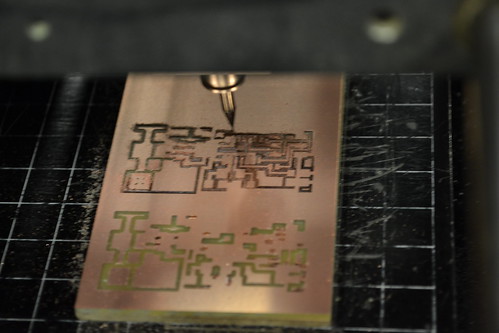

Milling the PBC was easy and fast though there were a few hiccups. I initially ran the interior cut file with a 1/32". It ran half the file before I realized it. I reset the origin of the file and ran the file with the right bit.

The board must have been curved because the bit did not mill through the copper on one side. I lowered the of the bit and had to run the file two more time before it was adequately cut.

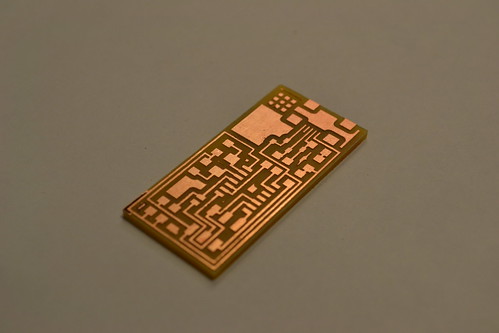

The board came out clean, I scraped off all burs and separated copper strips. The cut out pass did not quite cut all the way through but it was thin enough that the board could be snapped out cleanly.

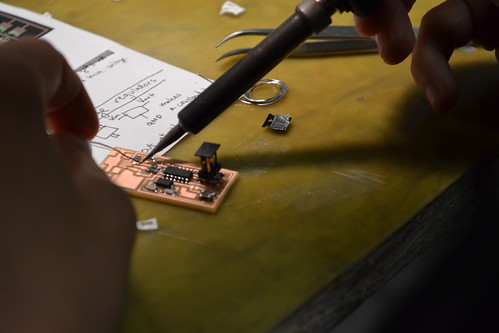

This was my first time soldering. It takes some practice to get the hang of. A helpful tips to working with such small components. Place a bead a solder on the pad before placing the component on the board. This allows the component to easily be placed without moving around to much.

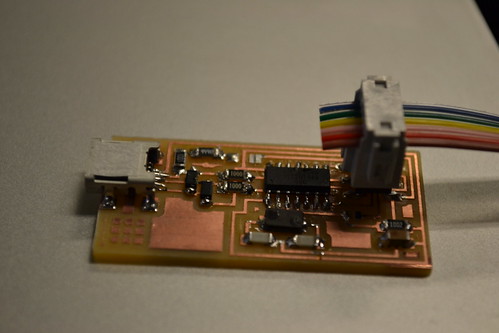

The board was easily programmed but when it came time to test the board it was not recognizable. After some testing it was determined that one of the resistor had cracked. This was probably due to extra heat from soldering or from the removal process of the 0 Ohm resistor. Once the resistor was replace the board was easily recognized by the computer.