Software

Since I had already done a special PCB and programmed it two weeks before, I decided to catch up on some projects. I redid the PCB to a sligthly nicer version, I 3D printed a housing for my fan-agent design (see final project pitch), and laser cut the 'fans'. Next I programmed it.

Then I took the opportunity to redo my mold from last week (make it nicer), and my chair from the SomethingBig-week, -and added an ottoman and a table just for kicks!

Software (and some other stuff)

PCB (milled in modella): |

|---|

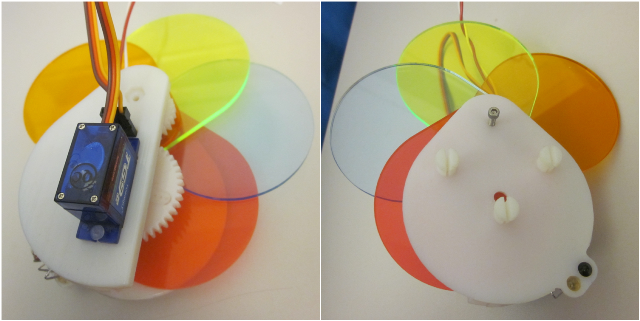

Housing+gears (3D printed):

|

Fans (laser cut acryllic): |

Program (AVRstudio) while(1) if(readIRavg || readIR) } |

Assembly:

The PCB still needed a bit of hacking to work properly, but next version will be perfect(!)... Here's a video of the current progress: |

| Molding&Casting in chocolate! |