HOW TO MAKE (ALMOST) ANYTHING

TIFFANY TSENG - FALL 2011

project proposal

laser cutting

pcbs

shopbot

molding & casting

microcontrollers

3D scanning

input devices

output devices

interfaces

project update

networking

final project

| 07 // 3D SCANNING AND PRINTING |

|

ASSIGNMENT This week's assignment was to use a 3D scanner to scan an object and print an object using a 3D printer. I own a Labbit, which is a vinyl rabbit toy with interchangeable pieces that fit in its mouth.

Each piece has a peg that fits into a hole in the rabbit's mouth. The ice cream cone piece that came with my Labbit broke, so I wanted to scan and print a new piece for my Labbit. 3D SCANNING I began with trying to use the ZCorp handheld scanner in the architecture shop. I added white markers to my ice cream piece:

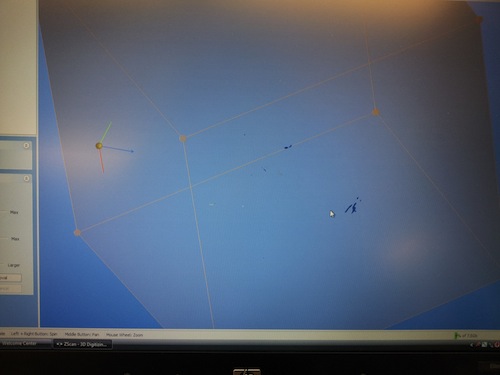

Unfortunately, even on high resolution, the ice cream cone didn't show up in the ZScan software:

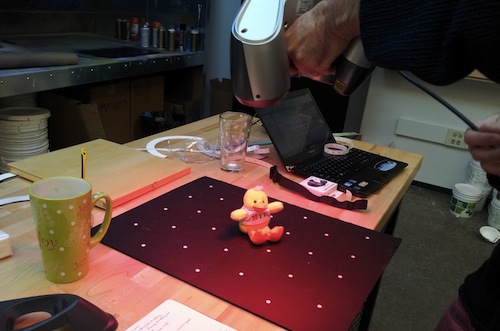

I then attempted to scan a stuffed animal duck that I had, but this did not turn out very well either:

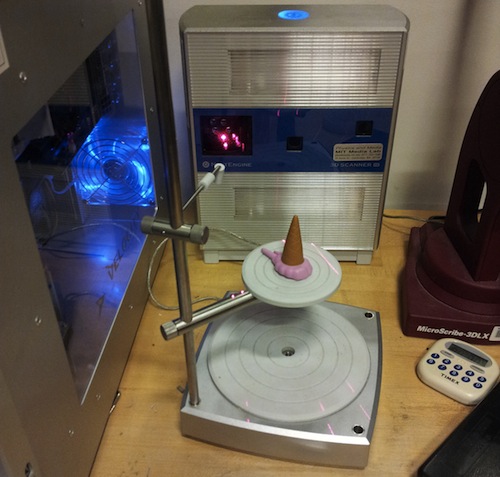

I then decided to try using the scanners in the Media Lab shop. Many thanks to Tom for helping me scan my piece using the NextEngine scanner.

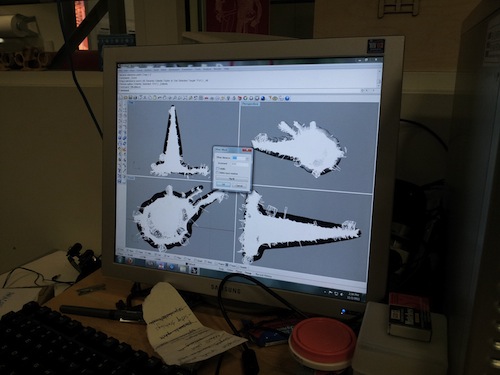

3D PRINTING Since we weren't actually allowed to send the files to the printer or remove them, the printing exercise was really just another exercise in modeling. My original plan was to take the scanned model, clean it up, and then send an STL of the file to print. However, the model was quite messy and hard to deal with, and I realized it would be faster to model the piece from scratch than it would be to attempt to fix the scanned model. I was determined to learn how to use Rhino this week, so I started off modeling my ice cream cone in Rhino. I had a hard time figuring out how to align bodies – what is the equivalent of SolidWork's "Mate" in Rhino?! As a result, when it came time to submit the file, I rushed to create the model in SolidWorks instead. The model was printed using the Dimension ABS printer. I'm very pleased with the result; it fit perfectly on my Labbit!

PAINTING I borrowed some acrylic-based paint from Jen and painted the 3D printed piece. I also experimented with the Krylon spray paint for plastic, which had a very glossy finish. Unfortunately, I didn't have enough different colors to experiment with (I just used the available colors in the CBA shop), so I decided to stick with the acrylic paint.

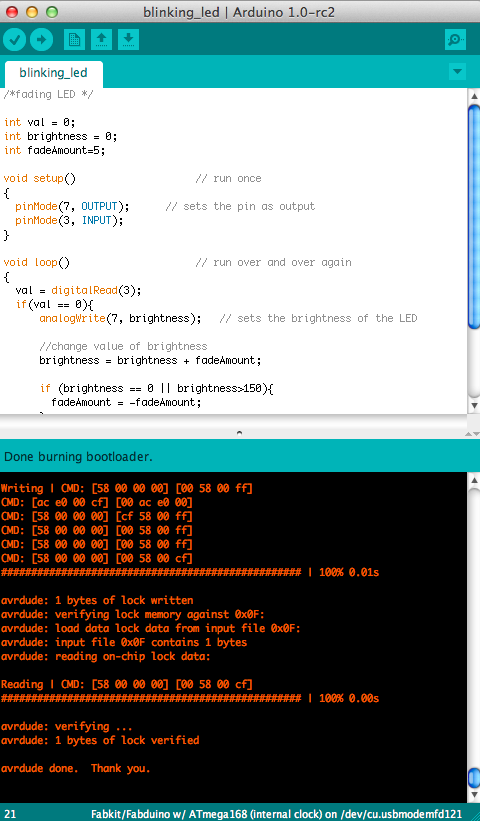

FABKIT BOARD I got help from David Mellis to complete my Fabkit board. It turned out that one pin on the ATMEGA microcontroller was not connected to the copper pad.

DESIGN FILES |