Mill and Cast

I am quite into watching blacksmith making sword. So I want to make a sword this week.

-------------

-------------

-------------

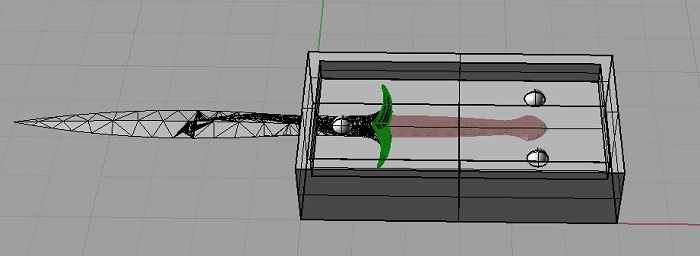

Model the wax male mold

I downloaded a .stl file and the length of sword is about 24in, I scale down the sword,

but to mill the entire sword the thickness of sword will be smaller than 0.1in,

so I just mill the handle, but the thickness of handle is still really thin.

-------------

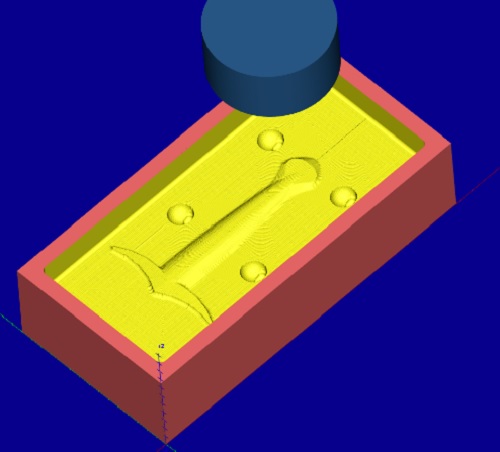

MasterCam Setup

setting up the MasterCam file.

-------------

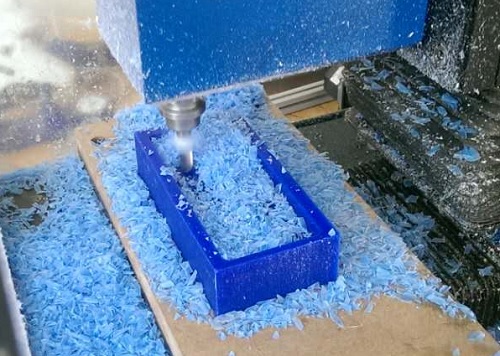

Milling using Intelitek

-------------

The wax is perfectly milled.

-------------

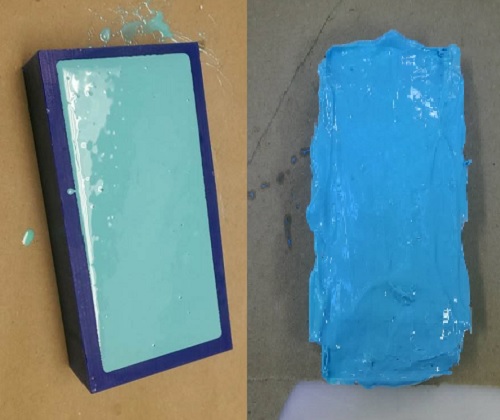

Pouring my oomoo mix.

The left one is a successful pour. The right one has really high viscocity, because

the oomoo was stored in the venting hood, the low temperature in venting hood is really low.

I put the oomoo in the room temperature and it works good.

Casting my sword

I pour the hydrostone into the mold, and wait for about 5min, and clamp two pieces together.

The part is too slender, the edge just break when I tear apart the mold.

-------------

-------------

-------------