Week 01 ~ Computer-Controlled Cutting

Laser Cutting

Goal: a light-weight bed-side table based on simple design rules.

A stacked tower based on simple design rules (90 deg rotation and vertical translation): sketch and CAD in Onshape.

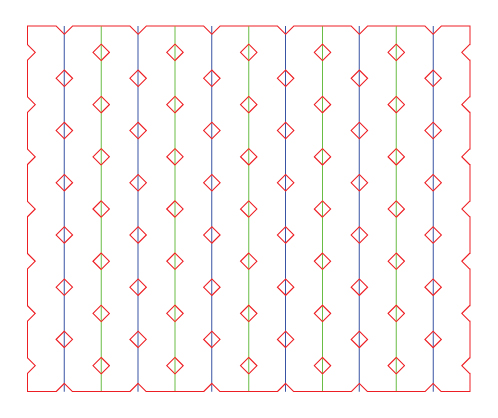

Making the cut-pattern in illustrator (red = cuts, blue = top folds, green = bottom folds). It was important to have different colors for the top and bottom folds so that we could selectively 'skip' them in the laser-cutter print setup.

Making the cut-pattern in illustrator (red = cuts, blue = top folds, green = bottom folds). It was important to have different colors for the top and bottom folds so that we could selectively 'skip' them in the laser-cutter print setup.

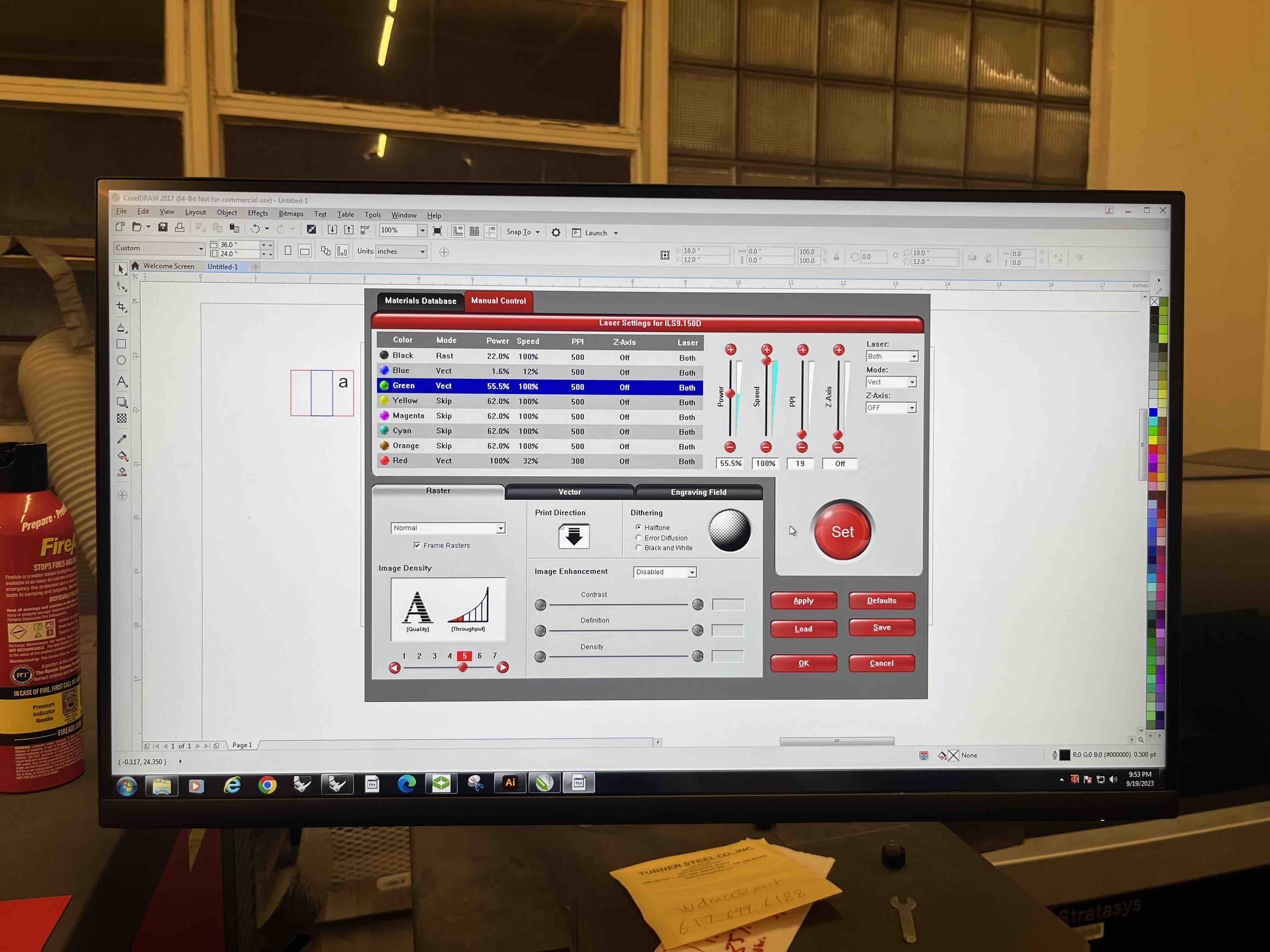

Universal lasercutter interface showing line-colors and the ability to "skip" lines, so that we can flip the cardboard for the scoring of the folds on the back.

Universal lasercutter interface showing line-colors and the ability to "skip" lines, so that we can flip the cardboard for the scoring of the folds on the back.

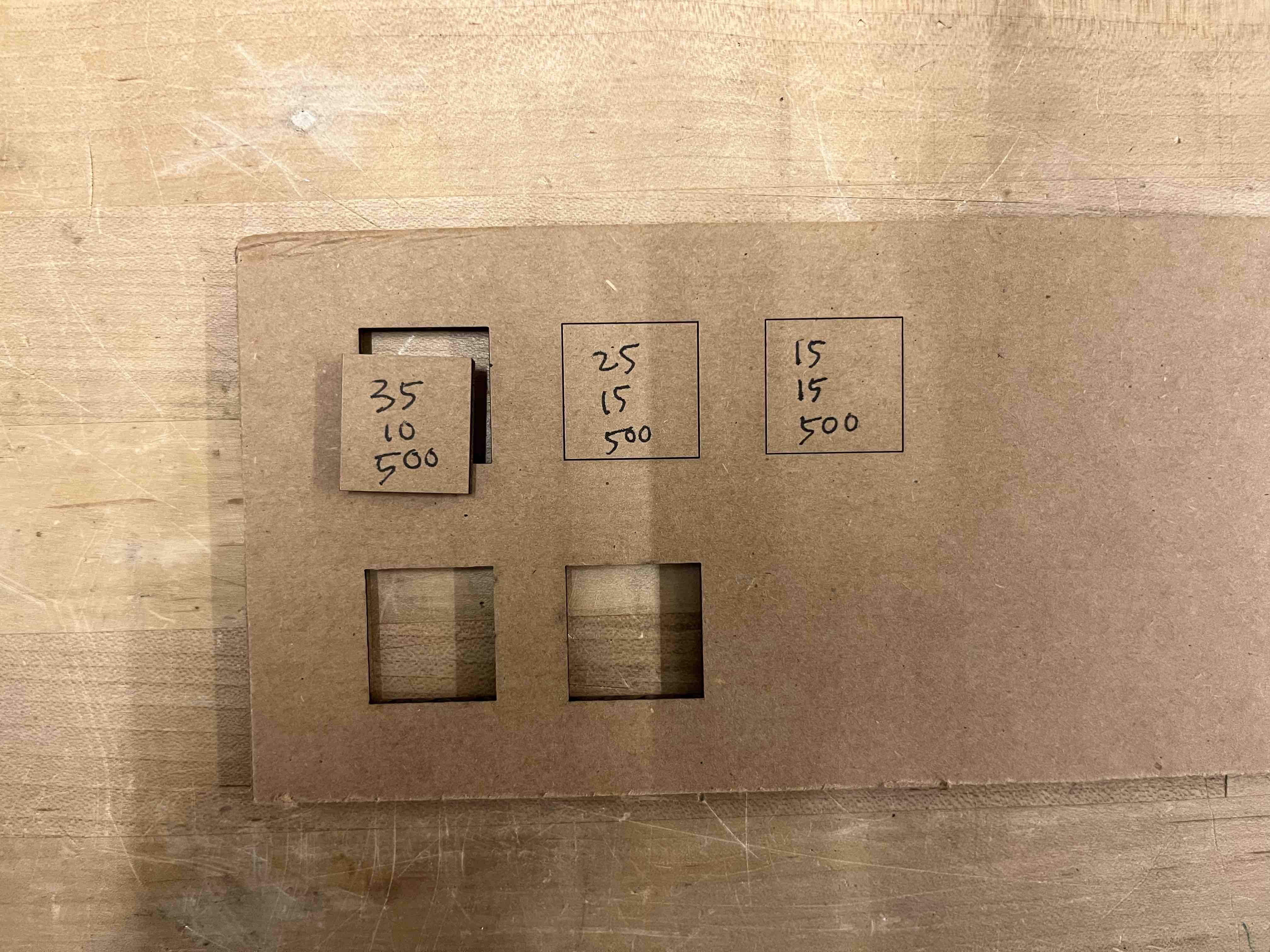

Doing tests of different power/speed/PPI (pulse-per-inch) settings to figure out the ideal scoring settings to allow the cardboard to be folded wihtout going to far.

Doing tests of different power/speed/PPI (pulse-per-inch) settings to figure out the ideal scoring settings to allow the cardboard to be folded wihtout going to far.

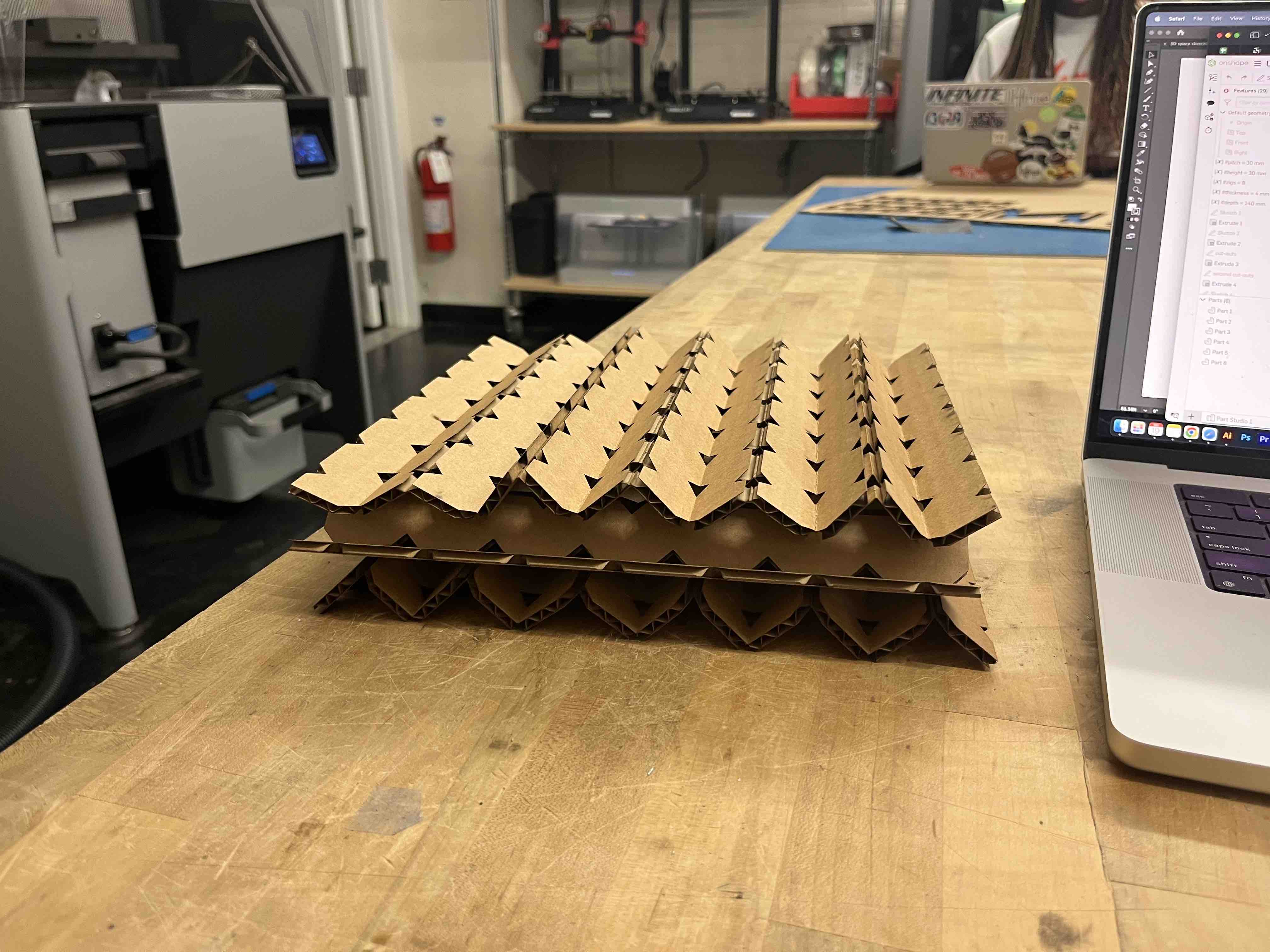

Folded sheets stacked

Slimmer sheets

Folded sheets stacked

Slimmer sheets

Book load-test

Book load-test

In a way the final structure mirrors what cardboard already is ~ Bill McKenna from N52/MAD: "You have recreated cardboard"

Cardboard explorations for the future: compliant mechanisms made from cardboard/experimenting with bi-stability to make snap-fit style connector out of cardboard or paper (see some quick sketches below).

Quick sketch of a cardboard grabber in illustrator; cardboard model of a bi-stable snap-fit connector

Trying to anticipate the constraints of a compliant snap-fit design through sketches in illustrator.

Trying to anticipate the constraints of a compliant snap-fit design through sketches in illustrator.

Vinyl Cutting

For the vinyl cutting I went with the most classic example of a laptop-sticker. The main takeaway was to always make sure to unclamp the lever at the back when done.

Vinyl-cutter in N52/MAD workshop space

Vinyl-cutter in N52/MAD workshop space

Stickers

Stickers

Some quick ideas for further explorations: using vinyl cutting as a way of fabricating something for substantial (e.g. as an adhesive substrate for something else to attach to)? Creating cardboard/vinyl composites, where the vinyl could be used for hinges/compliant areas.

Files: [1] zigzag_cut_pattern.dxf [2] smiley_vinylcut_positive_negative.png