This week, we had an optional training in welding, which I have always wanted to learn. We got a demonstration of spot welding, MIG welding, and TIG welding, and then got to try our hand at MIG welding.

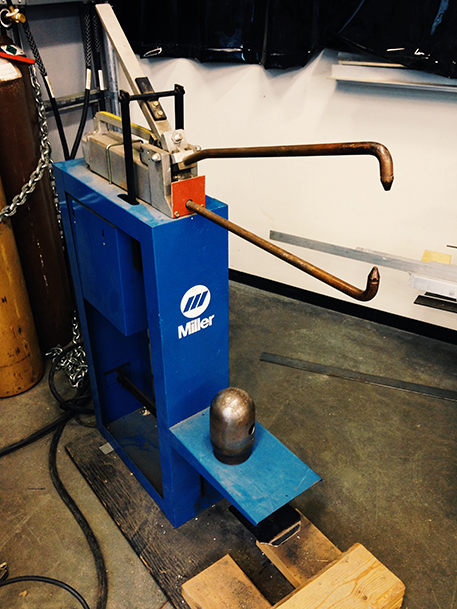

The spot welder holds together pieces of metal between two electrodes. As current moves through the electrodes, the metal melts and fuses together. Whether or not the metals fuse depends on the amount of current applied, and how long the current runs through the metals. If you apply too much current or let it pass through the metals too long, you'll create a hole instead of a weld. With the correct current and duration, the weld is small and circular and very clean.

Spot welder.

TIG welding is a kind of arc welding that uses a Tungsten electrode to create an arc between the electrode tip and the metal. A filler metal, which melts and fuses to the main plate, is used in this process. You hold the electrode in one hand, and the filler metal stick in the other hand, pushing or pulling the filler metal stick where the arc meets the metal to create a spot or a line.

TIG welder.

MIG welding is also a form of arc welding, but the elctrode for this kind of welding is also the filler material, so there is no need to use a filler stick as you would with TIG welding. The welding gun for MIG welding has a wire feed unit which automatically feeds out the consumable wire which is fused to the metal.

MIG welder.

Safety is very important for all forms of welding. We wore fire resistant coats and gloves, as well as a welding helmet that has an auto-darkening filter. The auto-darkening filter glass on the helmet darkens automatically when the incorporated sensors detect bright welding arcs. Without this protection, you can damage your eyes.

Trials with MIG, TIG, (center) and spot welding (far right).