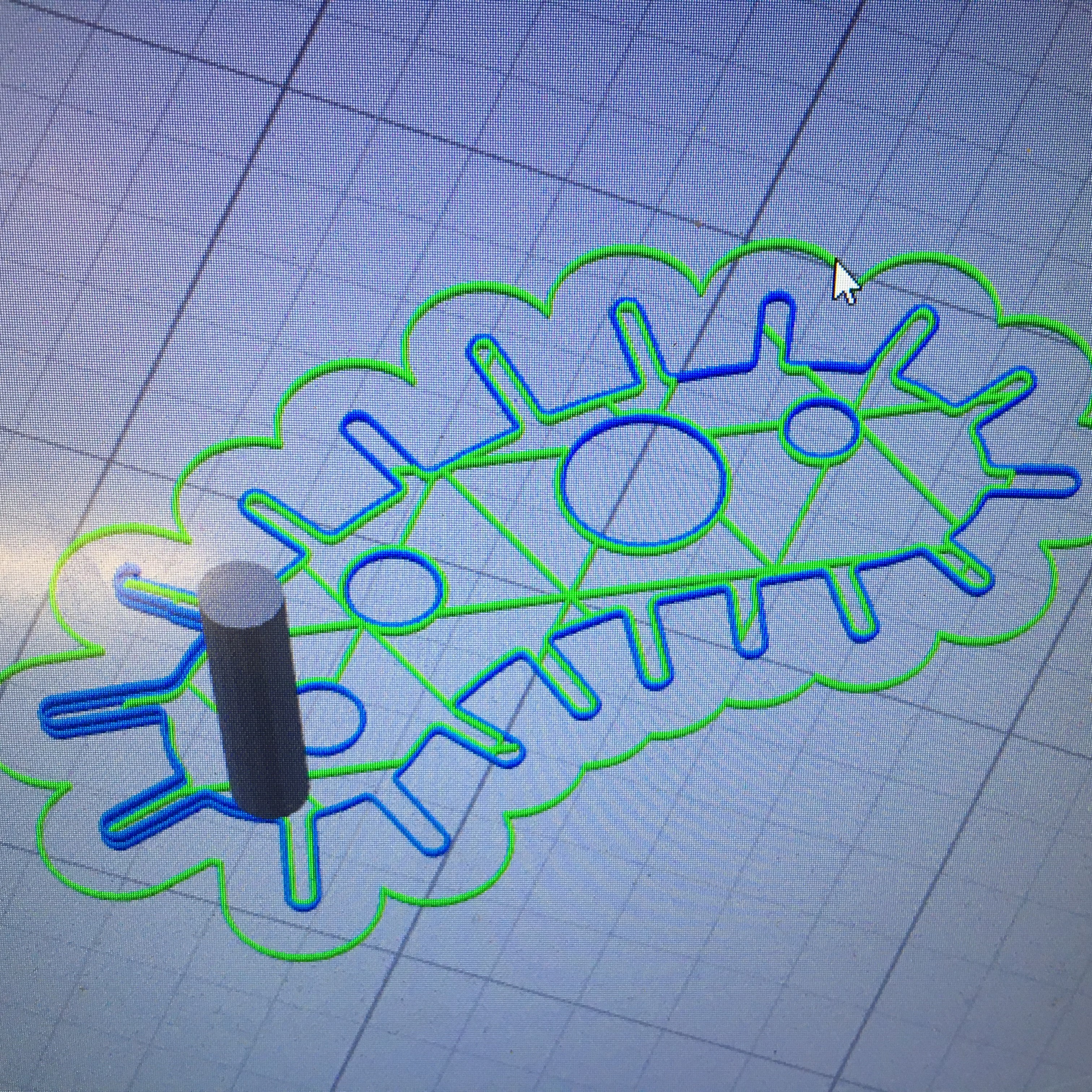

Lab notes:

The first part of the lab was mixing and testing the gel. This was challenging because the gell froze at ambient temperatures, so we had to work quickly to keep it cold enough and liquid enough to mix with the bacteria. Even so the gell clogged the pippet and I needed to put it back in the fridge to allow it to cool down and re-liqify.

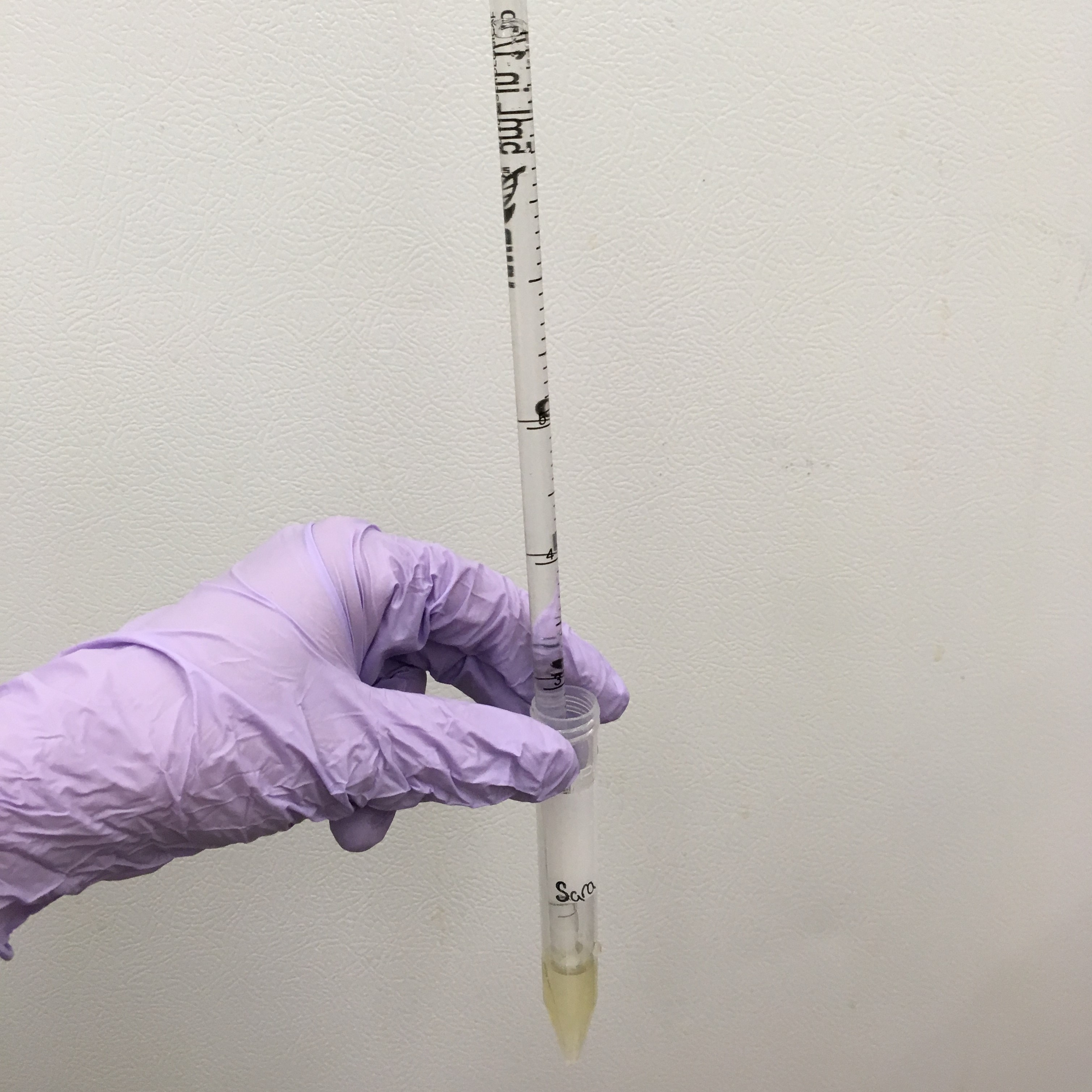

After the samples were mixed we tested the gels consistency by hand pipetting it to see if it was solid enough to allow layer stack up, if it was too liquid the layers would flow together.