FabISP Programmer

This week I am making a programmer for burning programm into a microcontroller.

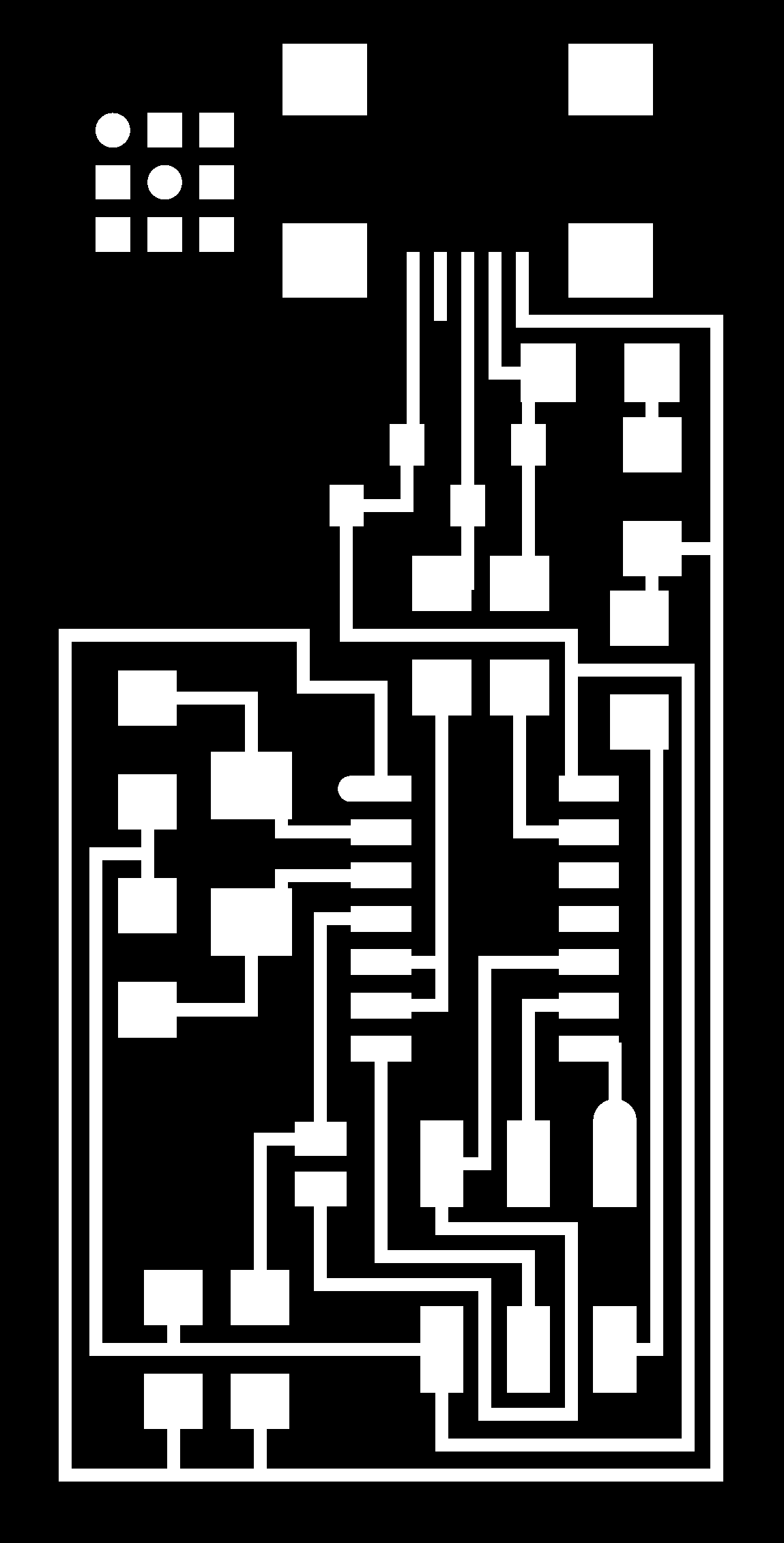

I used the provided traces and interior designs for milling.

-------------

Stage 1: Milling the Circuits Board

I used the default design on the class website.

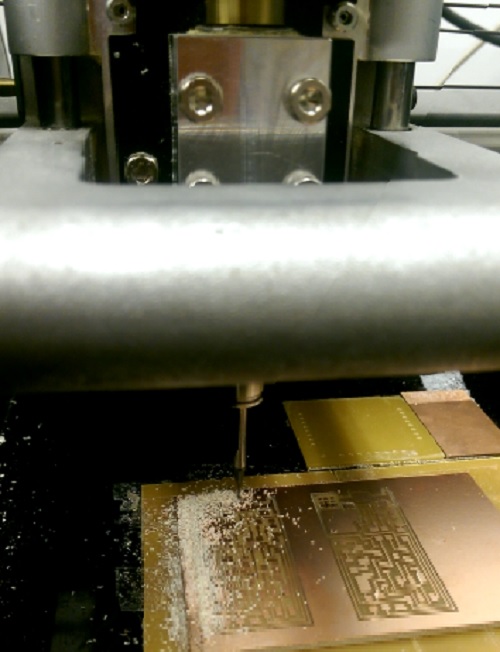

I used a double-sided tape to firmly place the copper board on the milling machine bed.

Designs for my programmer.

Copper board is milled by a milling machine.

The first time, the upper part of the circuits board copper is not totally cut

The endmill did not penetrate deep enough to have a enough clearance between

two traces. I found out the bed is not level, the upper part of the bed is lower.

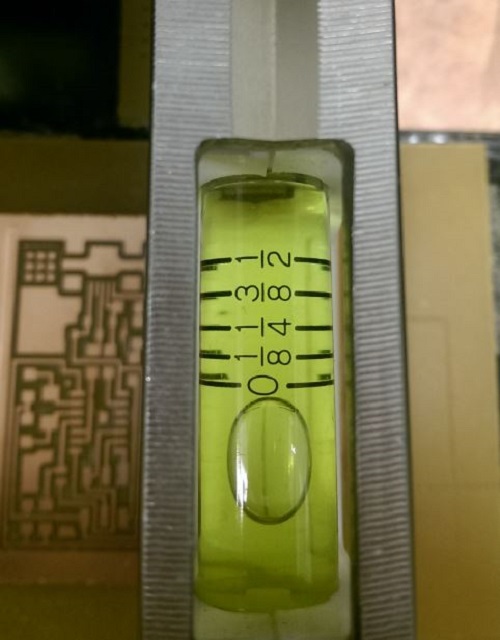

Cosidering the unlevel bed, I zero z-coordinate relative to the upper part

of the board, then set the lower left side as origin.

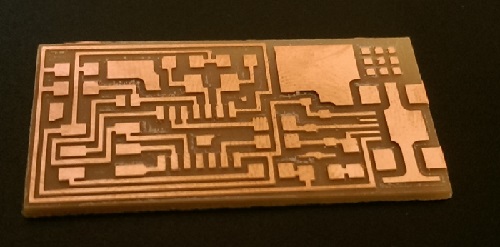

The second time, my PCB board was perfectly milled.

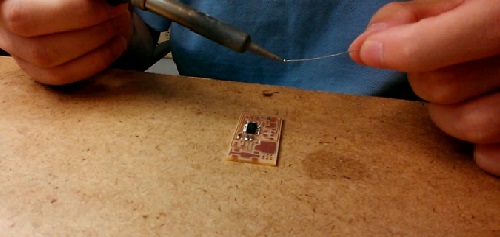

Stage 2: Soldering the Components

With PCB board ready, I just soldered the resisters, capcitors, diodes

and microcontroller to the board,

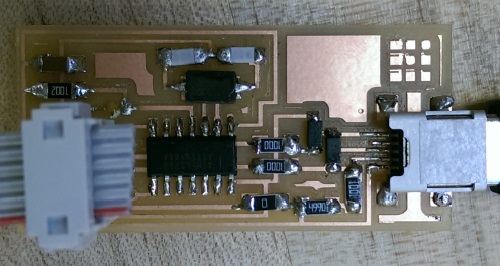

Stage 3: Burn Code into my Microcontroller

If the soldered circuit is a vessel, then the program I am about to

burn into the microcontroller is the soul of this entire board.

This step is very straight forward, I connected my board to a programmer,

the programmer was connected to a computer. I opened the firmware and wrote

the code into my microcontroller.

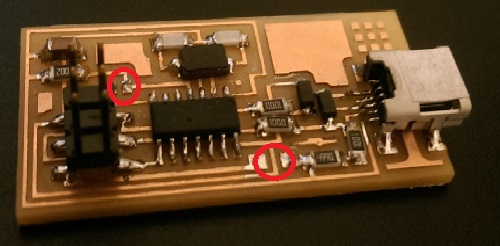

Stage 4: Desolder the Jumper wire

I desoldered the jumper wires, where the red circles were.

and I have a programmer to program other chips.

-------------

-------------

-------------