week 2: fab ISP

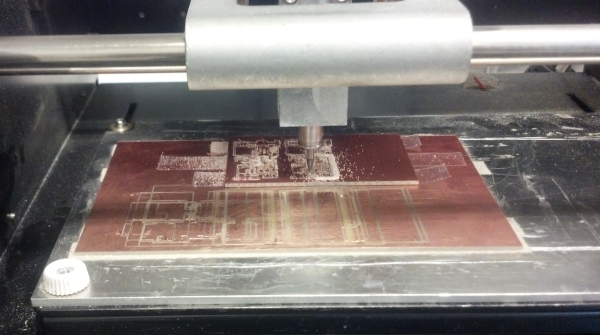

milling

this week we made somthing right up my alley: an in-system programmer, or ISP. this is a nifty little piece of circuitry that can translate a programme from a computer to other microcontrollers--this seems complicated, but it's astonishingly simple and takes only a very few components to make. it's also a fairly easy build: we took a piece of copper-plated board and used a modela milling machine (with a teeny tiny 1/64" bit) to cut out the traces (described by a .png), then soldered on some surface-mount components.

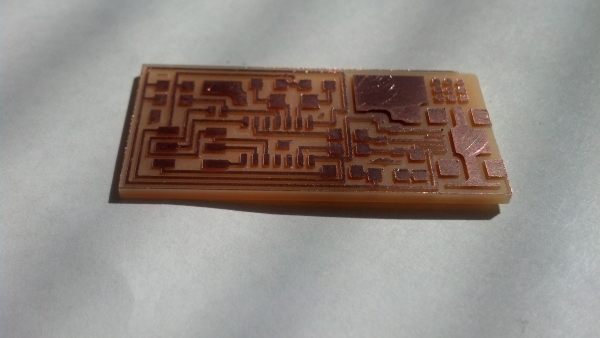

milling the traces

the board after milling--note the little copper burrs.

i actually had some trouble milling this board--the bits were pretty old and didn't cut very cleanly. the z-zeroing was a little off, too, making the area between the traces a lot deeper than expected. i also managed to not tighten the set screws properly while cutting out the exterior of the board, and the bit actually fell out and cut a line straight across one of the boards. luckily i was milling two at once and once i fixed the bit i managed to salvage the second.

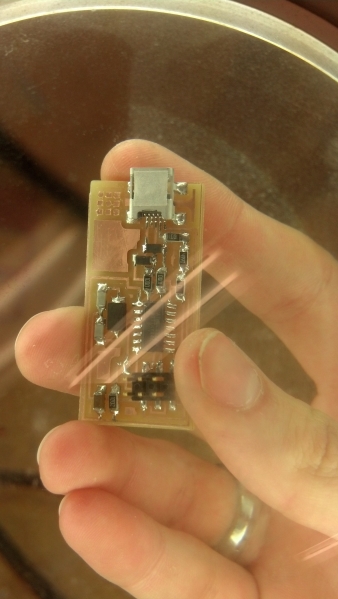

soldering

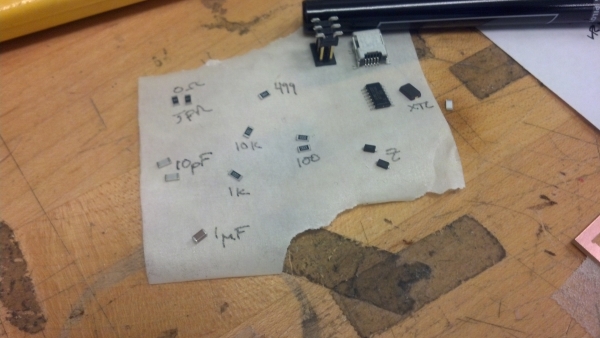

soldering surface-mount components is challenging at best, and though these aren't the tiniest parts available (they're 1206s, so each resistor and capacitor is about the size of a grain of rice) they're still pretty damn small. the last time i soldered something this little i was working under a microscope, but i didn't have that luxury today. i did, however, have plenty of flux, which made my job much easier. something else that made life a lot easier was sticking components to a piece of masking tape and labelling them so i didn't accidentally knock them off the desk.

eventually i ended up with something pretty good-looking, so i rinsed it to get all the flux residue off and decided to call it a day. this is actually a really important step that a couple of people forgot--the flux will start to corrode the board after a day or so if you don't rinse it off. this will make you sad. rinse your board.

programming the board

programming was suprisingly easy once i got hold of a computer with the right software setup. one of my classmates had it on his laptop and everything went smoothly as soon as i plugged in my board. the best tutorial for softare setup is here. once that's done, you can actually use your board to programme other boards, which is damn awesome.