03.11 Update

For this week I've set a few goals to familiarize myself with a few basics before diving into machine design + building as follows :

- Arduino + Breadboards

- Stepping-motors vs servo-motors

- KiCad + PCB production workflow

Arduino Tests

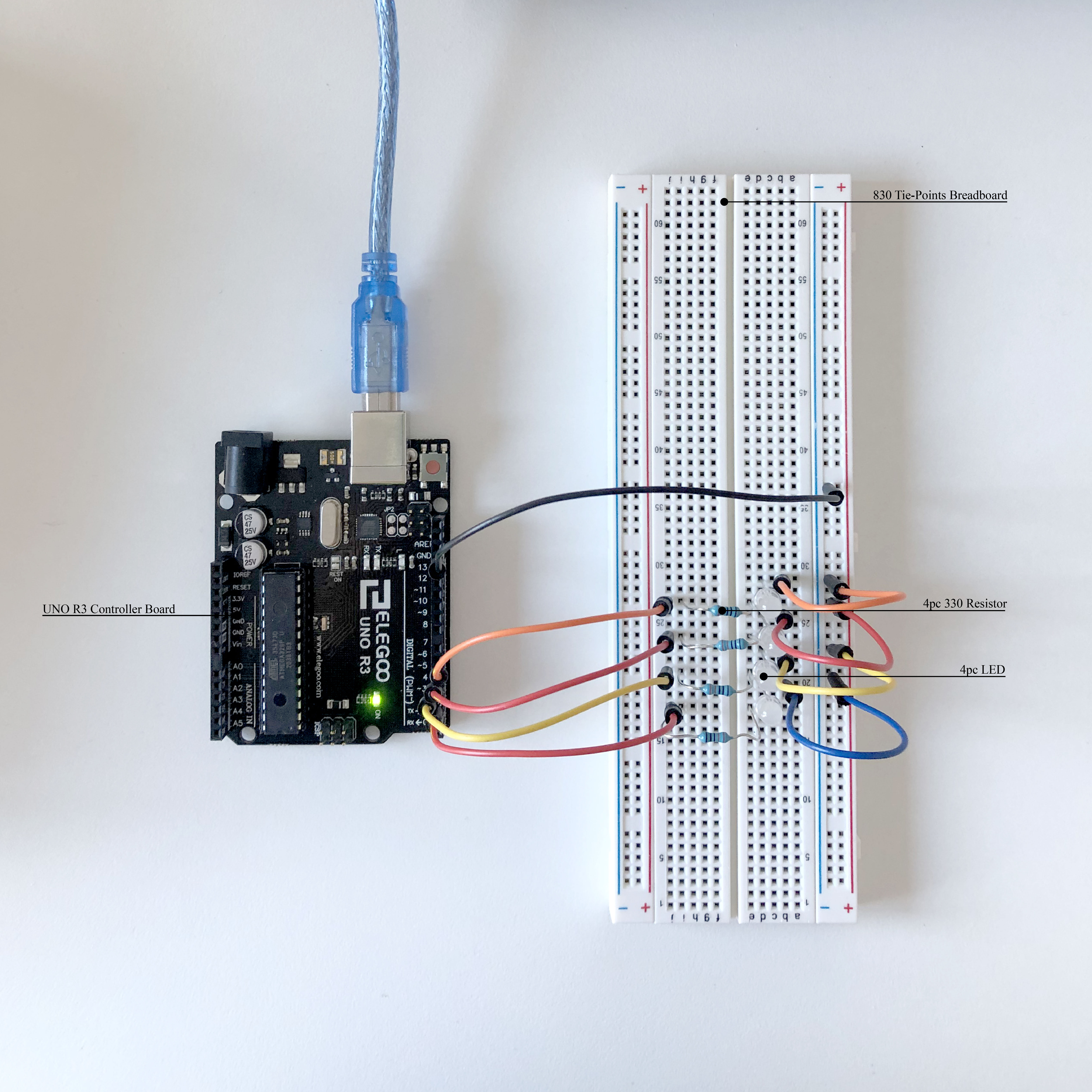

1 - Blinking light test

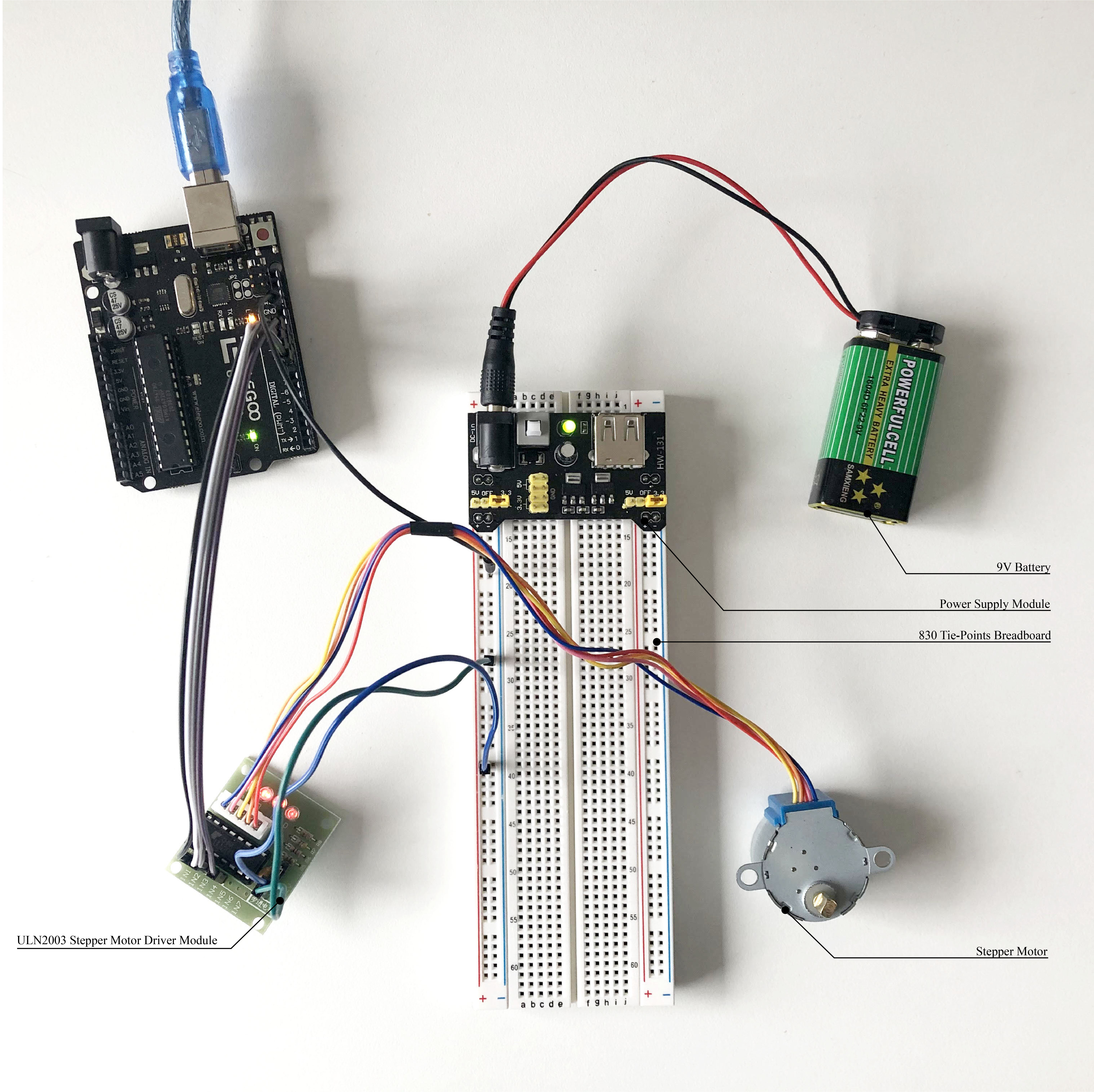

2 - Stepper Motor

Understanding Stepper Motors:

- Stepper motors consist of a rotor with permanent magnets and a stator (a stationary portion of an electric generator or motor)

- Stepper motors have a high pole count (50-100), hence they're able to offer precision drive control for motion control applications

- They have a high torque at low speeds

- They produce high vibrations levels and are prone to resonance issues. Although they produce high amounts of heat which may be problematic in some cases

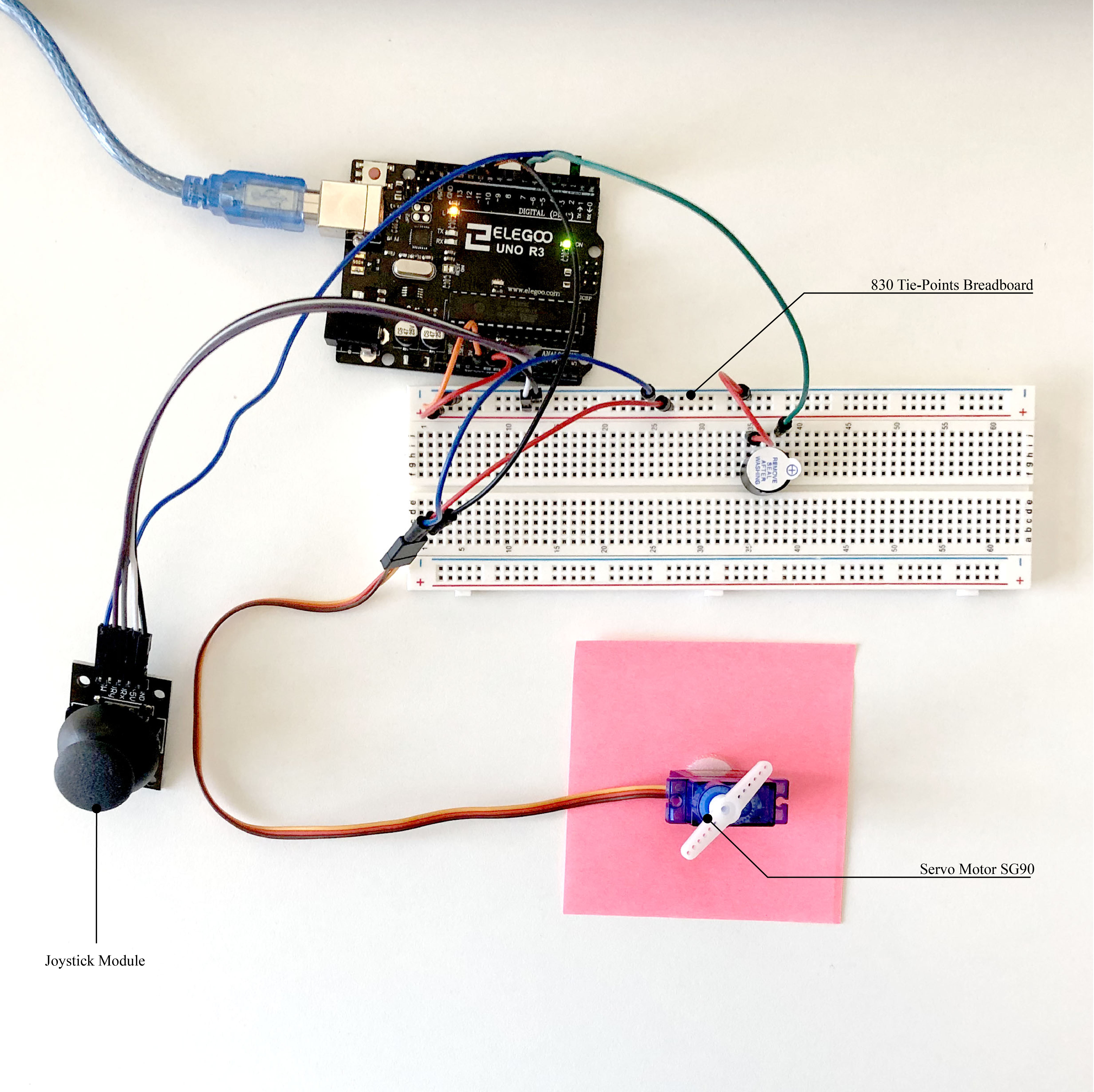

3 - Servo Motor

Understanding Servo Motors:

- A servo motor is a self-contained electrical device, that rotate parts of a machine with high efficiency and precision

- They're able to provide high levels of torque at high speed

- They do not suffer from vibrations or resonance issues

- Servo motors require an encoder to adjust pulses for position control

- The need for an encoder and gearbox makes the system mechanically complex and hence costlier than stepper-motors

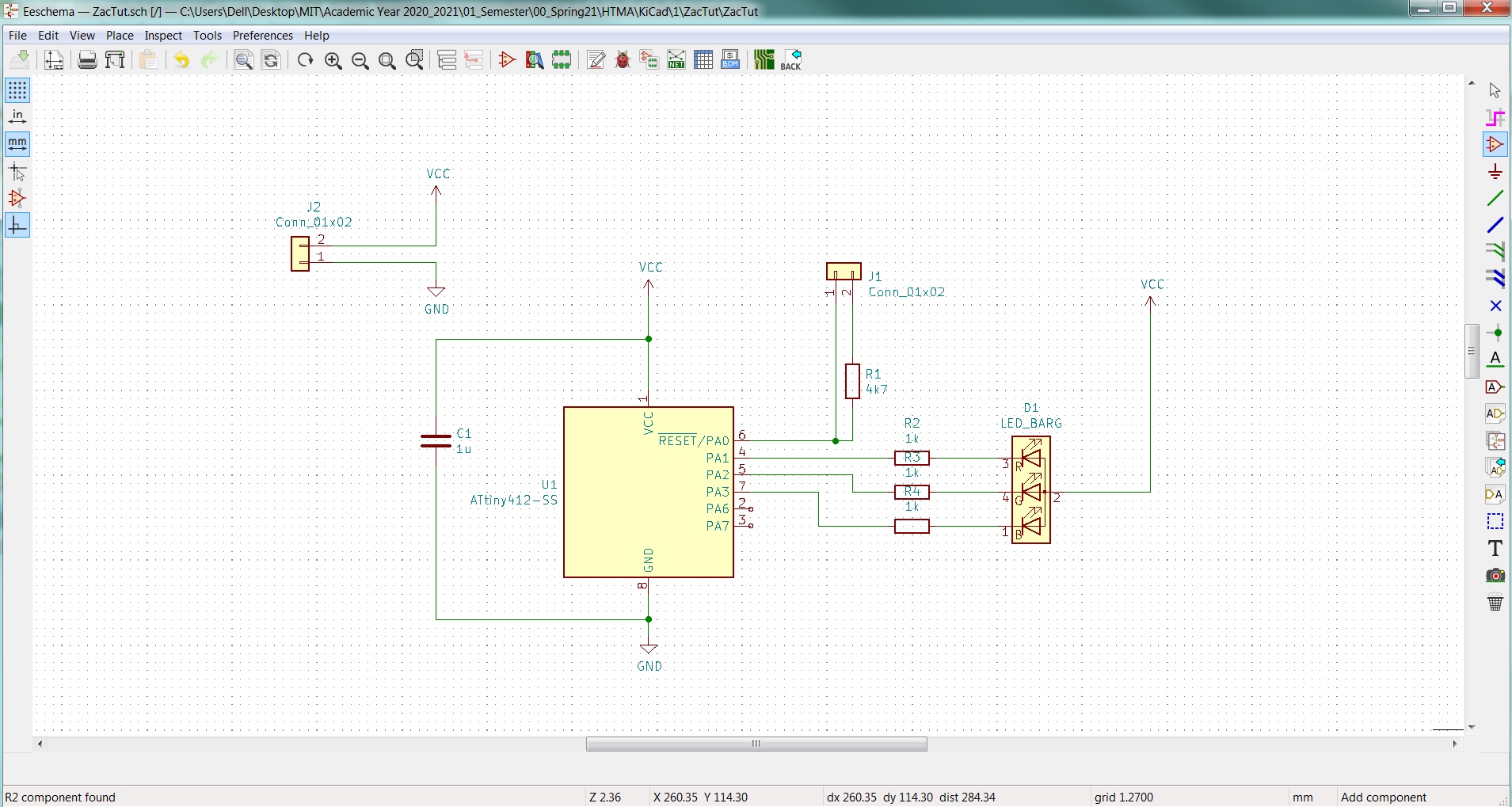

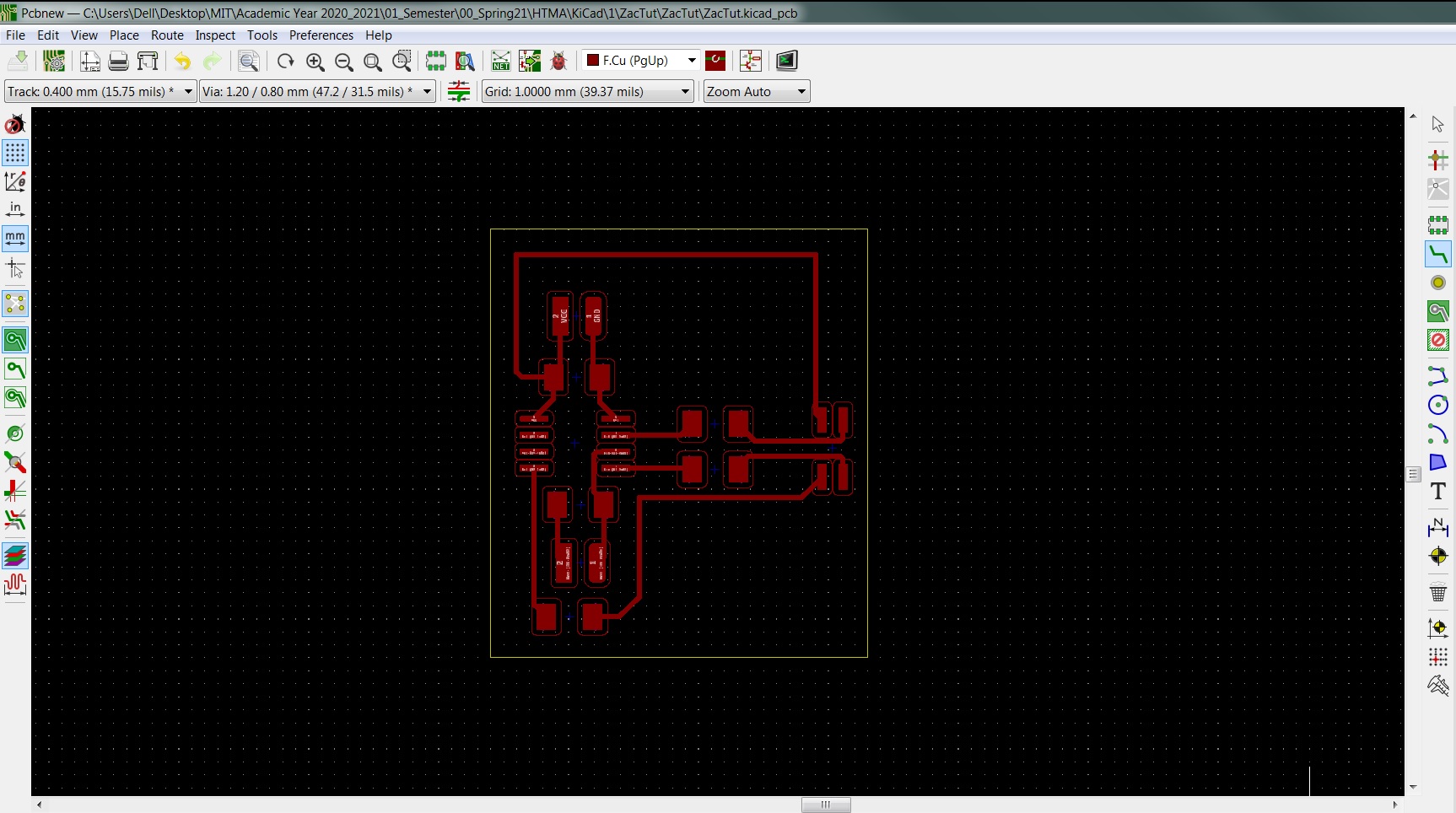

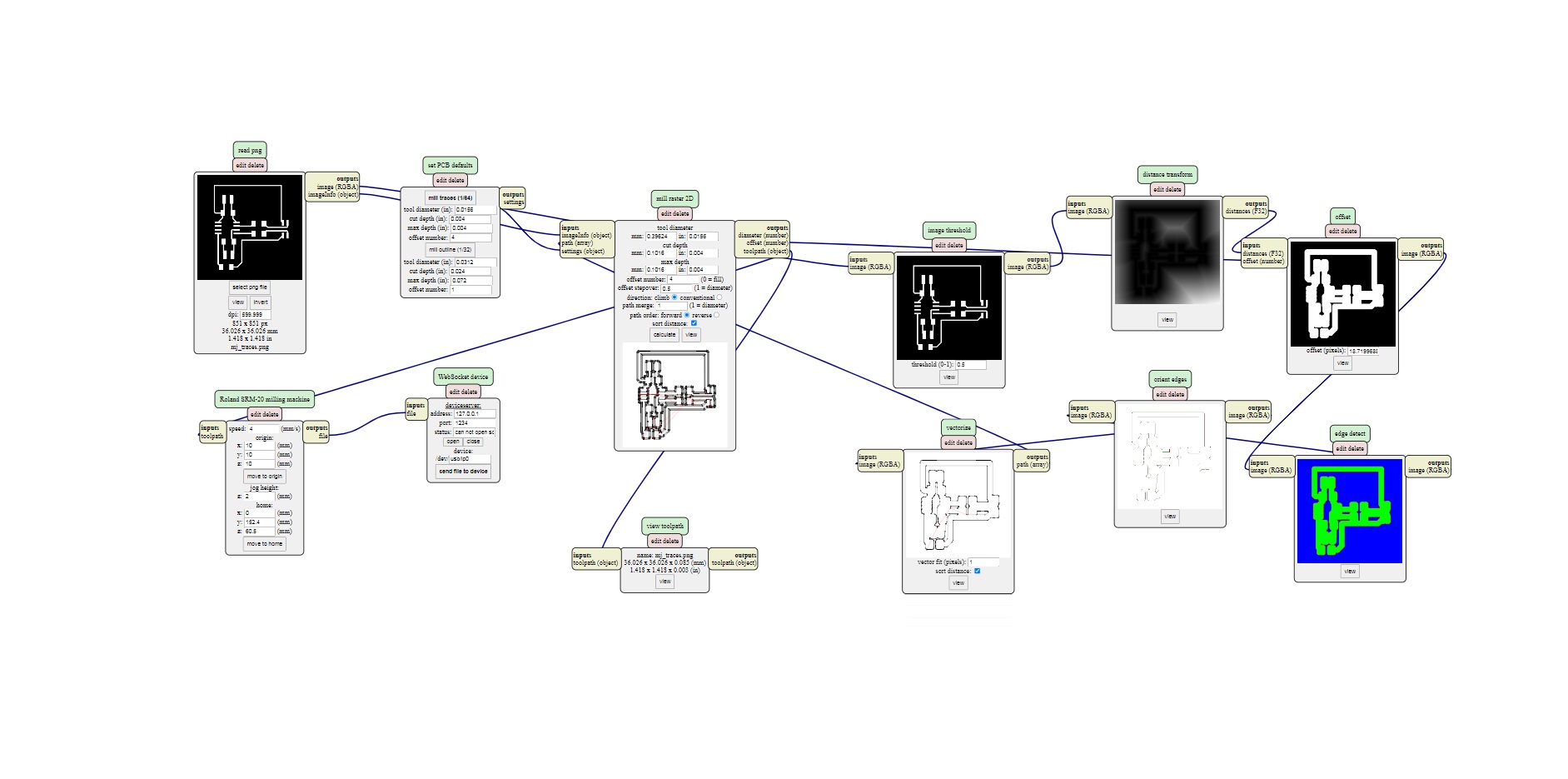

PCB Production Workflow

For the PCB production workflow, I have been following along HTMAA 20 Tutorial done by Zach as well as Getting To Blinky 5.0

I feel pretty comfortable with the production process of generating black and white images then moving to mods to generate the toolpaths; however, I haven't fully grasped circuit design just yet. I'm hoping in the following weeks with a few more PCB design exercises I'll have a better understanding of it.

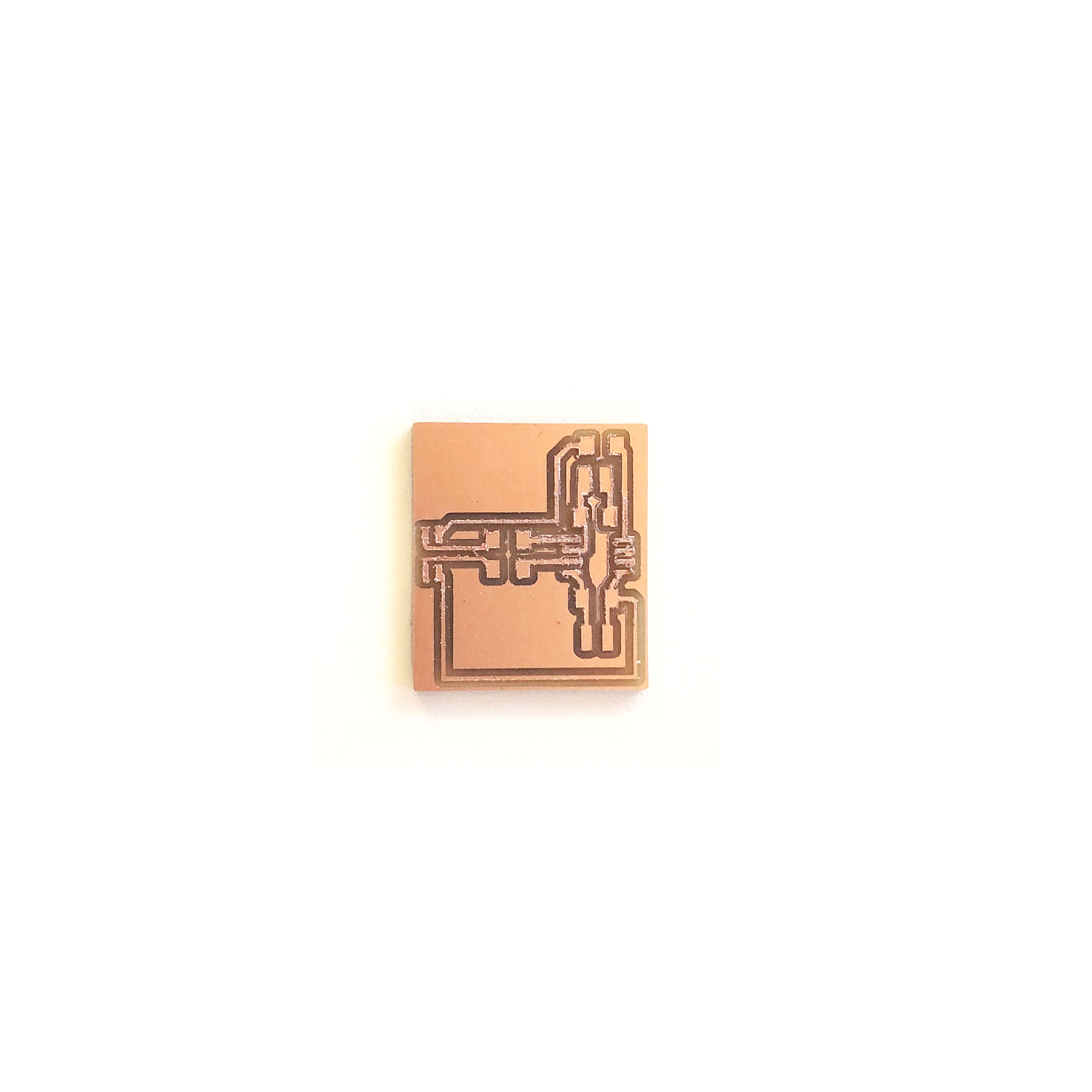

The routed PCB seems somewhat muddled and not as clean as I anticipated. I've used a 1/64 bit for routing and a 1/32 bit for cutting the outline. I'm assuming there's a spacing issue between the components in which some are packed tightly together, so on the 4th pass of the engraving those paths would be unintentionally merged together.

The routed PCB seems somewhat muddled and not as clean as I anticipated. I've used a 1/64 bit for routing and a 1/32 bit for cutting the outline. I'm assuming there's a spacing issue between the components in which some are packed tightly together, so on the 4th pass of the engraving those paths would be unintentionally merged together.