This week, we focused on electronics design. Our assignment was to redraw the echo hello-world board, add an LED and a button, check the design rules within Eagle, mill the board, and then assemble it. I used the Sparkfun Eagle tutorials on JF's website to learn how to use the software.

Materials and tools:

- Eagle (to design the schematic and board)

- Copper-plated sheet

- Modela milling machine with two sizes of end mills: 1/64” and 1/32”

- Fab modules to communicate directly with the Modela

- Solder, flux, tweezers, copper braid, components

- Music to help the soldering process go smoothly

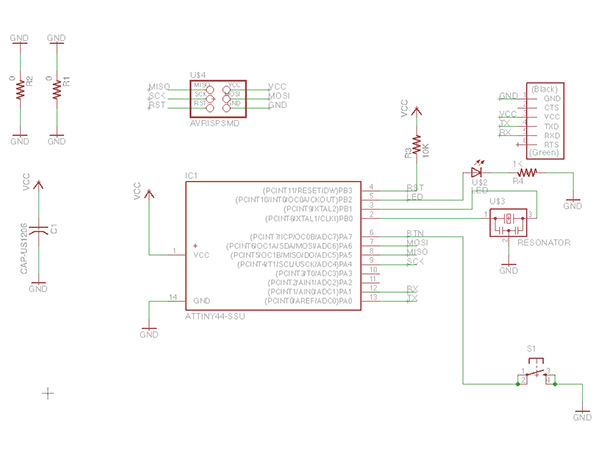

Eagle Schematic

I encountered many problems this week, at both the design and fabrication ends. The most difficult part of designing the board was laying the traces in Eagle. I found it really challenging to fit everything together, and my board ultimately looks like a mess — a far cry from the beautiful and orderly boards we milled last time. My limited electronics knowledge made it a bit frustrating to make decisions when designing the schematic, and I later realized I had some redundant parts (extra resistors). I ended up getting a lot of help with my schematic from JF, who was amazingly helpful and responsive.

From JF, learned a lot about best practices for documentation and setup in Eagle: use net names (but not for unused nets), point VCC up and GND down, add values to components like capacitors and resistors, use the "show" tool to highlight the nets to make sure they are connected appropriately, and use a fixed grid with 45 degree traces rather than an arbitrary grid and angles.

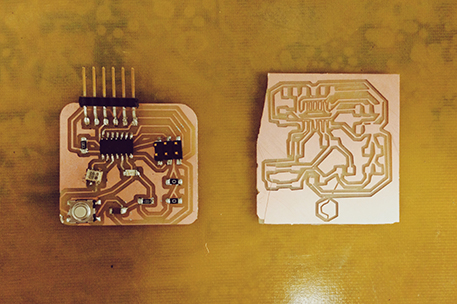

Failure #1, on the right.

When I first attempted to mill the board, it came out very choppy (unstuffed board to the right, above). I believe this is because I exported from Eagle at too low resolution. The board that ended up cutting smoothly was exported from Eagle at 600dpi.

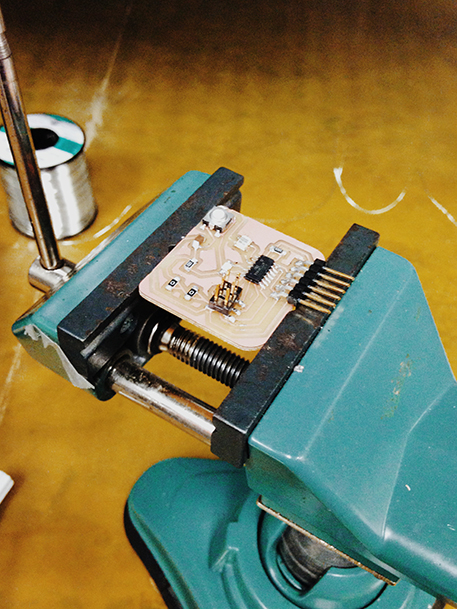

I used a clamp again to help me solder.

I used a clamp to move the board up a little lower than my hands when soldering. While I in the basement soldering room, I worked alongside Alan Kwan who helped me troubleshoot some of my issues (like which way to orient the switch and LEDs). Unfortunately, when I tried to solder the resonator to the board (for the third time...) I accidentally ripped up some of the copper traces. If anyone has any good tips for soldering the resonator, I'd love to hear them for next time!