Danielle Aspitz

MAS.863 | How to Make (Almost) Anything

Geo-Flower Dome

Press-fit geodesic dome with three alternating shapes

_1. Idea

2. Hands-on experimentations and realizations

3. Design

4. Fabrication

_

1. Idea

This week's assignment was to cut something on the vinylcutter, to make a parametric press-fit construction kit, and to document both processes.

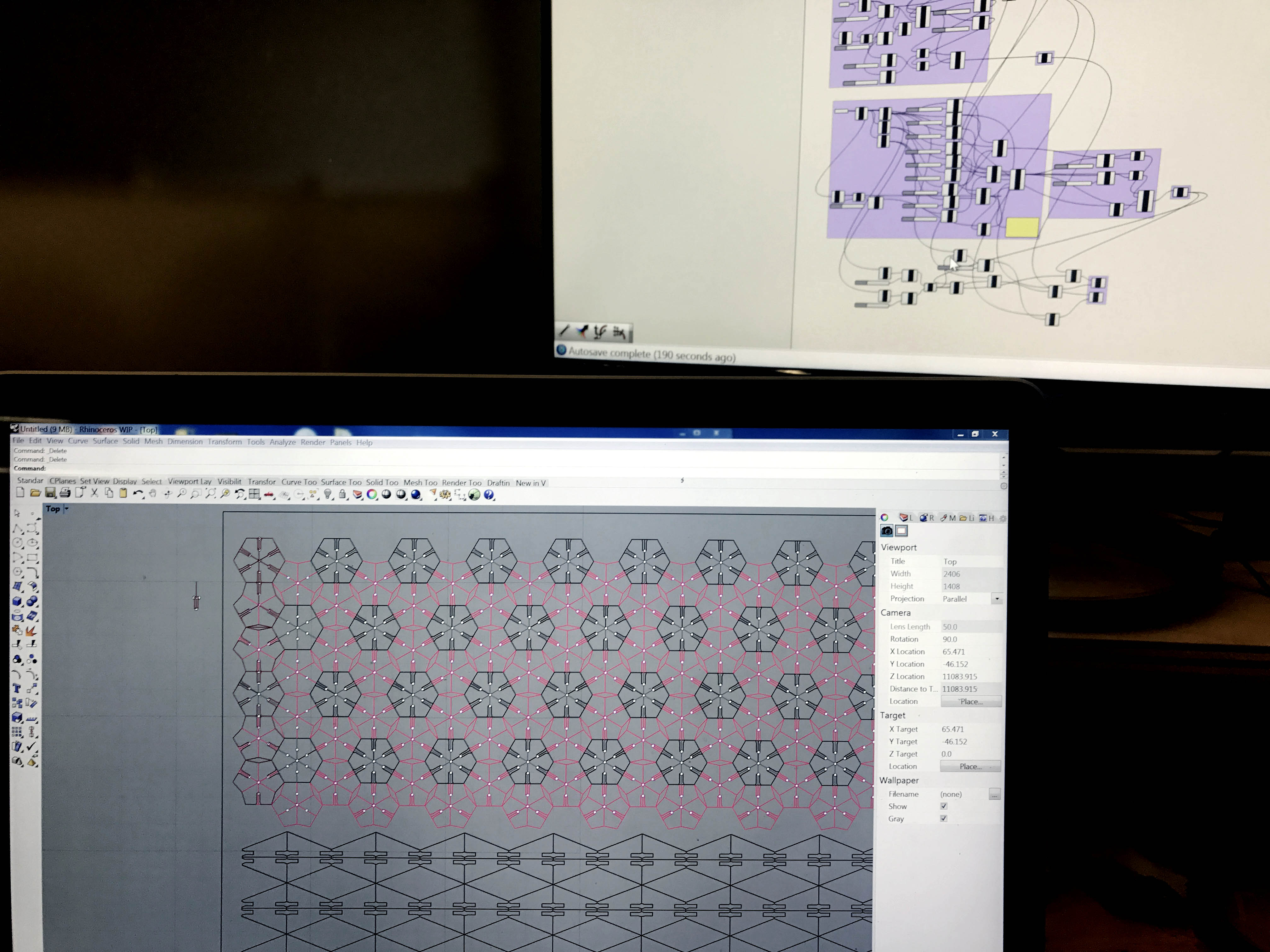

Quite quickly I found upon discovering what a press-fit kit is and browsing for inspiration I landed on a project that seemed doable and fun. I spent far too much time trying to wrestle with the creation of a geodesic dome in grasshopper, which is surprisingly difficult. As it turns out you need Kangaroo and Weaverbird installed in order to populate the sphere with equally-sized polygons rather than subdivisions relating to the curvature of the sphere. Even still I was frustrated to find that the polygons were approximately equal but not EXACTLY equal, which deeply annoyed me and proved the entire process fairly useless. I did in the end use the form to calculate the angles between polygons, and to roughly estimate size and quantity of the polygons I wanted lasercut. However ultimately I wound up laying out the pieces to be cut in a more manual fashion.

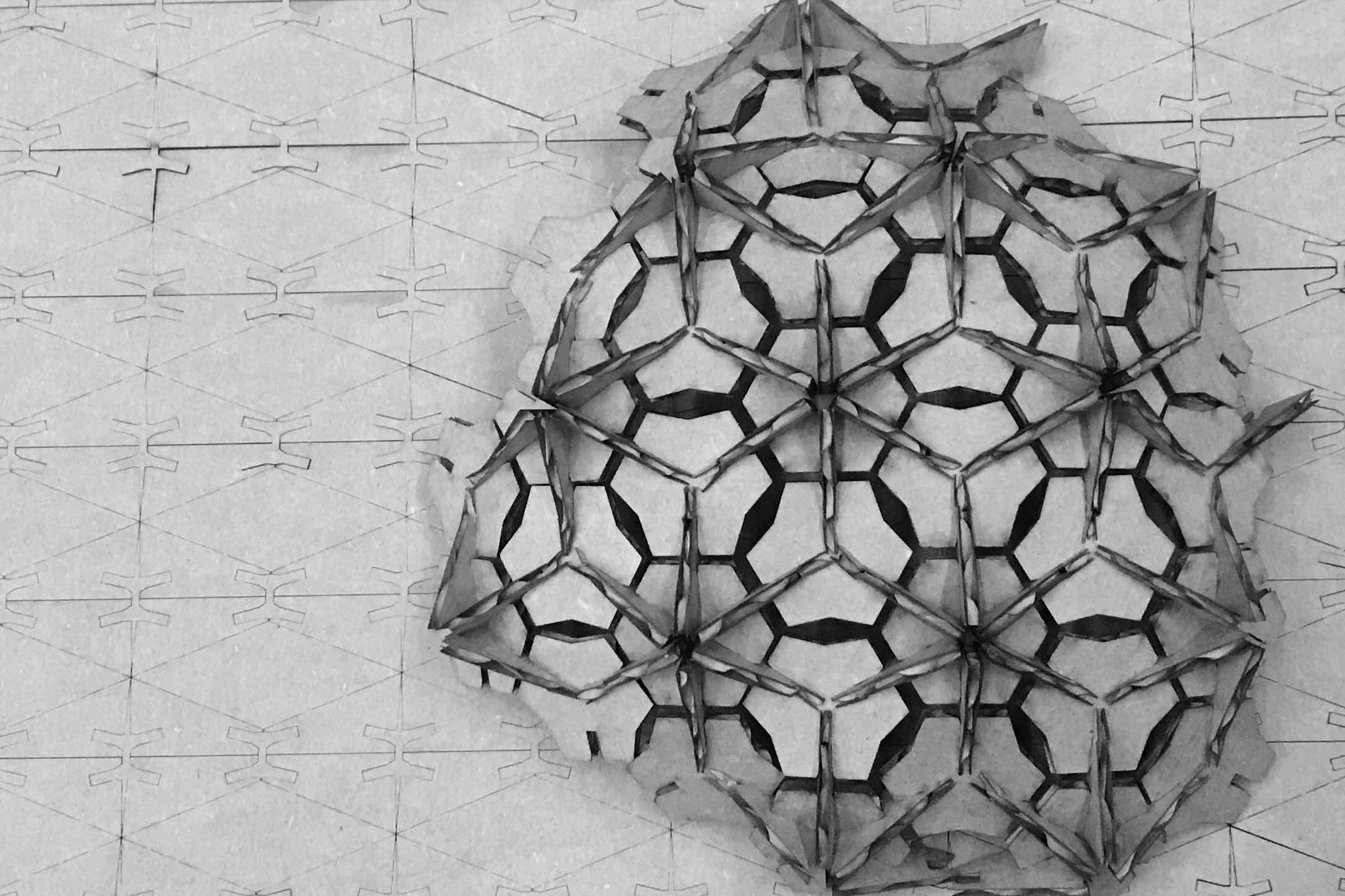

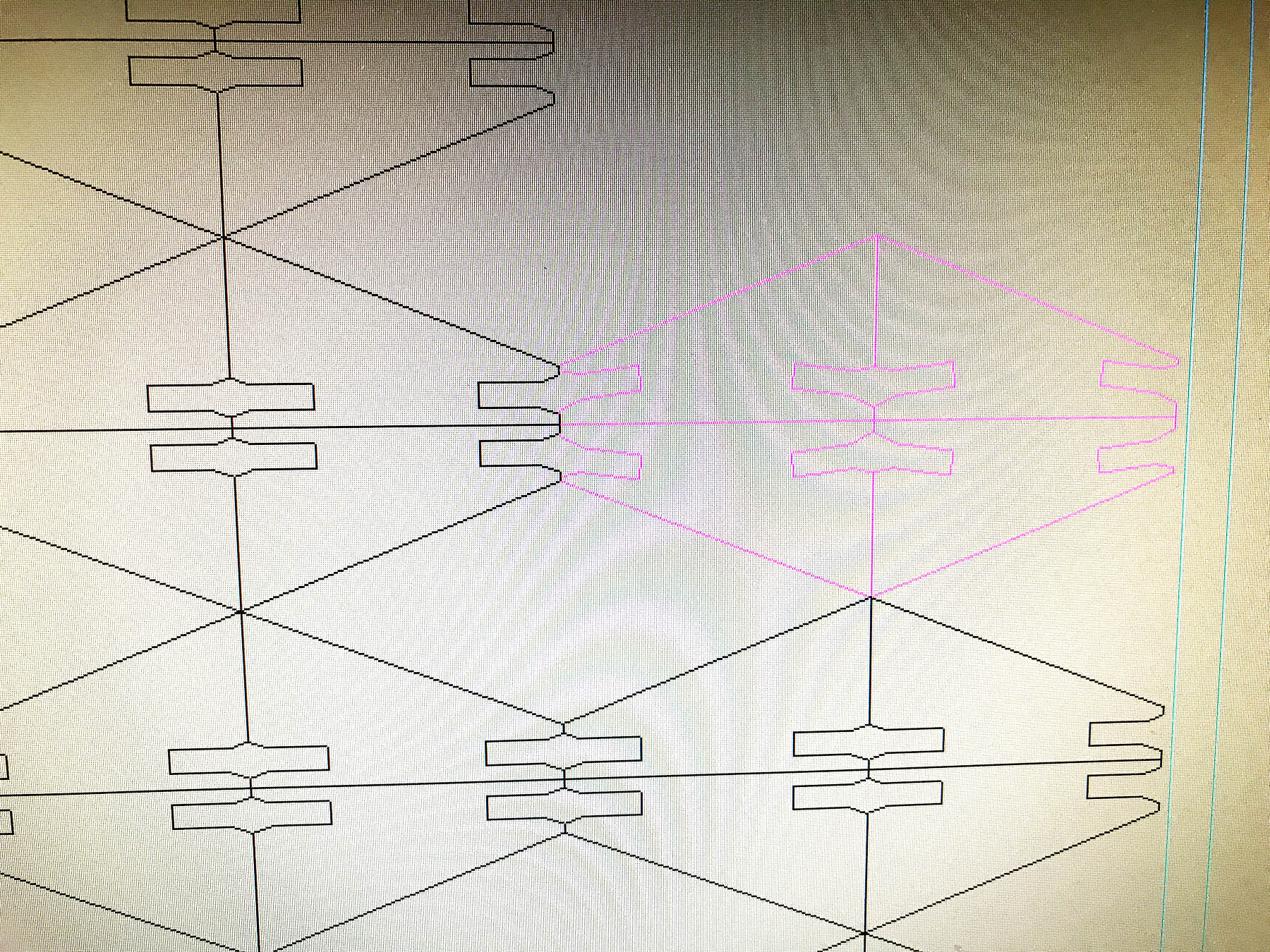

Figure 1. Wrestling between fully parametric and a more "analog" digital process

Another early Grasshopper hurdle was trying to assign within the geodesic dome which hexagons were full hexagon with 6 slots and which were notched hexagons with only three slots. I had originally thought this might be a 6 to one ratio, because every full hexagon had 6 notched ones surrounding it. It took me until giving up and resorting to analog to realize that this ratio was actually 2 to 1, notched to full as the notched ones are recycled throughout the dome while the full ones are not. Another realization that in reality it was not even 2:1 but 1:1:1 as in each formation it was one notched, one mirrored notched and one full.

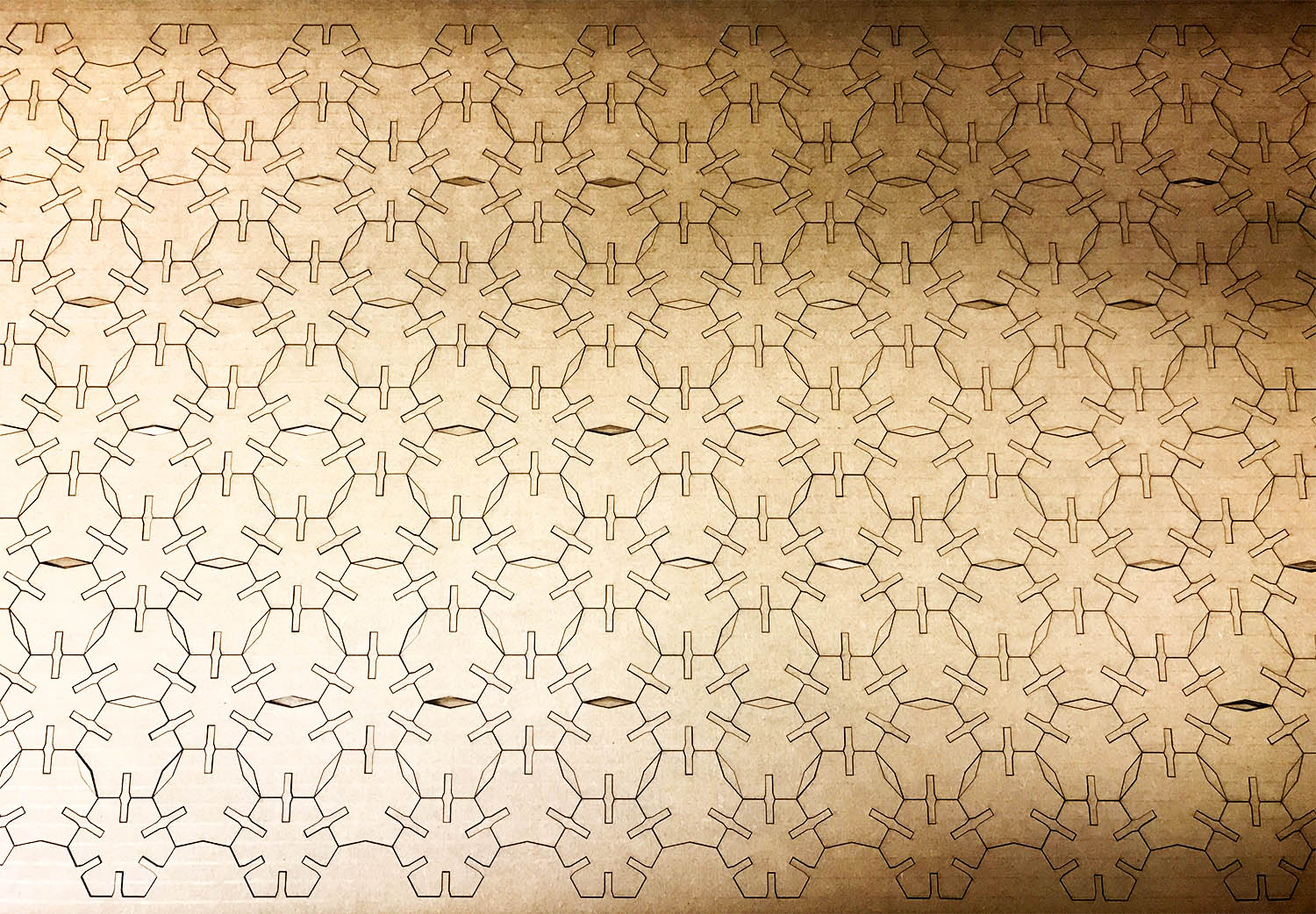

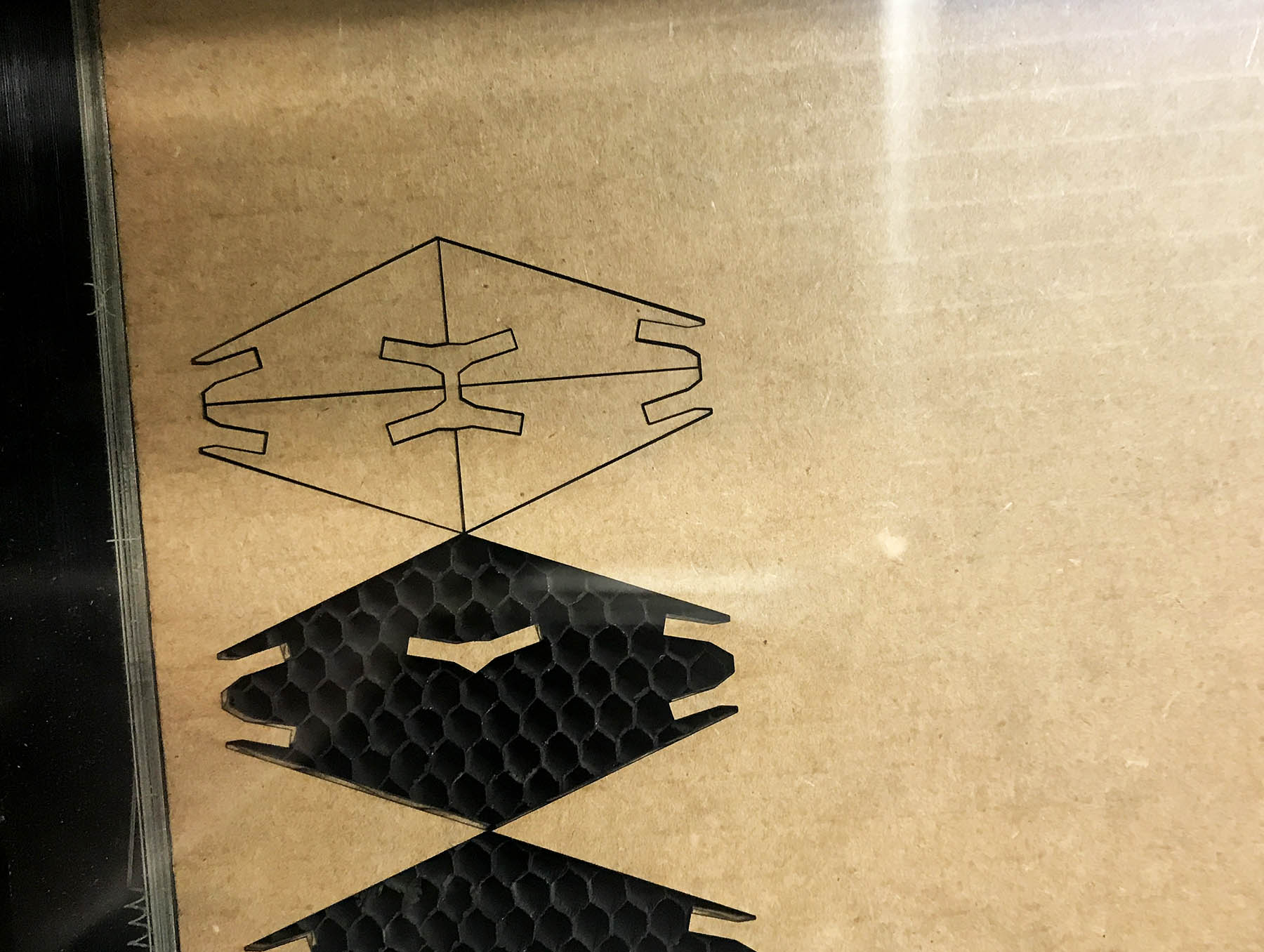

Figure 2. Discovering the ratio and cutting the sheets!

2. Hands-on experimentations and realizations

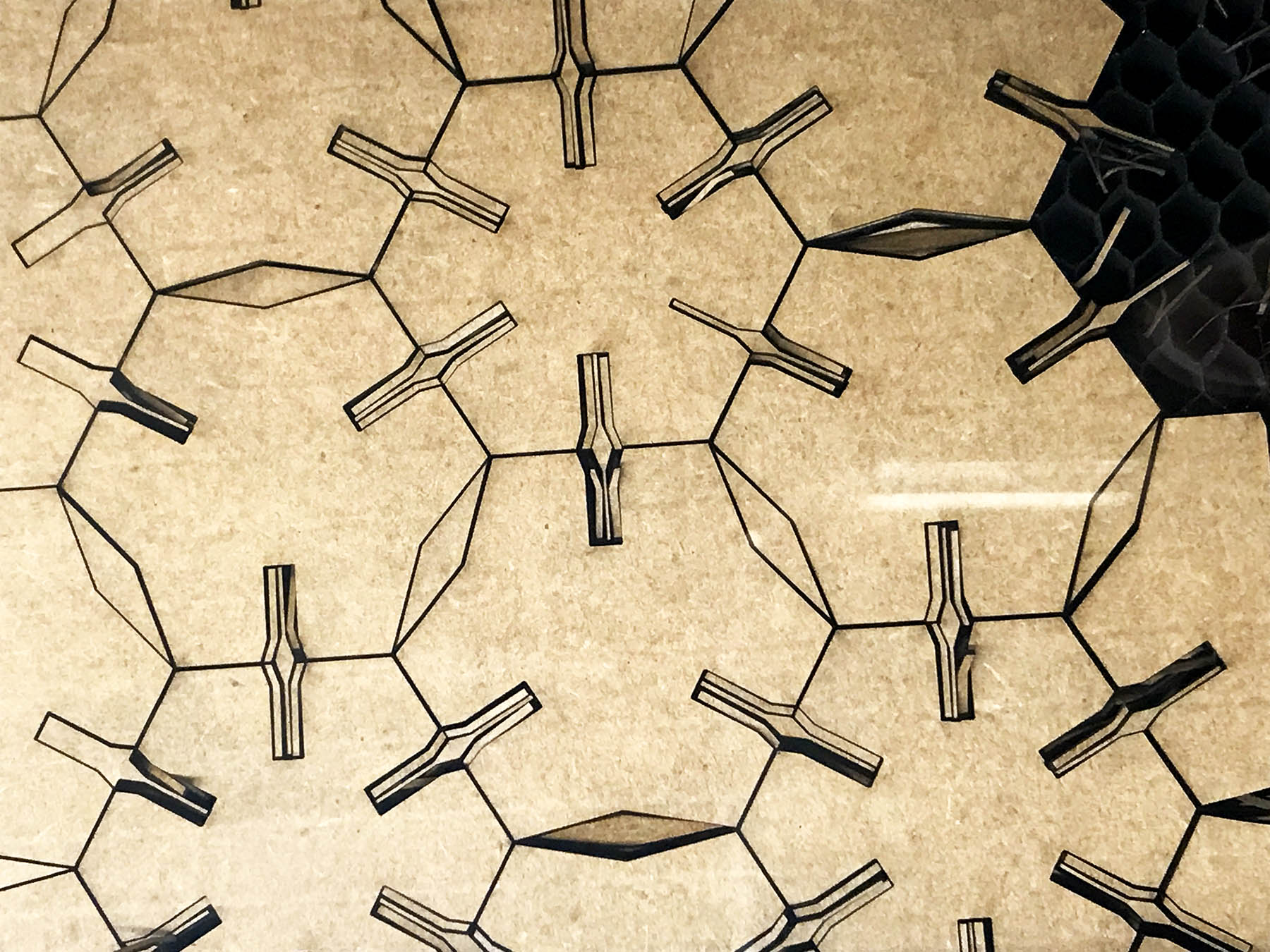

It was an interesting experience of going back and forth between parametric to analog. The parametric attempt informed me of the information I needed to find (the ratio of notched hexagons to full ones) and the analog clearly informed me of this detail. Once I had my hexagons laid out it was time to find the optimal notch size for the press-fit. I tested a few sizes, but ultimately do regret not doing the comb technique because while the joints fit well they are a tad bit too tight so it takes a small amount of effort to push each joint together.

Figure 3. Testing out varying notch sizes

Figure 4. Testing angled notches to help inform Geodesic Dome form

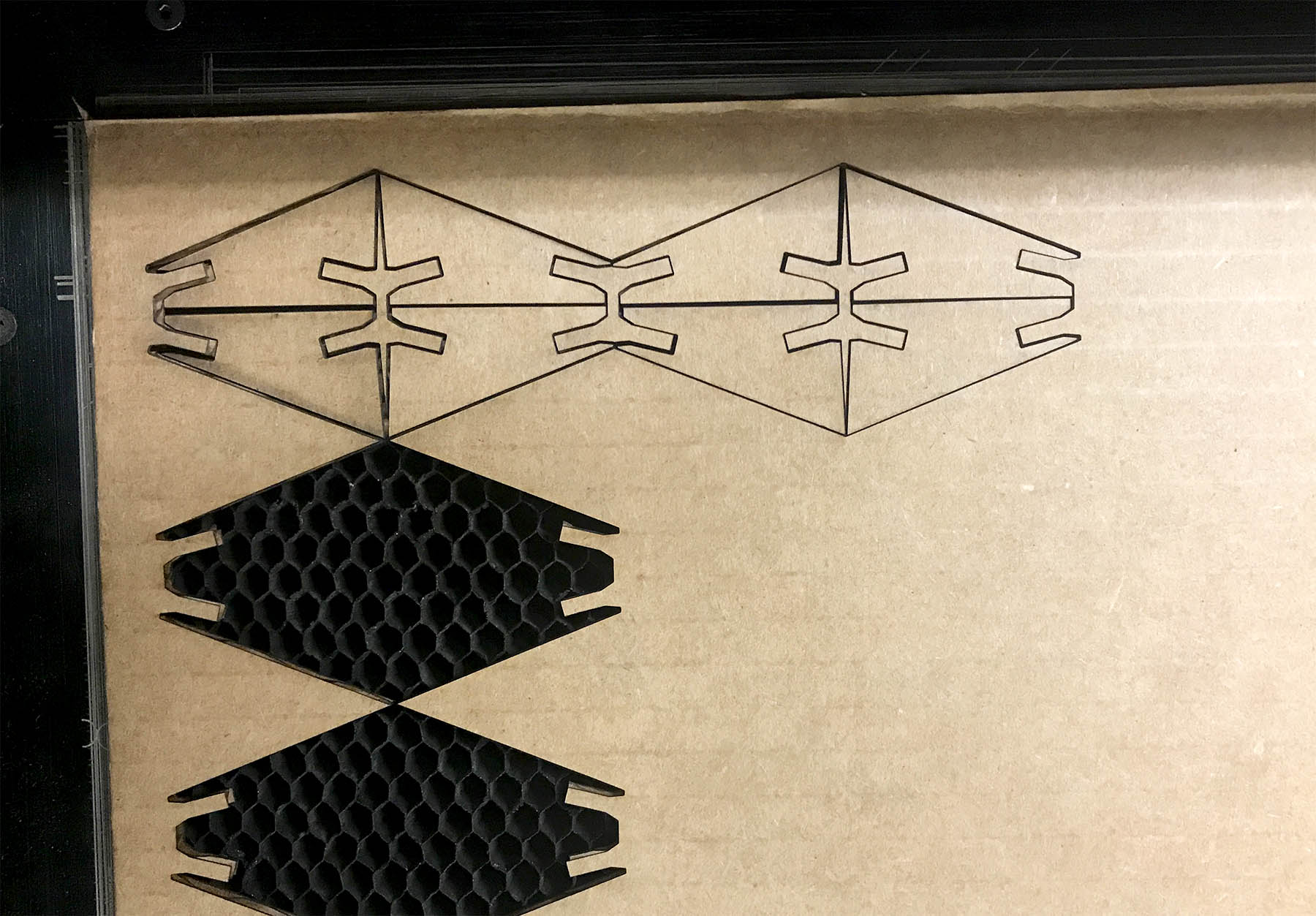

Figure 5. Increasing the slope to that measured in Grasshopper Geo-Dome model

Figure 6. Continuing Angle slice through entire side of joint piece

3. Design

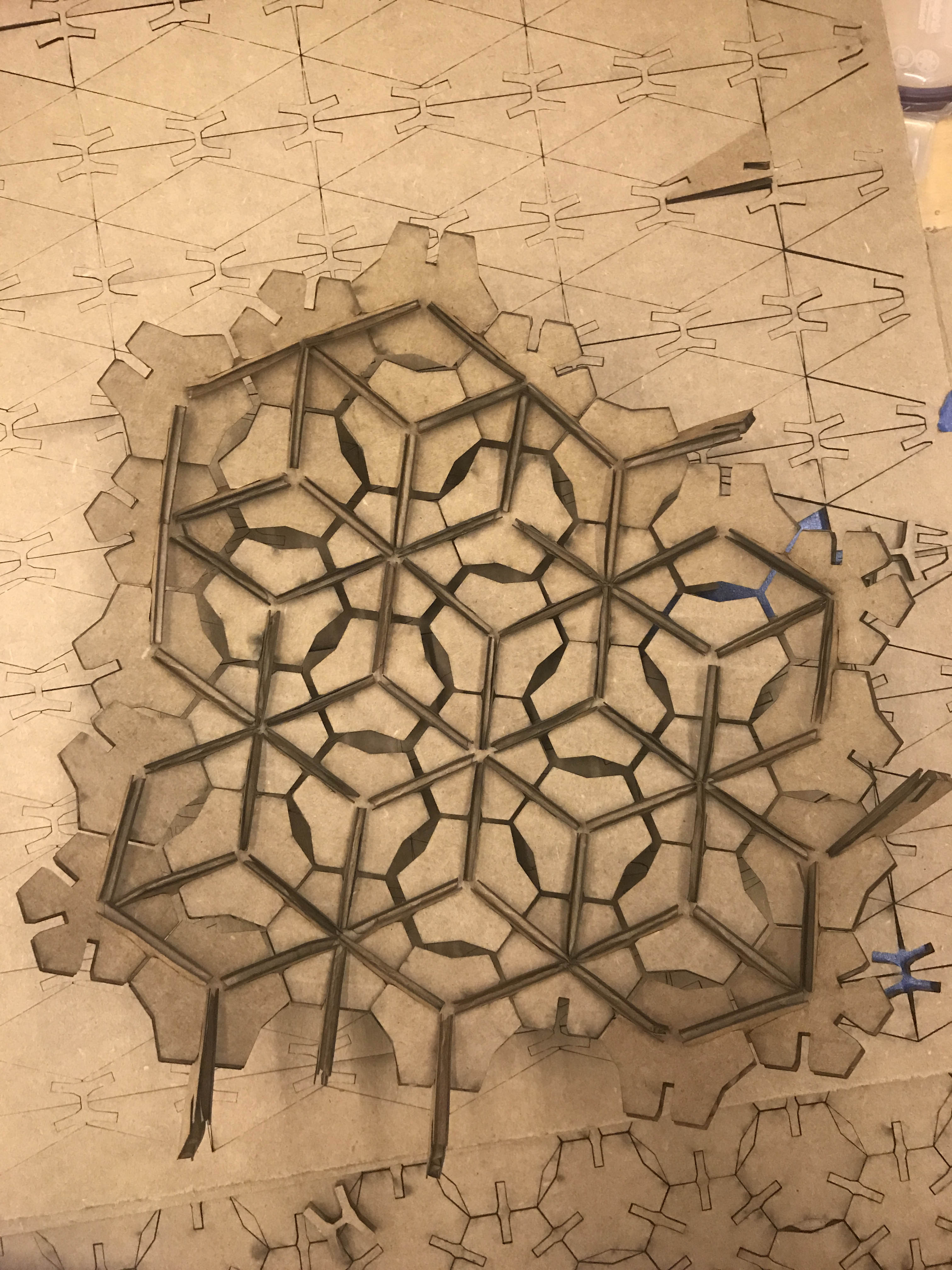

Figure 7. Pressing pieces together

Figure 8. Finishing up cuts and beginning assembly

4. Fabrication