04.08 Update

Inkjet Print Head

- Each cartridge contains approx 12 million ink droplets which is the equivalent of about 750,000 characters

- The print-head should not touch any media, it's possible to produce legible prints by squirting ink from a distance of 1/2"& under the right conditions the print-head can shoot up to 6"

- The cartridge does not use the two left-most contacts on the flex cable, as they are shorted together - one use is to implement a "loop back" detection circuit to verify whether or not the cable is plugged to the connector

- Each nozzle is completely independent of the others, although a single ink supply feeds all nozzles.

- Since the resistor is heated by current flow - it's important that the voltage pulse and duration is no more than 40 microjoules of energy as to not burn the resistor

- Do not fire more than two droplets at a time. The droplets from the nozzles must also be physically separated from each other. For example, #1 + #7 or #8 + #2

- Wait a total of 800 microseconds before firing the next droplet out of the same nozzle as a minimum for pulse spacing between successive droplets.

We continued to develop the print-head and have switched our FPC connector to the Würth Elektronik connector - which has a 1.0mm pitch, this time around the print flex cable fit well.

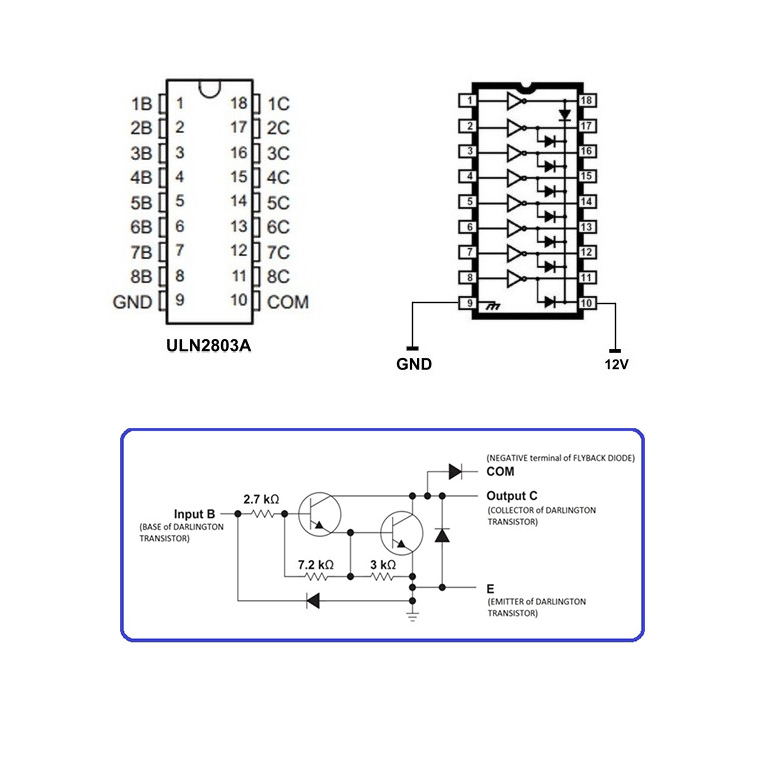

- Control inductive loads - the darlington array act as seperate 8 individual switches that can be turned off and on as desired.

- Drive multiple loads - it is capable of driving 8 loads at a time

We used a simple Arduino code to send electrical pulses to a single nozzle to squirt ink. After a few trial and errors, it worked! :) We had a little fun with free-hand printing.

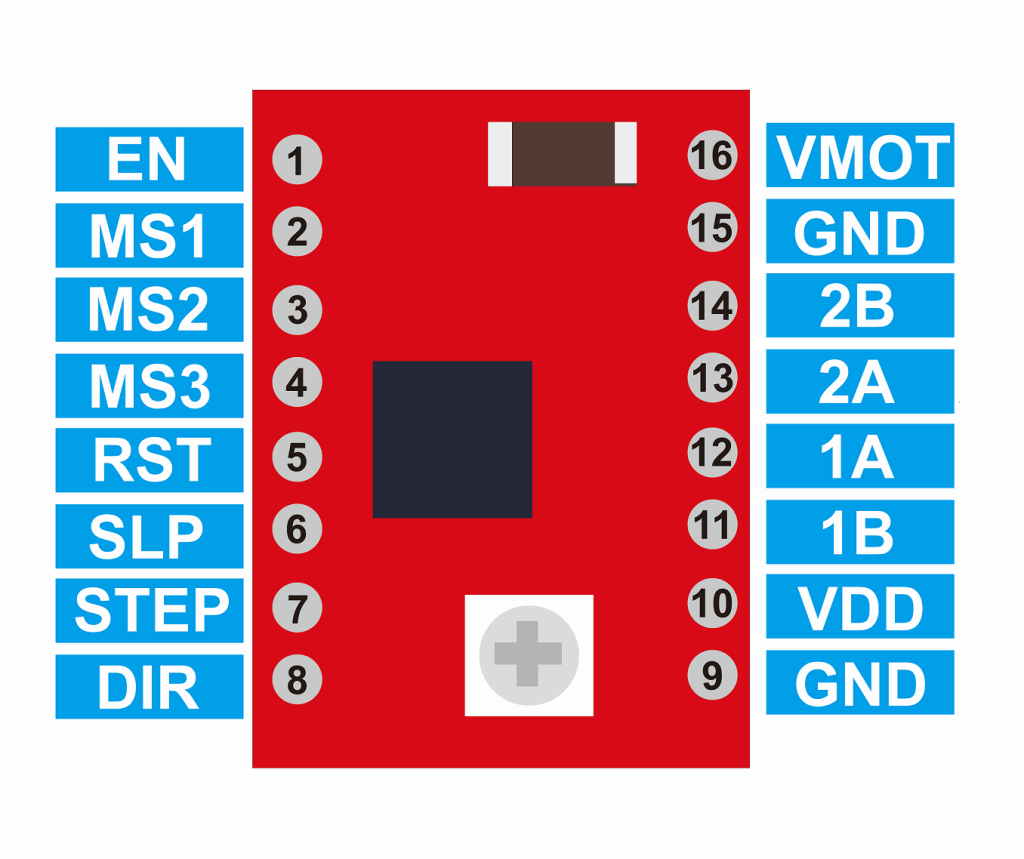

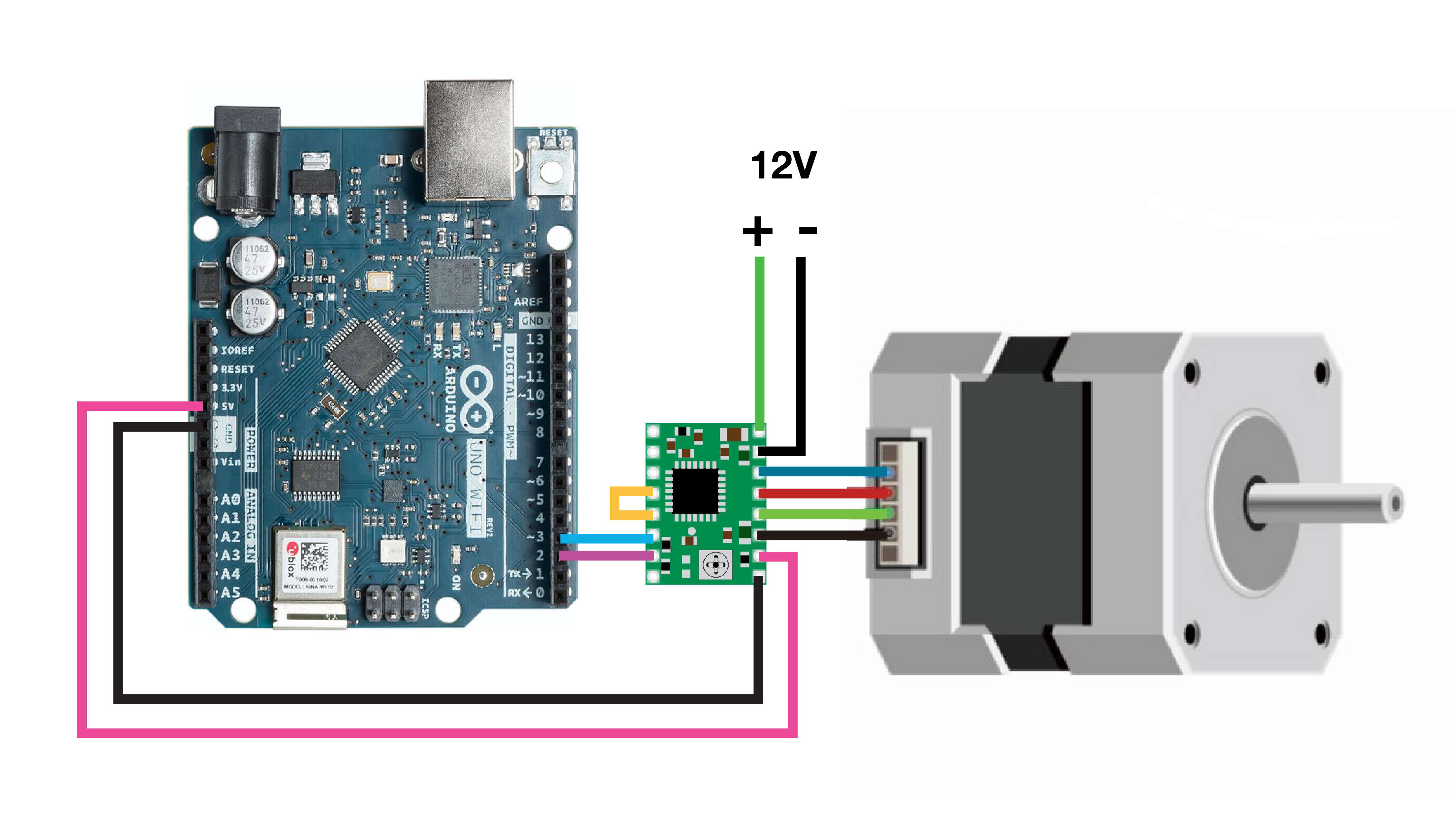

TinyZ Motor Tests

- VDD & GND : Connected to 5V and GND of Controller

- VMOT & GND :Used to power the motor

- 1A, 1B, 2A, 2B :Connected to the 4 coils of motor

- DIRECTION : Motor direction control pin

- STEP : Steps control pin

- MS1, MS2, MS3 : Microstep selection pins

- SLEEP : Pins for controlling power states

Current Limit = Vref x 2.5

Nema17 = 2A (as extracted from the data sheet - from the following

website )

2 = Vref x 2.5

Vref = 0.8V