04.22 Update

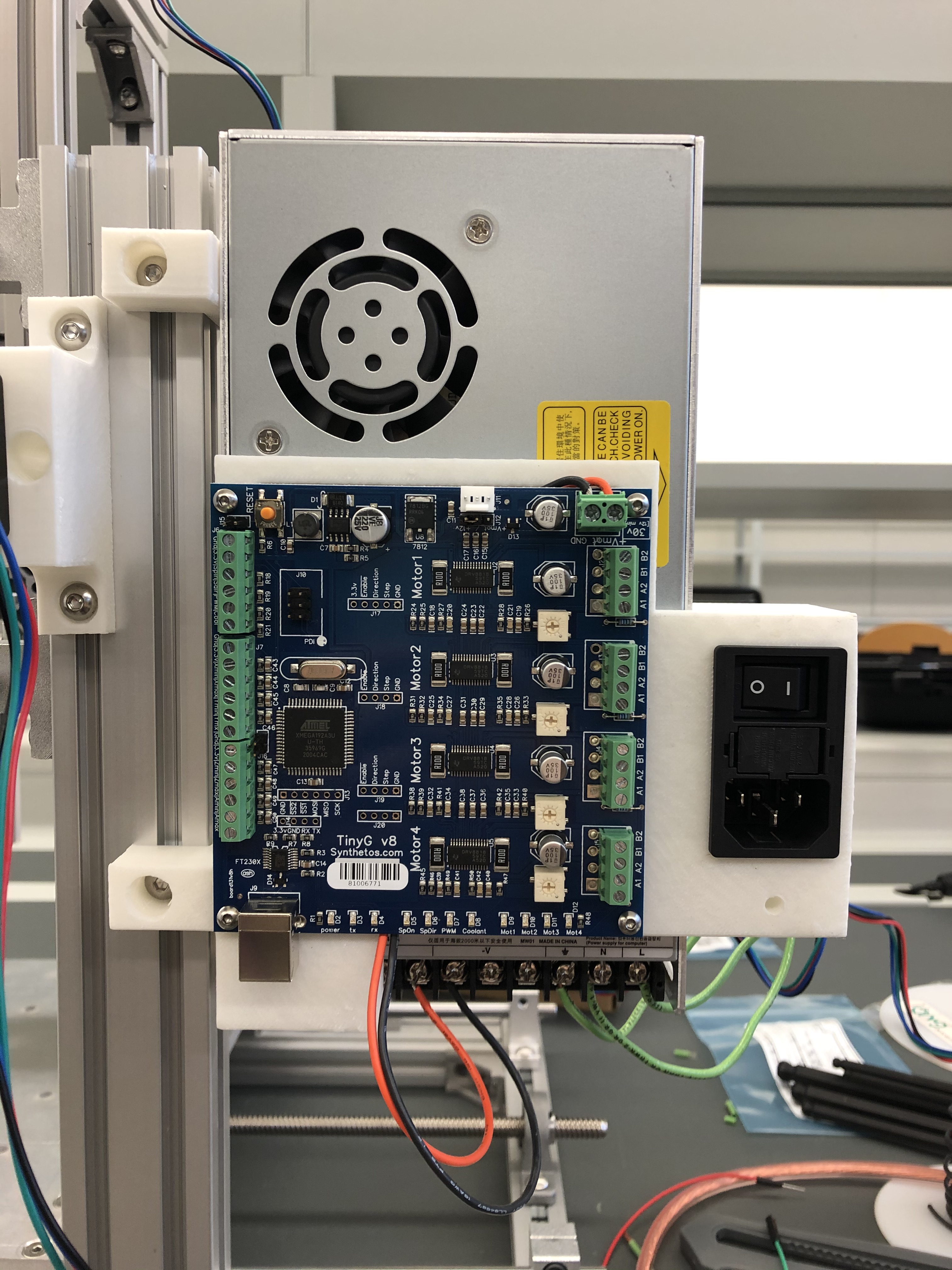

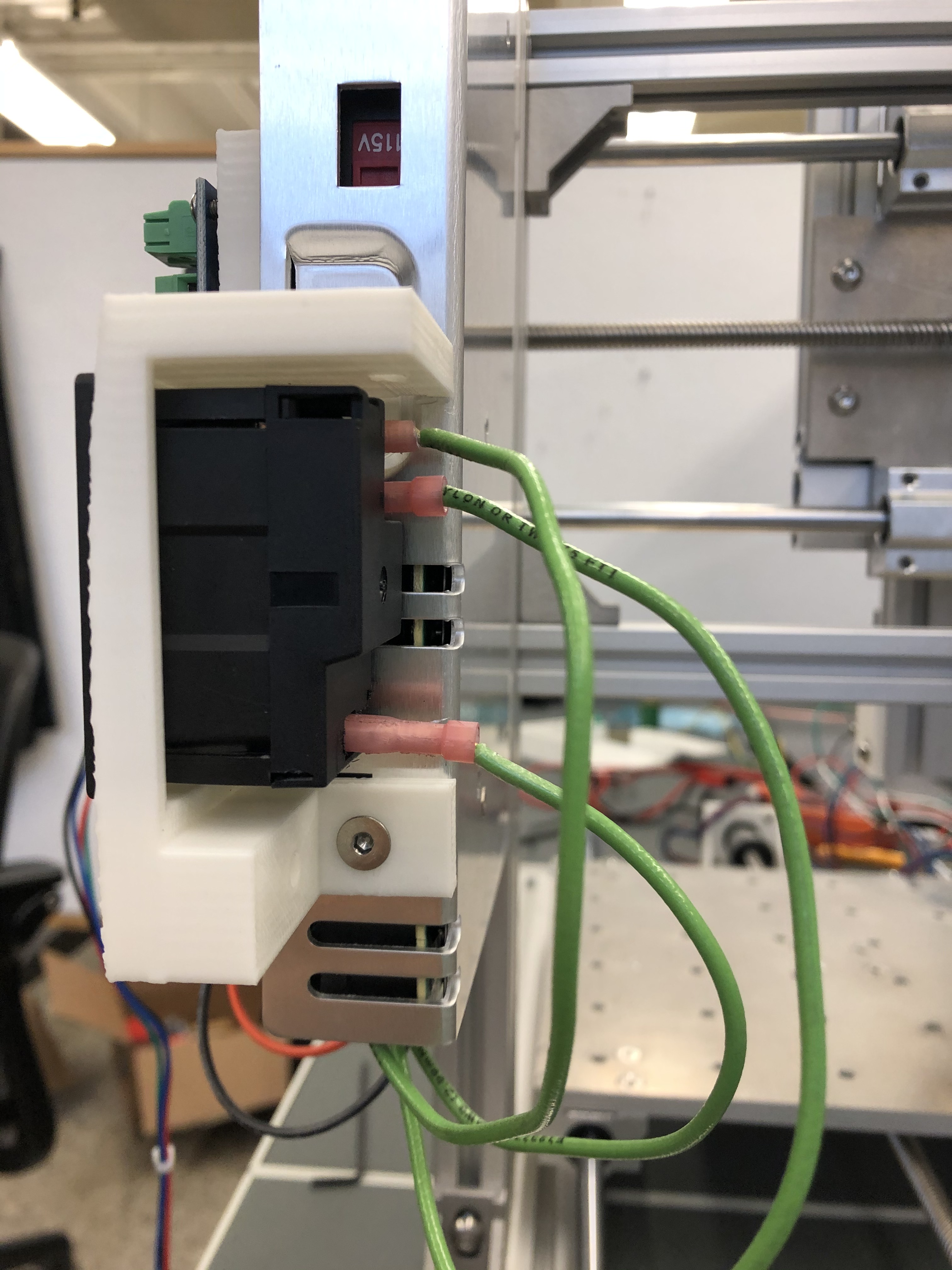

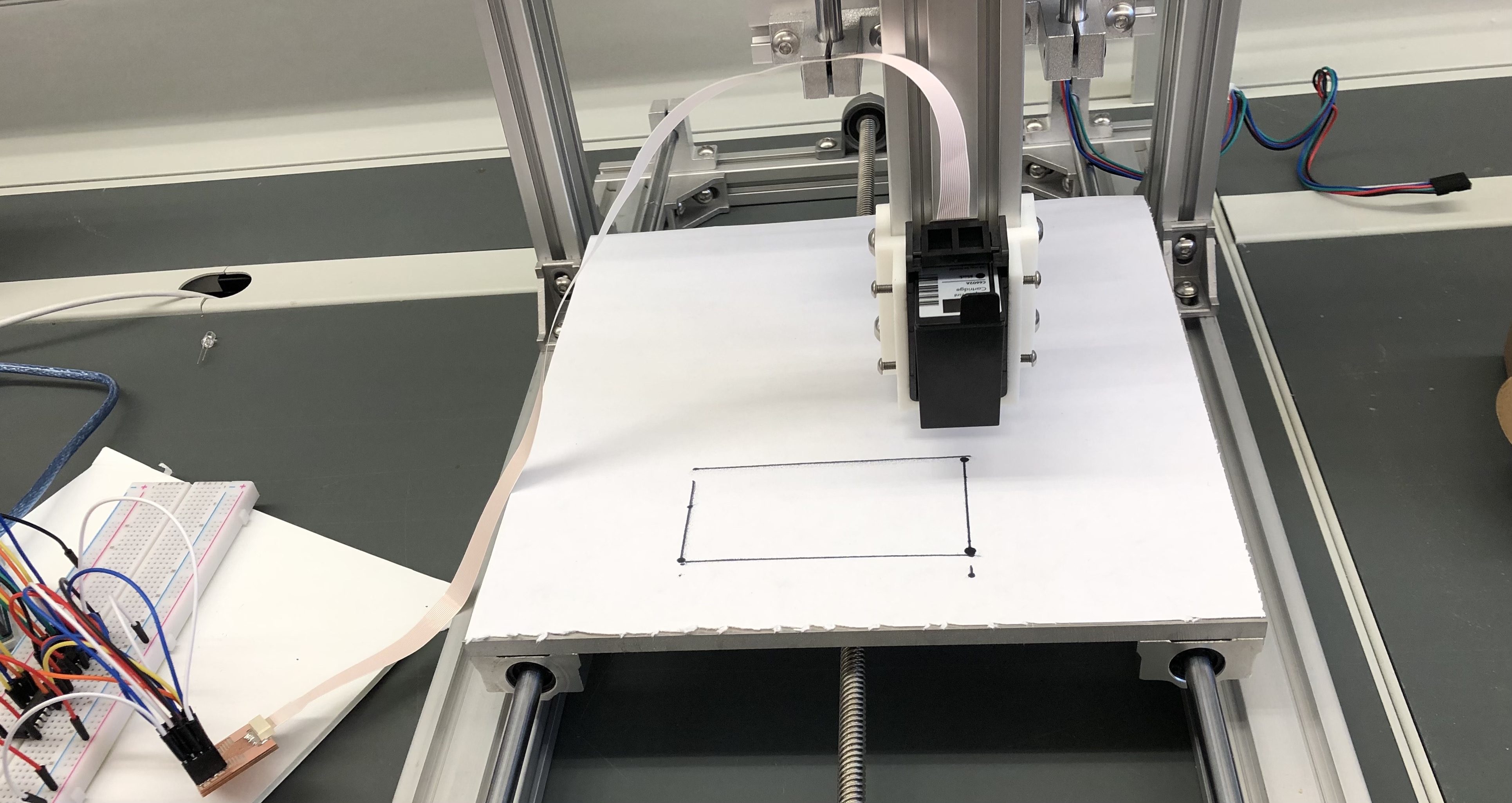

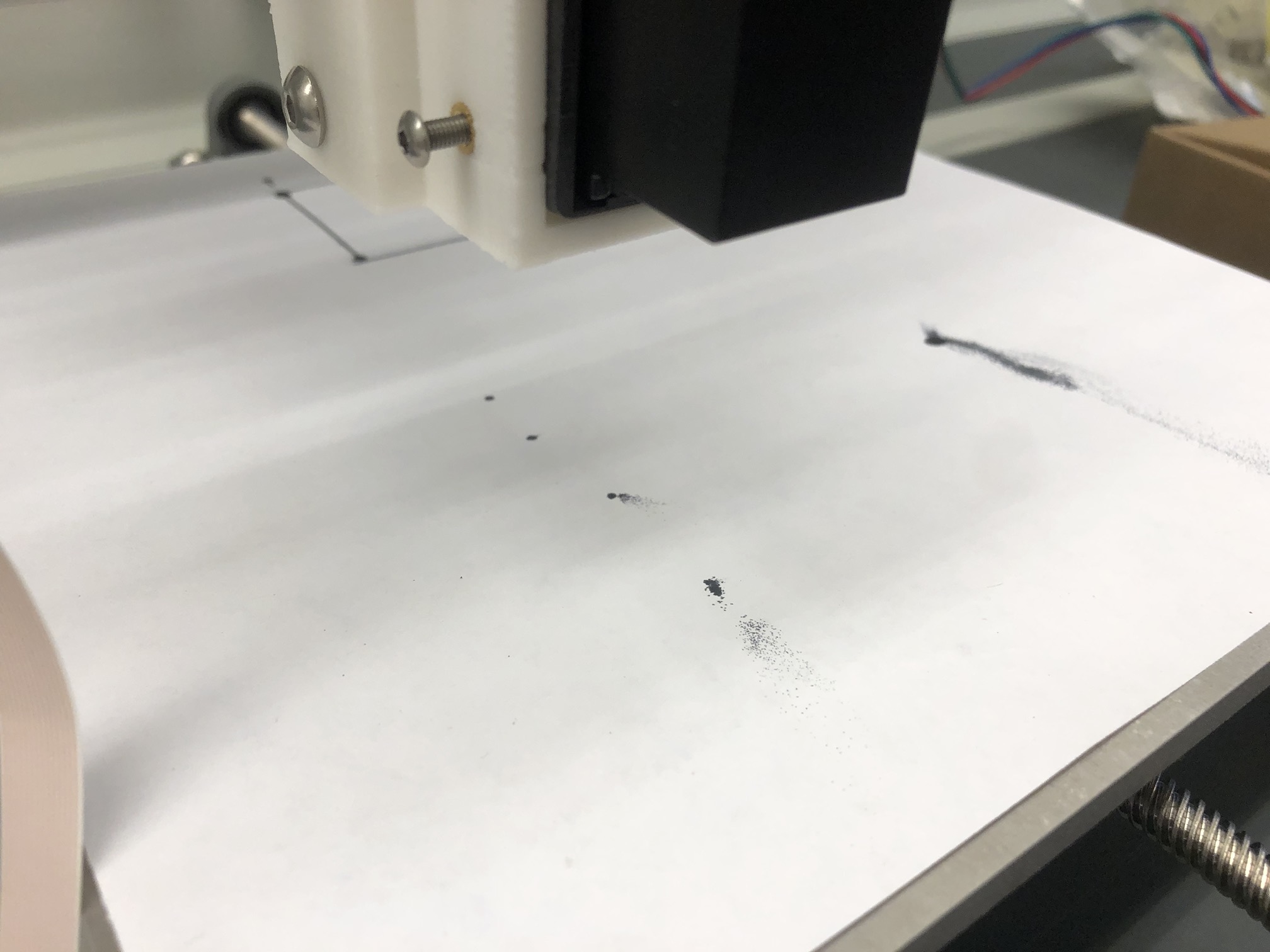

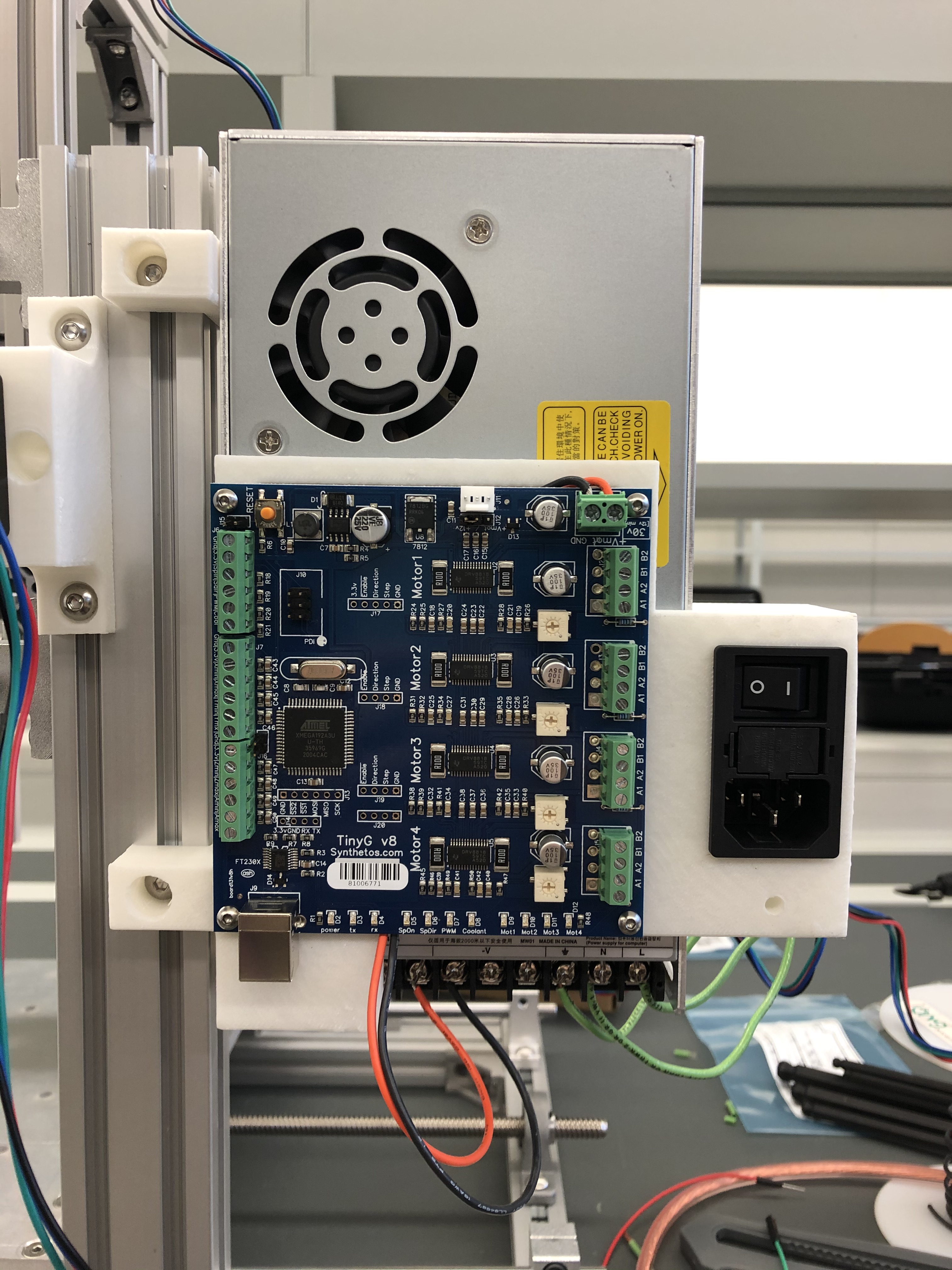

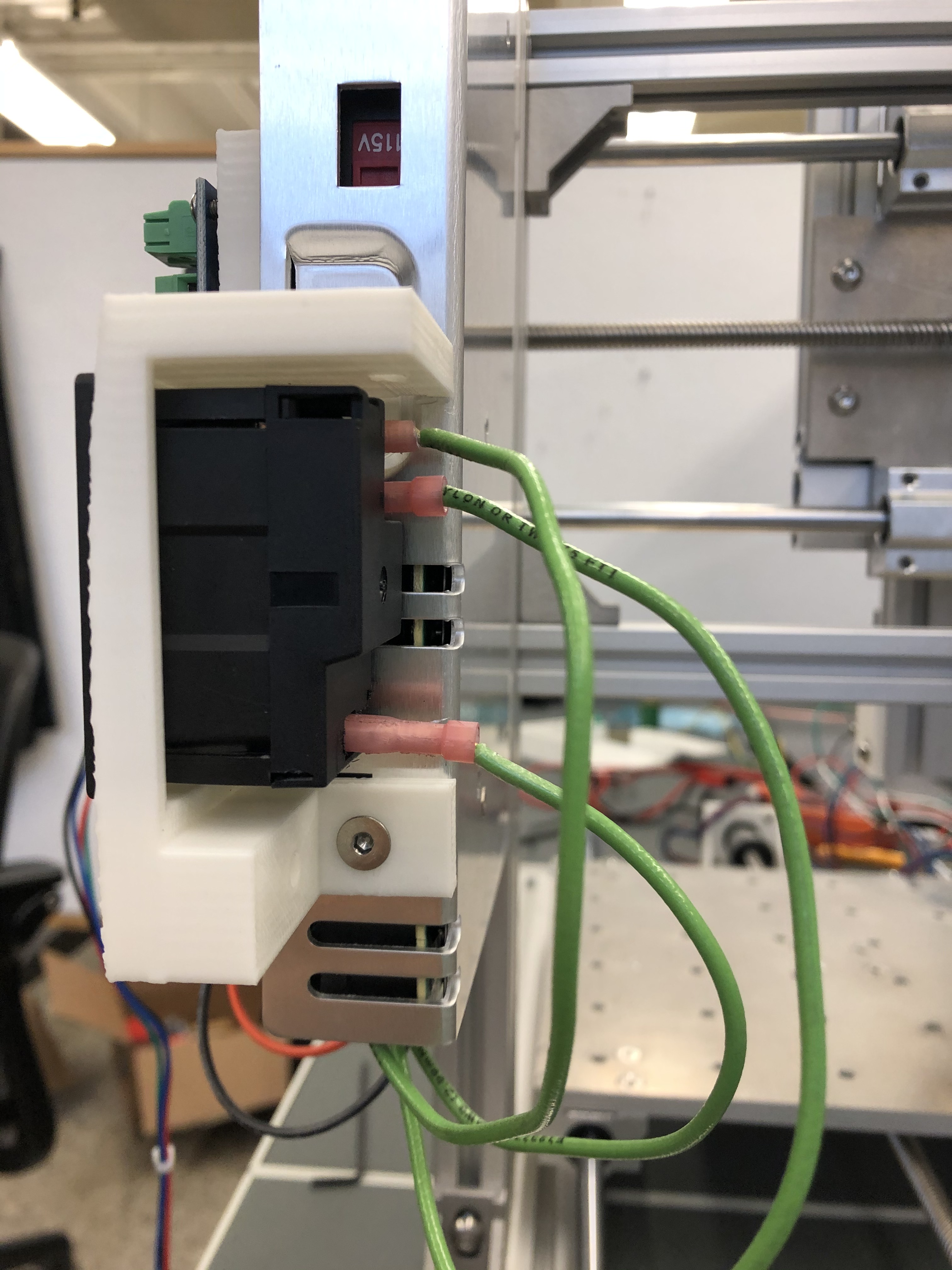

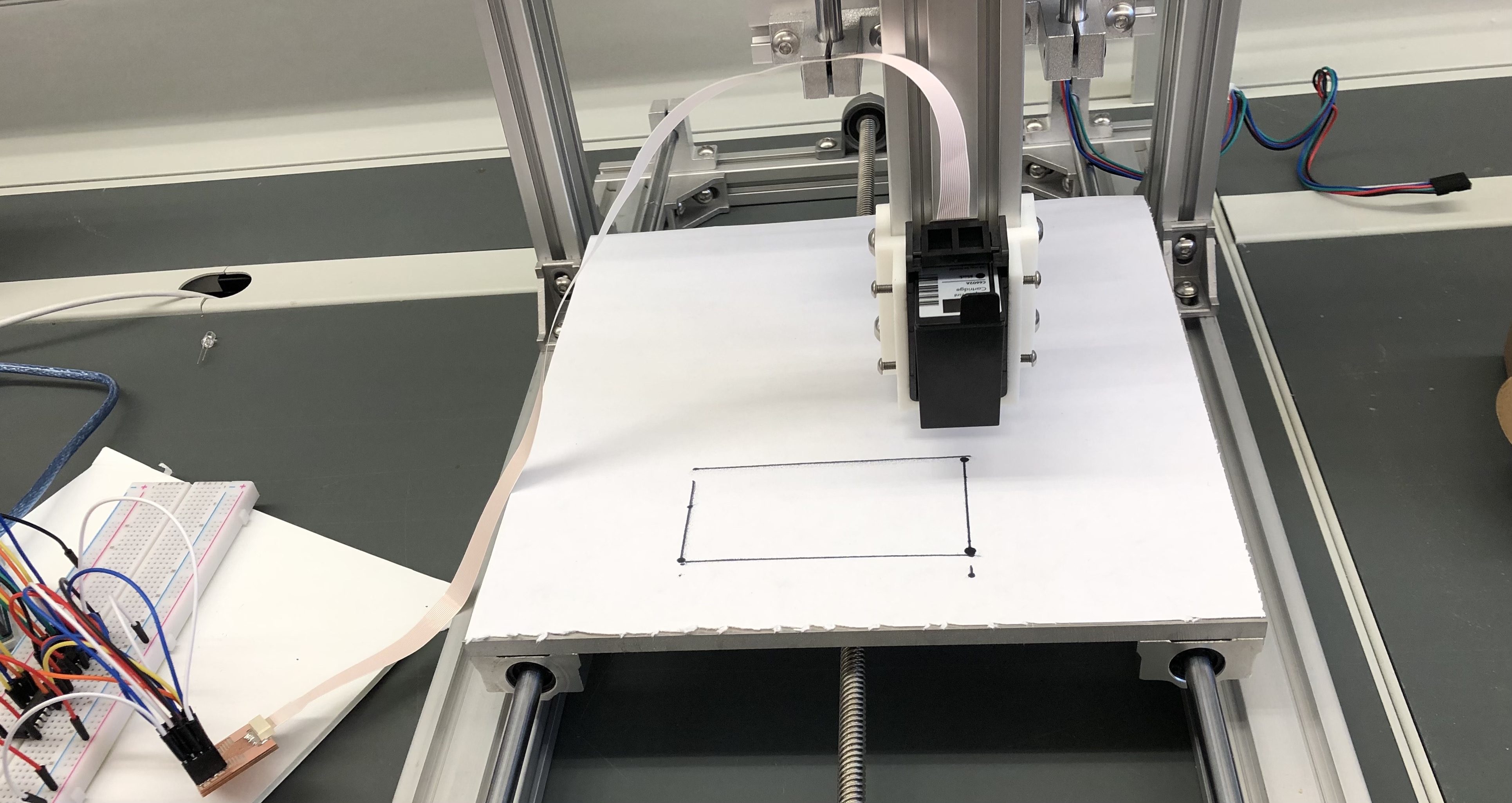

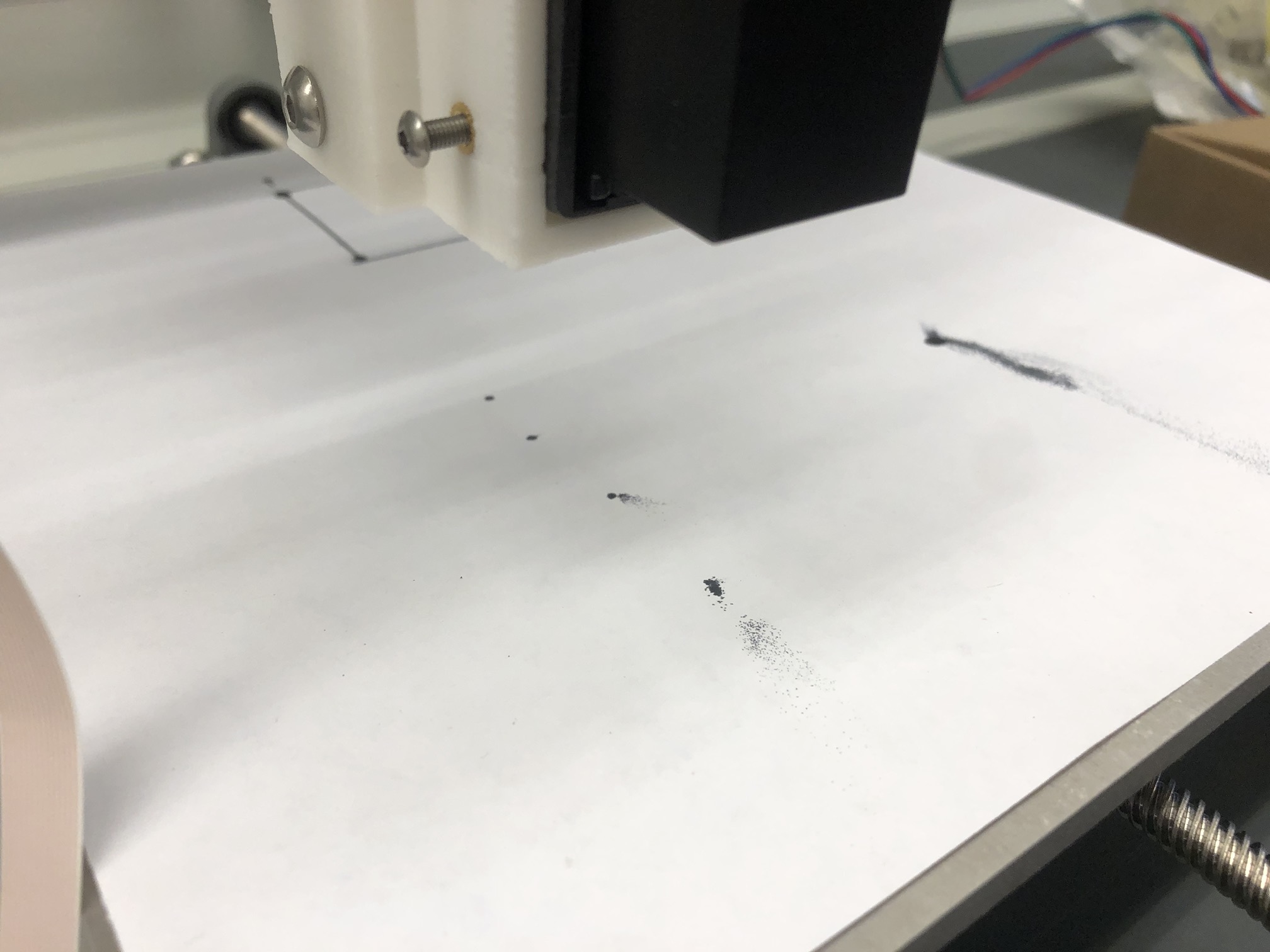

This week we started working on tinyG, wiring it to the power source and attaching it to tinyZ through a 3d printed component which attaches to the aluminum frame.