week 6: molding & casting

as of today, i've spent a full seven days holed up in bed with what MIT Medical has deemed a "flu-like illness," so--of course--i didn't manage to start this week's assignment until the night before the project was due. (that, incedentally, is tonight. forgive any desperation that seeps through.) i wanted to be a little ambitious for this week's assignment--maybe even get a head-start on my final project and cast a draft of the handle. alas, that was not to be, given the unfortunate time constraints. so i decided to make a small present for my girlfriend instead, because i am a sap like that.

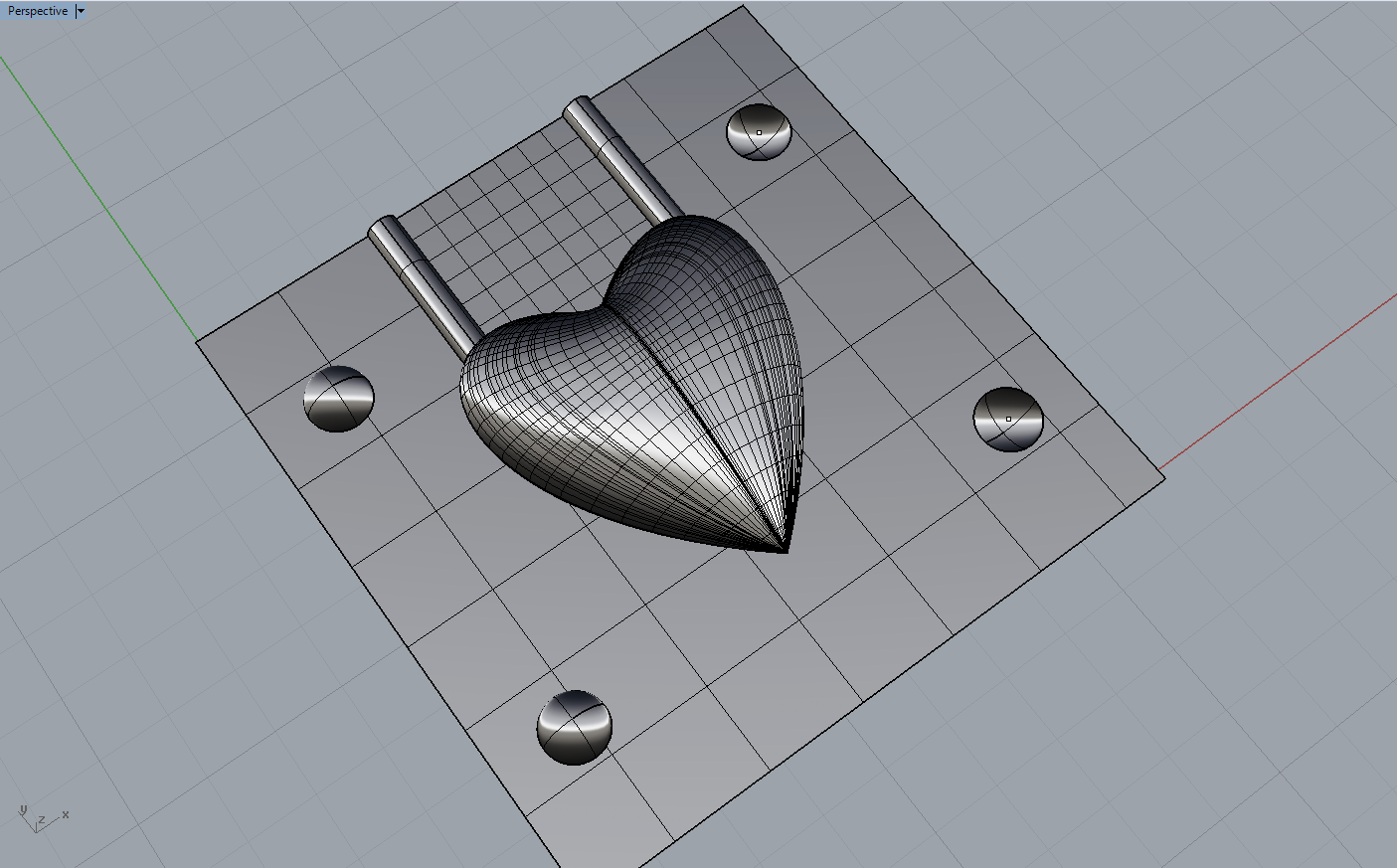

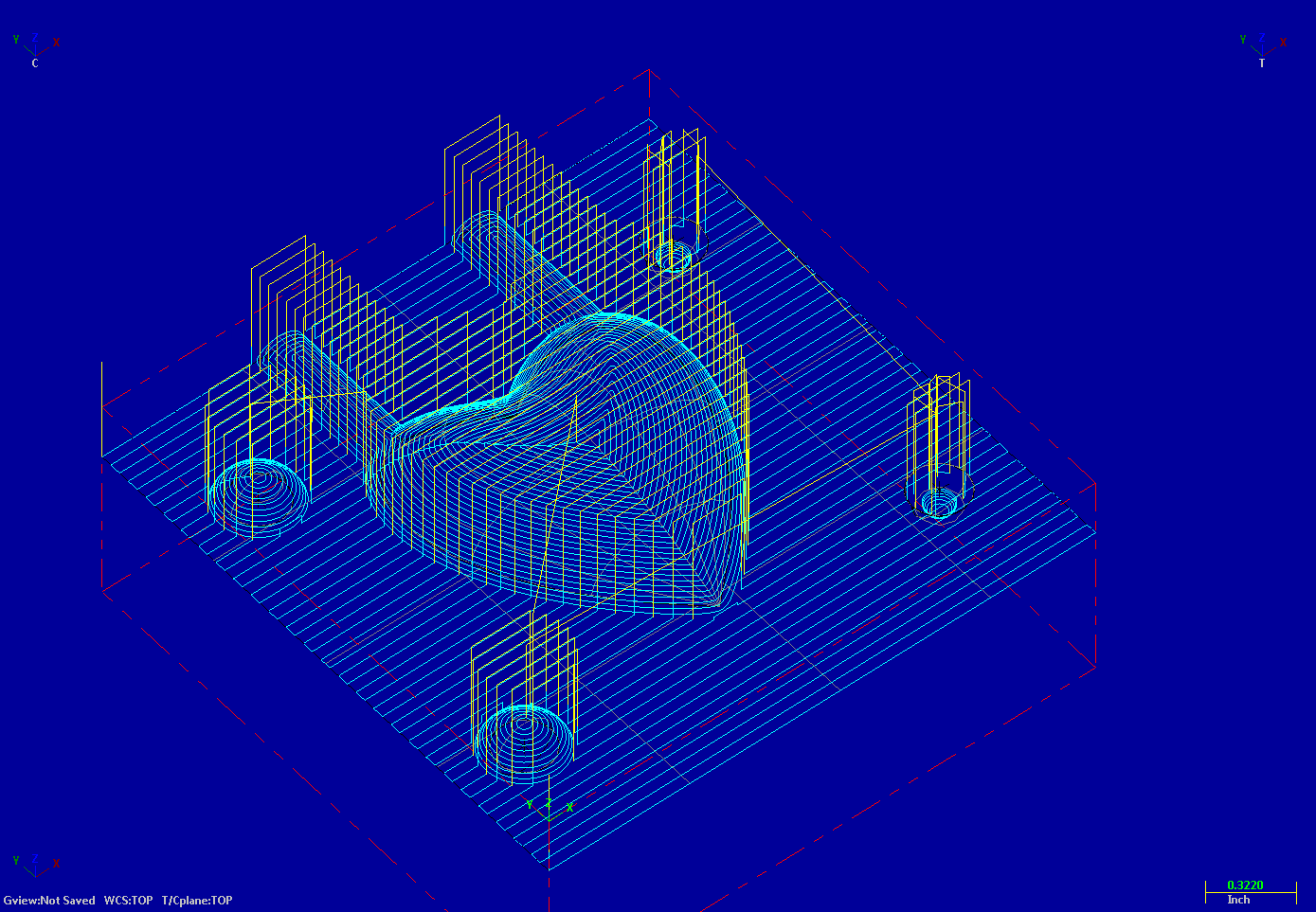

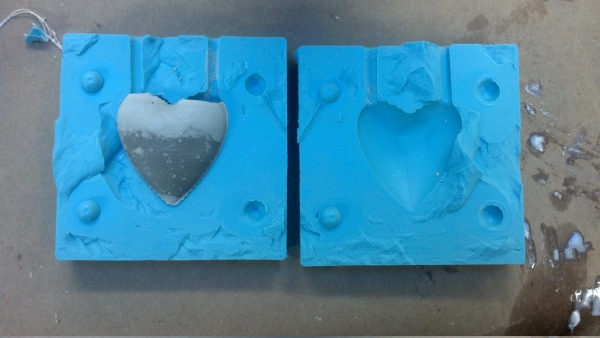

james once again saved my ass and whipped up a mastercamm file that would allow me to mill the reverse mold on the ShopBot--this meant that i could spend significantly less time making a higher-quality mold versus an enormous amount of time producing the same-quality mold on the modela. he even included tracks to pour the casting material into and pegs so the mold lines up correctly.

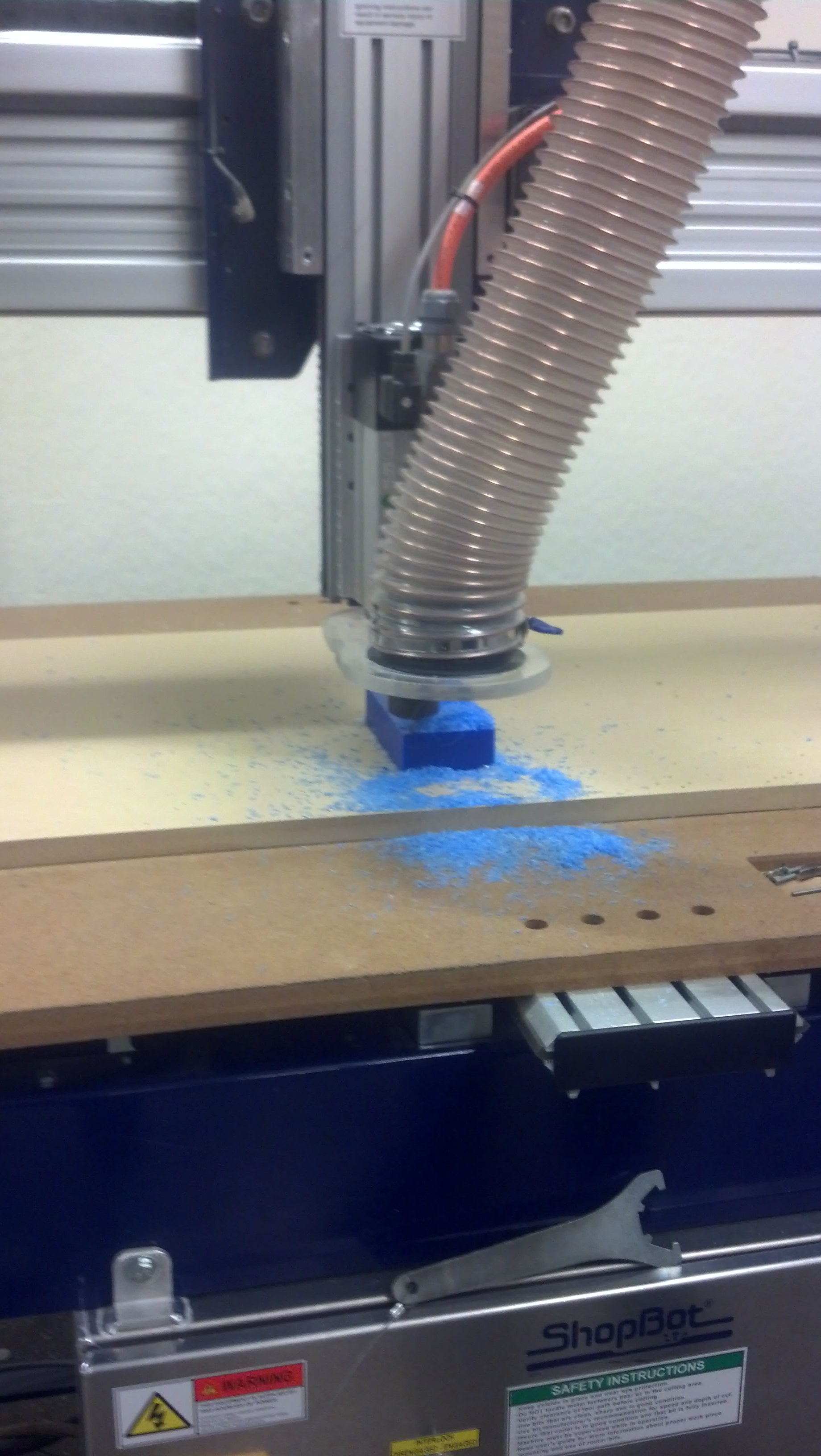

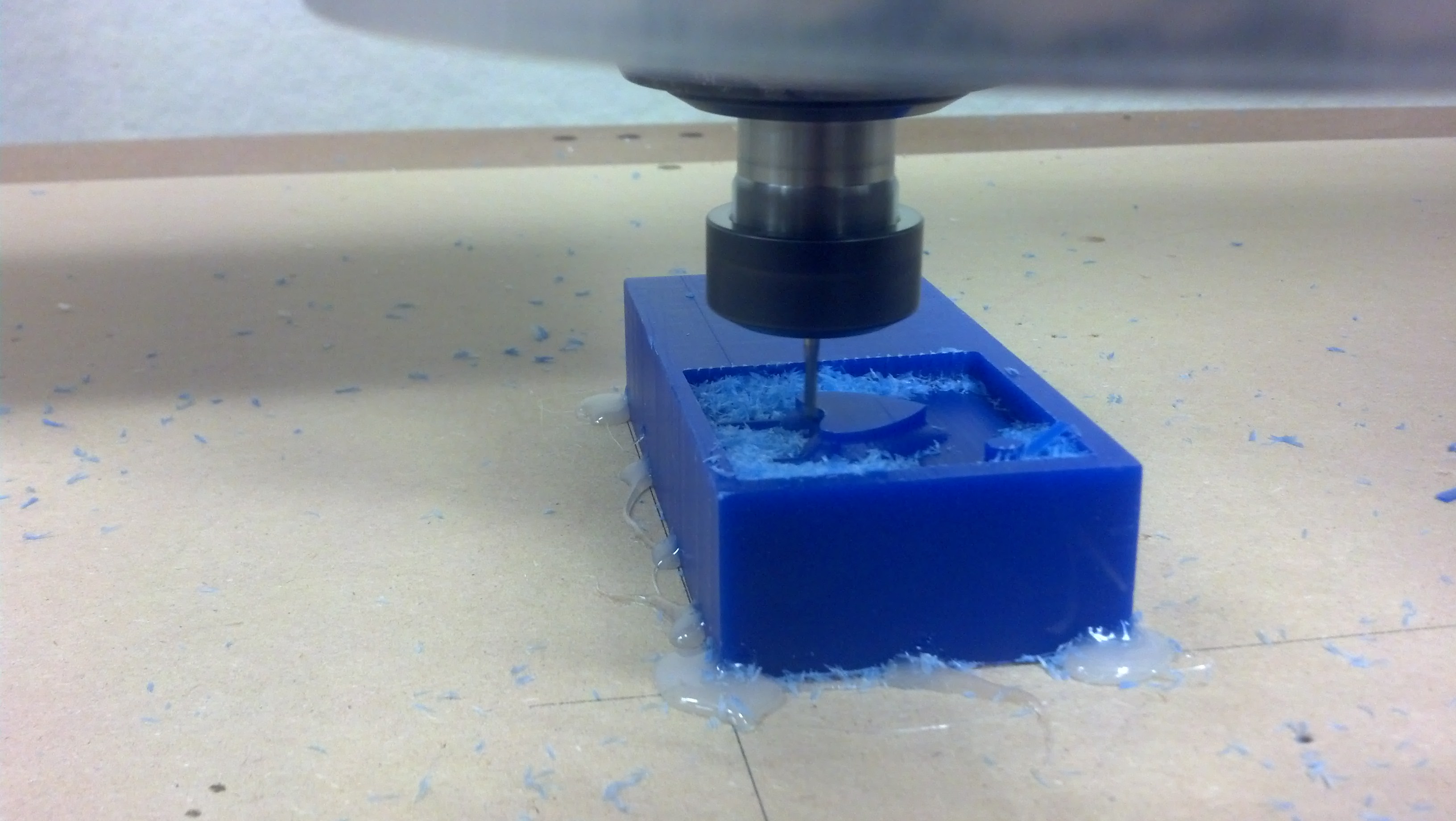

the wax machined beautifully: i was surprised by how quick and easy the whole process was. i hadn't had a chance to use the ShopBot before, but i definitely want to use it again. behold, the fruits of my labours:

now that i had a reverse mold, the next step was to mix some oomoo and pour a positive mold from which i could directly cast. this was a distressingly messy process, especially since i couldn't find gloves anywhere in the shop (next time, i'll remember to bring my own). i managed to spill plenty on myself, which i then scrubbed off (violently) with gojo. hopefully i've gotten it all; i'd rather not wake up tomorrow with casted fingers.

the mold cured for just over five hours; i removed it from the wax, trimmed off some of the edges, and filled it with drystone. there were some air bubbles in the oomoo, but none of them were close to any relevant surfaces so i doubt they'll be a problem. the drystone was really cool--it's definitely not a newtonian fluid, and i had a little bit too much fun mixing it. it poured quite well, though, and i had no problem getting it to pour into the very little holes at the top of the mold. i've left it to cure overnight; hopefully by tomorrow morning it will have set!

apparently five hours wasn't actually long enough to cure the oomoo, because when i tried to open the mold this happened:

and there was also apparently a huge air bubble that i missed which cut off one corner of the heart. ah well, so it goes. i'll try again under more relaxed time constraints--let things dry overnight and maybe use something more interesting to cast the heart. drystone is cool, but i'm not hugely fond of the way it looks when dry. next time--metal, perhaps?