Our assignment for the week was to 3D scan and 3D print something...

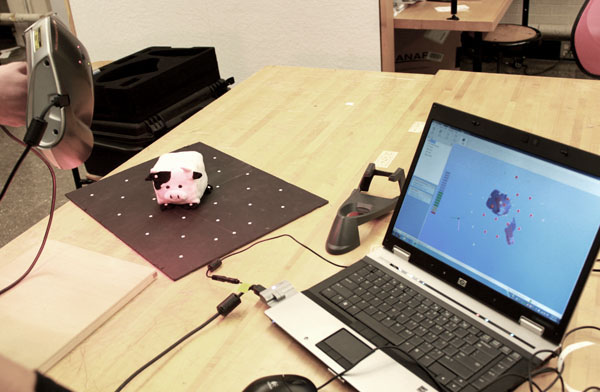

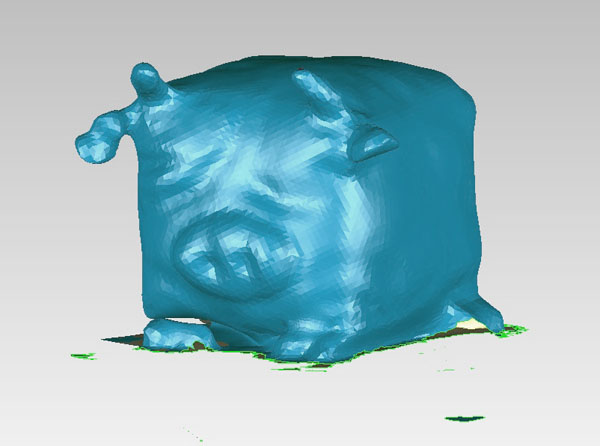

ZSCAN 3D SCANNER:

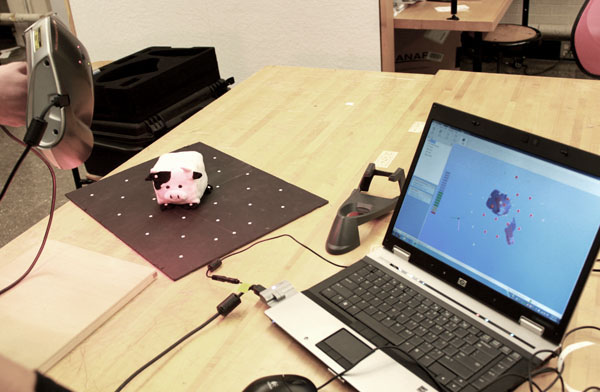

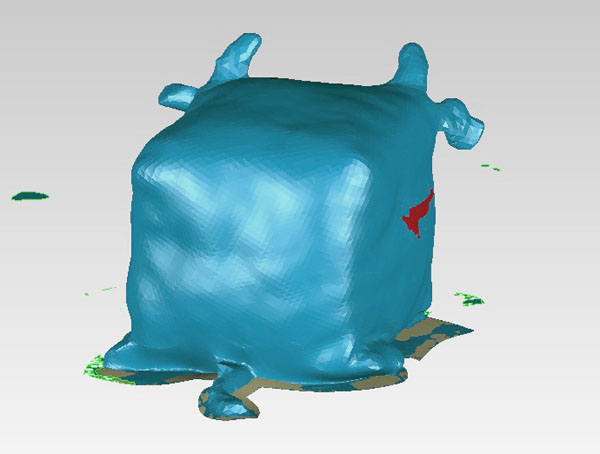

In the architecture lab we have a ZScan 3D scanner. It is a handheld device that you can use to capture the surface of an object (in

conjunction with a series of reference dots). The process of calibrating the device and adjusting it to the material of the object was

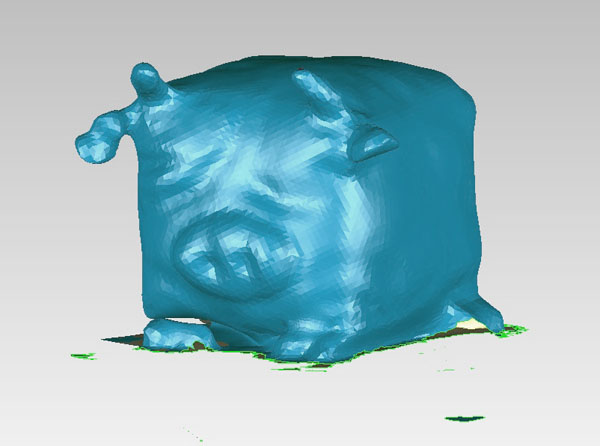

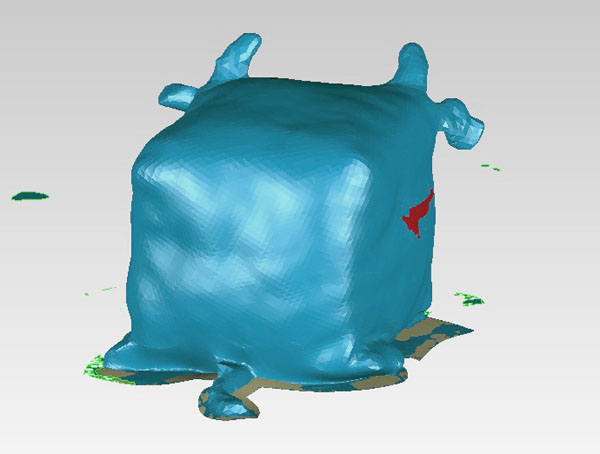

a bit cumbersome, but worked relatively well after that. The scanner had a bit of trouble with the high contrast in material (black and white),

but for the most part, did a decent job of capturing the object. Also, the Geomagic software was pretty incredible at cleaning up gaps and

giving extra definition to things the scanner missed. Unfortunately, the license on the computer was just a trial, so I couldn't save the file

as anything but a Geomagic .wrp format.

SETTING UP:

SCANNING:

GEOMAGIC:

123D CATCH:

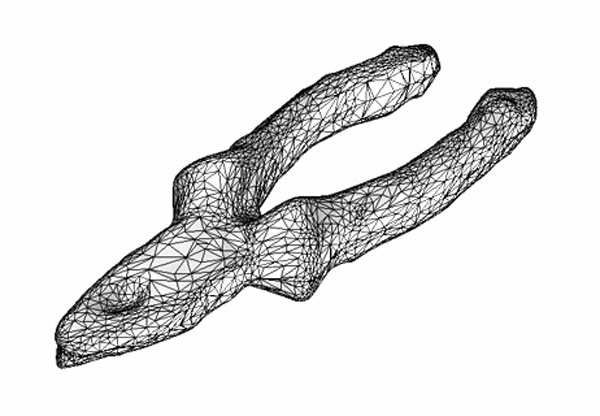

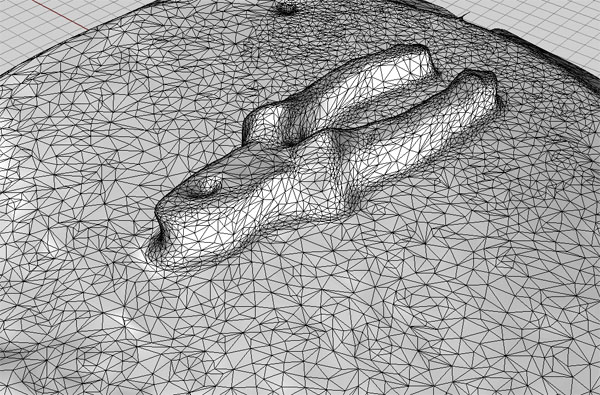

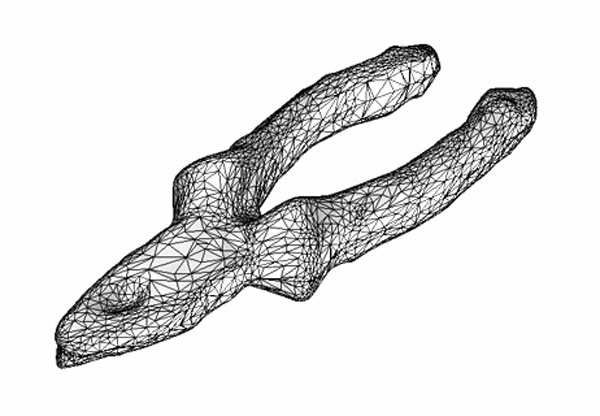

I also wanted to try the 123D Catch app, so I scanned a pair of pliers I had lying around. I was really surprised at the ease of use and quality

of the scan with this option! You just take a series of pictures (up to 40) and it spits out a nice mesh complete with texture materials.

PLIERS:

MESH:

RENDERED:

3D PRINT:

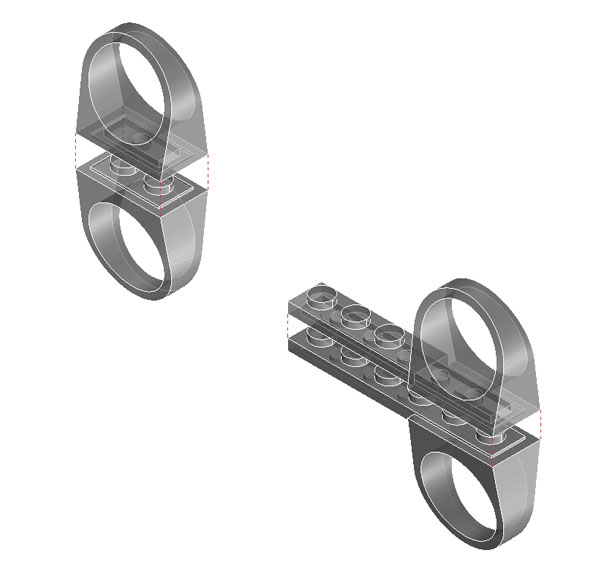

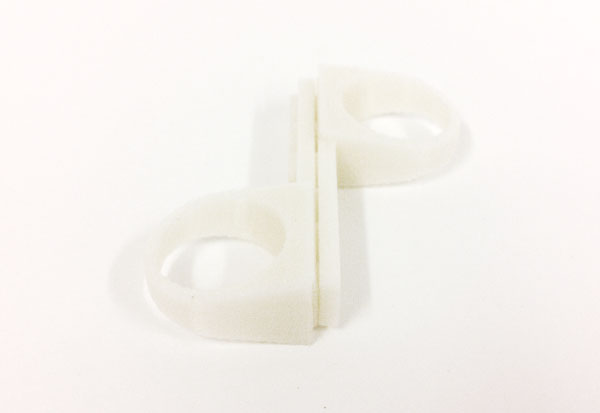

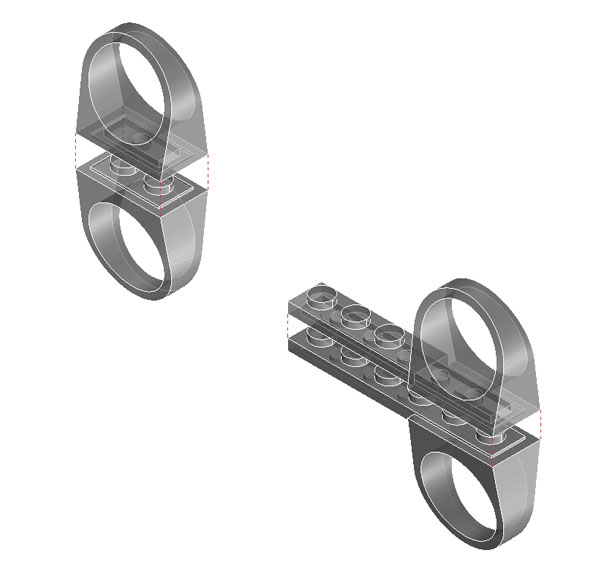

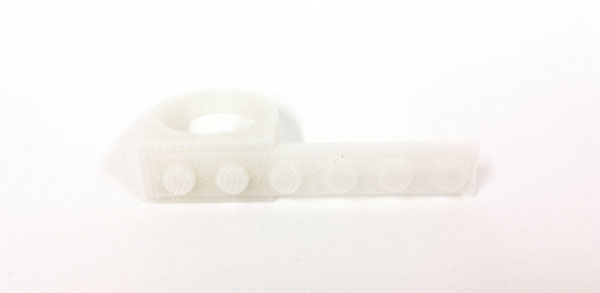

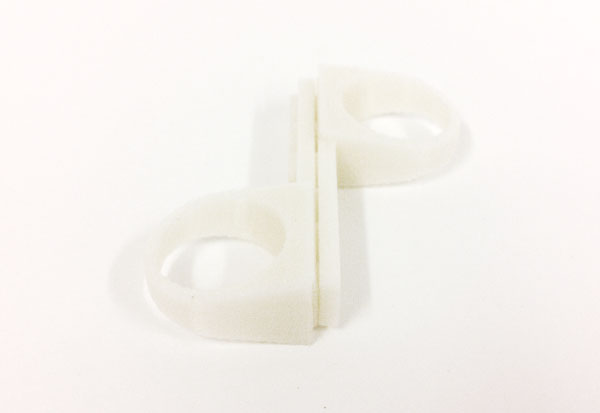

I have a lego ring that I bought from a museum this past summer. I know that this ring and real legos are cast objects, but I ever since

I got this ring, I have wanted a matching ring into which my ring can snap. So, I modeled my ring (the geometry is pretty straightforward, but

I did take some time to measure it precisely) and made a copy of the ring with the underside of the lego facing out. I then decided

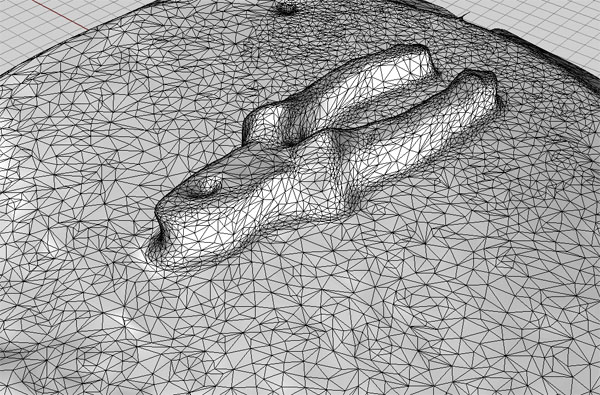

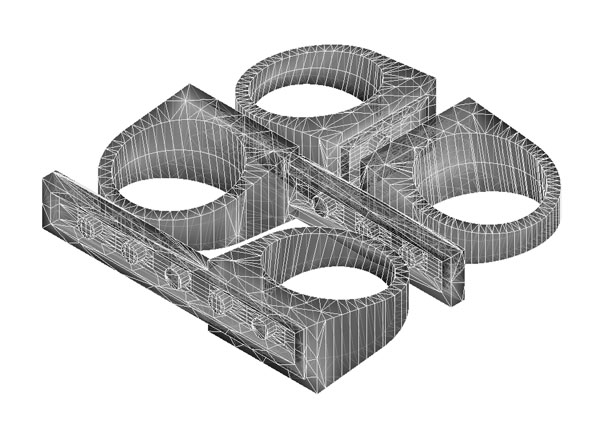

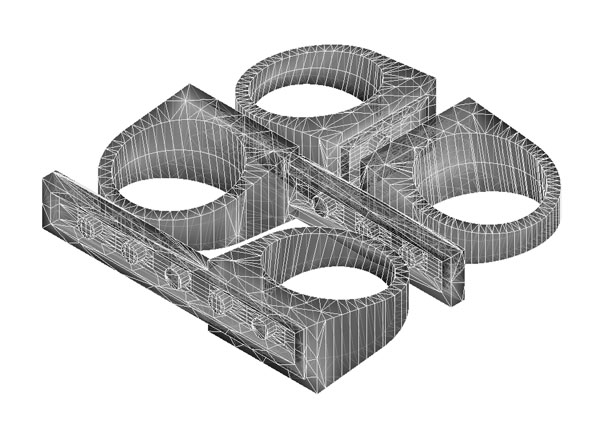

to do another style of ring with a longer lego brick. Once I had my four rings modeled in Rhino as NURBS surfaces, I converted them to meshes and made sure

they were watertight. For this there are three commands you need to know: Weld with an angle tolerance of 180 to glue adjacent triangle points together

no matter what, UnifyMeshNormals to change all the triangles so they are oriented the same way, and SelNakedMeshEdgePt to check for holes or gaps.

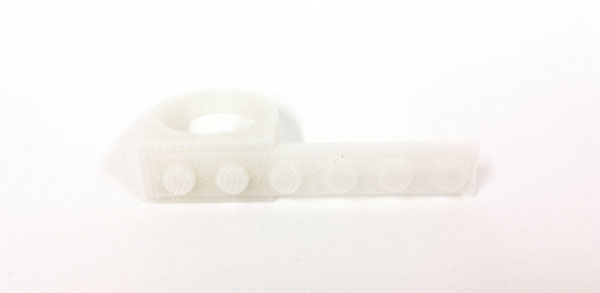

Finally, I exported the meshes as an STL file and sent it off to the Dimension Elite ABS Printer.

MODELING IN RHINO:

MESHES:

3D PRINTS!: