3D Scanning

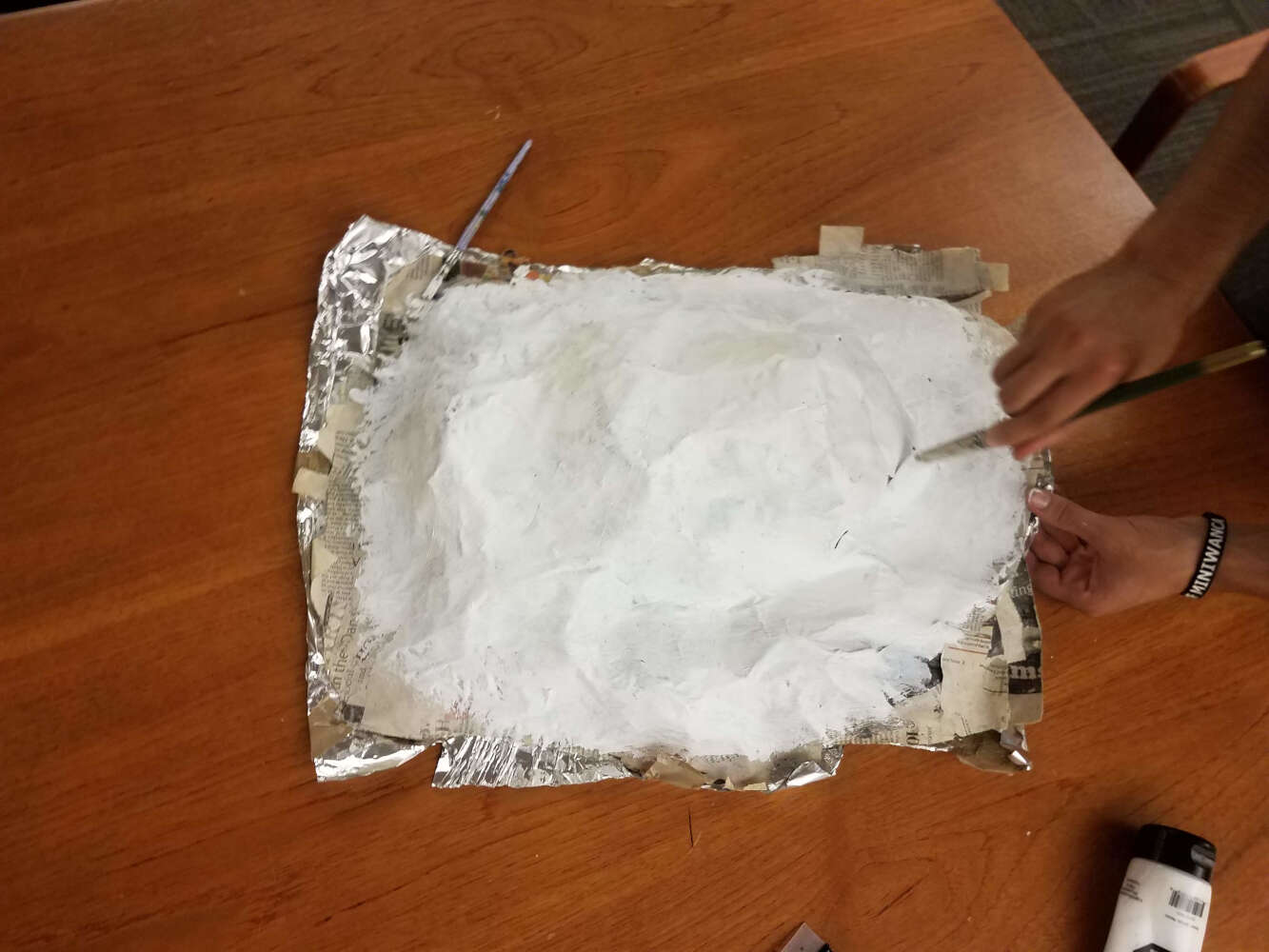

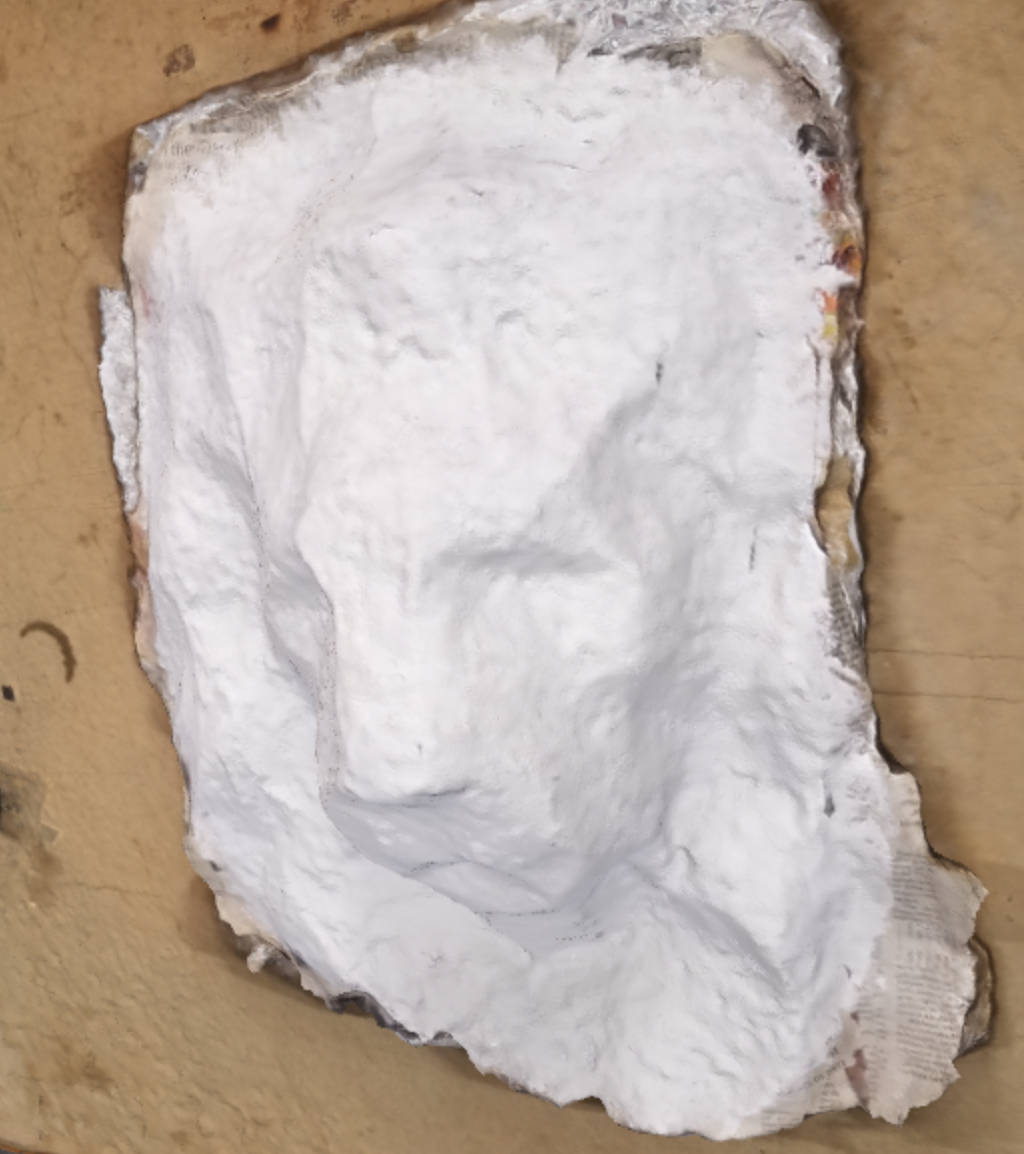

My goal this week was to practice some 3D scanning techniques so I could work on making up a model of the old lion head from the club. In preparation for this, we have a (slightly anglicized) paper mache mold of the old head. It's super low resolution, but my friend and I painted it to hopefully smooth some of the bumps a bit. The goal would be to scan the original head, somewhere in the construction around our old space, but the backup plan is to do some 3D sculpting to make this crappy mold into something that looks historic.

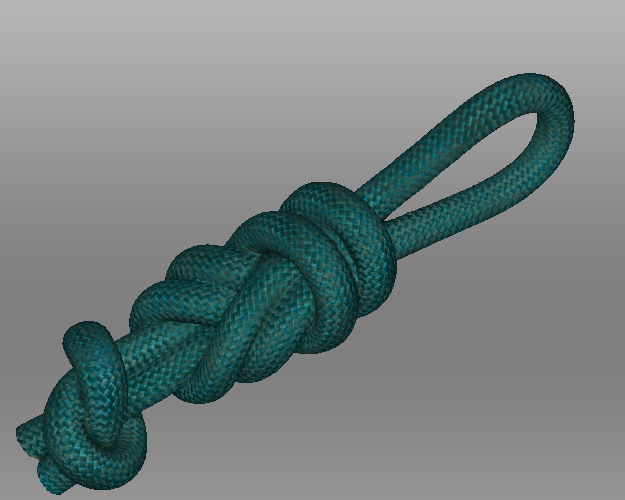

In the meantime, I used a structured light 3D scanner (the Artec Space Spider) to scan a knot of rope I had, in order to print it on the 3D printer. This was mostly to go through the whole pipeline of 3D scanning and printing, and was more of a learning exercise than other things I've done.

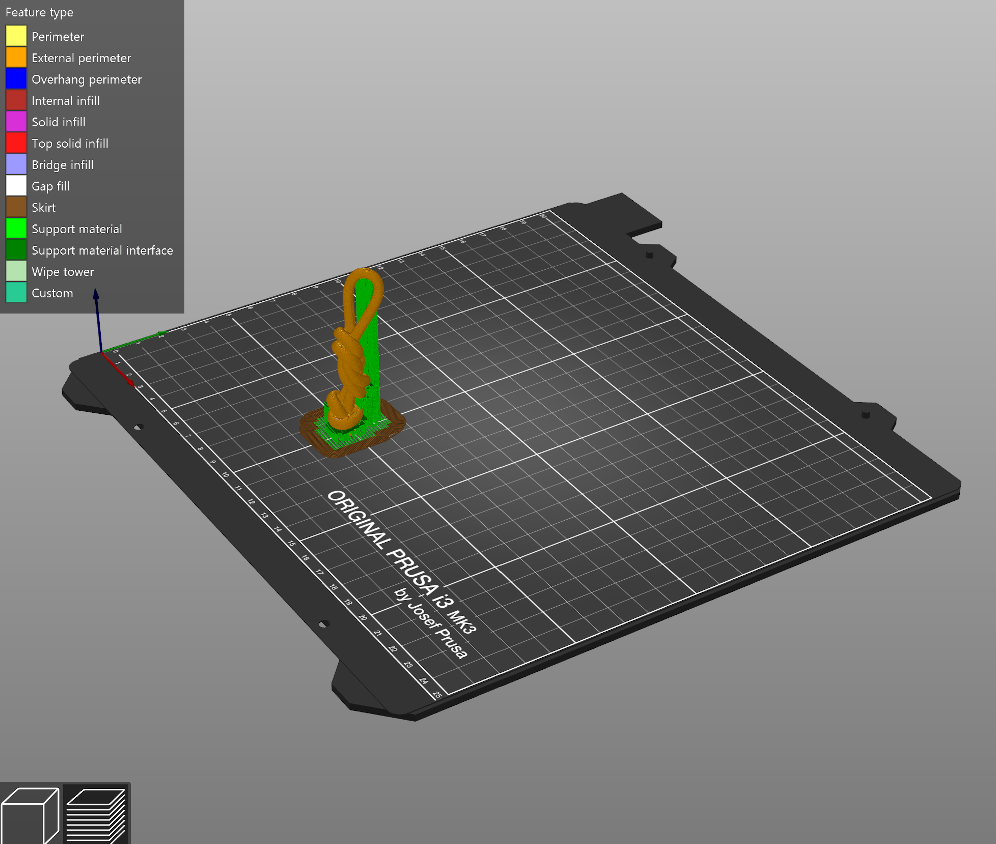

After aligning and filling in the scan, I cut some pieces that wouldn't save right, and saved the file and texture. I passed those on to the Prusa slicer software, and got ready to export.

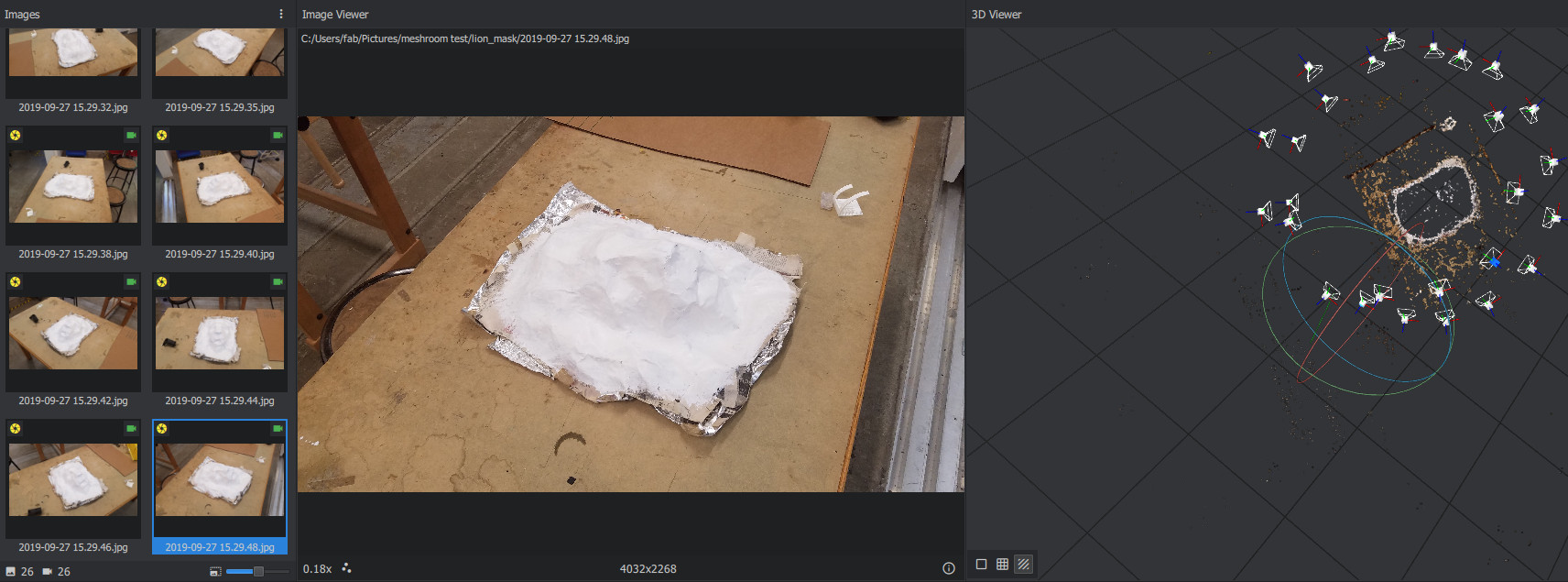

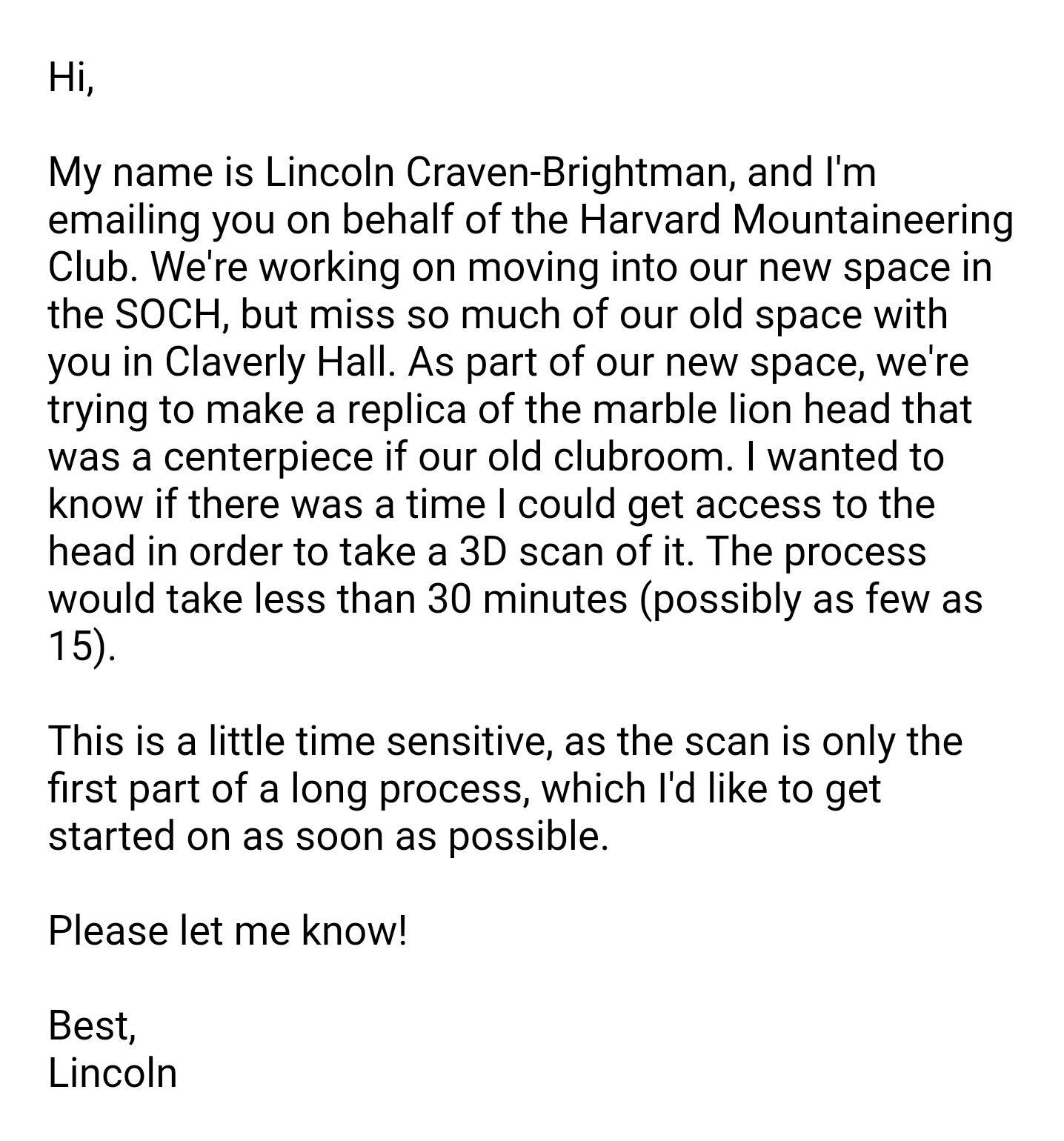

In the meantime, I worked with Jeremy Guillette to try out Meshroom, a photogrammetry software. He took 26 photos of the lion head, and I was ASTOUNDED at how well it came out. If I can get access to the original head, this would reduce the amount of sculpting touch-ups I have to do by a LOT. I sent some professional sounding emails to the administration of Adams House in order to try to get access to the head.

3D Printing

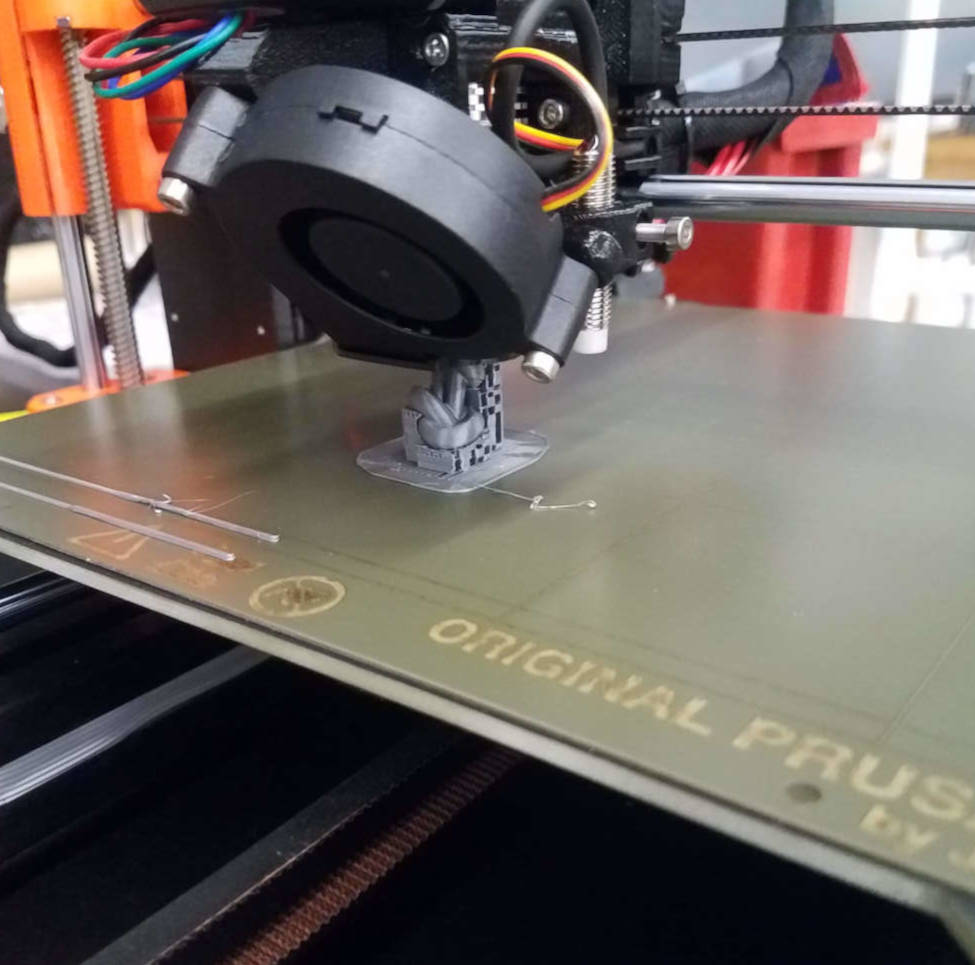

To characterize the printer (the Prusa i3 Mk3), I printed a copy of a compact test model that I found on Thingiverse.

After that, I loaded my rope model into Prusa Slicer. I oriented it to have what seemed to me to be the most supported position, and enabled supports only to the base plate. Then I sent it off to print!

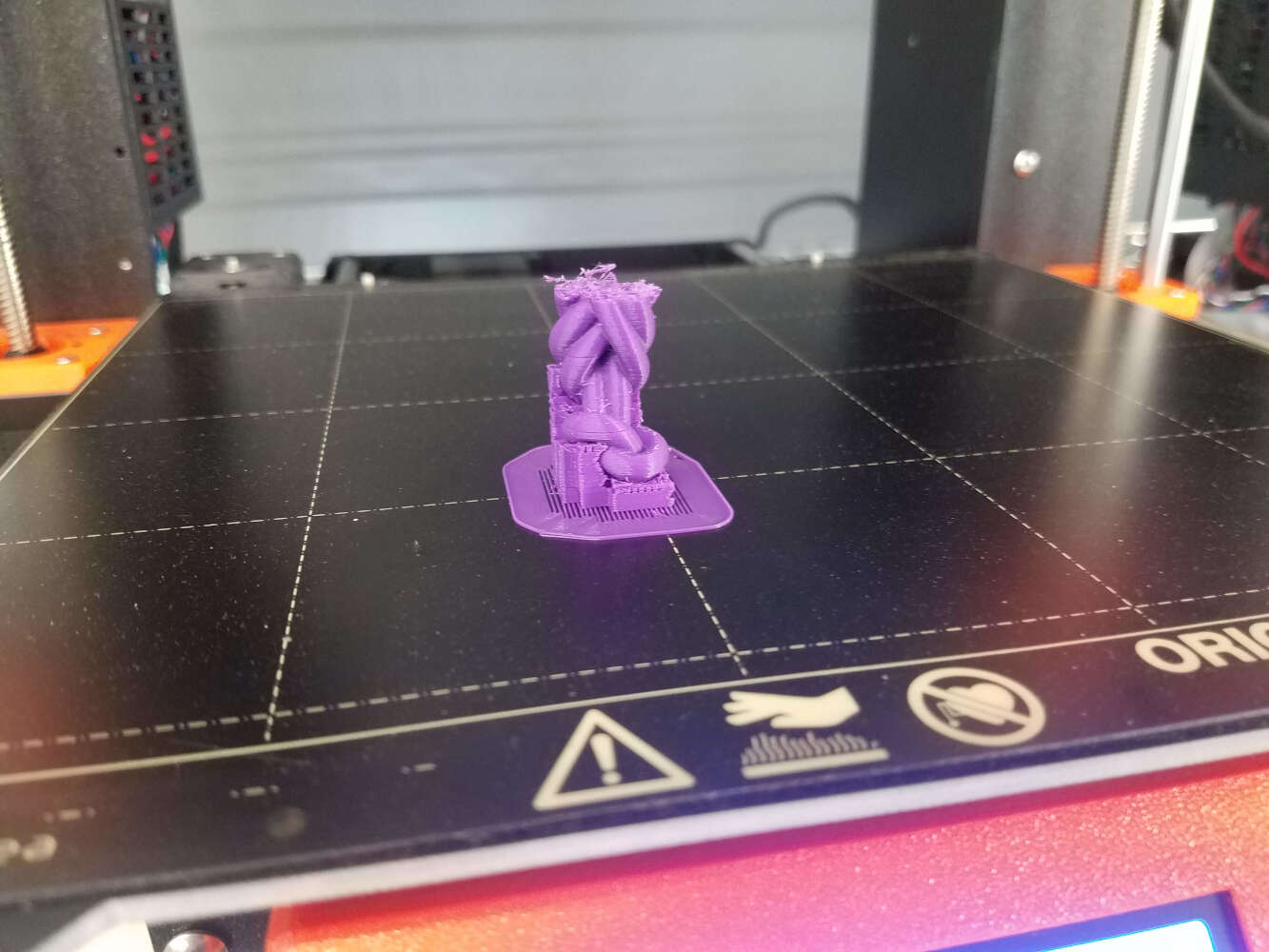

Unfortunately, the printer I sent it to was having problems. I never fully diagnosed if it was the printer itself or just the filament, but it clogged on two separate attempts to print. As a test, I tried to see if I could smooth the layer lines using a heat gun on the second failed test, but it warped it pretty badly, so I chose not to do that for the final.

I tried again on another printer, and it finally seemed to work! I removed the support structures with a small knife, and I'm happy with the result. I want to learn to use the FormLabs printer next, because the resolution on that looks crazy cool, but I don't know how much 3D printing ideas I have, yet. My plans for the additive component of my final project will probably be in casting, with the goal to be casting the lion head in some mock marble resin. Either way, this was good practice!