Machine goals

For this week, almost the whole lab got together to make a machine! The idea was to make a polar 2D painter, with no real motivation. You can check out the full project on our group page

My part

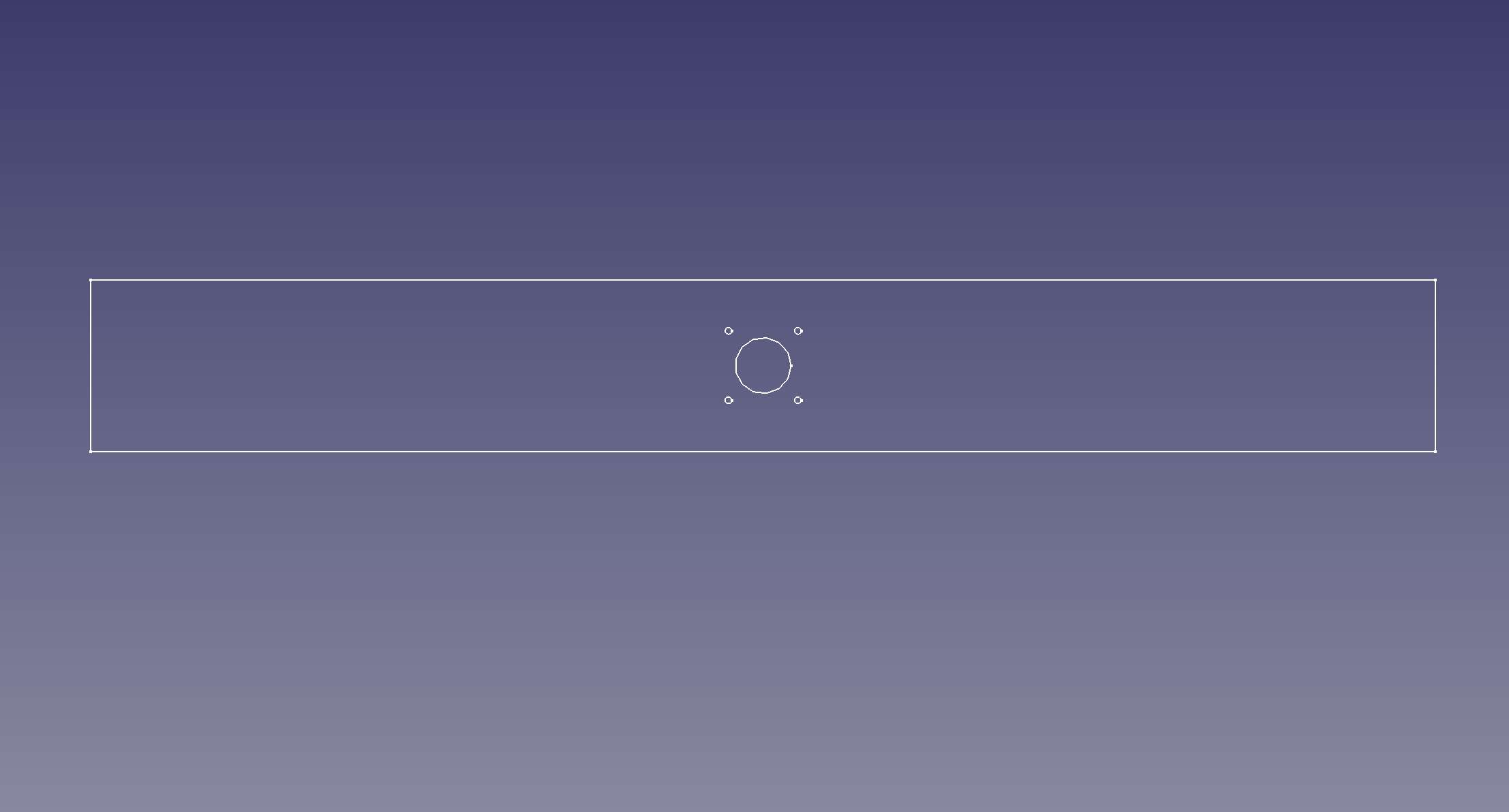

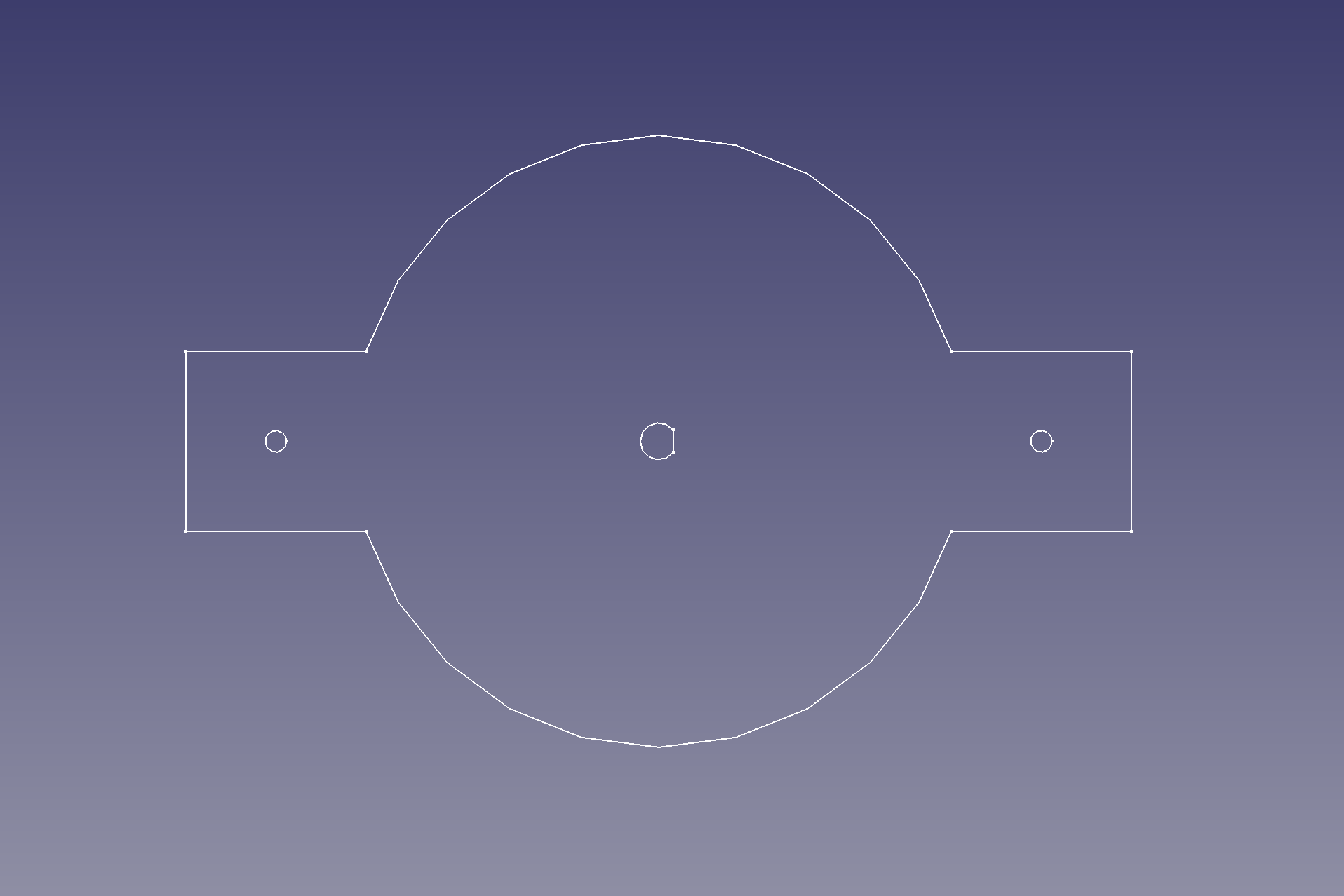

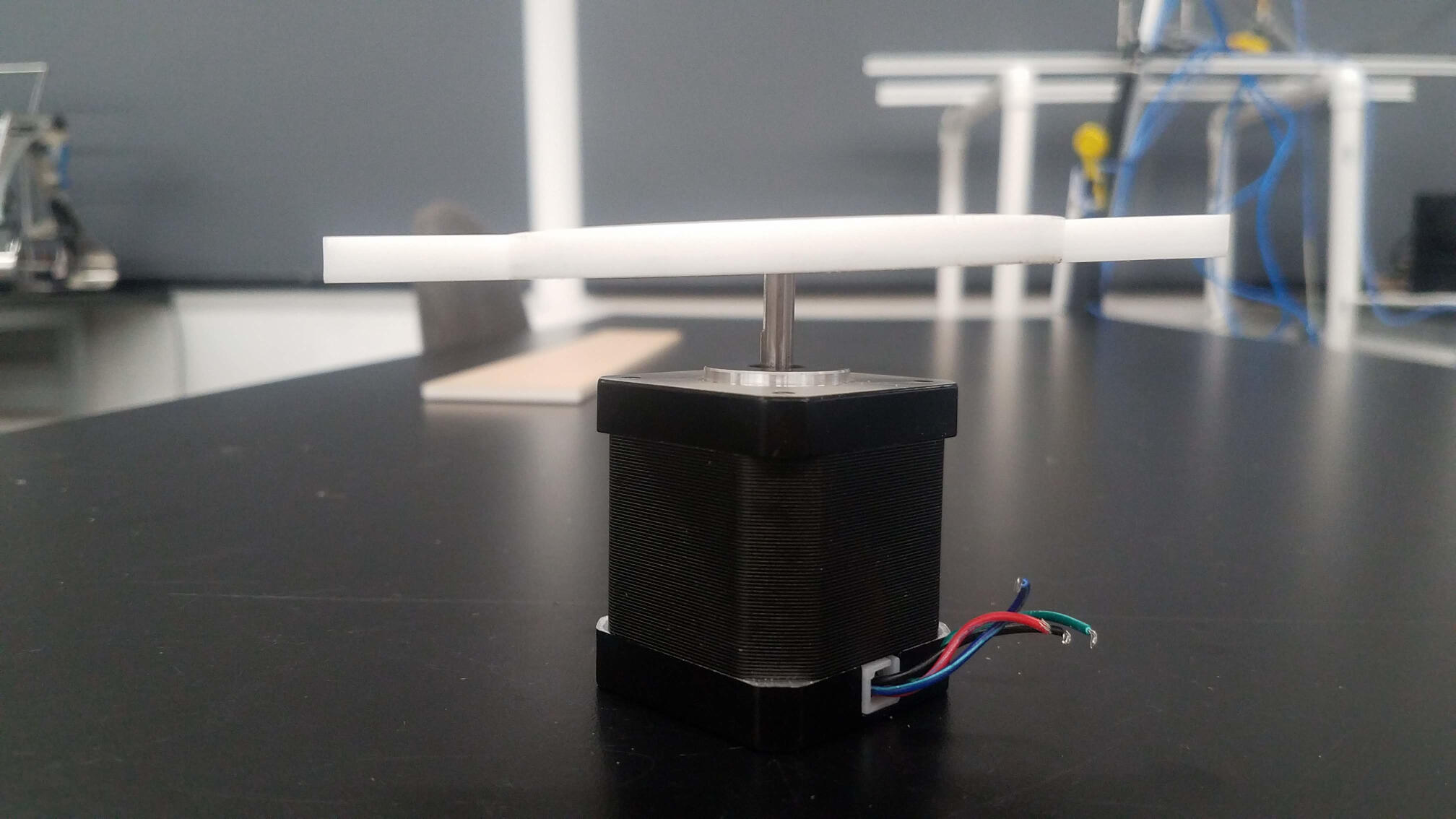

I focused on the rotating base of the design, along with Harshal Singh and Phil Brooks. Harshal started with the design process for the base, and passed that on to me. I made some adjustments, and ended up with two components -- a base with a stepper motor that attaches to the frame, and a plate with a D-shaped hole to connect to the stepper motor. The stepper motor came with a control board, and programming it was Joonhaeng Lee's job.

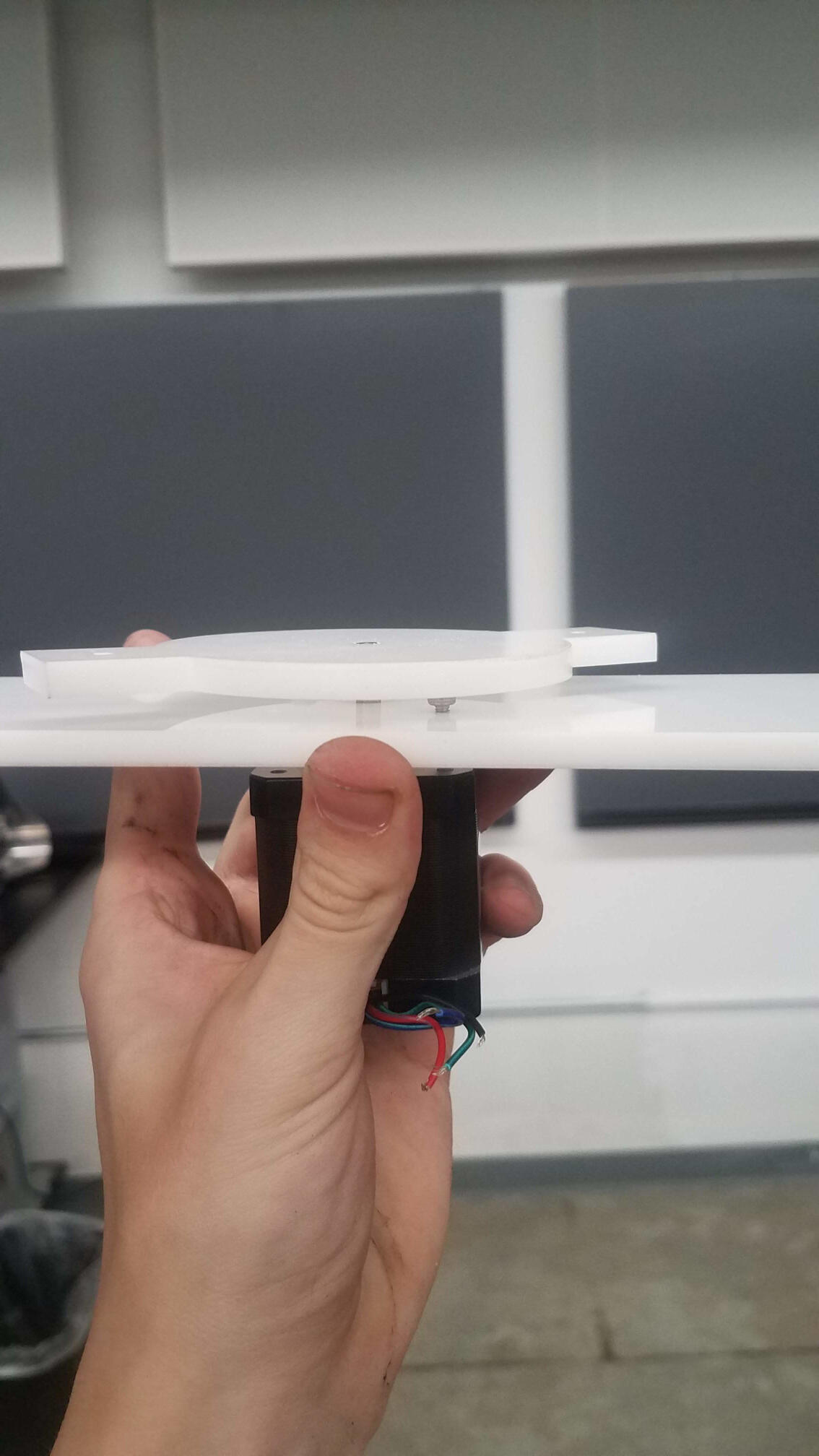

I laser cut the pieces out of acryllic, just like the rest of the frame. I had to make sure the stepper motor could spin the base plate. I definitely shouldn't have worried -- it spun it no problem. I had to actively work to try to stop it. I worked with Joonhaeng to connect the motor right, and we got both the linear and rotational motion going at the same time!

Unfortunately, the connector plate was uneven on the motor. This was due to misalignment in the laser cutter, which needs some calibration. The edges were slightly slanted, which was very noticeable with that tight of a fit. I tried to file it a bit, and did a quick test assembly to show that it worked out. I had to run to get some other things done before Thanksgiving break, though, so I passed what I had on to Phil. Check out his page for the next steps that he took!

I had to run to get some other things done before Thanksgiving break, though, so I passed what I had on to Phil. Check out his page for the next steps that he took! Everyone else did an amazing job with their parts, and the final product was really cool -- I was super impressed with the coding that got it able to draw right angled lines in polar.