Final Project Progress

This page tracks my progress toward my final project.

Review of Previous Progress

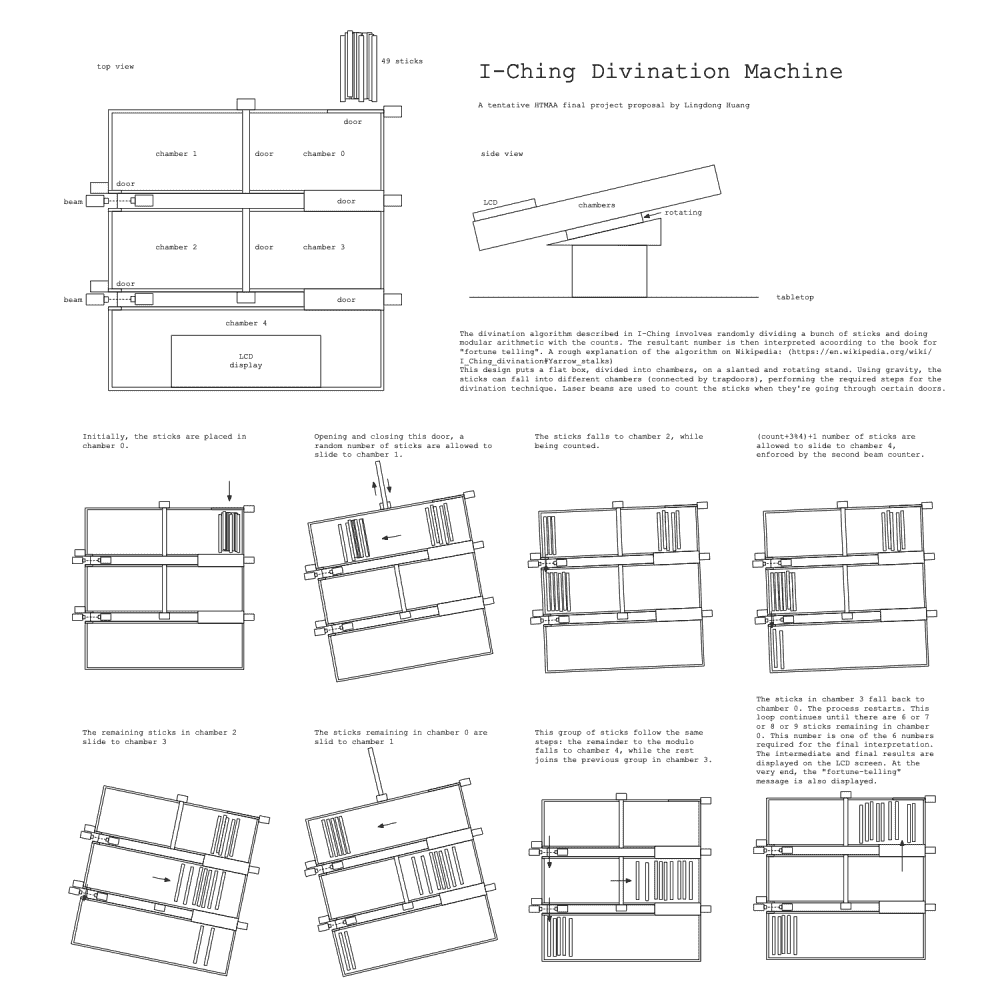

My final project is an I-Ching divination machine. You can read about the idea and initial sketches here.

In input devices week, I studied phototransistors, which I want to use to count the falling sticks. Details here.

In output devices week, I studied OLED and servos, which I want to use for displaying divination results and openning and shutting trapdoors respectively. Details here.

Materials

I bought some potential materials for the sticks:

Metal sticks, metal balls, wooden sticks.

I realize that sticks might fall on their sides inside my machine, and hence unable to pass through the tiny trapdoors.

Therefore my plan now is to get the metal balls working first, and then “upgrade” to sticks if the balls are successfull.

For sticks, I might need to make ends more pointy, so when they fall on top of each other, they don't vertically stack, which will be undesirable and breaks the mechanism.

Another possibility is to use broken endmills. They're smooth and roll well. They're short, and have a pointy end. However, where can I find 49 broken endmills?

I bought some wood for constructing the box, and some acrylics for the front panel:

Unfortunately the acrylics are too soft and thin, and they are not very clear. They are not clear enough to look like clear acrylics, and too clear to look like semi-clear acrylics. They look like dirty window panels. I might need to buy better ones.

I plan to laser cut the wood.

Electronics

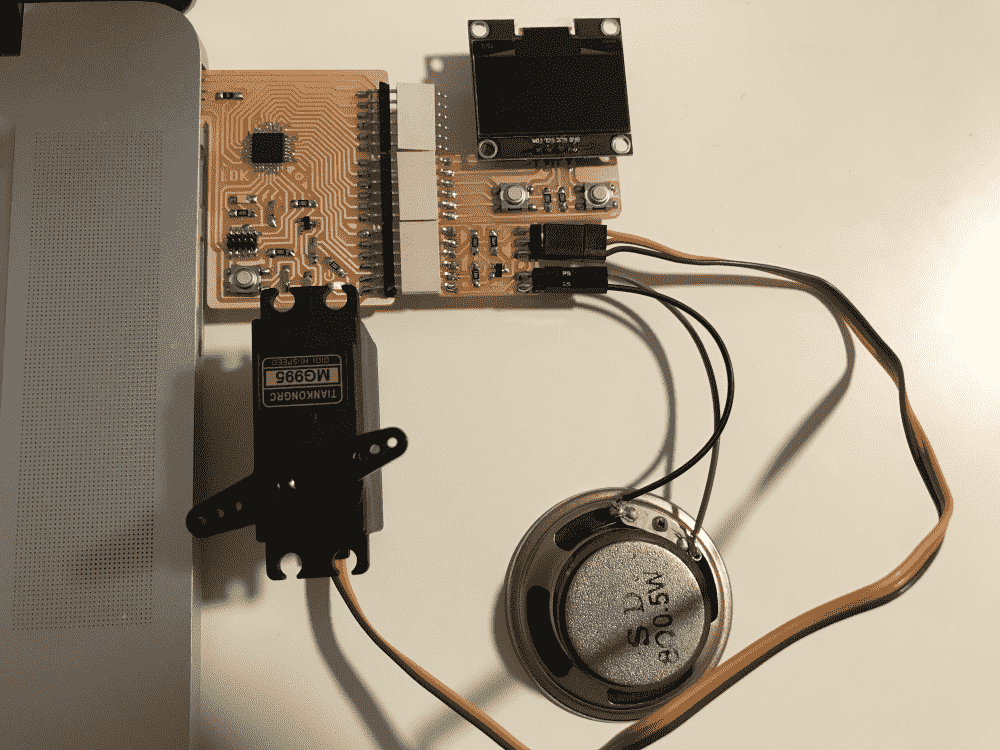

I bought a bunch of tiny servos, because the ones we have at the shop look too bulky. I cut a board to connect them to my new breakout board.

You can see in the below video, I am testing each servo, and how fast they can move a slight amount forward and back, required for driving my trapdoors.

I also made a pair of new phototransistor and LED boards. Previously, I was unable to get the phototransistor to be affected by an LED, because the LED was too dim. Some time later I figured that white LED's are probably brighter than the red ones, but mistakenly used 1000 resistor as 100 resistor, and was mistakenly convinced that the white ones are not bright either. I discovered the mistake and now use 100 resistor. The LED is very bright.

Below you can see a video of how I used a finger to quickly block and unblock the space between the phototransistor and the LED. On the screen the readings change by about 50 (out of range 0-1023) which should count as detectable. For the final setup the two will be much closer, and I can shield them from room lighting, so I think I'll be able to get a reliable falling-object detection.

Software

Though the divinition is a relatively convoluted process, I don't think the software would be a challenge for me. I've written the divinition algorithm a couple times before. The components will mostly act sequentially, so processing power won't be a huge problem.

However, the trapdoor and the phototransistor immediately underneath it might need to act in quick succession, possibly with overlapping time. I've written non-blocking software pulse width modulation in output devices week, which can be adapted here.

Ideally I will be able to display Chinese characters on the OLED. Space might be an issue, and I might need to bring in an SD card. But currently I believe with some encoding tricks I can get some short passages from I-Ching to fit in the SAMD21E.

Unsolved Mysteries

- How to cut metal rods that are too long?

- Is a phototransistor+LED mechanism better, or pressure plate/weight scale one better? Or something else?

- How to make the LED/phototransistor more directional and less ambient?

- How to fix servos onto the structure? Nails? Screws? Bolts? Do I add holes in my design, or drill them later?

- What mechanism for the trapdoors? Rotationally, like guillotine paper cutters? Or with a gear and a rack to make them slide sideways?

- How to fix something onto the spinning thing on the servo? 3D print something to fit onto the spindle thing? Screw it onto the plastic blade thing that comes with the servos?

- How to make sticks not fall down on their sides?

- How to do "synchronous detectoin" for LED+phototransistor?

- What parameter I should use for laser cutting my wood and acrylics?

- Can the servo, that spins underneath the box to rotate the box, support the weight of everything on top? Should the main part of that servo be in the box, or in the stand?

- Where to hide my circuits? How tu run the wires?