Assignment 1

01 - Collecting Material

Scan - Trace - Fit Geometry - Extract - Cut

I started the assignment by collecting scrap material from the Architecture Shop. I photographed this with my phone using a ruler for scale, and imported this into Rhino where I scaled and traced it. My photographs were a bit skewed, and so i gave myself a 0.25 inch inset boundary in case of distortion in photographs.

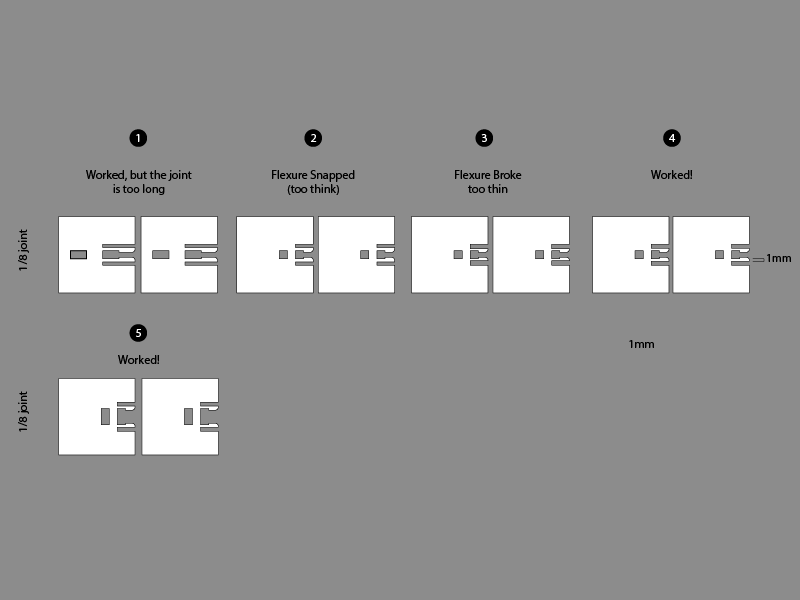

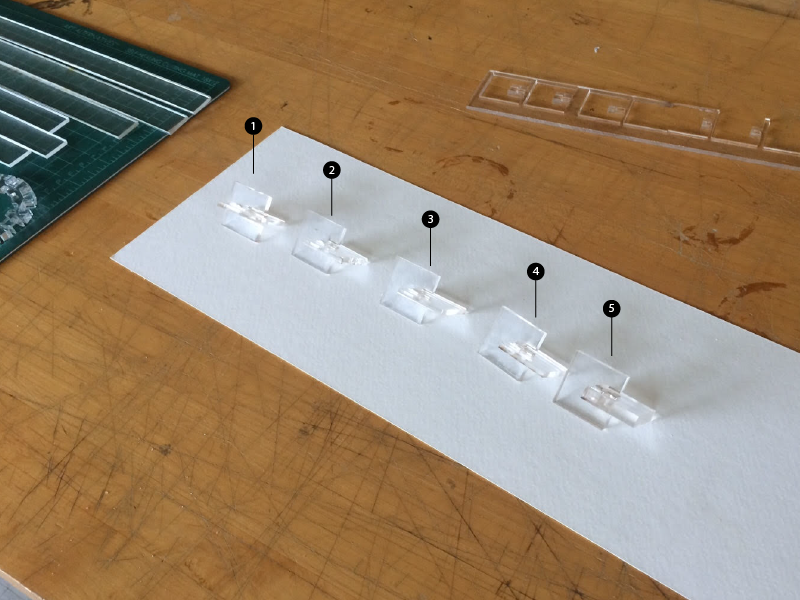

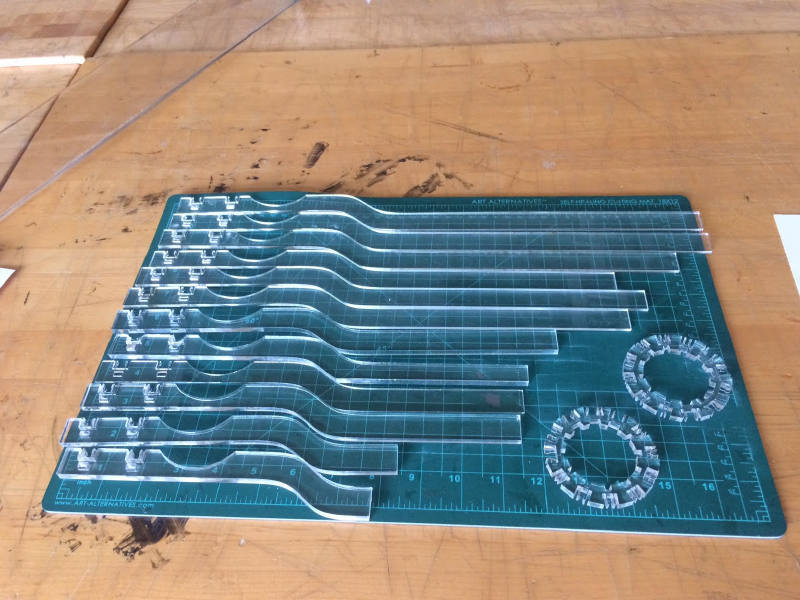

02 - Testing Joints in Acrylic

I tested a variety of flexture joints with different dimensions. The best optino was a 1/8th inch square joint, with a 1mm thick flexture tooth.

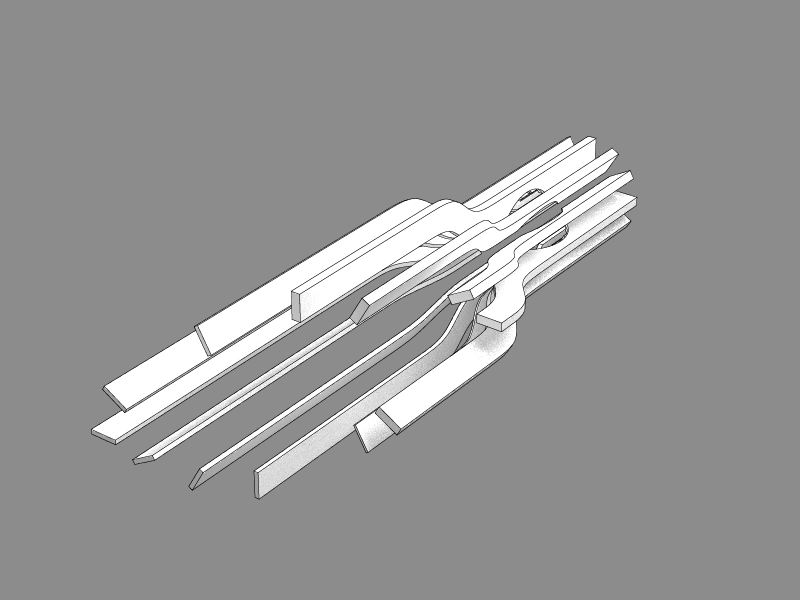

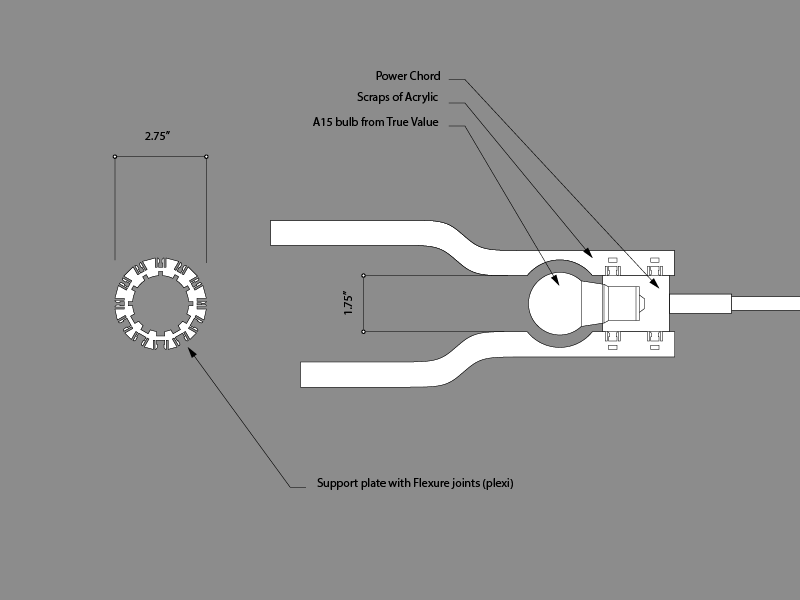

03 - Design Geometry

04 - Fabrication

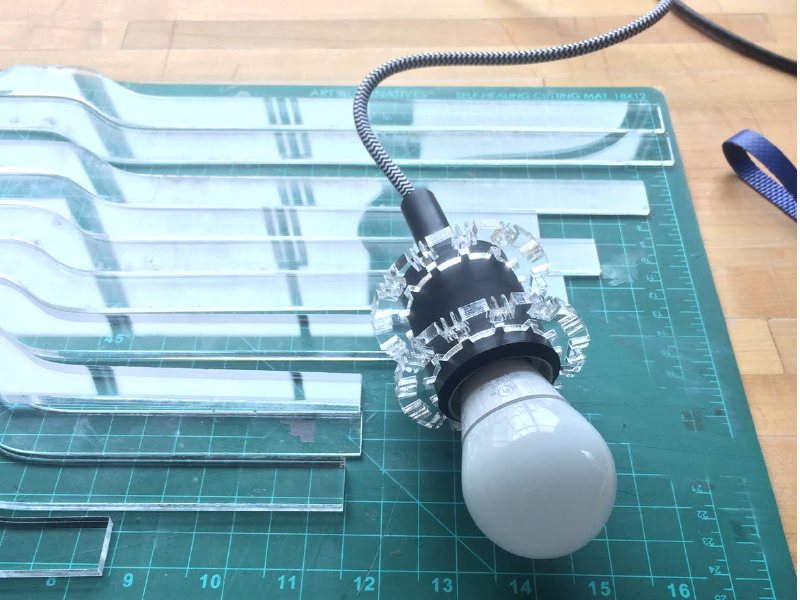

0.25" plexi was cut into a ring, and squeezed around the bulb. The Rings have flexure joints on them to hold the plexiglass blades.

04 - End Result

It was good to get something made! If I was to repeat this lamp i would go for a different design methodoloy. I think the most interesting aspect of the project is the scrap collection phase; and the challenge is to find a design which uses more scrap parts. Either a design that adapts to whatever chunks you give it, or aggregating lots of little pieces.