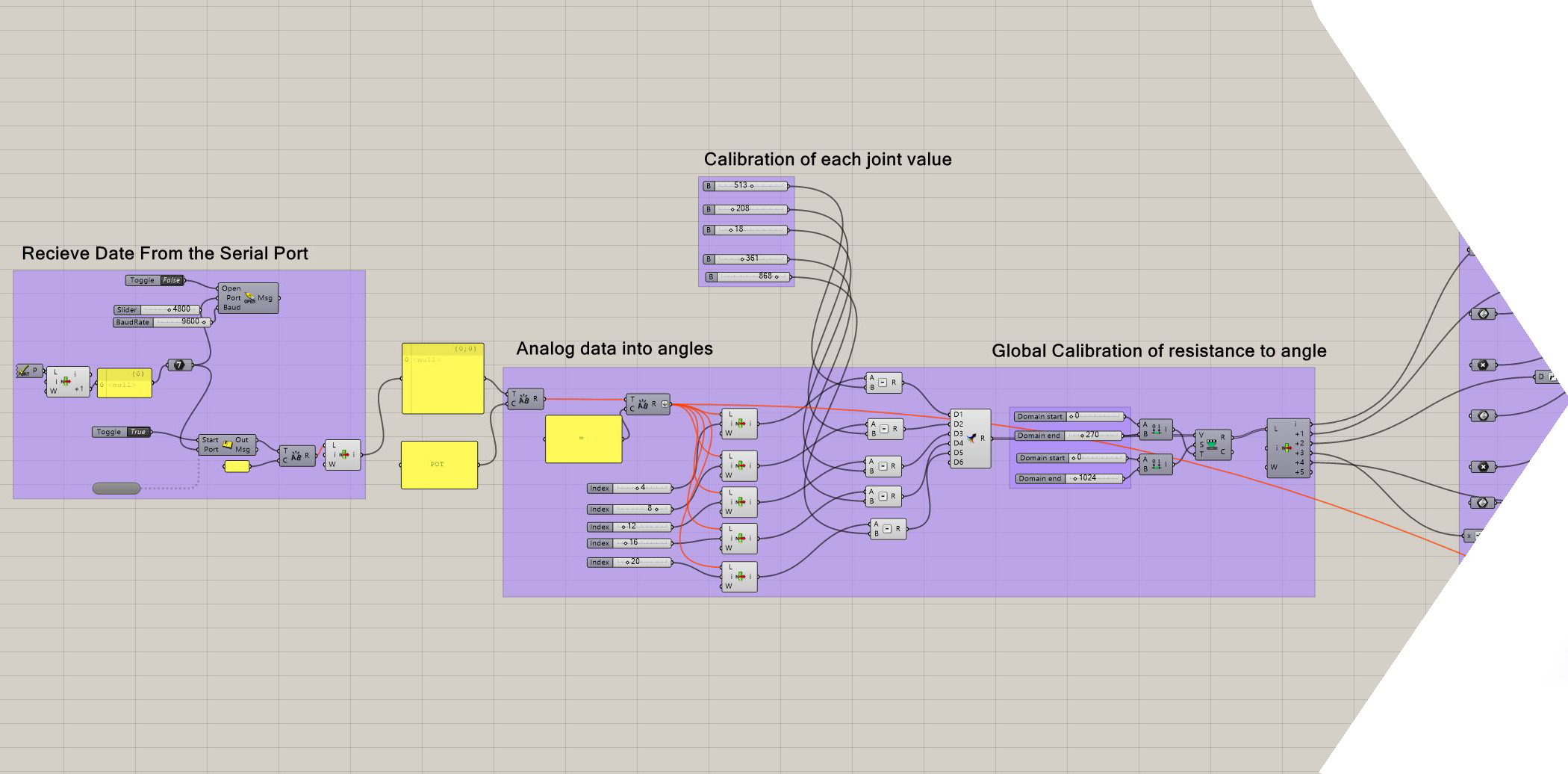

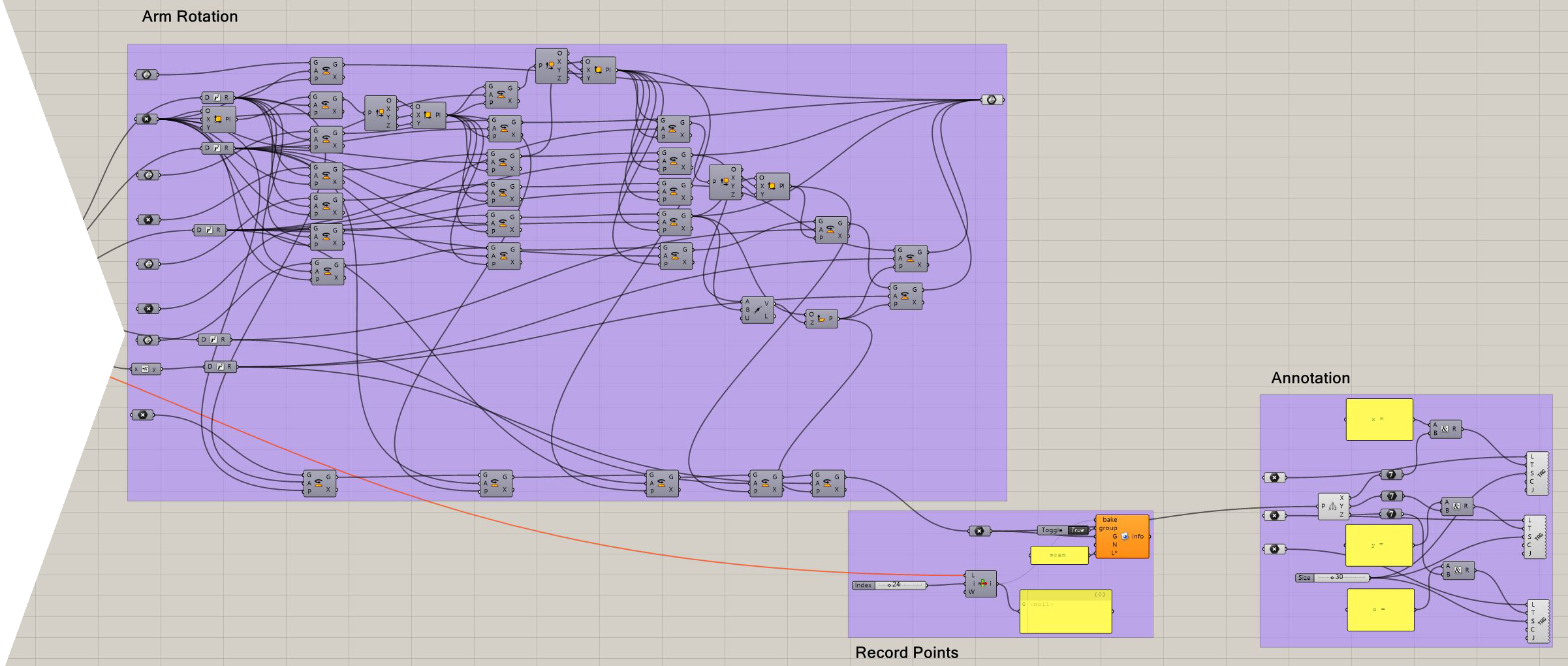

For my how to recycle almost anything final project I am making a digitizing arm. In the spirit of circular development, my first 'loop' is to make an arm, then a digitizing button, and then a lazer distance measuring device. For now I am focusing on the design of the arm. The project is a variation on Will Langford's Handheld CNC arm, and other homemade arms. This project began with an attempt to create a rotational capacitive sensors, but ultimatly I couldn't make them work. This struggle is documented in weeks 10 and 11. I then invested time in creating a well integrated set of parts for some high precision honeywell 10k rotary potentiometers.

The base sits on a slew bearing, 3d printed on the Sindoh Wox. It runs smoothly but has the disadvantage of locking the potentiometer in place (making it hard to repair)

3d Printing is an ugly way to make things - but it does at least allow you to iterate. The 3D wox typically prints to 1/64 inch resolution, and through testing the output, i was able to calibrate the rotating joints to run smoothly. Being able to print allowed me to make changes to the design as I was producing it.

| Item | Quantity | Price | Vendor |

|---|---|---|---|

| Honeywel 10k Potentiometer | 5 | $10.20 | Amazon |

| ATtiny44 | 1 | $0.86 | Digi-Key |

| PIN HD (Male SMT RA 1x6) | 2 | $0.60 | Digi-Key |

| PIN HD (Male 2x2) | 5 | $0.52 | Digi-Key |

| PIN HD (Male 2x3) | 5 | $0.83 | Digi-Key |

| PIN HD (TH Male 1X3) | 2 | $0.66 | Digi-Key |

| CONN IDC SOCKET(Female 2x2) | 2 | $0.70 | Digi-Key |

| CONN IDC SOCKET(Female 2x3) | 4 | $0.80 | Digi-Key |

| LED 1206 | 1 | $0.34 | Digi-Key |

| Push Button | 1 | $1.06 | Digi-Key |

| Resistors - 10k | 2 | $0.10 | Digi-Key |

| Resistors - 0 Ohm | 2 | $0.10 | Digi-Key |

| Capacitors - 1uF | 1 | $0.25 | Digi-Key |

| 4-40 nuts - 1/2" | 20 | $0.07 | Blick |

| 4-40 bolts - 1/2" | 20 | $0.20 | Blick |

| 4ft ribbon cable 0.6gauge | 1 | $1.65 | Digi-Key |

| Total Cost | $74.83 | (Excluding Shipping) |