05.20 Update

We are a week away from the final presentation, so we've began to fine-tune and clean up some of our systems.

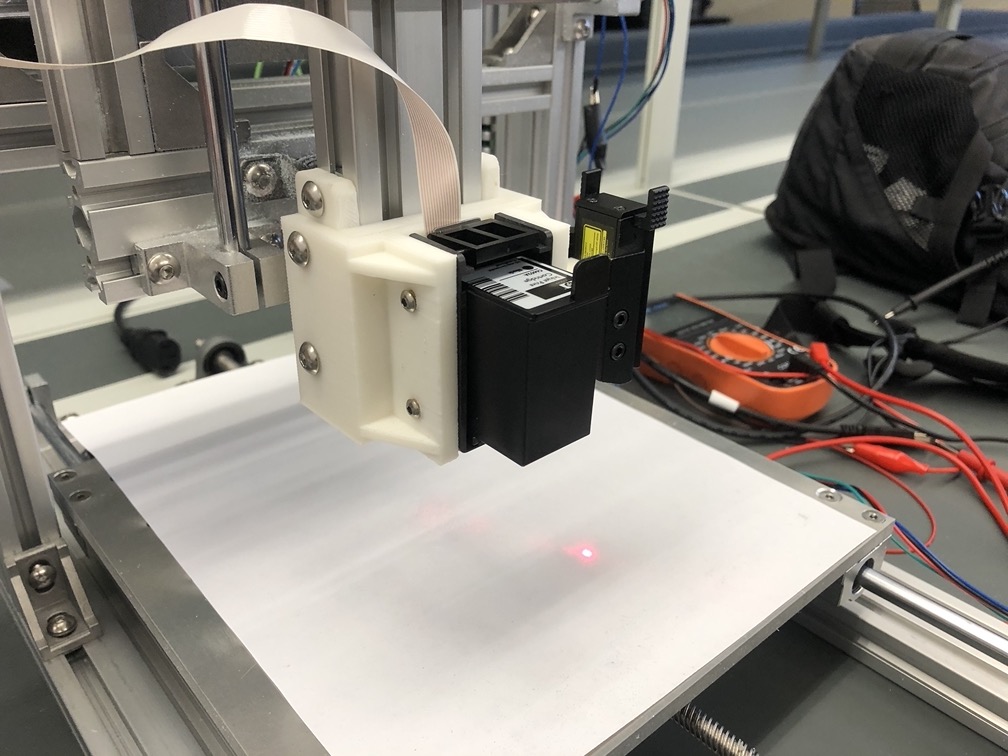

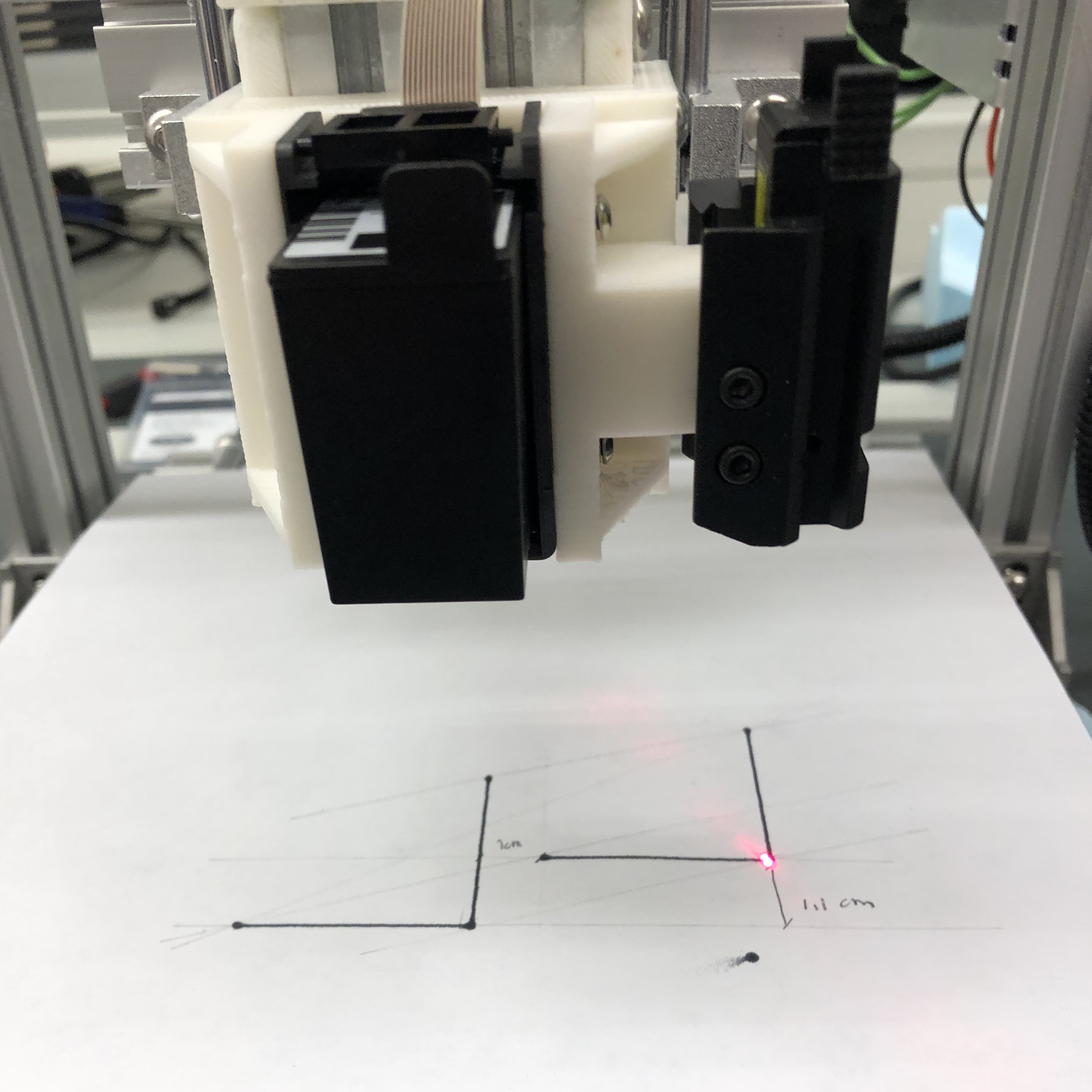

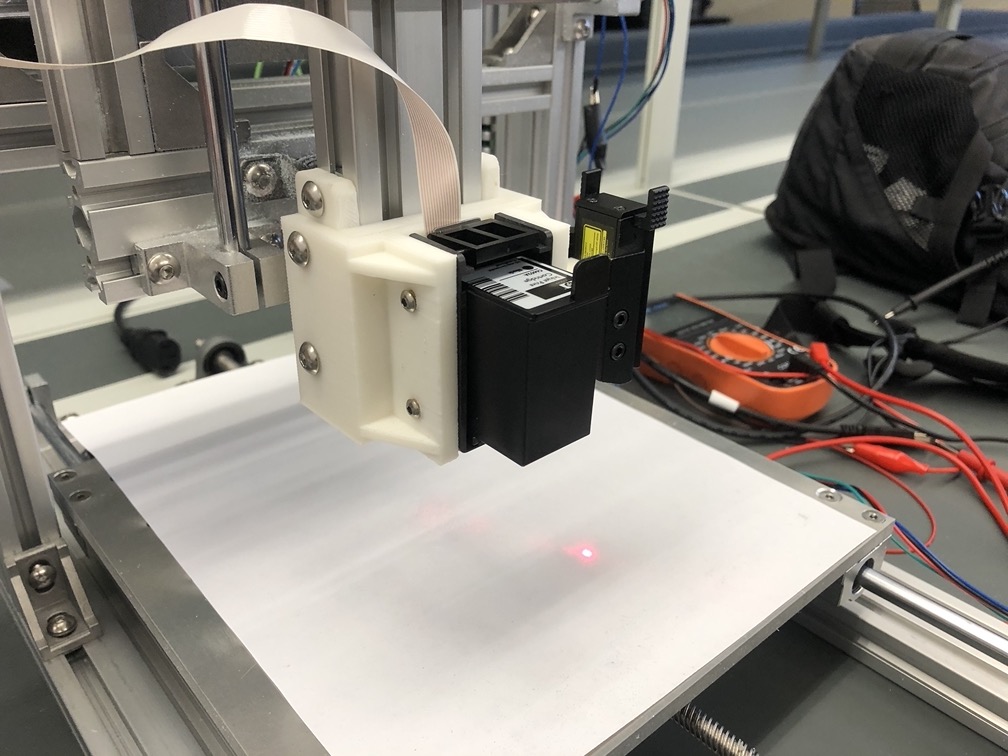

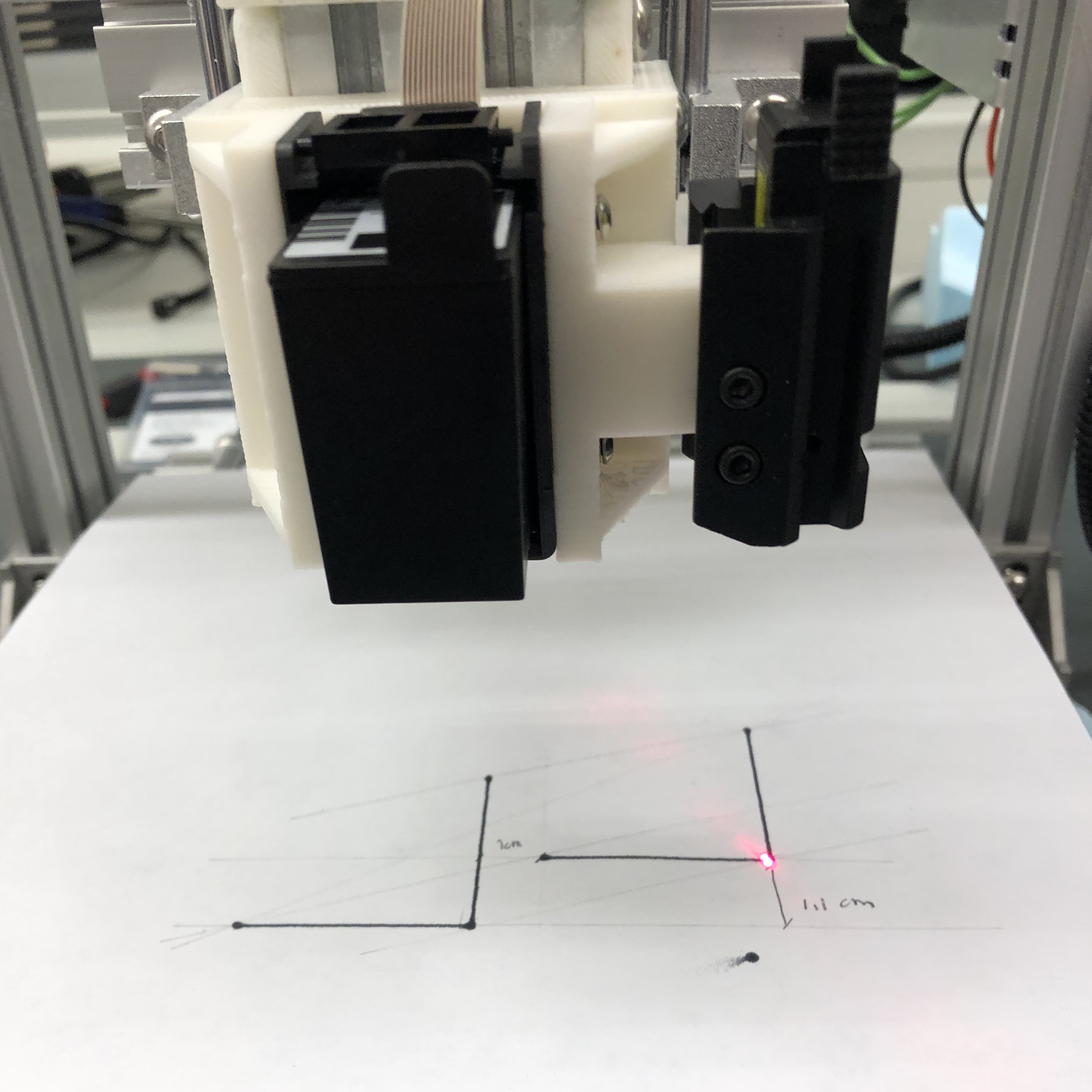

The printer carriage has been remade to accomodate a laser to help us set up our origin.

- Our Motivations - Existing flat bed printers are expensive, less at desktop scale, do not accept as much variation in the Z axis

- Video of Use Examples

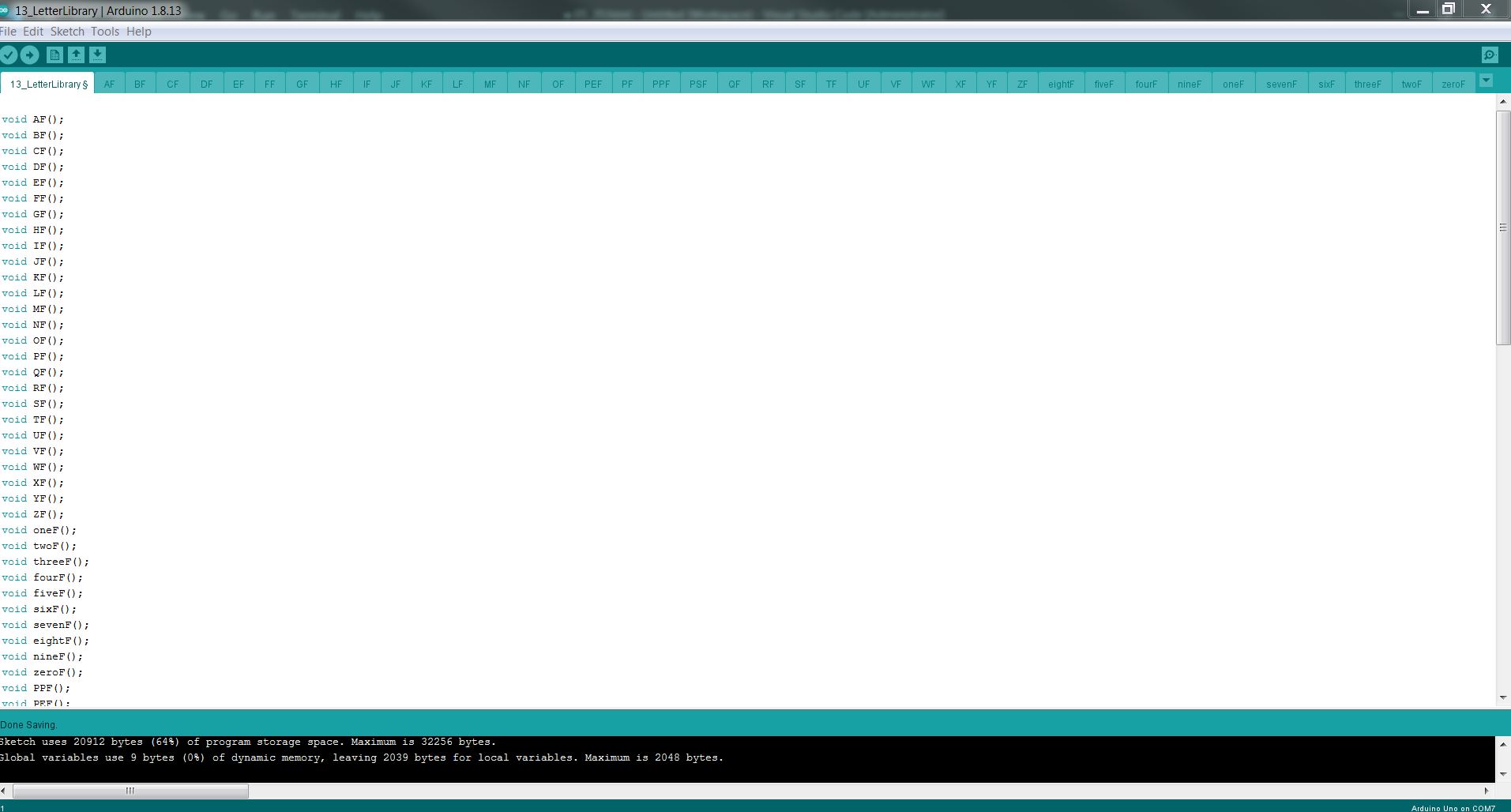

- Explanation of System/Current Methods of Use

- Possible Implications/Future Explorations

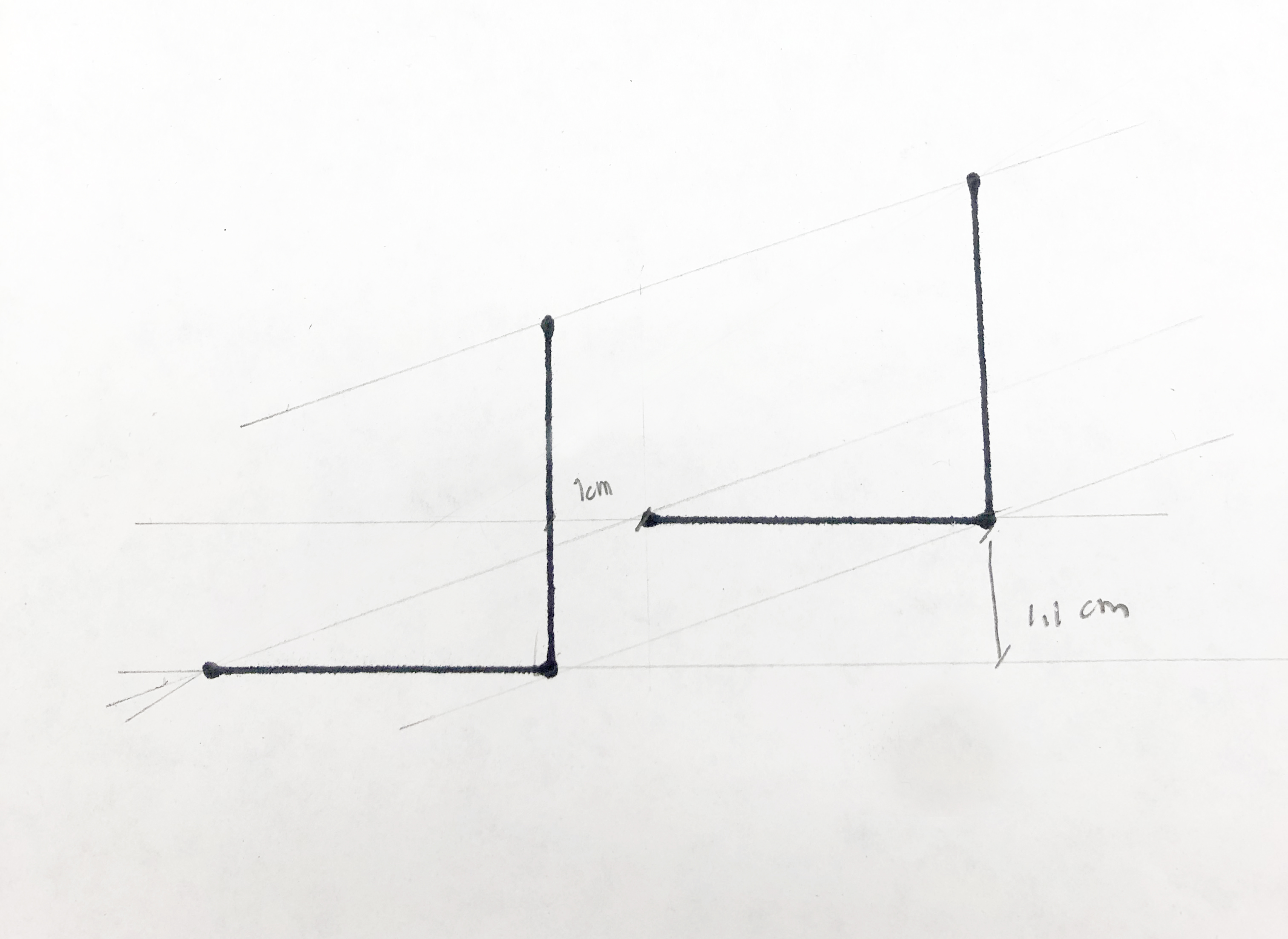

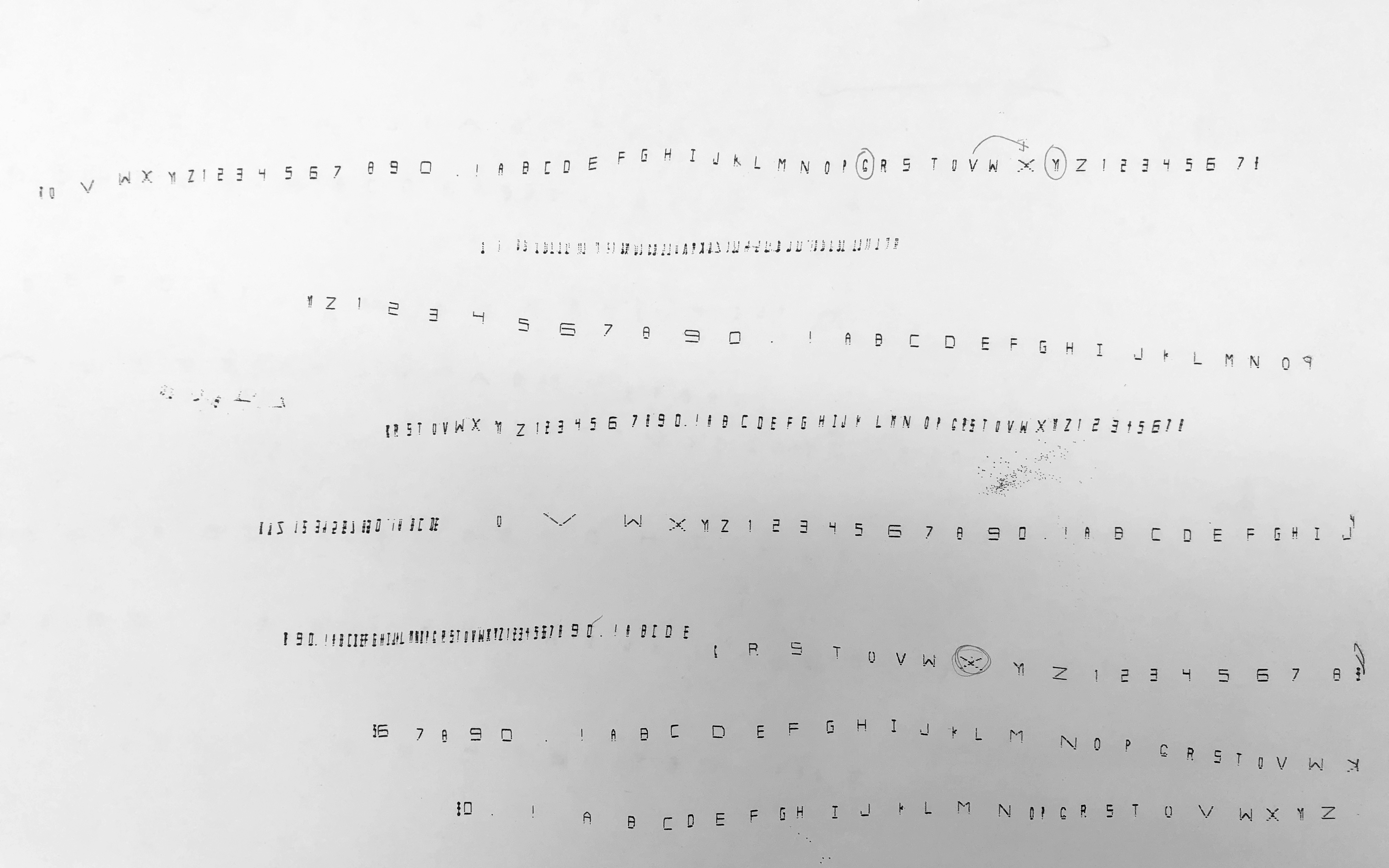

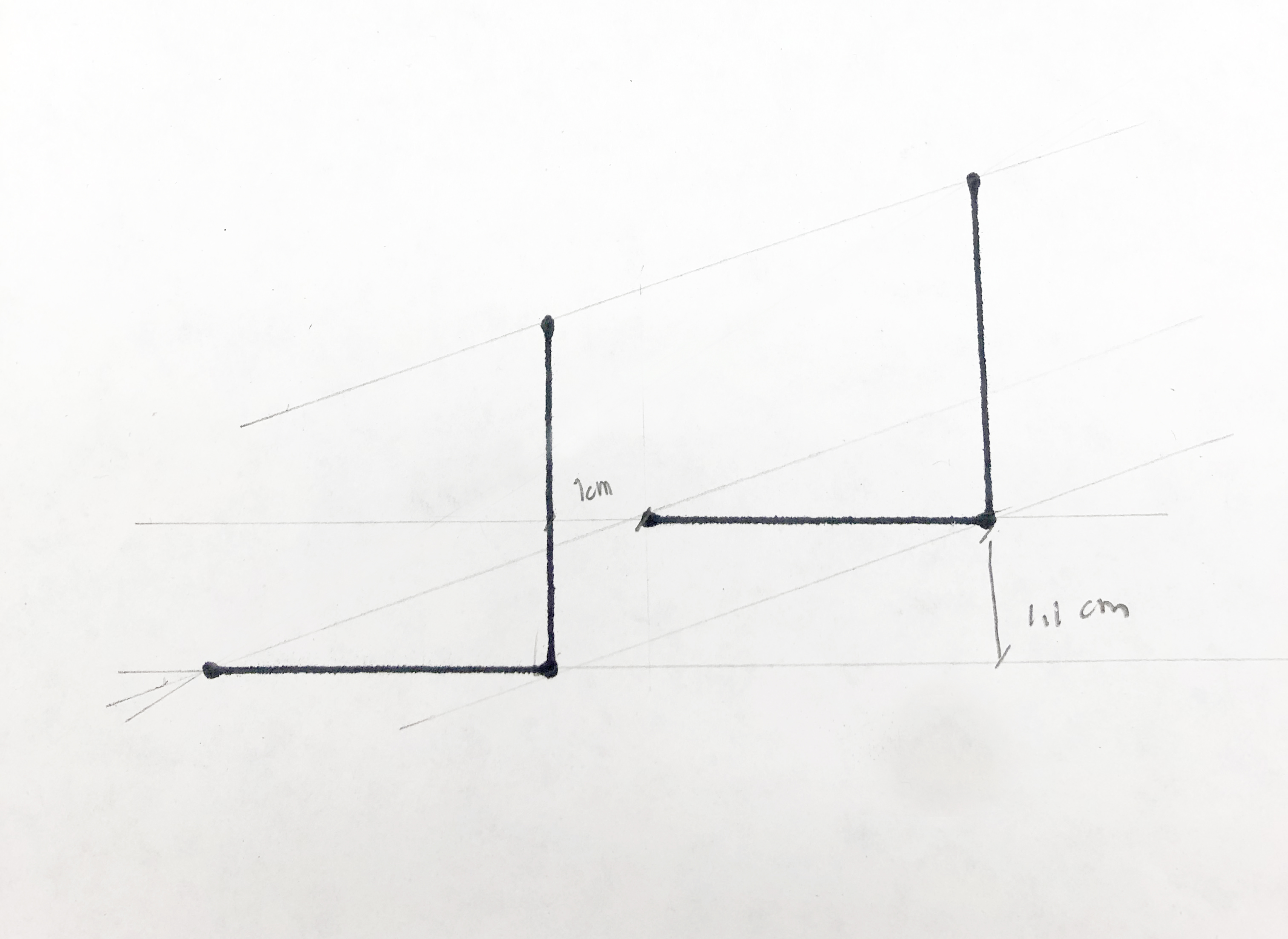

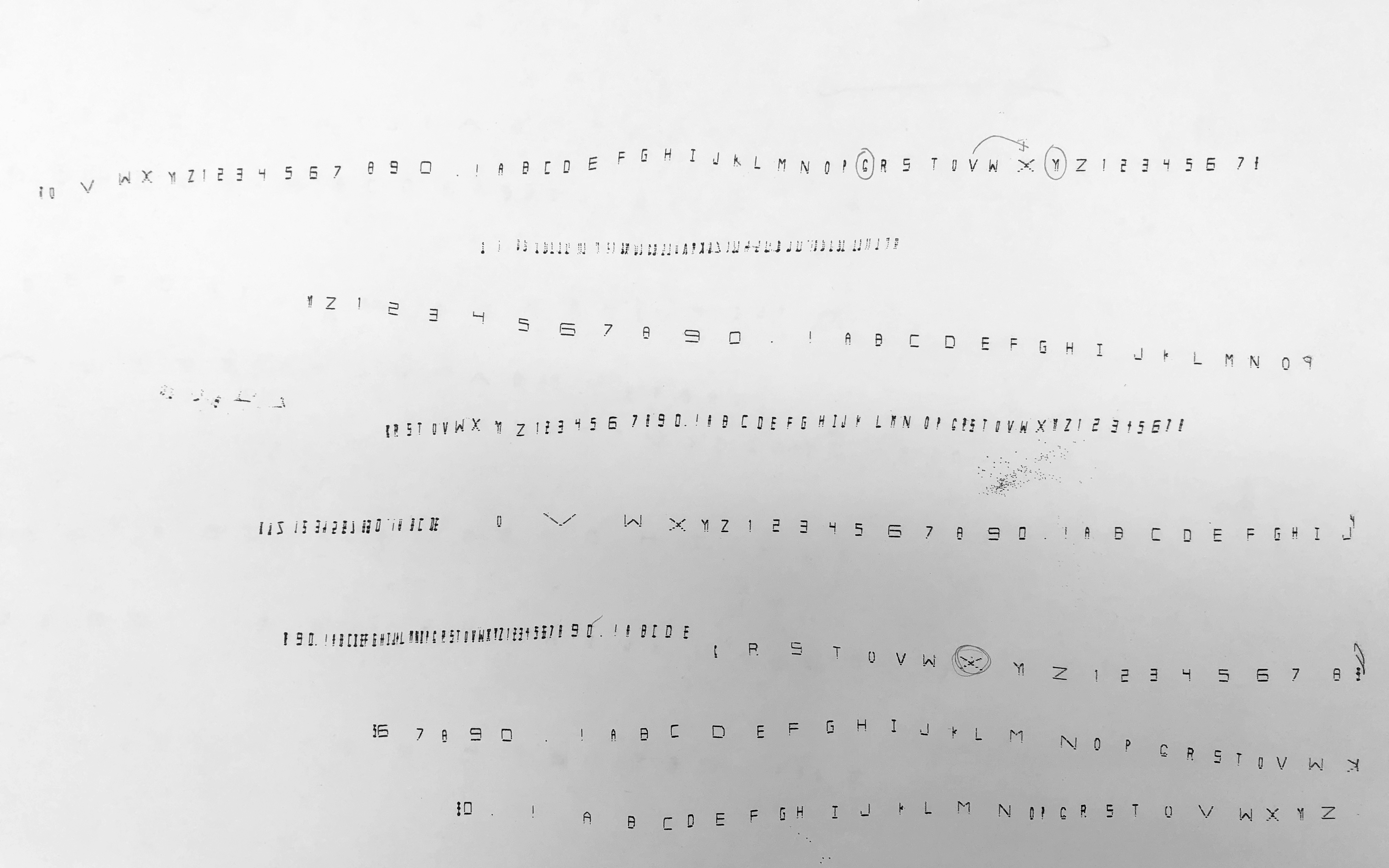

- Examples of hacked printhead capabilites, printing text, printing drawings, printing single lineweight, printing with all 12 inkjets

- Printing on paper

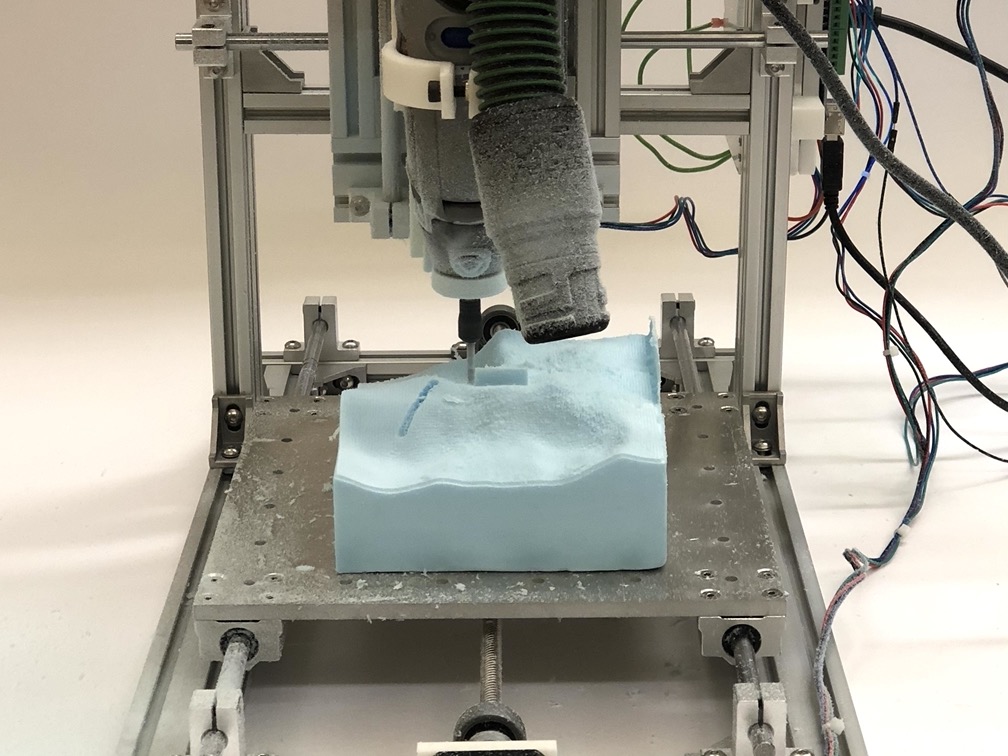

- Printing on flat substrates with varied thicknesses

- Printed T-Shirts

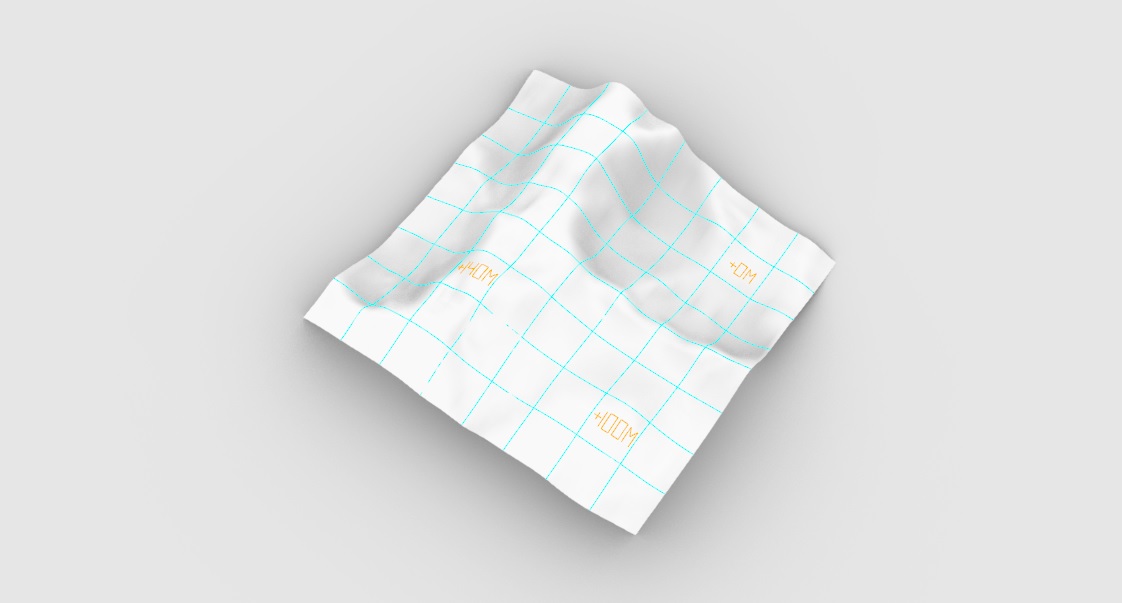

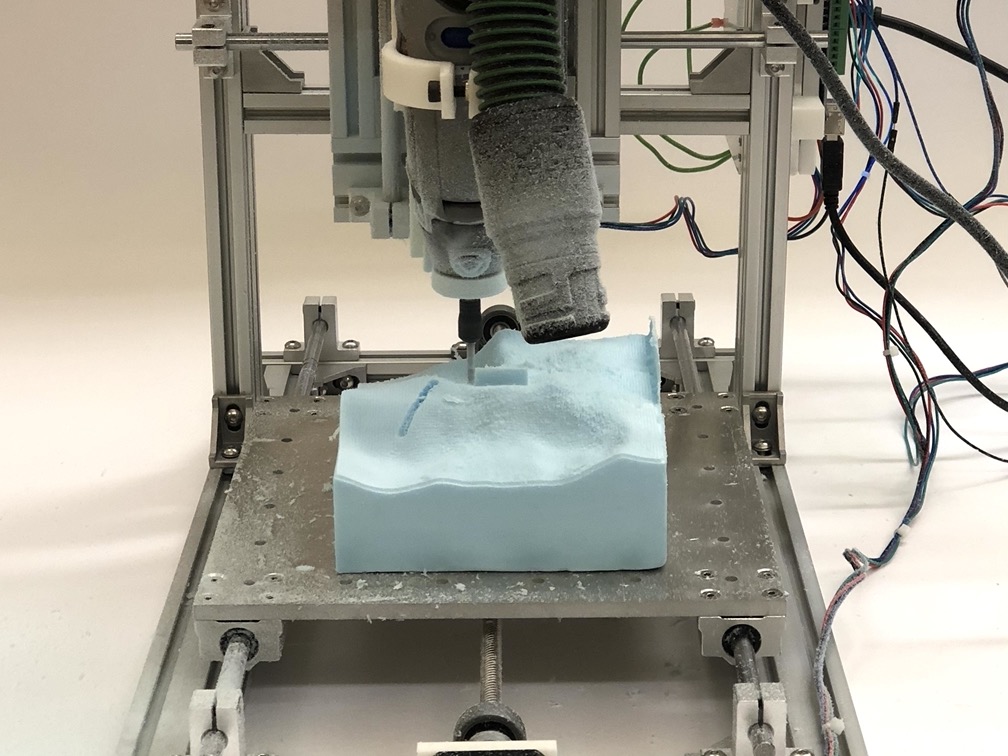

- Printing on 3d Surfaces also milled on same machine

- Implications of Z-Axis with Printing

- Printing with UV Cured Ink

- Assembly Instructions Printed on Parts

- Scaled up Possibilities for applications in things like Architecture/Automotive