Final Project - I-Ching Divination Machine

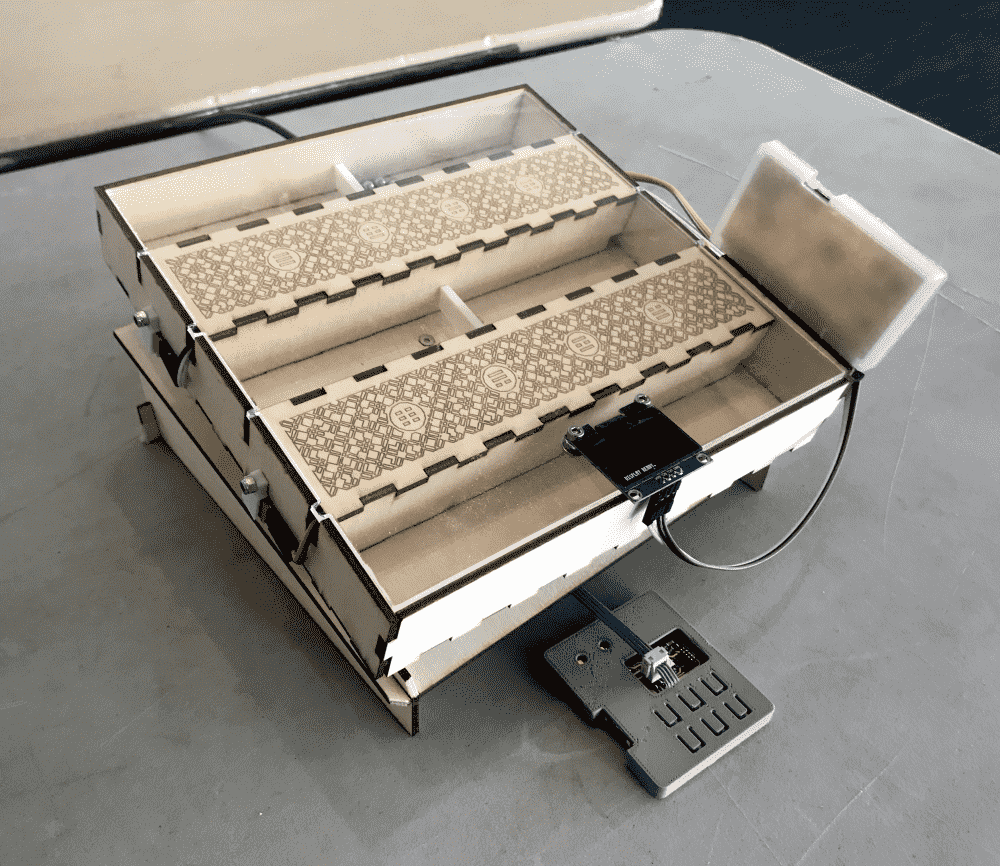

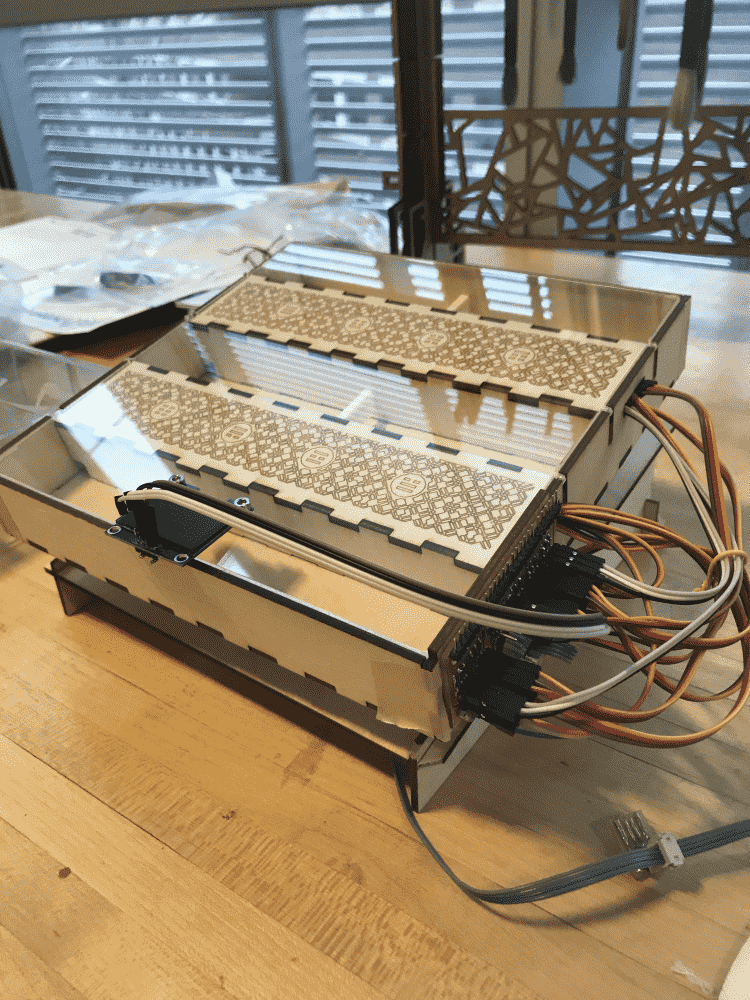

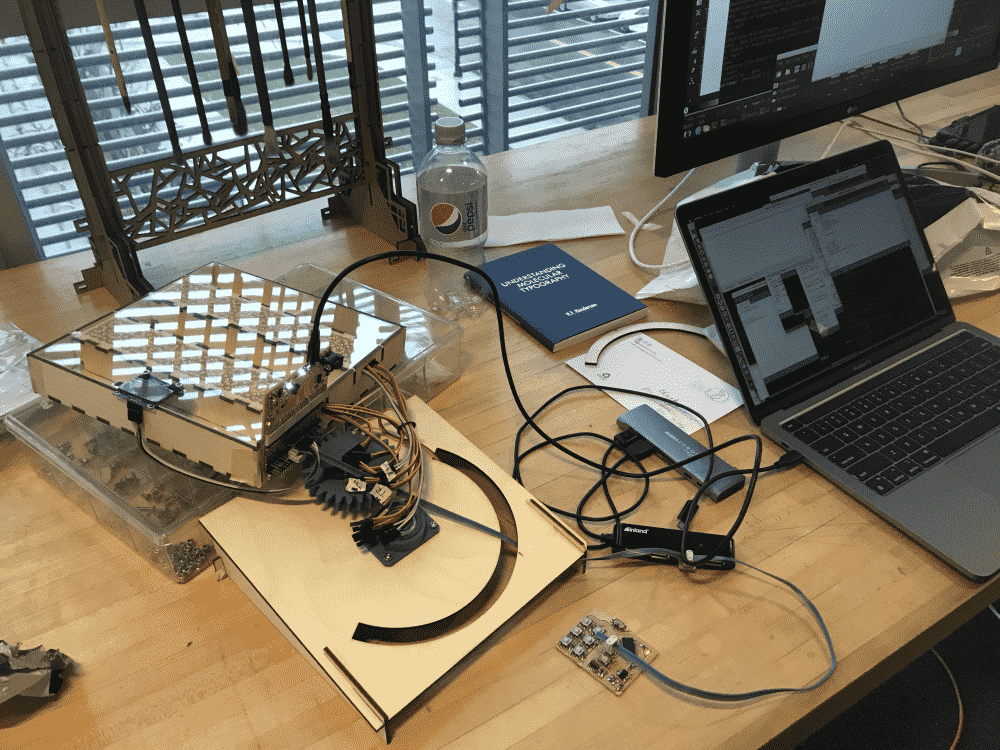

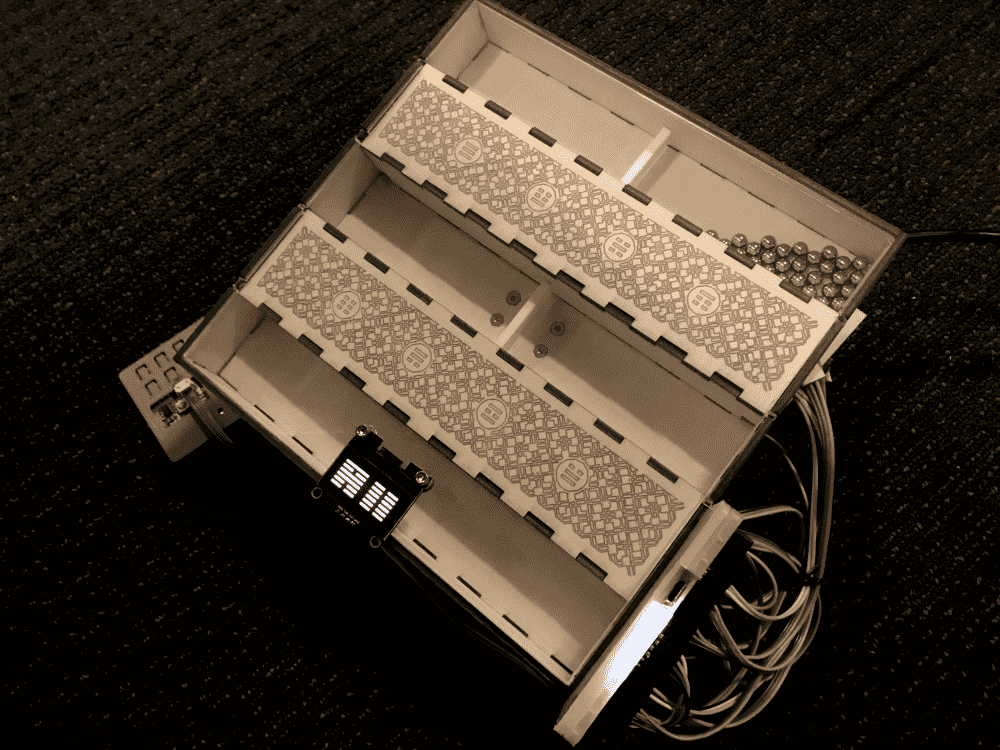

My final project is an I-Ching divination machine, that fully automates the divination procedure described in the classic text (in a relatively authentic manner). For disbelievers of Tao, it can also be used as a physical random number generator.

I-Ching is a 3-thousand-year-old Chinese book used for a type of cleromancy, or prediction of the future using a random number generation. With divination being the “high tech” of its time, the method likely influenced the decision of many important people. Later the book became an important philosophical text due to commentaries added by later philosophers such as Confucius.

The method of divination (sans the symbolic gestures, with my rephrasing):

- Take 49 sticks.

- Arbitrarily divide them into two groups, with N and M each.

- Find (N+3)%4 + 1, and discard that number of sticks away from N.

- Find (M+2)%4 + 2, and discard that number of sticks away from M.

- Combine the two groups of remaining sticks.

- Repeat steps 2-5 three times.

- The remaining sticks should be one of 24, 28, 32 and 36. Divide the number by 4, and record the quotient.

- Repeat steps 1-7 six times.

- Now we have six integer, each of them ranges from 6 to 9. The numbers correspond to Yin-Yang and young/old: 6 = old yin, 7 = young yang, 8 = young yin, 9 = old yang.

- The next part is a bit hand wavy and require some understanding of Taoist philosophy, but you can understand it as such: Look up the numbers in a lookup table (i.e. I-Ching), which maps them to a fortune-telling message. The messages are usually very cryptic and ambiguous metaphors, and interpreting them which has been subject of research for thousands of years, is not in the scope of my machine. The machine only does the the random number generator part.

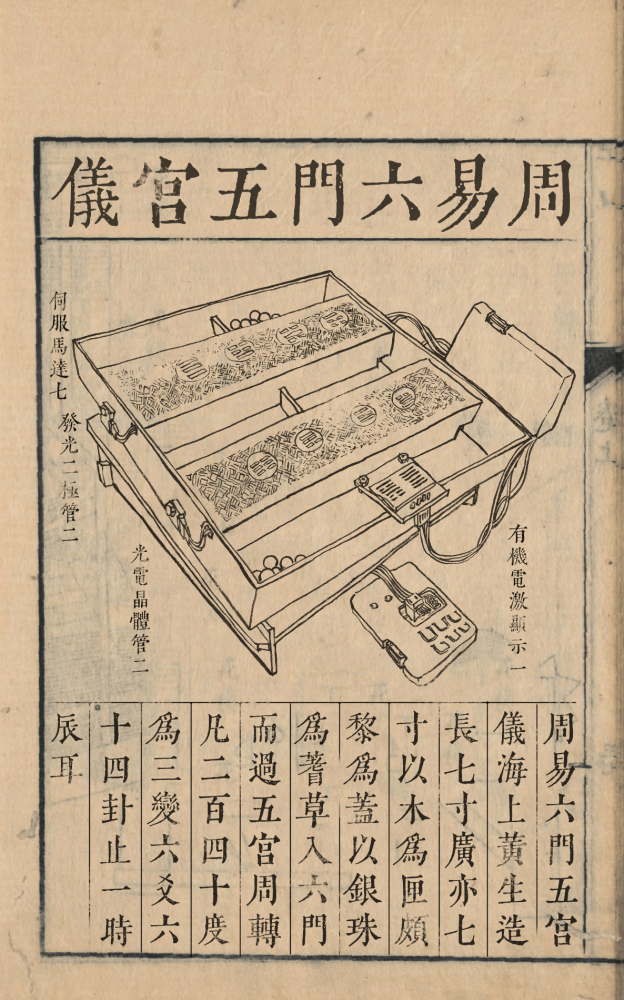

As shown above, my design is an exact reconstruction based on an illustration of the machine found in an ancient Chinese book (just kidding).

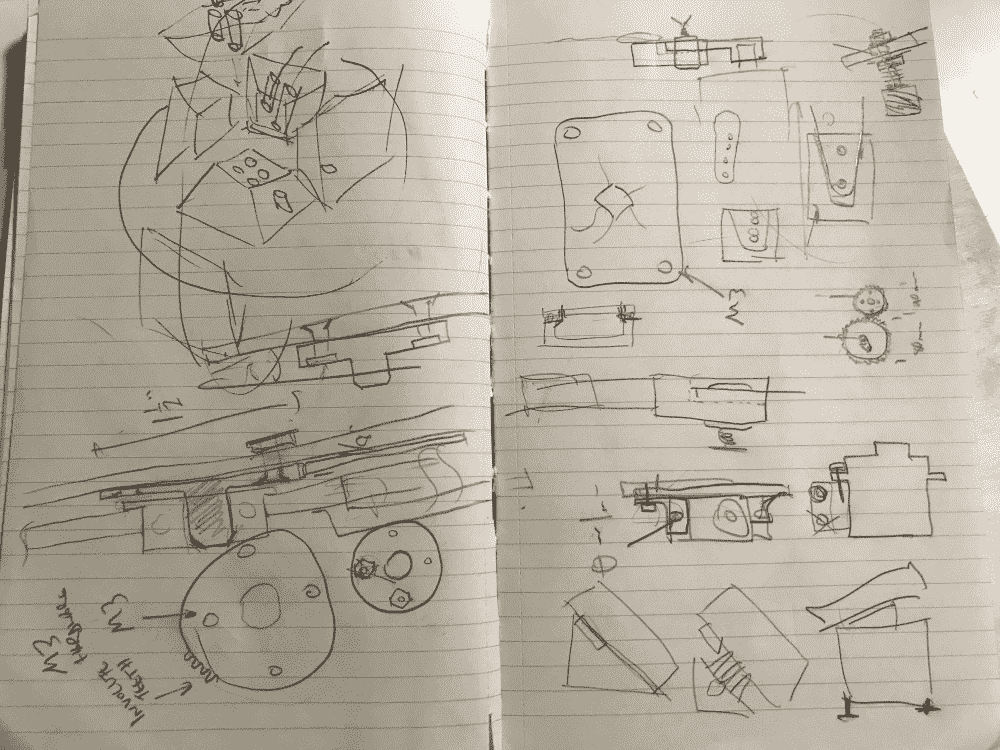

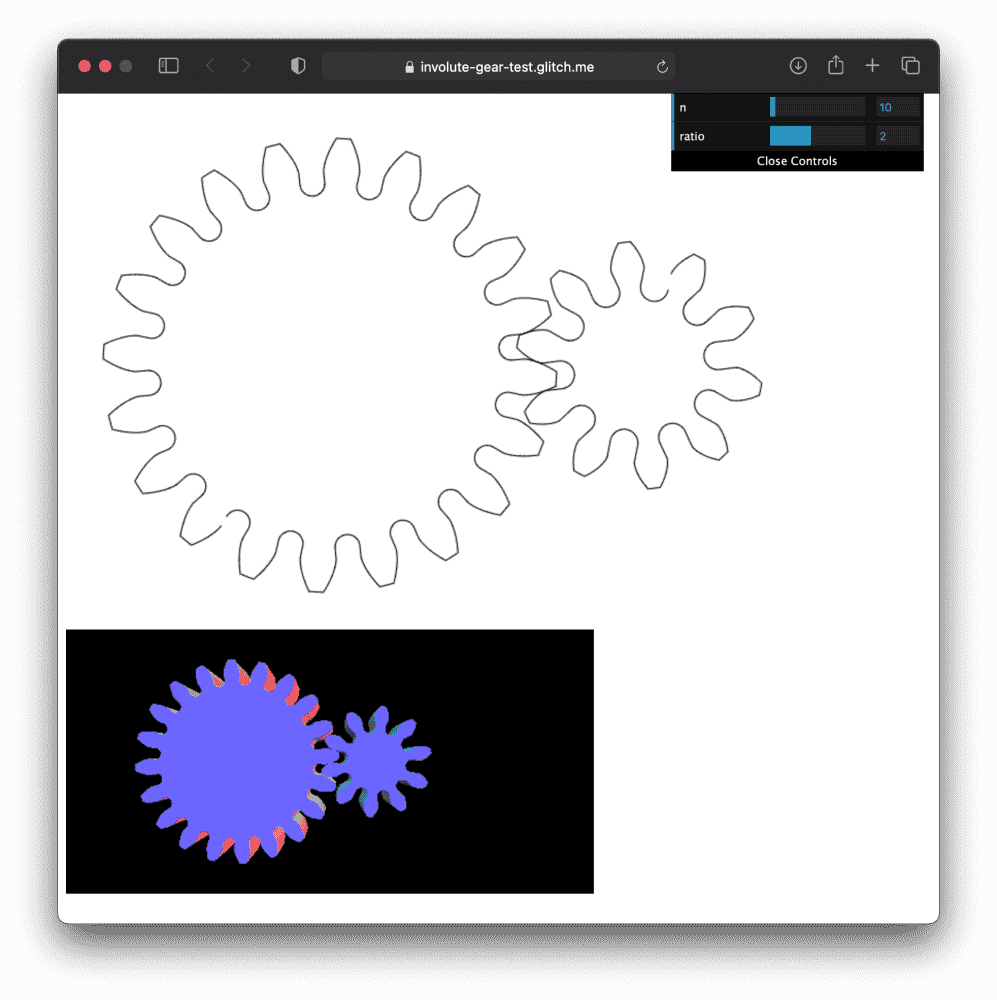

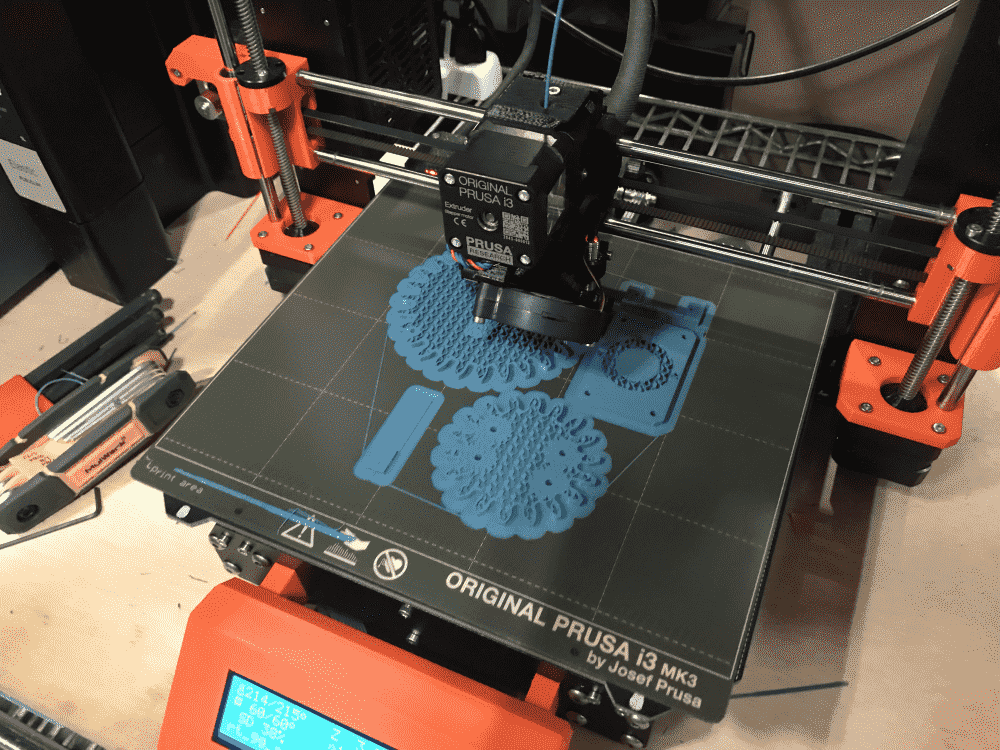

In fact, my entire design is generated with a JavaScript program, found below. You can try the online demo here.

// unit: mm

const is_node = typeof process != 'undefined';

let createCanvas;

let readImage;

let findContours, approxPolyDP;

let fs;

if (is_node){

fs = require('fs');

;({createCanvas} = require('canvas'));

;({Image} = require('canvas'));

;({findContours,approxPolyDP} = require('./findcontours.js'));

var earcut = require('./earcut.js');

readImage = function(pth){

let img = new Image();

img.src = fs.readFileSync(pth);

return img;

}

}else{

;({findContours, approxPolyDP} = FindContours);

createCanvas = function(w,h){

let cnv = document.createElement('canvas');

cnv.width = w;

cnv.height = h;

return cnv;

}

readImage = function(pth){

return document.querySelectorAll(`[src="${pth}"]`)[0];

}

var renderer;

var scene;

var camera;

render_faces = function(faces){

if (!renderer){

scene = new THREE.Scene();

camera = new THREE.PerspectiveCamera( 75, 1, 0.1, 2000 );

camera.position.x = 0;

camera.position.y = 0;

camera.position.z = 100;

camera.lookAt(0,0,0);

renderer = new THREE.WebGLRenderer({});

renderer.setSize( 256,256 );

material = new THREE.MeshNormalMaterial();

}

while(scene.children.length > 0){

scene.remove(scene.children[0]);

}

// const controls = new THREE.OrbitControls( camera, renderer.domElement );

// controls.update();

let vertices = new Float32Array(faces.flat().map(xyz=>[xyz[0],xyz[1],xyz[2]]).flat());

// console.log(faces);

const geometry = new THREE.BufferGeometry();

geometry.setAttribute( 'position', new THREE.BufferAttribute( vertices, 3 ) );

geometry.setAttribute( 'normal', new THREE.BufferAttribute( new Float32Array(vertices.length).fill(0), 3 ) );

// geometry.computeFaceNormals();

geometry.computeBoundingBox();

let box = geometry.boundingBox;

let siz = new THREE.Vector3();

box.getSize(siz);

let mesh = new THREE.Mesh( geometry, material );

mesh.matrixAutoUpdate = true;

scene.add(mesh);

let cnvs = [];

for (let i = 0; i < 12; i++){

geometry.rotateY(PI/6);

geometry.computeVertexNormals();

geometry.attributes.normal.needsUpdate = true;

geometry.computeBoundingBox();

let box = geometry.boundingBox;

let cen = new THREE.Vector3();

box.getCenter(cen);

camera.position.set(cen.x,cen.y,Math.max(siz.x,siz.y)*1.5+box.min.z+20);

renderer.render( scene, camera );

let cnv = createCanvas(renderer.domElement.width,renderer.domElement.height);

let ctx = cnv.getContext('2d');

ctx.drawImage(renderer.domElement,0,0);

cnvs.push(cnv);

}

return cnvs;

}

download_stl = function(pth,faces){

let name = `${pth}-${new Date().getTime()}.stl`;

let data = to_stl_bin(faces);

var a = document.createElement("a");

document.body.appendChild(a);

a.style = "display: none";

var blob = new Blob([data], {type: "model/stl"});

var url = window.URL.createObjectURL(blob);

a.href = url;

a.download = name;

a.click();

window.URL.revokeObjectURL(url);

}

download_svg = function(pth,text){

var element = document.createElement('a');

element.setAttribute('href', 'data:text/plain;charset=utf-8,' + encodeURIComponent(text));

element.setAttribute('download', pth);

element.style.display = 'none';

document.body.appendChild(element);

element.click();

document.body.removeChild(element);

}

}

const PI = Math.PI;

const cos = Math.cos;

const sin = Math.sin;

var WOOD_THICK = 3.15; // 25.4 * 1/8

var BEARING_GEAR_R = 22;

var BEARING_INNER_R = 5.98;

var BEARING_OUTER_R = 14.05;

var BEARING_THICK = 8;

var BEARING_LOWER_THICK = 6;

var BEARING_CHAMF = 3;

var BEARING_BOLT_THICK = 6;

var BEARING_BOLT_R = 4.8;

var BEARING_GEAR_THICK = 10;

var BEARING_GEAR_HOLE_DX = 12;

var BEARING_GEAR_HOLE_DY = 6;

var BEARING_GEAR_TEETH = 18;

// var BEARING_GEAR_R = 30;

// var BEARING_INNER_R = 6.5;

// var BEARING_OUTER_R = 13.5;

// var BEARING_THICK = 8;

// var BEARING_LOWER_THICK = 6;

// var BEARING_CHAMF = 3;

// var BEARING_BOLT_THICK = 6;

// var BEARING_BOLT_R = 4.5;

// var BEARING_GEAR_THICK = 10;

// var BEARING_GEAR_HOLE_DX = 16;

// var BEARING_GEAR_HOLE_DY = 8;

// var BEARING_GEAR_TEETH = 18;

var BEARING_BRACK_R = 18;

var BEARING_BRACK_THICK = 13;

var BEARING_BRACK_PL_THICK = 3;

var BEARING_BRACK_PL_W = 36;

var BEARING_BRACK_PL_H = 50;

var BEARING_BRACK_PL_CHAMF = 3;

var BEARING_BRACK_HOLE_DX = 13;

var BEARING_BRACK_HOLE_DY = 21;

// var BEARING_BRACK_R = 20;

// var BEARING_BRACK_THICK = 13;

// var BEARING_BRACK_PL_THICK = 3;

// var BEARING_BRACK_PL_W = 40;

// var BEARING_BRACK_PL_H = 60;

// var BEARING_BRACK_PL_CHAMF = 3;

// var BEARING_BRACK_HOLE_DX = 15;

// var BEARING_BRACK_HOLE_DY = 25;

var MG995_GEAR_RATIO = 1.5;

var MG995_GEAR_R = BEARING_GEAR_R*MG995_GEAR_RATIO;

var MG995_GEAR_TEETH = BEARING_GEAR_TEETH*MG995_GEAR_RATIO;

var MG995_GEAR_THICK = BEARING_GEAR_THICK;

var MG995_SINK_THICK = 4;

var MG995_WIRE_THICK = 2;

var MG995_HOLE_R = 2.05;

var MG995_HOLE_DX = 3.55;

var MG995_HOLE_DY = 4.75;

var MG995_W = 40.4;

var MG995_D = 20.15;

var MG995_W_GAP = 0.6;

var MG995_AXIS_RX = 30.15;

var MG995_AXIS_LX = MG995_W-MG995_AXIS_RX;

var NINEG_W = 22.7;

var NINEG_D = 11.8;

var NINEG_HOLE_DX = 2.5;

var NINEG_HOLE_R = 1.05;

var NINEG_HORN_THICK = 1.4;

var NINEG_AXIS_LX = 6.2;

var NINEG_AXIS_RX = NINEG_W-6.2;

var NINEG_TOTAL_H = 31.6;

var NINEG_LOWER_H = 15.8;

var NINEG_CABLE_H = 8.2;

var NINEG_CABLE_W = 3;

var NINEG_ARM_W = 9;

var NINEG_ARM_LEN = 50;

var NINEG_ARM_STEM_LEN = 12;

var NINEG_ARM_ROOT_LEN = 5;

var NINEG_ARM_LEAF_LEN = NINEG_ARM_LEN-NINEG_ARM_ROOT_LEN-NINEG_ARM_STEM_LEN;

var NINEG_ARM_THICK = 5;

var NINEG_SINK_THICK = 3;

var NINEG_LEAF_THICK = 1;

var NINEG_BRACK_H = 9.5;

var NINEG_BRACK_FRONT_THICK = 2.5;

var NINEG_BRACK_SIDE_THICK = 1.5;

var NINEG_BRACK_BACK_THICK = 2;

var NINEG_BRACK_BOLT_THICK = 4;

var NINEG_BRACK_TOP_THICK = 2.4;

var NINEG_BRACK_W = 8;

var NINEG_BRACK_HOLE_DX = 3.5;

var NINEG_BRACK_HOLE_DY = 4.5;

var NINEG_BRACK2_HOLE_DX = 3.31;

var NINEG_BRACK2_HOLE_DY = 4.34;

// var NINEG_BRACK2_HOLE_DX = 2.65;

// var NINEG_BRACK2_HOLE_DY = 3;

var NINEG_BRACK2_SINK_THICK = 5;

var NINEG_BRACK2_BACK_THICK = 7;

var NINEG_ASM_TOTAL_H = NINEG_TOTAL_H + NINEG_SINK_THICK - NINEG_HORN_THICK;

var NINEG_ASM_TOTAL_W = NINEG_W+NINEG_BRACK_W*2;

var M3_HOLE_D = 3.2;

var MEZZ_H = Math.ceil(Math.max(40,NINEG_ASM_TOTAL_H,BEARING_GEAR_HOLE_DY*2+M3_HOLE_D*2));

var MEZZ_SIDE_SLOT_W = 8;

var CHAMBER_H = 35;

var CHAMBER_LW = 100;

var CHAMBER_RW = 100;

var BOX_W = CHAMBER_LW+CHAMBER_RW;

var BOX_H = CHAMBER_H*3+MEZZ_H*2+WOOD_THICK*4;

var BOX_D = 25;

var BOX_X_FINGER_CNT = 17;

var BOX_Y_FINGER_CNT = 17;

var BOX_Z_FINGER_CNT = 3;

var BASE_X_FINGER_CNT = 17;

var BASE_Y_FINGER_CNT = 17;

var BASE_W = 200;

var BASE_H = 200;

var BASE2_SLOT_DX = 6;

var BASE2_SLOT_DY = 5;

var BASE2_SLOT_LEN = 30;

var BASE_RAIL_R = 80;

var BASE_RAIL_W = 12;

var BASE_DEG = 10;

var BASE_ELEV_H = 20;

var BASE_BACK_DX = 5;

var BASE_BACK_H = 20;

var LED_DY = 8.5;

var LED_W = 8.78;

var LED_R = 2.4;

var LED_BRACK_W = 10;

var LED_BRACK_H = 9.2;

var LED_BRACK_INNER_H = 8.6;

var LED_BRACK_THICK = 4;

var LED_BRACK_SINK_THICK = 1.65;

var LED_BRACK_PL_W = 6;

var LED_BRACK_PL_H = 6;

var LED_BRACK_PL_HOLE_DX = 3.5;

var LED_BRACK_PL_HOLE_DY = 3;

var LED_BRACK_PL_THICK = 3;

var LED_BRACK_ROOF_W = 3;

var LED_BRACK_ROOF_THICK = 1;

var BALL_D = 7;

var M3_HEXNUT_D = 5.51;

var NINEG_ARM2_THICK = 4;

var NINEG_ARM2_W = 13;

var NINEG_ARM2_LEN = CHAMBER_H+WOOD_THICK+NINEG_AXIS_LX+NINEG_BRACK_W;

var NINEG_ARM2_ROOT_LEN = 5;

var NINEG_ARM2_STEM_LEN = 12;

var NINEG_ARM2_LEAF_LEN = NINEG_ARM2_LEN-NINEG_ARM2_ROOT_LEN-NINEG_ARM2_STEM_LEN;

var NINEG_ARM3_FLEX_THICK = 8;

var NINEG_ARM3_STEM_THICK = 2.5;

var NINEG_ARM3_STEM_LEN = 25;

var NINEG_ARM3_FLEX_DY = 21;

var TRIG_SLOPE_W = 9;

var TRIG_SLOPE_THICK = BOX_D;

var TRIG_SLOPE_SINK_THICK = 10;

var TRIG_SLOPE2_W = 5;

var TRIG_SLOPE2_THICK = BOX_D;

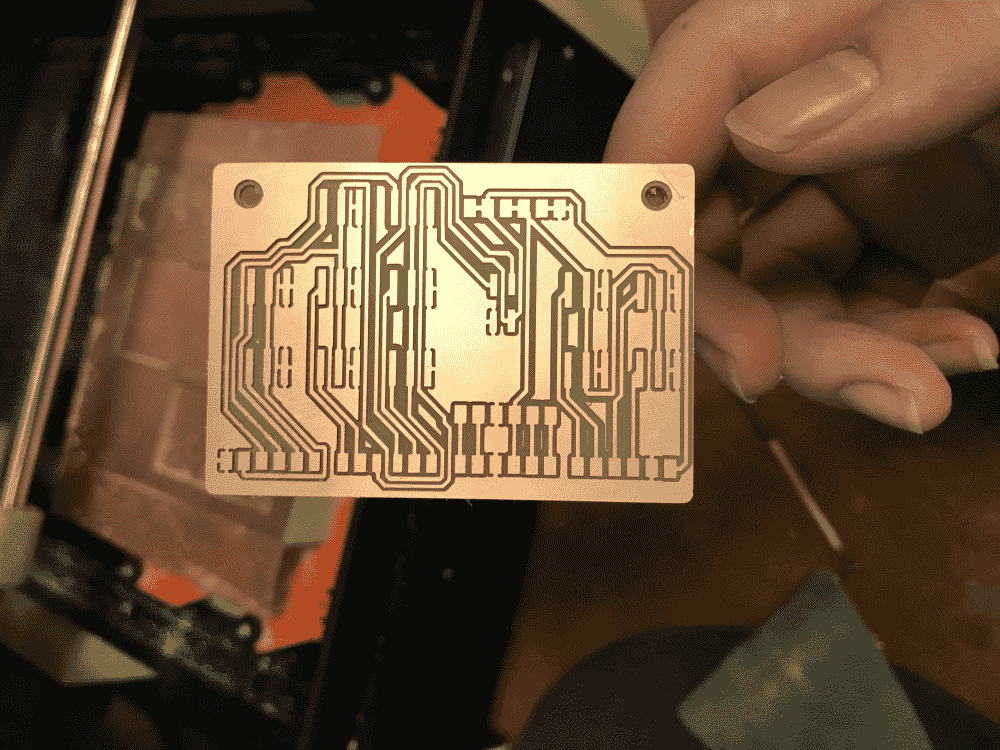

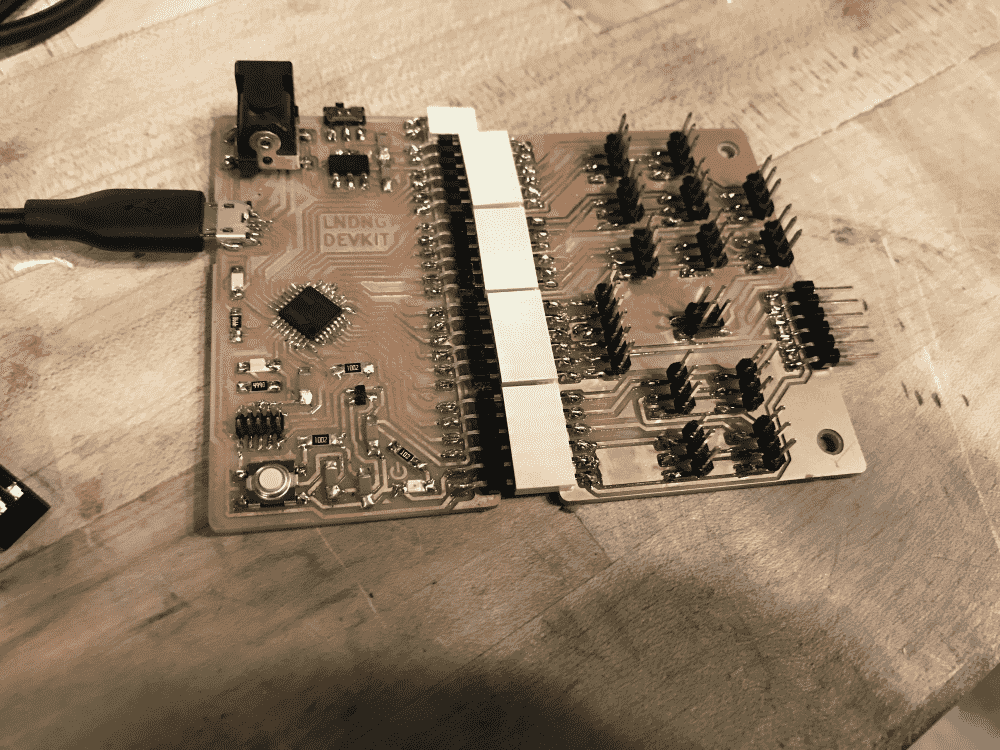

var PCB_W = 75.1;

var PCB_H = 39.1;

// var PCB_THICK = 13;

var PCB_BOARD_THICK = 1.65;

var PCB_THICK = 4.8;

var PCB_CASE_WALL_THICK = 3.5;

var PCB_CASE_INNER_WALL_THICK = 1.5;

var PCB_CASE_BOTTOM_THICK = 1.4;

var PCB_CASE_TOP_THICK = 0.9;

var PCB_CASE_CHAMF = 2.3;

var PCB_CASE_CHAMF1 = 2;

var PCB_CASE_CHAMF2 = 1;

var PCB_CASE_W = PCB_W+PCB_CASE_WALL_THICK*2;

var PCB_CASE_H = PCB_H+PCB_CASE_WALL_THICK*2;

var PCB_CASE_TEETH_R = 0.5;

var PCB_CASE_TEETH_THICK = 1.9;

var PCB2_W = 68.48;

// var PCB2_H = 47.3;

var PCB2_H = 34.65;

var PCB2_HOLE_DX = 4.4;

var PCB2_HOLE_DY = 5.08;

var PCB3_W = 54.1;

var PCB3_H = 45.9;

var PCB3_THICK = 4.75;

var PCB3_CASE_WALL_THICK = 4.1;

var PCB3_CASE_INNER_WALL_THICK = 1.7;

var PCB3_CASE_BOTTOM_THICK = 1.8;

var PCB3_CASE_TOP_THICK = 0.6;

var PCB3_CASE_W = PCB3_W+PCB3_CASE_WALL_THICK*2;

var PCB3_CASE_H = PCB3_H+PCB3_CASE_WALL_THICK*2;

var PCB3_CASE_CHAMF = 3;

var PCB3_CASE_CHAMF1 = 2;

var PCB3_CASE_CHAMF2 = 1;

// var PANEL_BRACK_DX = 5;

var SENSOR_HOLE_DX = 15.7;

var SENSOR_HOLE_DY = 11;

var OLED_HOLE_DIST = 30;

var OLED_HOLE_DY = 23;

console.log(BOX_W,'x',BOX_H);

let jsr = 0x5EED;

function rand(){

jsr^=(jsr<<17);

jsr^=(jsr>>13);

jsr^=(jsr<<5);

return (jsr>>>0)/4294967295;

}

function seg_isect(p0x, p0y, p1x, p1y, q0x, q0y, q1x, q1y, is_ray = false) {

let d0x = p1x - p0x;

let d0y = p1y - p0y;

let d1x = q1x - q0x;

let d1y = q1y - q0y;

let vc = d0x * d1y - d0y * d1x;

if (vc == 0) {

return null;

}

let vcn = vc * vc;

let q0x_p0x = q0x - p0x;

let q0y_p0y = q0y - p0y;

let vc_vcn = vc / vcn;

let t = (q0x_p0x * d1y - q0y_p0y * d1x) * vc_vcn;

let s = (q0x_p0x * d0y - q0y_p0y * d0x) * vc_vcn;

if (0 <= t && (is_ray || t < 1) && 0 <= s && s < 1) {

return t;

}

return null;

}

function dist(x0,y0,x1,y1){

return Math.hypot(x0-x1,y0-y1);

}

function trace(ctx,epsilon=1){

let cnv = ctx.canvas;

let dat = ctx.getImageData(0,0,cnv.width,cnv.height).data;

let im = [];

for (let i = 0; i < dat.length; i+=4){

im.push(dat[i]>128?255:0);

}

let contours = findContours(im,cnv.width,cnv.height);

for (let i = 0; i < contours.length; i++){

contours[i] = approxPolyDP(contours[i].points,epsilon);

// contours[i] = contours[i].map(x=>[x[0],x[1]])

}

contours = contours.filter(x=>x.length>=3);

return contours;

}

function draw_svg(polylines,W,H,SCALE=1){

W*=SCALE;

H*=SCALE;

polylines = scal_poly(polylines,SCALE);

let o = `<svg xmlns="http://www.w3.org/2000/svg" width="${W}" height="${H}"><path stroke="black" stroke-width="1" fill="none" d="M0 0 ${W} 0 ${W} ${H} 0 ${H} z"/>`

for (let i = 0; i < polylines.length; i++){

o += `<path stroke="black" stroke-width="0.5" fill="none" d="M`

for (let j = 0; j < polylines[i].length; j++){

let [x,y] = polylines[i][j];

o += `${x} ${y} `;

}

o += ' z"/>';

}

o += `</svg>`

return o;

}

function to_stl_bin(faces){

let nb = 84+faces.length*50;

console.log(`writing stl (binary)... estimated ${Math.round((nb/1048576)*100)/100} MB`);

let o = new Uint8Array(nb);

let a = new ArrayBuffer(4);

let b = new Uint32Array(a);

b[0] = faces.length;

o.set(new Uint8Array(a),80);

for (let i = 0; i < faces.length; i++){

let d = [

faces[i][0][0],faces[i][0][1],faces[i][0][2],

faces[i][1][0],faces[i][1][1],faces[i][1][2],

faces[i][2][0],faces[i][2][1],faces[i][2][2],

]

let a = new ArrayBuffer(36);

let b = new Float32Array(a);

d.map((x,j)=>b[j]=x);

o.set(new Uint8Array(a),84+i*50+12);

}

return o;

}

function rot_pt_2d(x,y,th){

return [

x*cos(th)-y*sin(th),

x*sin(th)+y*cos(th),

]

}

function rot_path_2d(p,th){

return p.map(x=>rot_pt_2d(...x,th))

}

function involute(r){

let n = 100;

let p = [];

for (let i = 0; i < n; i++){

let t = i/n;

let a = t*PI/2;

let x = r*cos(a)+a*r*sin(a);

let y = r*sin(a)-a*r*cos(a);

p.push([x,y])

}

return p;

}

function circle(r,n=200){

let p = [];

for (let i = 0; i < n; i++){

let t = i/(n-1);

let a = t * PI*2;

let x = r*cos(a);

let y = r*sin(a);

p.push([x,y]);

}

return p;

}

function chamf_rect(w,h,r){

return [

[-w/2+r,-h/2],

[w/2-r,-h/2],

[w/2,-h/2+r],

[w/2,h/2-r],

[w/2-r,h/2],

[-w/2+r,h/2],

[-w/2,h/2-r],

[-w/2,-h/2+r],

]

}

function rect_xywh(x,y,w,h){

return [

[x,y],[x+w,y],[x+w,y+h],[x,y+h]

]

}

function fillet_rect(x,y,w,h,tl,tr,br,bl) {

let n = 10;

let poly = [];

if (tl){

for (let i = 0; i < n+1; i++) {

let a = (i/n)*PI/2;

let xx = x+tl-cos(a)*tl;

let yy = y+tl-sin(a)*tl;

poly.push([xx,yy]);

}

}else{

poly.push([x,y+tl]);

}

if (tr){

for (let i = 0; i < n+1; i++) {

let a = (i/n)*PI/2;

let xx = x+w-tr+sin(a)*tr;

let yy = y+tr-cos(a)*tr;

poly.push([xx,yy]);

}

}else{

poly.push([x+w-tr,y]);

}

if (br){

for (let i = 0; i < n+1; i++) {

let a = (i/n)*PI/2;

let xx = x+w-br+cos(a)*br;

let yy = y+h-br+sin(a)*br;

poly.push([xx,yy]);

}

}else{

poly.push([x+w,y+h-br])

}

if (bl){

for (let i = 0; i < n+1; i++) {

let a = (i/n)*PI/2;

let xx = x+bl-sin(a)*bl;

let yy = y+h-bl+cos(a)*bl;

poly.push([xx,yy]);

}

}else{

poly.push([x+bl,y+h])

}

return poly;

}

function semicircle(r,a0){

let n = 100;

let p = [];

for (let i = 0; i < n; i++){

let t = i/(n-1);

let a = a0+t * PI;

let x = r*cos(a);

let y = r*sin(a);

p.push([x,y]);

}

return p;

}

function isect_paths(p,q){

for (let i = 0; i < p.length-1; i++){

for (let j = 0; j < q.length-1; j++){

let a = p[i];

let b = p[i+1];

let c = q[j];

let d = q[j+1];

let t = seg_isect(...a,...b,...c,...d);

if (t!=null){

return [

a[0]*(1-t)+b[0]*t,

a[1]*(1-t)+b[1]*t,

]

}

}

}

}

function trim_path(p,q){

for (let i = 0; i < p.length-1; i++){

for (let j = 0; j < q.length-1; j++){

let a = p[i];

let b = p[i+1];

let c = q[j];

let d = q[j+1];

let t = seg_isect(...a,...b,...c,...d);

if (t!=null){

return p.slice(0,i+1).concat([[

a[0]*(1-t)+b[0]*t,

a[1]*(1-t)+b[1]*t,

]]);

}

}

}

return p;

}

function gear(r,n){

let pa = 0.11*PI;

let mod = r*2/n;

let add = mod;

let ded = mod*1.157;

let r0 = cos(pa) * r;

let r1 = r + add;

let r2 = r - ded;

let inv = involute(r0);

let ref = circle(r);

let inn = circle(r2);

let out = circle(r1);

let ang = PI/n;

let p = isect_paths(inv,ref);

let a0 = Math.atan2(p[1],p[0]);

a0*=2

let a1 = ang+a0;

let in1 = inv.map(x=>[x[0],-x[1]]);

in1 = rot_path_2d(in1,a1);

let in0 = trim_path(inv,out);

let tip = trim_path(rot_path_2d(out,PI/2).reverse(),inv);

tip = trim_path(tip.reverse(),in1);

in1 = trim_path(in1,out);

let ac = ang-a0;

let rc = Math.tan(ac/2)*r0

let cc = semicircle(rc,PI/2)

cc = cc.map(x=>[x[0]+r2,x[1]]);

cc = rot_path_2d(cc,ang*1.5+a0/2);

inn = rot_path_2d(inn,PI/2)//.reverse();

in0 = trim_path(in0.reverse(),inn).reverse();

in1 = trim_path(in1.reverse(),inn);

let pl = [];

for (let i = 0; i < n; i++){

let ia = rot_path_2d(in0,ang*2*i);

let ib = rot_path_2d(in1,ang*2*i);

let ic = rot_path_2d(cc, ang*2*i);

let it = rot_path_2d(tip,ang*2*i);

pl.push(...ia,...it,...ib,...ic.reverse());

}

return approxPolyDP(rot_path_2d(pl,ang/2-a0/2-PI/n),0.05);

}

function dilate(ctx){

let ctx2 = createCanvas(ctx.canvas.width,ctx.canvas.height).getContext('2d');

ctx2.drawImage(ctx.canvas,0,0);

ctx2.globalCompositeOperation = "lighter";

ctx2.drawImage(ctx.canvas,-1,0);

ctx2.drawImage(ctx.canvas,0,-1);

ctx2.drawImage(ctx.canvas,0,1);

ctx2.drawImage(ctx.canvas,1,0);

ctx2.drawImage(ctx.canvas,-1,-1);

ctx2.drawImage(ctx.canvas,-1,1);

ctx2.drawImage(ctx.canvas,1,-1);

ctx2.drawImage(ctx.canvas,1,1);

return ctx2;

}

function erode(ctx){

let ctx2 = createCanvas(ctx.canvas.width,ctx.canvas.height).getContext('2d');

ctx2.drawImage(ctx.canvas,0,0);

ctx2.globalCompositeOperation = "multiply";

ctx2.drawImage(ctx.canvas,-1,0);

ctx2.drawImage(ctx.canvas,0,-1);

ctx2.drawImage(ctx.canvas,0,1);

ctx2.drawImage(ctx.canvas,1,0);

ctx2.drawImage(ctx.canvas,-1,-1);

ctx2.drawImage(ctx.canvas,-1,1);

ctx2.drawImage(ctx.canvas,1,-1);

ctx2.drawImage(ctx.canvas,1,1);

return ctx2;

}

function trsl_poly(poly,x,y){

return poly.map(xys=>xys.map(xy=>[xy[0]+x,xy[1]+y]));

}

function scal_poly(poly,x){

return poly.map(xys=>xys.map(xy=>[xy[0]*x,xy[1]*x]));

}

function trsl_mesh(mesh,x,y,z){

return mesh.map(xys=>xys.map(xy=>[xy[0]+x,xy[1]+y,xy[2]+z]));

}

function extrude(p,d){

let ft = triangulate(p);

let f1 = ft.map(xys=>xys.map(xy=>[xy[0],xy[1],0]).reverse());

let f2 = ft.map(xys=>xys.map(xy=>[xy[0],xy[1],d]));

let ff = [...f1,...f2]

for (let k = 0; k < p.length; k++){

let vs = p[k];

for (let i = 0; i < vs.length; i++){

let j = (i+1)%vs.length;

let a = [...vs[i],0]

let b = [...vs[j],0]

let c = [...vs[i],d]

let e = [...vs[j],d]

if (!k){

ff.push([a,b,e],[a,e,c]);

}else{

ff.push([a,e,b],[a,c,e]);

}

}

}

return ff;

}

function make_tube(rs,zs,n){

let cs = [];

for (let i = 0; i < rs.length; i++){

let c = [];

for (let j = 0; j < n; j++){

let a = j/n*PI*2;

let x = cos(a)*rs[i];

let y = sin(a)*rs[i];

c.push([x,y,zs[i]]);

}

cs.push(c);

}

let ff = [];

for (let i = 0; i < cs.length-1; i++){

for (let j = 0; j < n; j++){

let a = cs[i][j];

let b = cs[i][(j+1)%n];

let c = cs[i+1][j]

let d = cs[i+1][(j+1)%n];

ff.push([a,b,d],[a,d,c]);

}

}

return ff;

}

function clone(p){

return JSON.parse(JSON.stringify(p));

}

function triangulate(p){

p = clone(p);

let poly = p[0];

let holes = p.slice(1);

let idx = [];

let q = poly;

while (holes.length){

idx.push(q.length);

q.push(...holes.pop());

}

let trigs = earcut(q.flat(),idx.length?idx:null);

let faces = [];

for (let i = 0; i < trigs.length; i+=3){

let a = trigs[i];

let b = trigs[i+1];

let c = trigs[i+2];

faces.push([q[a],q[b],q[c]]);

}

return faces;

}

function get_bbox(points){

let xmin = Infinity;

let ymin = Infinity;

let xmax = -Infinity;

let ymax = -Infinity

for (let i = 0;i < points.length; i++){

let [x,y] = points[i];

xmin = Math.min(xmin,x);

ymin = Math.min(ymin,y);

xmax = Math.max(xmax,x);

ymax = Math.max(ymax,y);

}

return {x:xmin,y:ymin,w:xmax-xmin,h:ymax-ymin};

}

function export_model(pth,faces){

console.log(pth);

let s = 1;//1/25.4;

faces = faces.map(xys=>xys.map(xy=>[xy[0]*s,xy[1]*s,xy[2]*s]));

if (is_node){

let stl = to_stl_bin(faces);

fs.writeFileSync(pth,stl);

}else{

let div = document.getElementById(pth);

if (!div){

div = document.createElement("div");

div.id = pth;

div.style = "display:inline-block;margin:1px";

document.body.appendChild(div);

}

div.innerHTML = `<div>${pth} <button>download</button></div>`;

div.getElementsByTagName("button")[0].onclick = function(){

download_stl(pth,faces);

}

let cnv = document.createElement("canvas");

let ctx = cnv.getContext('2d');

let cnvs = window.render_faces(faces);

cnv.width = cnvs[0].width;

cnv.height = cnvs[0].height;

let idx = 0;

clearTimeout(window['loop_'+pth]);

function loop(){

window['loop_'+pth] = setTimeout(loop,100);

ctx.drawImage(cnvs[idx],0,0);

idx = (idx+1)%cnvs.length;

}

loop();

div.appendChild(cnv);

}

}

// function export_outline(pth,polylines){

// console.log(pth);

// // polylines = scal_poly(polylines,1/25.4);

// let bb = get_bbox(polylines.flat());

// polylines = trsl_poly(polylines,-bb.x+10,-bb.y+10);

// fs.writeFileSync(pth,draw_svg(polylines,bb.w+20,bb.h+20));

// }

function export_outline(pth,polylines){

console.log(pth);

// polylines = scal_poly(polylines,1/25.4);

let bb = get_bbox(polylines.flat());

polylines = trsl_poly(polylines,-bb.x+10,-bb.y+10);

let svg = draw_svg(polylines,256,256);

if (is_node){

fs.writeFileSync(pth,svg);

}else{

let div = document.getElementById(pth);

if (!div){

div = document.createElement("div");

div.id = pth;

div.style = "display:inline-block;margin:1px";

document.body.appendChild(div);

}

div.innerHTML = `<div>${pth} <button>download</button></div><div>${svg}</div>`;

div.getElementsByTagName("button")[0].onclick = function(){

download_svg(pth,svg);

}

}

}

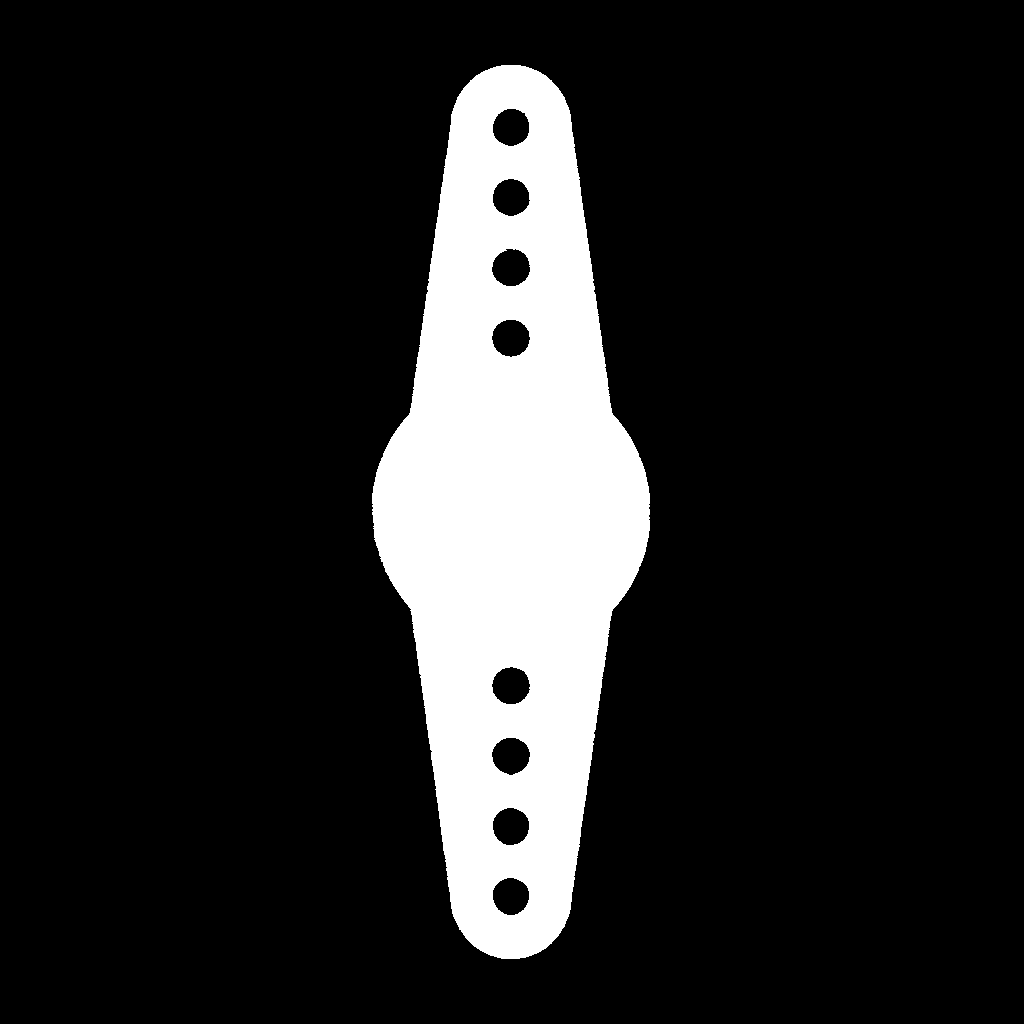

function load_mg995_horn(){

let img = readImage("horn_mg995.png");

let cnv = createCanvas(img.width,img.height);

let ctx = cnv.getContext('2d');

ctx.drawImage(img,0,0);

// let polylines = trace(ctx,1.5);

let ctx2 = dilate(ctx);

ctx2 = dilate(ctx2);

ctx2 = dilate(ctx2);

let polylines = [trace(ctx2,1.4)[0]];

let ctx3 = erode(ctx);

ctx3 = erode(ctx3);

polylines.push(...trace(ctx3,1.4).slice(1));

// polylines = polylines.concat(trace(ctx,1.5));

// fs.writeFileSync('out.svg',draw_svg(polylines,1024,1024));

polylines = polylines.map(xys=>xys.map(xy=>[

(xy[0]-512)/600*25.4,

(xy[1]-512)/600*25.4,

]));

// console.log(polylines)

return polylines;

}

function load_9g_horn(offset){

let img = readImage("horn_9g.png");

let cnv = createCanvas(img.width,img.height);

let ctx = cnv.getContext('2d');

let dy = offset/25.4*600;

ctx.drawImage(img,0,512+dy);

// let polylines = trace(ctx,1.5);

let ctx2 = dilate(ctx)

let polylines = [trace(ctx2,1.4)[0]];

let ctx3 = erode(ctx);

ctx3 = erode(ctx3);

ctx3 = erode(ctx3);

polylines.push(...trace(ctx3,1.4).slice(1));

// polylines = polylines.concat(trace(ctx,1.5));

// fs.writeFileSync('out.svg',draw_svg(polylines,1024,1024));

polylines = polylines.map(xys=>xys.map(xy=>[

(512-xy[0])/600*25.4,

(1024-xy[1])/600*25.4,

]));

// console.log(polylines)

return polylines;

}

function load_flexture_door(){

let img = readImage("flexture_door.png");

let cnv = createCanvas(img.width,img.height);

let ctx = cnv.getContext('2d');

ctx.drawImage(img,0,0);

// let polylines = trace(ctx,1.5);

let polylines = [trace(ctx,1.4)[0]];

// polylines = polylines.concat(trace(ctx,1.5));

// fs.writeFileSync('out.svg',draw_svg(polylines,1024,1024));

polylines = polylines.map(xys=>xys.map(xy=>[

(xy[0]-51)/21,

(xy[1]-225)/21,

]).reverse());

// console.log(polylines)

return polylines;

}

function hole(x,y,r){

return circle(r,32).map(xy=>[xy[0]+x,xy[1]+y]);

}

function m3_hole(x,y){

return hole(x,y,M3_HOLE_D/2);

}

function m3_hexnut_hole(x,y){

let r = M3_HEXNUT_D/2/Math.sqrt(3)*2;

let o = [];

for (let i = 0; i < 6; i++){

let a = i/6 * PI * 2;

let u = Math.cos(a)*r;

let v = Math.sin(a)*r;

o.push([x+u,y+v]);

}

return o;

}

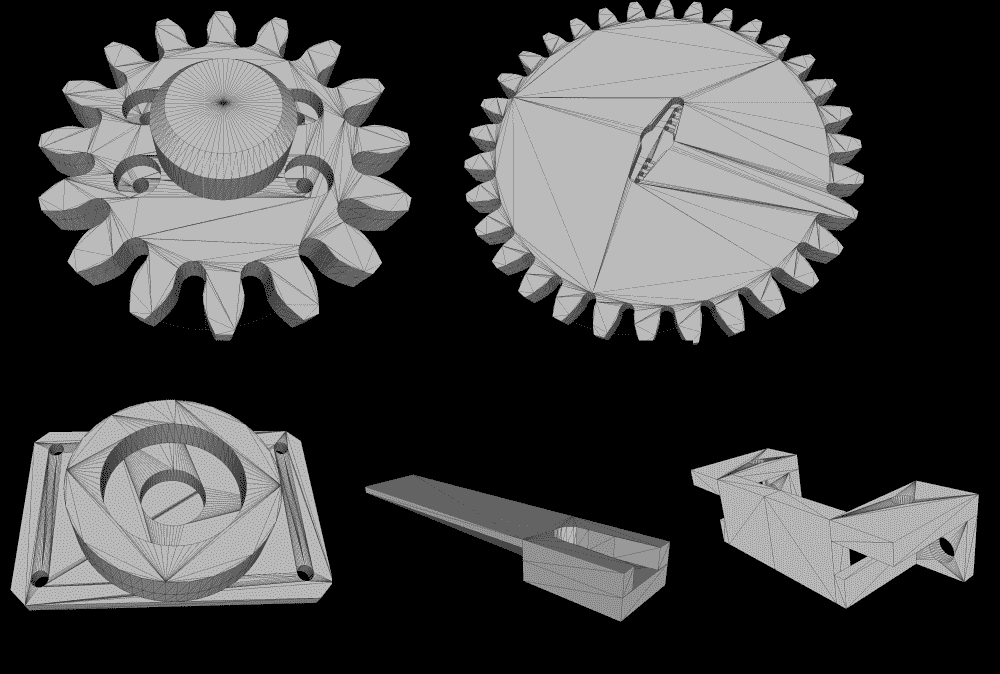

function mg995_gear(){

let g0 = gear(MG995_GEAR_R,MG995_GEAR_TEETH);

let hn = load_mg995_horn();

hn = [hn[0],hn[1],hn[3],hn[6],hn[8]];

// let g1 = gear(bearing_gear_r,bearing_gear_teeth);

// fs.writeFileSync('out.svg',draw_svg([

// ...trsl_poly([g0,...hn],100,100),...trsl_poly([g1],200,100)

// ],300,200,2));

let f0 = [g0].concat(hn.slice(1));

let f1 = [g0].concat([hn[0].slice().reverse()]);

// let ff = triangulate(f1);

// fs.writeFileSync('out.svg',draw_svg([

// ...trsl_poly(ff,100,100),

// ],300,200,2));

let d0 = MG995_GEAR_THICK-MG995_SINK_THICK-MG995_WIRE_THICK;

let part0 = extrude(f1, MG995_SINK_THICK);

let part1 = trsl_mesh(extrude(f0, d0),0,0,MG995_SINK_THICK);

let part2 = trsl_mesh(extrude(f1, MG995_WIRE_THICK),0,0,d0+MG995_SINK_THICK);

// console.log(part0);

export_model('part_mg995_gear.stl', part0.concat(part1).concat(part2))

}

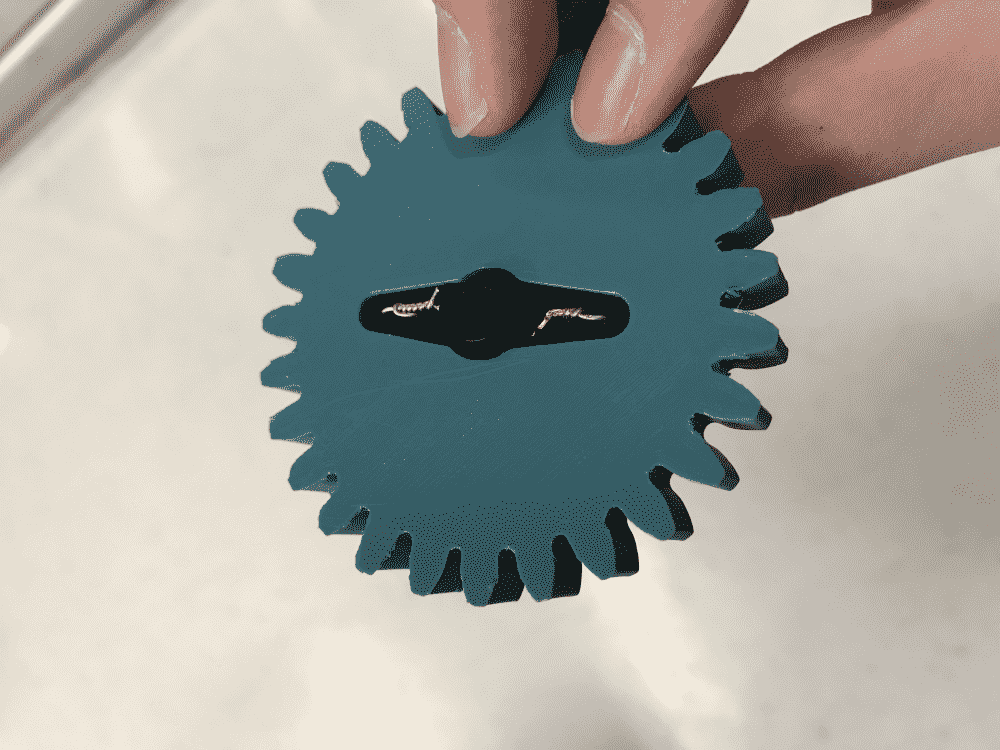

function bearing_gear(){

let g0 = gear(BEARING_GEAR_R,BEARING_GEAR_TEETH);

let f0 = [g0].concat([

m3_hole(-BEARING_GEAR_HOLE_DX,-BEARING_GEAR_HOLE_DY),

m3_hole( BEARING_GEAR_HOLE_DX,-BEARING_GEAR_HOLE_DY),

m3_hole(-BEARING_GEAR_HOLE_DX, BEARING_GEAR_HOLE_DY),

m3_hole( BEARING_GEAR_HOLE_DX, BEARING_GEAR_HOLE_DY),

]);

let d0 = BEARING_GEAR_THICK-BEARING_BOLT_THICK;

let part0 = extrude(f0, d0);

// let f1 = [g0].concat([

// hole(-BEARING_GEAR_HOLE_DX,-BEARING_GEAR_HOLE_DY,BEARING_BOLT_R),

// hole( BEARING_GEAR_HOLE_DX,-BEARING_GEAR_HOLE_DY,BEARING_BOLT_R),

// hole(-BEARING_GEAR_HOLE_DX, BEARING_GEAR_HOLE_DY,BEARING_BOLT_R),

// hole( BEARING_GEAR_HOLE_DX, BEARING_GEAR_HOLE_DY,BEARING_BOLT_R),

// ]);

let f1 = [g0].concat([

m3_hexnut_hole(-BEARING_GEAR_HOLE_DX,-BEARING_GEAR_HOLE_DY),

m3_hexnut_hole( BEARING_GEAR_HOLE_DX,-BEARING_GEAR_HOLE_DY),

m3_hexnut_hole(-BEARING_GEAR_HOLE_DX, BEARING_GEAR_HOLE_DY),

m3_hexnut_hole( BEARING_GEAR_HOLE_DX, BEARING_GEAR_HOLE_DY),

]);

let part1 = trsl_mesh(extrude(f1, BEARING_BOLT_THICK),0,0,d0);

let part2 = make_tube(

[BEARING_INNER_R,BEARING_INNER_R,BEARING_INNER_R-BEARING_CHAMF,0],

[

BEARING_GEAR_THICK,

BEARING_GEAR_THICK+BEARING_THICK,

BEARING_GEAR_THICK+BEARING_THICK+BEARING_CHAMF,

BEARING_GEAR_THICK+BEARING_THICK+BEARING_CHAMF

],64);

export_model('part_bearing_gear.stl', part0.concat(part1).concat(part2));

}

function bearing_bracket(){

let g0 = circle(BEARING_BRACK_R,64);

let g1 = circle(BEARING_OUTER_R,64);

let g2 = circle(BEARING_INNER_R,64);

let f0 = [g0].concat([g1])

let part0 = extrude(f0, BEARING_LOWER_THICK);

let d1 = BEARING_BRACK_THICK-BEARING_BRACK_PL_THICK-BEARING_LOWER_THICK;

// let part1 = make_tube(

// [0,BEARING_BRACK_R,BEARING_BRACK_R,0],

// [BEARING_LOWER_THICK,BEARING_LOWER_THICK,BEARING_LOWER_THICK+d1,BEARING_LOWER_THICK+d1],64

// );

let f1 = [g0].concat([g2])

let part1 = trsl_mesh(extrude(f1, d1), 0,0,BEARING_LOWER_THICK);

let g3 = chamf_rect(BEARING_BRACK_PL_W,BEARING_BRACK_PL_H,BEARING_BRACK_PL_CHAMF);

let f2 = [g3].concat([

m3_hole(-BEARING_BRACK_HOLE_DX,-BEARING_BRACK_HOLE_DY),

m3_hole( BEARING_BRACK_HOLE_DX,-BEARING_BRACK_HOLE_DY),

m3_hole(-BEARING_BRACK_HOLE_DX, BEARING_BRACK_HOLE_DY),

m3_hole( BEARING_BRACK_HOLE_DX, BEARING_BRACK_HOLE_DY),

]);

let part2 = trsl_mesh(extrude(f2, BEARING_BRACK_PL_THICK),0,0,BEARING_LOWER_THICK+d1);

export_model('part_bearing_bracket.stl', part0.concat(part1).concat(part2));

}

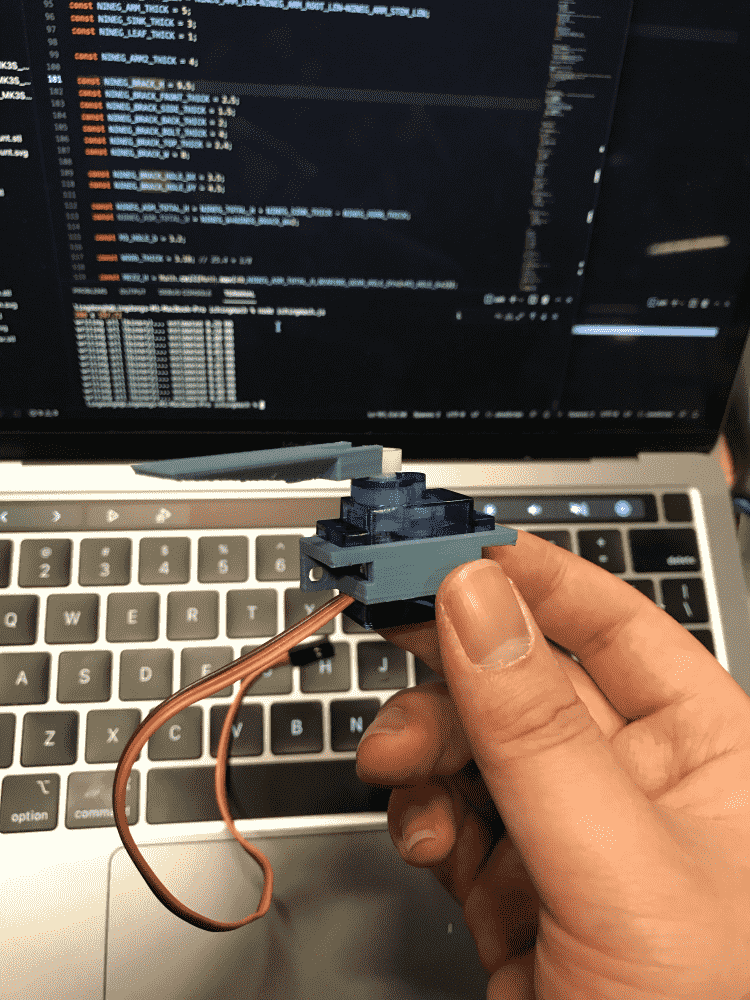

function nineg_arm(){

let hn = load_9g_horn(5);

// hn[0].reverse();

hn.splice(1,1);

hn.splice(2,1);

hn.splice(3,1);

let fpi = 0;

let hn0 = hn[0];

for (let i = 0; i < hn0.length; i++){

if (hn0[i][1] < hn0[fpi][1]){

fpi = i;

}else if (hn0[i][1] < hn0[fpi][1]+0.001 && hn0[i][0] < hn0[fpi][0]){

fpi = i;

}

}

hn0 = hn0.slice(fpi).concat(hn0.slice(0,fpi));

let g0 = [

[NINEG_ARM_W/2,0],

[NINEG_ARM_W/2,NINEG_ARM_STEM_LEN],

[-NINEG_ARM_W/2,NINEG_ARM_STEM_LEN],

[-NINEG_ARM_W/2,0]

];

let f0 = [[...hn0,...g0]];

let part0 = extrude(f0, NINEG_SINK_THICK);

let f1 = [g0].concat(hn.slice(1));

let part1 = trsl_mesh(extrude(f1, NINEG_ARM_THICK-NINEG_SINK_THICK),0,0,NINEG_SINK_THICK);

let part2 = trsl_mesh(extrude([[

[NINEG_ARM_W/2,0],

[NINEG_ARM_W/2,NINEG_ARM_LEAF_LEN],

[-NINEG_ARM_W/2,NINEG_ARM_LEAF_LEN],

[-NINEG_ARM_W/2,0]

]],NINEG_LEAF_THICK),0,NINEG_ARM_STEM_LEN,0);

let l0 = NINEG_ARM_STEM_LEN;

let l1 = NINEG_ARM_LEN-NINEG_ARM_ROOT_LEN;

let w = NINEG_ARM_W;

let part3 = [

[[-w/2,l1,NINEG_LEAF_THICK],[0,l0,NINEG_ARM_THICK],[w/2,l1,NINEG_LEAF_THICK]],

[[-w/2,l1,NINEG_LEAF_THICK],[-w/2,l0,NINEG_LEAF_THICK],[0,l0,NINEG_ARM_THICK]],

[[w/2,l1,NINEG_LEAF_THICK],[0,l0,NINEG_ARM_THICK],[w/2,l0,NINEG_LEAF_THICK]],

[[0,l0,NINEG_ARM_THICK],[-w/2,l0,NINEG_LEAF_THICK],[w/2,l0,NINEG_LEAF_THICK]],

[[-w/2,l1,NINEG_LEAF_THICK],[w/2,l1,NINEG_LEAF_THICK],[w/2,l0,NINEG_LEAF_THICK]],

[[-w/2,l1,NINEG_LEAF_THICK],[w/2,l0,NINEG_LEAF_THICK],[-w/2,l0,NINEG_LEAF_THICK]],

]

export_model('part_9g_arm.stl', part0.concat(part1).concat(part2).concat(part3));

}

function nineg_arm2(){

let hn = load_9g_horn(5);

// hn[0].reverse();

hn.splice(1,1);

hn.splice(2,1);

hn.splice(3,1);

let fpi = 0;

let hn0 = hn[0];

for (let i = 0; i < hn0.length; i++){

if (hn0[i][1] < hn0[fpi][1]){

fpi = i;

}else if (hn0[i][1] < hn0[fpi][1]+0.001 && hn0[i][0] < hn0[fpi][0]){

fpi = i;

}

}

hn0 = hn0.slice(fpi).concat(hn0.slice(0,fpi));

let g0 = [

[NINEG_ARM_W/2,0],

[NINEG_ARM_W/2,NINEG_ARM2_STEM_LEN],

[-NINEG_ARM_W/2,NINEG_ARM2_STEM_LEN],

[-NINEG_ARM_W/2,0]

];

let f0 = [[...hn0,...g0]];

let part0 = extrude(f0, NINEG_SINK_THICK);

let f1 = [g0].concat(hn.slice(1));

let part1 = trsl_mesh(extrude(f1, NINEG_ARM2_THICK-NINEG_SINK_THICK),0,0,NINEG_SINK_THICK);

let l0 = NINEG_ARM2_STEM_LEN;

let l1 = NINEG_ARM2_LEN-NINEG_ARM2_ROOT_LEN;

let w = NINEG_ARM_W/2-NINEG_ARM2_W;

let part2 = [

[[w,l0,0],[w,l1,NINEG_ARM2_THICK],[w,l1,0]],

[[w,l0,0],[w,l0,NINEG_ARM2_THICK],[w,l1,NINEG_ARM2_THICK]],

[[w,l0,0],[w,l1,0],[NINEG_ARM_W/2,l0,NINEG_ARM2_THICK/2]],

[[w,l1,0],[NINEG_ARM_W/2,l1,NINEG_ARM2_THICK/2],[NINEG_ARM_W/2,l0,NINEG_ARM2_THICK/2]],

[[w,l0,NINEG_ARM2_THICK],[NINEG_ARM_W/2,l0,NINEG_ARM2_THICK/2],[w,l1,NINEG_ARM2_THICK]],

[[w,l1,NINEG_ARM2_THICK],[NINEG_ARM_W/2,l0,NINEG_ARM2_THICK/2],[NINEG_ARM_W/2,l1,NINEG_ARM2_THICK/2]],

[[w,l1,0],[w,l1,NINEG_ARM2_THICK],[NINEG_ARM_W/2,l1,NINEG_ARM2_THICK/2]],

[[w,l0,0],[NINEG_ARM_W/2,l0,NINEG_ARM2_THICK/2],[w,l0,NINEG_ARM2_THICK]],

]

export_model('part_9g_arm2.stl', part0.concat(part1).concat(part2));

}

function nineg_arm3(){

let hn = load_9g_horn(5);

// hn[0].reverse();

hn.splice(1,1);

hn.splice(2,1);

hn.splice(3,1);

let fpi = 0;

let hn0 = hn[0];

for (let i = 0; i < hn0.length; i++){

if (hn0[i][1] < hn0[fpi][1]){

fpi = i;

}else if (hn0[i][1] < hn0[fpi][1]+0.001 && hn0[i][0] < hn0[fpi][0]){

fpi = i;

}

}

hn0 = hn0.slice(fpi).concat(hn0.slice(0,fpi));

let g0 = [

[NINEG_ARM_W/2,0],

[NINEG_ARM_W/2,NINEG_ARM3_STEM_LEN],

[-NINEG_ARM_W/2,NINEG_ARM3_STEM_LEN],

[-NINEG_ARM_W/2,0]

];

let f0 = [[...hn0,...g0]];

let part0 = extrude(f0, NINEG_SINK_THICK);

let f1 = [g0].concat(hn.slice(1));

let part1 = trsl_mesh(extrude(f1, NINEG_ARM_THICK-NINEG_SINK_THICK),0,0,NINEG_SINK_THICK);

let part2 = trsl_mesh(extrude([[

[NINEG_ARM_W/2,0],

[NINEG_ARM_W/2,NINEG_ARM3_STEM_THICK],

[-NINEG_ARM_W/2,NINEG_ARM3_STEM_THICK],

[-NINEG_ARM_W/2,0]

]],MEZZ_H/2+NINEG_ARM3_STEM_THICK/2),0,NINEG_ARM3_STEM_LEN,0);

let part3 = trsl_mesh(extrude([[

[0,0],

[NINEG_ARM_W,0],

[NINEG_ARM_W,NINEG_ARM_LEN-NINEG_ARM_ROOT_LEN-NINEG_ARM3_STEM_LEN-NINEG_ARM3_FLEX_THICK-NINEG_ARM3_STEM_THICK],

[0,NINEG_ARM_LEN-NINEG_ARM_ROOT_LEN-NINEG_ARM3_STEM_LEN-NINEG_ARM3_FLEX_THICK-NINEG_ARM3_STEM_THICK]

]],NINEG_ARM3_STEM_THICK),-NINEG_ARM_W/2,NINEG_ARM3_STEM_LEN+NINEG_ARM3_STEM_THICK,MEZZ_H/2-NINEG_ARM3_STEM_THICK/2);

let part32 = trsl_mesh(extrude([[

[0,0],

[NINEG_ARM_W,0],

[NINEG_ARM_W,NINEG_ARM_LEN-NINEG_ARM_ROOT_LEN-NINEG_ARM3_STEM_LEN-NINEG_ARM3_FLEX_THICK-NINEG_ARM3_STEM_THICK],

[0,NINEG_ARM_LEN-NINEG_ARM_ROOT_LEN-NINEG_ARM3_STEM_LEN-NINEG_ARM3_FLEX_THICK-NINEG_ARM3_STEM_THICK]

]],NINEG_ARM3_STEM_THICK),-NINEG_ARM_W/2,NINEG_ARM3_STEM_LEN+NINEG_ARM3_STEM_THICK,0);

let l0 = NINEG_ARM3_STEM_LEN;

let l1 = NINEG_ARM_LEN-NINEG_ARM_ROOT_LEN;

let w = NINEG_ARM_W;

let part4 = trsl_mesh(extrude([[

[0,0],

[NINEG_ARM_W,0],

[NINEG_ARM_W,NINEG_ARM3_FLEX_THICK],

[0,NINEG_ARM3_FLEX_THICK]

]],MEZZ_H-19.05),-NINEG_ARM_W/2,l1-NINEG_ARM3_FLEX_THICK,0);

let fd = load_flexture_door();

let part5 = extrude(fd,NINEG_ARM3_FLEX_THICK).map(xys=>xys.map(xy=>[-xy[1]-NINEG_ARM_W/2,xy[2]+l1-NINEG_ARM3_FLEX_THICK,xy[0]+NINEG_ARM3_FLEX_DY]).reverse())

export_model('part_9g_arm3.stl', part0.concat(part1).concat(part2).concat(part3).concat(part32).concat(part4).concat(part5));

}

function nineg_arm3_noflex(){

let hn = load_9g_horn(5);

// hn[0].reverse();

hn.splice(1,1);

hn.splice(2,1);

hn.splice(3,1);

let fpi = 0;

let hn0 = hn[0];

for (let i = 0; i < hn0.length; i++){

if (hn0[i][1] < hn0[fpi][1]){

fpi = i;

}else if (hn0[i][1] < hn0[fpi][1]+0.001 && hn0[i][0] < hn0[fpi][0]){

fpi = i;

}

}

hn0 = hn0.slice(fpi).concat(hn0.slice(0,fpi));

let g0 = [

[NINEG_ARM_W/2,0],

[NINEG_ARM_W/2,NINEG_ARM3_STEM_LEN],

[-NINEG_ARM_W/2,NINEG_ARM3_STEM_LEN],

[-NINEG_ARM_W/2,0]

];

let f0 = [[...hn0,...g0]];

let part0 = extrude(f0, NINEG_SINK_THICK);

let f1 = [g0].concat(hn.slice(1));

let part1 = trsl_mesh(extrude(f1, NINEG_ARM_THICK-NINEG_SINK_THICK),0,0,NINEG_SINK_THICK);

let part2 = trsl_mesh(extrude([[

[NINEG_ARM_W/2,0],

[NINEG_ARM_W/2,NINEG_ARM3_STEM_THICK],

[-NINEG_ARM_W/2,NINEG_ARM3_STEM_THICK],

[-NINEG_ARM_W/2,0]

]],MEZZ_H/2+NINEG_ARM3_STEM_THICK/2),0,NINEG_ARM3_STEM_LEN,0);

let part3 = trsl_mesh(extrude([[

[0,0],

[NINEG_ARM_W,0],

[NINEG_ARM_W,NINEG_ARM_LEN-NINEG_ARM_ROOT_LEN-NINEG_ARM3_STEM_LEN-NINEG_ARM3_FLEX_THICK-NINEG_ARM3_STEM_THICK],

[0,NINEG_ARM_LEN-NINEG_ARM_ROOT_LEN-NINEG_ARM3_STEM_LEN-NINEG_ARM3_FLEX_THICK-NINEG_ARM3_STEM_THICK]

]],NINEG_ARM3_STEM_THICK),-NINEG_ARM_W/2,NINEG_ARM3_STEM_LEN+NINEG_ARM3_STEM_THICK,MEZZ_H/2-NINEG_ARM3_STEM_THICK/2);

let part32 = trsl_mesh(extrude([[

[0,0],

[NINEG_ARM_W,0],

[NINEG_ARM_W,NINEG_ARM_LEN-NINEG_ARM_ROOT_LEN-NINEG_ARM3_STEM_LEN-NINEG_ARM3_FLEX_THICK-NINEG_ARM3_STEM_THICK],

[0,NINEG_ARM_LEN-NINEG_ARM_ROOT_LEN-NINEG_ARM3_STEM_LEN-NINEG_ARM3_FLEX_THICK-NINEG_ARM3_STEM_THICK]

]],NINEG_ARM3_STEM_THICK),-NINEG_ARM_W/2,NINEG_ARM3_STEM_LEN+NINEG_ARM3_STEM_THICK,0);

let l0 = NINEG_ARM3_STEM_LEN;

let l1 = NINEG_ARM_LEN-NINEG_ARM_ROOT_LEN;

let w = NINEG_ARM_W;

let part4 = trsl_mesh(extrude([[

[0,0],

[NINEG_ARM_W,0],

[NINEG_ARM_W,NINEG_ARM3_FLEX_THICK-1.2],

[0,NINEG_ARM3_FLEX_THICK-1.2]

]],MEZZ_H),-NINEG_ARM_W/2,l1-NINEG_ARM3_FLEX_THICK,0);

export_model('part_9g_arm3_noflex.stl', part0.concat(part1).concat(part2).concat(part3).concat(part4));

}

function nineg_bracket(){

// let part0 = trsl_mesh(extrude([[

// [-NINEG_W/2,NINEG_BRACK_TOP_THICK+NINEG_BRACK_BOLT_THICK],

// [0,NINEG_BRACK_TOP_THICK+NINEG_BRACK_BOLT_THICK],

// [0,NINEG_BRACK_H],

// [-NINEG_W/2,NINEG_BRACK_H],

// ]],NINEG_BRACK_FRONT_THICK),0,0,NINEG_D);

let part0 = trsl_mesh(extrude([[

[-NINEG_W/2,0],

[0,0],

[0,NINEG_BRACK_H],

[-NINEG_W/2,NINEG_BRACK_H],

]],NINEG_BRACK_FRONT_THICK),0,0,NINEG_D);

let part1 = trsl_mesh(extrude([[

[0,NINEG_BRACK_TOP_THICK+NINEG_BRACK_BOLT_THICK],

[NINEG_BRACK_SIDE_THICK,NINEG_BRACK_TOP_THICK+NINEG_BRACK_BOLT_THICK],

[NINEG_BRACK_SIDE_THICK,NINEG_BRACK_H],

[0,NINEG_BRACK_H],

]],NINEG_D+NINEG_BRACK_FRONT_THICK-NINEG_BRACK_BACK_THICK),0,0,NINEG_BRACK_BACK_THICK);

let part2 = extrude([[

[0,NINEG_BRACK_TOP_THICK],

[NINEG_BRACK_W,NINEG_BRACK_TOP_THICK],

[NINEG_BRACK_W,NINEG_BRACK_H],

[0,NINEG_BRACK_H],

], m3_hole(NINEG_BRACK_HOLE_DX+NINEG_BRACK_SIDE_THICK,NINEG_BRACK_HOLE_DY+NINEG_BRACK_TOP_THICK)

],NINEG_BRACK_BACK_THICK);

let part3 = extrude([[

[0,0],

[NINEG_BRACK_W,0],

[NINEG_BRACK_W,NINEG_D+NINEG_BRACK_FRONT_THICK],

[0,NINEG_D+NINEG_BRACK_FRONT_THICK],

], //hole(NINEG_HOLE_DX,NINEG_D/2,NINEG_HOLE_R)

],NINEG_BRACK_TOP_THICK).map(xys=>xys.map(xy=>[xy[0],xy[2],xy[1]]).reverse());

let part4 = extrude([

hole(NINEG_HOLE_DX,NINEG_D/2,NINEG_HOLE_R)

],-NINEG_BRACK_TOP_THICK).map(xys=>xys.map(xy=>[xy[0],xy[2],xy[1]]));

let partl = trsl_mesh(part0.concat(part1).concat(part2).concat(part3).concat(part4),NINEG_W/2,0,0);

let partr = partl.map(xys=>xys.map(xy=>[-xy[0],xy[1],xy[2]]).reverse());

export_model('part_9g_bracket.stl', partl.concat(partr));

}

function nineg_bracket2(){

let part0 = trsl_mesh(extrude([[

[-NINEG_W/2,0],

[0,0],

[0,NINEG_BRACK_H],

[-NINEG_W/2,NINEG_BRACK_H],

]],NINEG_BRACK_FRONT_THICK),0,0,NINEG_D);

let part1 = trsl_mesh(extrude([[

[0,NINEG_BRACK_TOP_THICK+NINEG_BRACK_BOLT_THICK],

[NINEG_BRACK_SIDE_THICK,NINEG_BRACK_TOP_THICK+NINEG_BRACK_BOLT_THICK],

[NINEG_BRACK_SIDE_THICK,NINEG_BRACK_H],

[0,NINEG_BRACK_H],

]],NINEG_D+NINEG_BRACK_FRONT_THICK-NINEG_BRACK2_BACK_THICK),0,0,NINEG_BRACK2_BACK_THICK);

let part2 = extrude([[

[0,NINEG_BRACK_TOP_THICK],

[NINEG_BRACK_W,NINEG_BRACK_TOP_THICK],

[NINEG_BRACK_W,NINEG_BRACK_H],

[0,NINEG_BRACK_H],

], m3_hole(NINEG_BRACK2_HOLE_DX+NINEG_BRACK_SIDE_THICK,NINEG_BRACK2_HOLE_DY+NINEG_BRACK_TOP_THICK)

],NINEG_BRACK2_BACK_THICK-NINEG_BRACK2_SINK_THICK);

let part5 = trsl_mesh(extrude([[

[0,NINEG_BRACK_TOP_THICK],

[NINEG_BRACK_W,NINEG_BRACK_TOP_THICK],

[NINEG_BRACK_W,NINEG_BRACK_H],

[0,NINEG_BRACK_H],

], m3_hexnut_hole(NINEG_BRACK2_HOLE_DX+NINEG_BRACK_SIDE_THICK,NINEG_BRACK2_HOLE_DY+NINEG_BRACK_TOP_THICK)

],NINEG_BRACK2_SINK_THICK),0,0,NINEG_BRACK2_BACK_THICK-NINEG_BRACK2_SINK_THICK);

let part3 = extrude([[

[0,0],

[NINEG_BRACK_W,0],

[NINEG_BRACK_W,NINEG_D+NINEG_BRACK_FRONT_THICK],

[0,NINEG_D+NINEG_BRACK_FRONT_THICK],

], //hole(NINEG_HOLE_DX,NINEG_D/2,NINEG_HOLE_R)

],NINEG_BRACK_TOP_THICK).map(xys=>xys.map(xy=>[xy[0],xy[2],xy[1]]).reverse());

let part4 = extrude([

hole(NINEG_HOLE_DX,NINEG_D/2,NINEG_HOLE_R)

],-NINEG_BRACK_TOP_THICK).map(xys=>xys.map(xy=>[xy[0],xy[2],xy[1]]));

let partl = trsl_mesh(part0.concat(part1).concat(part2).concat(part3).concat(part4).concat(part5),NINEG_W/2,0,0);

let partr = partl.map(xys=>xys.map(xy=>[-xy[0],xy[1],xy[2]]).reverse());

export_model('part_9g_bracket2.stl', partl.concat(partr));

}

function led_bracket(){

let part0 = extrude([[

[0,0],

[LED_BRACK_W,0],

[LED_BRACK_W,LED_BRACK_H],

[0,LED_BRACK_H],

]],LED_BRACK_THICK-LED_BRACK_SINK_THICK);

let part1 = trsl_mesh(extrude([[

[0,0],

[LED_BRACK_W,0],

[LED_BRACK_W,LED_BRACK_H],

[LED_W,LED_BRACK_H],

[LED_W,LED_BRACK_H-LED_BRACK_INNER_H],

[0,LED_BRACK_H-LED_BRACK_INNER_H]

]],LED_BRACK_SINK_THICK),0,0,LED_BRACK_THICK-LED_BRACK_SINK_THICK);

let part2 = extrude([[

[0,0],

[LED_BRACK_PL_W,0],

[LED_BRACK_PL_W,LED_BRACK_PL_H],

[0,LED_BRACK_PL_H],

],m3_hole(LED_BRACK_PL_HOLE_DX,LED_BRACK_PL_HOLE_DY),

],LED_BRACK_PL_THICK).map(xys=>xys.map(xy=>[xy[2],xy[1]+LED_BRACK_H-LED_BRACK_PL_H,-xy[0]]));

let part3 = trsl_mesh(extrude([[

[LED_BRACK_W-LED_BRACK_ROOF_W,0],

[LED_BRACK_W,0],

[LED_BRACK_W,LED_BRACK_H],

[LED_BRACK_W-LED_BRACK_ROOF_W,LED_BRACK_H],

]],LED_BRACK_ROOF_THICK),0,0,LED_BRACK_THICK);

let partl = part0.concat(part1).concat(part2).concat(part3);

let partr = partl.map(xys=>xys.map(xy=>[-xy[0],xy[1],xy[2]]).reverse());

export_model('part_led_bracket.stl', partr);

}

function led_bracket2(){

let h = LED_BRACK_H + 1;

let ih = LED_BRACK_INNER_H + 1;

let st = LED_BRACK_SINK_THICK+1;

let wt = LED_BRACK_W- LED_W;

let part0 = extrude([[

[0,0],

[LED_BRACK_W+wt,0],

[LED_BRACK_W+wt,h],

[0,h],

]],LED_BRACK_THICK-st);

let part1 = trsl_mesh(extrude([[

[0,0],

[LED_BRACK_W+wt,0],

[LED_BRACK_W+wt,h],

[LED_BRACK_W,h],

[LED_BRACK_W,h-ih],

[wt,h-ih],

[wt,h],

[0,h]

]],st),0,0,LED_BRACK_THICK-st);

let part2 = extrude([[

[0,0],

[LED_BRACK_PL_W,0],

[LED_BRACK_PL_W,LED_BRACK_PL_H],

[0,LED_BRACK_PL_H],

],m3_hole(LED_BRACK_PL_HOLE_DX,LED_BRACK_PL_HOLE_DY),

],LED_BRACK_PL_THICK).map(xys=>xys.map(xy=>[xy[0]+LED_BRACK_W+wt,xy[1]+LED_BRACK_H-LED_BRACK_PL_H,xy[2]+LED_BRACK_THICK-LED_BRACK_PL_THICK]));

// let part3 = trsl_mesh(extrude([[

// [LED_BRACK_W-LED_BRACK_ROOF_W,0],

// [LED_BRACK_W,0],

// [LED_BRACK_W,LED_BRACK_H],

// [LED_BRACK_W-LED_BRACK_ROOF_W,LED_BRACK_H],

// ]],LED_BRACK_ROOF_THICK),0,0,LED_BRACK_THICK);

let partl = part0.concat(part1).concat(part2);

// let partr = partl.map(xys=>xys.map(xy=>[-xy[0],xy[1],xy[2]]).reverse());

export_model('part_led_bracket2.stl', partl);

}

function trig_slope(){

let part0 = extrude([[

[0,0],[TRIG_SLOPE_W,TRIG_SLOPE_W],

[0,TRIG_SLOPE_W*2]

],m3_hole(M3_HEXNUT_D/2+0.5,TRIG_SLOPE_W),

],TRIG_SLOPE_THICK-TRIG_SLOPE_SINK_THICK);

let part1 = trsl_mesh(extrude([[

[0,0],[TRIG_SLOPE_W,TRIG_SLOPE_W],

[0,TRIG_SLOPE_W*2]

],...trsl_poly([rot_path_2d(m3_hexnut_hole(0,0),PI/2)],M3_HEXNUT_D/2+0.5,TRIG_SLOPE_W),

],TRIG_SLOPE_SINK_THICK),0,0,TRIG_SLOPE_THICK-TRIG_SLOPE_SINK_THICK);

export_model('part_trig_slope.stl', part0.concat(part1));

}

function trig_slope2(){

let part0 = extrude([[

[0,0],[TRIG_SLOPE2_W,TRIG_SLOPE2_W],

[0,TRIG_SLOPE2_W*2]

]],TRIG_SLOPE2_THICK);

export_model('part_trig_slope2.stl', part0);

}

function finger_edge(len,cnt,first_high){

let o = [];

for (let i = 0; i < cnt+1; i++){

let x = (i/cnt)*len;

if (i % 2 == 0){

if (i == 0){

if (first_high){

o.push([x,-WOOD_THICK]);

}else{

o.push([x,0]);

}

}else{

if (first_high){

o.push([x,0],[x,-WOOD_THICK]);

}else{

o.push([x,-WOOD_THICK],[x,0]);

}

}

}else{

if (i == cnt){

if (first_high){

o.push([x,-WOOD_THICK]);

}else{

o.push([x,0]);

}

}else{

if (first_high){

o.push([x,-WOOD_THICK],[x,0]);

}else{

o.push([x,0],[x,-WOOD_THICK]);

}

}

}

}

return o;

}

function finger_hole(len,cnt){

let o = [];

for (let i = 1; i < cnt; i+=2){

let x0 = (i/cnt)*len;

let x1 = ((i+1)/cnt)*len;

o.push([

[x0,0],[x1,0],[x1,WOOD_THICK],[x0,WOOD_THICK]

]);

}

return o;

}

function nineg_cable_hole(x,y){

return [

[x-NINEG_CABLE_W/2,y-NINEG_CABLE_H/2],

[x+NINEG_CABLE_W/2,y-NINEG_CABLE_H/2],

[x+NINEG_CABLE_W/2,y+NINEG_CABLE_H/2],

[x-NINEG_CABLE_W/2,y+NINEG_CABLE_H/2]

];

}

function nineg_cable_hole_3x(x,y){

return [

[x,y-NINEG_CABLE_H/2],

[x+NINEG_CABLE_W*3,y-NINEG_CABLE_H/2],

[x+NINEG_CABLE_W*3,y+NINEG_CABLE_H/2],

[x,y+NINEG_CABLE_H/2]

];

}

function box_back(){

let o = [];

o.push(...finger_edge(BOX_W,BOX_X_FINGER_CNT));

o.push(...trsl_poly([rot_path_2d(finger_edge(BOX_H,BOX_Y_FINGER_CNT),PI/2)],BOX_W,0)[0]);

o.push(...trsl_poly([rot_path_2d(finger_edge(BOX_W,BOX_X_FINGER_CNT),PI)],BOX_W,BOX_H)[0]);

o.push(...trsl_poly([rot_path_2d(finger_edge(BOX_H,BOX_Y_FINGER_CNT),PI/2+PI)],0,BOX_H)[0]);

let oo = [o];

oo.push(...trsl_poly(finger_hole(BOX_W,BOX_X_FINGER_CNT),0,CHAMBER_H));

oo.push(...trsl_poly(finger_hole(BOX_W,BOX_X_FINGER_CNT),0,CHAMBER_H+WOOD_THICK+MEZZ_H));

oo.push(...trsl_poly(finger_hole(BOX_W,BOX_X_FINGER_CNT),0,CHAMBER_H+WOOD_THICK+MEZZ_H+WOOD_THICK+CHAMBER_H));

oo.push(...trsl_poly(finger_hole(BOX_W,BOX_X_FINGER_CNT),0,CHAMBER_H+WOOD_THICK+MEZZ_H+WOOD_THICK+CHAMBER_H+WOOD_THICK+MEZZ_H));

let cable_x = 8;

oo.push(m3_hole(NINEG_ARM_LEN-NINEG_AXIS_LX-NINEG_BRACK_SIDE_THICK-NINEG_BRACK_HOLE_DX, CHAMBER_H+WOOD_THICK+NINEG_ASM_TOTAL_H-NINEG_LOWER_H+NINEG_BRACK_TOP_THICK+NINEG_BRACK_HOLE_DY));

oo.push(m3_hole(NINEG_ARM_LEN-NINEG_AXIS_LX+NINEG_W+NINEG_BRACK_SIDE_THICK+NINEG_BRACK_HOLE_DX, CHAMBER_H+WOOD_THICK+NINEG_ASM_TOTAL_H-NINEG_LOWER_H+NINEG_BRACK_TOP_THICK+NINEG_BRACK_HOLE_DY));

// oo.push(nineg_cable_hole_3x(NINEG_ARM_LEN-NINEG_AXIS_LX+NINEG_W+NINEG_BRACK_W+cable_x, CHAMBER_H+WOOD_THICK+NINEG_ASM_TOTAL_H-NINEG_LOWER_H+NINEG_BRACK_TOP_THICK+NINEG_BRACK_HOLE_DY))

oo.push(m3_hole(NINEG_ARM_LEN-NINEG_AXIS_LX-NINEG_BRACK_SIDE_THICK-NINEG_BRACK_HOLE_DX, CHAMBER_H+WOOD_THICK+MEZZ_H+WOOD_THICK+CHAMBER_H+WOOD_THICK+NINEG_ASM_TOTAL_H-NINEG_LOWER_H+NINEG_BRACK_TOP_THICK+NINEG_BRACK_HOLE_DY));

oo.push(m3_hole(NINEG_ARM_LEN-NINEG_AXIS_LX+NINEG_W+NINEG_BRACK_SIDE_THICK+NINEG_BRACK_HOLE_DX, CHAMBER_H+WOOD_THICK+MEZZ_H+WOOD_THICK+CHAMBER_H+WOOD_THICK+NINEG_ASM_TOTAL_H-NINEG_LOWER_H+NINEG_BRACK_TOP_THICK+NINEG_BRACK_HOLE_DY));

oo.push(m3_hole(SENSOR_HOLE_DX, CHAMBER_H+WOOD_THICK+SENSOR_HOLE_DY));

oo.push(m3_hole(SENSOR_HOLE_DX, CHAMBER_H+WOOD_THICK+MEZZ_H+WOOD_THICK+CHAMBER_H+WOOD_THICK+SENSOR_HOLE_DY));

// oo.push(nineg_cable_hole_3x(NINEG_ARM_LEN-NINEG_AXIS_LX+NINEG_W+NINEG_BRACK_W+cable_x, CHAMBER_H+WOOD_THICK+MEZZ_H+WOOD_THICK+CHAMBER_H+WOOD_THICK+NINEG_ASM_TOTAL_H-NINEG_LOWER_H+NINEG_BRACK_TOP_THICK+NINEG_BRACK_HOLE_DY));

oo.push(m3_hole(BOX_W-(NINEG_ARM_LEN-NINEG_AXIS_RX-NINEG_BRACK_SIDE_THICK-NINEG_BRACK_HOLE_DX), BOX_H-(CHAMBER_H+WOOD_THICK+NINEG_ASM_TOTAL_H-NINEG_LOWER_H+NINEG_BRACK_TOP_THICK+NINEG_BRACK_HOLE_DY)));

oo.push(m3_hole(BOX_W-(NINEG_ARM_LEN-NINEG_AXIS_RX+NINEG_W+NINEG_BRACK_SIDE_THICK+NINEG_BRACK_HOLE_DX), BOX_H-(CHAMBER_H+WOOD_THICK+NINEG_ASM_TOTAL_H-NINEG_LOWER_H+NINEG_BRACK_TOP_THICK+NINEG_BRACK_HOLE_DY)));

oo.push(m3_hole(BOX_W-(NINEG_ARM_LEN-NINEG_AXIS_RX-NINEG_BRACK_SIDE_THICK-NINEG_BRACK_HOLE_DX), BOX_H-(CHAMBER_H+WOOD_THICK+MEZZ_H+WOOD_THICK+CHAMBER_H+WOOD_THICK+NINEG_ASM_TOTAL_H-NINEG_LOWER_H+NINEG_BRACK_TOP_THICK+NINEG_BRACK_HOLE_DY)));

oo.push(m3_hole(BOX_W-(NINEG_ARM_LEN-NINEG_AXIS_RX+NINEG_W+NINEG_BRACK_SIDE_THICK+NINEG_BRACK_HOLE_DX), BOX_H-(CHAMBER_H+WOOD_THICK+MEZZ_H+WOOD_THICK+CHAMBER_H+WOOD_THICK+NINEG_ASM_TOTAL_H-NINEG_LOWER_H+NINEG_BRACK_TOP_THICK+NINEG_BRACK_HOLE_DY)));

oo.push(m3_hole(CHAMBER_LW-NINEG_ARM2_THICK/2+NINEG_ASM_TOTAL_H-NINEG_LOWER_H+NINEG_BRACK_TOP_THICK+NINEG_BRACK_HOLE_DY, CHAMBER_H+WOOD_THICK+NINEG_BRACK_W-NINEG_BRACK_SIDE_THICK-NINEG_BRACK_HOLE_DX));

oo.push(m3_hole(CHAMBER_LW-NINEG_ARM2_THICK/2+NINEG_ASM_TOTAL_H-NINEG_LOWER_H+NINEG_BRACK_TOP_THICK+NINEG_BRACK_HOLE_DY, CHAMBER_H+WOOD_THICK+NINEG_BRACK_W+NINEG_W+NINEG_BRACK_SIDE_THICK+NINEG_BRACK_HOLE_DX));

oo.push(m3_hole(CHAMBER_LW-NINEG_ARM2_THICK/2+NINEG_ASM_TOTAL_H-NINEG_LOWER_H+NINEG_BRACK_TOP_THICK+NINEG_BRACK_HOLE_DY, CHAMBER_H+WOOD_THICK+MEZZ_H+WOOD_THICK+CHAMBER_H+WOOD_THICK+NINEG_BRACK_W-NINEG_BRACK_SIDE_THICK-NINEG_BRACK_HOLE_DX));

oo.push(m3_hole(CHAMBER_LW-NINEG_ARM2_THICK/2+NINEG_ASM_TOTAL_H-NINEG_LOWER_H+NINEG_BRACK_TOP_THICK+NINEG_BRACK_HOLE_DY, CHAMBER_H+WOOD_THICK+MEZZ_H+WOOD_THICK+CHAMBER_H+WOOD_THICK+NINEG_BRACK_W+NINEG_W+NINEG_BRACK_SIDE_THICK+NINEG_BRACK_HOLE_DX));

oo.push(m3_hole(BOX_W/2-BEARING_GEAR_HOLE_DX,BOX_H/2-BEARING_GEAR_HOLE_DY));

oo.push(m3_hole(BOX_W/2+BEARING_GEAR_HOLE_DX,BOX_H/2-BEARING_GEAR_HOLE_DY));

oo.push(m3_hole(BOX_W/2-BEARING_GEAR_HOLE_DX,BOX_H/2+BEARING_GEAR_HOLE_DY));

oo.push(m3_hole(BOX_W/2+BEARING_GEAR_HOLE_DX,BOX_H/2+BEARING_GEAR_HOLE_DY));

export_outline("part_box_back.svg",oo);

let part0 = extrude(oo, WOOD_THICK);

export_model("part_box_back.stl",part0);

}

function mezz_top(){

let o = [];

o.push(...finger_edge(BOX_W,BOX_X_FINGER_CNT));

o.shift();

o.pop();

// o.splice(o.length/2,0,

// [BOX_W/2-NINEG_ARM2_THICK/2,0],[BOX_W/2-NINEG_ARM2_THICK/2,0],

// );

// o.push(...trsl_poly([rot_path_2d(finger_edge(BOX_D,BOX_Z_FINGER_CNT),PI/2)],BOX_W,0)[0]);

// o.push(...trsl_poly([rot_path_2d(finger_edge(BOX_D,BOX_Z_FINGER_CNT),PI/2+PI)],0,BOX_D)[0]);

// o.pop();

o.push([BOX_W-BALL_D,0],[BOX_W-BALL_D,BALL_D],[BOX_W,BALL_D])

o.push([BOX_W,BOX_D-MEZZ_SIDE_SLOT_W],[BOX_W+WOOD_THICK,BOX_D-MEZZ_SIDE_SLOT_W],[BOX_W+WOOD_THICK,BOX_D]);

o.push(...trsl_poly([rot_path_2d(finger_edge(BOX_W,BOX_X_FINGER_CNT),PI)],BOX_W,BOX_D)[0]);

// o.push([0,BOX_D]);

o.push([-WOOD_THICK,BOX_D],[-WOOD_THICK,BOX_D-MEZZ_SIDE_SLOT_W],[0,BOX_D-MEZZ_SIDE_SLOT_W]);

o.push([0,BALL_D],[BALL_D,BALL_D],[BALL_D,0]);

let oo = [o];

oo.push([

[BOX_W/2+NINEG_ARM2_THICK/2,BOX_D-1.5],

[BOX_W/2+NINEG_ARM2_THICK/2,1.5],

[BOX_W/2-NINEG_ARM2_THICK/2,1.5],

[BOX_W/2-NINEG_ARM2_THICK/2,BOX_D-1.5],

]);

export_outline("part_mezz_top.svg",oo);

let part0 = extrude(oo, WOOD_THICK);

export_model("part_mezz_top.stl",part0);

}

function mezz_bottom(){

let o = [];

o.push(...finger_edge(BOX_W,BOX_X_FINGER_CNT));

o.shift();

o.pop();

o.push([BOX_W-BALL_D,0],[BOX_W-BALL_D,BALL_D],[BOX_W,BALL_D]);

o.push([BOX_W,BOX_D-MEZZ_SIDE_SLOT_W],[BOX_W+WOOD_THICK,BOX_D-MEZZ_SIDE_SLOT_W],[BOX_W+WOOD_THICK,BOX_D]);

o.push(...trsl_poly([rot_path_2d(finger_edge(BOX_W,BOX_X_FINGER_CNT),PI)],BOX_W,BOX_D)[0]);

// o.push([0,BOX_D]);

o.push([-WOOD_THICK,BOX_D],[-WOOD_THICK,BOX_D-MEZZ_SIDE_SLOT_W],[0,BOX_D-MEZZ_SIDE_SLOT_W]);

o.push([0,BALL_D],[BALL_D,BALL_D],[BALL_D,0]);

let oo = [o];

export_outline("part_mezz_bottom.svg",oo);

let part0 = extrude(oo, WOOD_THICK);

export_model("part_mezz_bottom.stl",part0);

}

function mezz_front(){

let o = [];

o.push(...finger_edge(BOX_W,BOX_X_FINGER_CNT,true));

o.push(...trsl_poly([rot_path_2d(finger_edge(BOX_W,BOX_X_FINGER_CNT,true),PI)],BOX_W,MEZZ_H)[0]);

let oo = [o];

// fs.writeFileSync('pat.png',pat.toBuffer('image/png'));

let pat0 = pattern3((BOX_W-8)*5,(MEZZ_H-8)*5,[[1,1,1],[0,0,1],[0,1,0],[1,0,0]]);

let contours0 = trace(pat0.getContext('2d'),1).map(xys=>xys.map(xy=>[xy[0]/5+4,xy[1]/5+4]));

contours0 = contours0.map(xys=>poly_area(xys)>0?xys:xys.reverse())

let pat1 = pattern3((BOX_W-8)*5,(MEZZ_H-8)*5,[[0,0,0],[1,1,0],[1,0,1],[0,1,1]]);

let contours1 = trace(pat1.getContext('2d'),1).map(xys=>xys.map(xy=>[xy[0]/5+4,xy[1]/5+4]));

contours1 = contours1.map(xys=>poly_area(xys)>0?xys:xys.reverse())

// oo.push(...contours);

export_outline("part_mezz_front_a.svg",oo.concat(contours0));

export_outline("part_mezz_front_b.svg",oo.concat(contours1));

// let part0 = extrude(oo, WOOD_THICK);

// export_model("part_mezz_front.stl",part0);

}

function box_top(){

let d = BOX_D + WOOD_THICK+WOOD_THICK;

let o = [];

o.push(...finger_edge(BOX_W,BOX_X_FINGER_CNT,true));

o.push(...trsl_poly([rot_path_2d(finger_edge(d,BOX_Z_FINGER_CNT),PI/2)],BOX_W,0)[0]);

o.push(...trsl_poly([rot_path_2d(finger_edge(d,BOX_Z_FINGER_CNT),PI/2+PI)],0,d)[0]);

let oo = [o];

export_outline("part_box_top.svg",oo);

let part0 = extrude(oo, WOOD_THICK);

export_model("part_box_top.stl",part0);

}

function box_left(){

let d = BOX_D + WOOD_THICK + WOOD_THICK;

let o = [[-WOOD_THICK,-WOOD_THICK]];

o.push(...finger_edge(BOX_H,BOX_Y_FINGER_CNT,true));

o.push([BOX_H+WOOD_THICK,-WOOD_THICK])

o.push(...trsl_poly([rot_path_2d(finger_edge(d,BOX_Z_FINGER_CNT,true),PI/2)],BOX_H,0)[0]);

let ys = [

CHAMBER_H,

// CHAMBER_H+WOOD_THICK+LED_DY,

CHAMBER_H+WOOD_THICK+MEZZ_H-WOOD_THICK,

CHAMBER_H+WOOD_THICK+MEZZ_H+WOOD_THICK+CHAMBER_H,

// CHAMBER_H+WOOD_THICK+MEZZ_H+WOOD_THICK+CHAMBER_H+WOOD_THICK+LED_DY,

CHAMBER_H+WOOD_THICK+MEZZ_H+WOOD_THICK+CHAMBER_H+WOOD_THICK+MEZZ_H-WOOD_THICK,

]

let whs = [

[MEZZ_SIDE_SLOT_W+WOOD_THICK*2,WOOD_THICK],

// [LED_W,LED_H],

[MEZZ_SIDE_SLOT_W+WOOD_THICK*2,WOOD_THICK*2],

[MEZZ_SIDE_SLOT_W+WOOD_THICK*2,WOOD_THICK],

// [LED_W,LED_H],

[MEZZ_SIDE_SLOT_W+WOOD_THICK*2,WOOD_THICK*2],

]

let ss = [];

for (let i = 0; i < ys.length; i++){

let [w,h] = whs[i];

ss.push(

[ys[i],d],

[ys[i],d-w],

[ys[i]+h,d-w],

[ys[i]+h,d],

);

}

o.push(...ss.reverse());

o.push(...trsl_poly([rot_path_2d(finger_edge(d,BOX_Z_FINGER_CNT,true),PI/2+PI)],0,d)[0]);

let oo = [o];

let ly = LED_R+0.5;

oo.push(hole(CHAMBER_H+WOOD_THICK+LED_DY,ly,LED_R));

oo.push(hole(CHAMBER_H+WOOD_THICK+MEZZ_H+WOOD_THICK+CHAMBER_H+WOOD_THICK+LED_DY,ly,LED_R));

let sy = (LED_BRACK_W+(LED_BRACK_W-LED_W))/2+ly+LED_BRACK_PL_HOLE_DX

oo.push(m3_hole(CHAMBER_H+WOOD_THICK+SENSOR_HOLE_DY,sy));

oo.push(m3_hole(CHAMBER_H+WOOD_THICK+MEZZ_H+WOOD_THICK+CHAMBER_H+WOOD_THICK+SENSOR_HOLE_DY,sy));

// oo.push(m3_hole(PANEL_BRACK_DX,PANEL_BRACK_DX));

export_outline("part_box_left.svg",oo);

let part0 = extrude(oo, WOOD_THICK);

export_model("part_box_left.stl",part0);

}

function box_right(){

let d = BOX_D + WOOD_THICK + WOOD_THICK;

let o = [[-WOOD_THICK,-WOOD_THICK]];

o.push(...finger_edge(BOX_H,BOX_Y_FINGER_CNT,true));

o.push([BOX_H+WOOD_THICK,-WOOD_THICK])

o.push(...trsl_poly([rot_path_2d(finger_edge(d,BOX_Z_FINGER_CNT,true),PI/2)],BOX_H,0)[0]);

let ys = [

CHAMBER_H,

// CHAMBER_H+WOOD_THICK+LED_DY,

CHAMBER_H+WOOD_THICK+MEZZ_H,

CHAMBER_H+WOOD_THICK+MEZZ_H+WOOD_THICK+CHAMBER_H,

// CHAMBER_H+WOOD_THICK+MEZZ_H+WOOD_THICK+CHAMBER_H+WOOD_THICK+LED_DY,

// CHAMBER_H+WOOD_THICK+MEZZ_H+WOOD_THICK+CHAMBER_H+WOOD_THICK+MEZZ_H,

BOX_H-PCB2_W,

]

let whs = [

[MEZZ_SIDE_SLOT_W+WOOD_THICK*2,WOOD_THICK],

// [LED_W,LED_H],

[MEZZ_SIDE_SLOT_W+WOOD_THICK*2,WOOD_THICK],

[MEZZ_SIDE_SLOT_W+WOOD_THICK*2,WOOD_THICK],

// [LED_W,LED_H],

// [MEZZ_SIDE_SLOT_W,WOOD_THICK],

[-PCB2_H+d,PCB2_W]

]

let ss = [];

for (let i = 0; i < ys.length; i++){

let [w,h] = whs[i];

ss.push(

[ys[i],d],

[ys[i],d-w],

[ys[i]+h,d-w],

[ys[i]+h,d],

);

}

o.push(...ss.reverse());

o.push(...trsl_poly([rot_path_2d(finger_edge(d,BOX_Z_FINGER_CNT,true),PI/2+PI)],0,d)[0]);

let oo = [o];

oo.push(m3_hole(BOX_H-PCB2_HOLE_DY,PCB2_HOLE_DX));

oo.push(m3_hole(BOX_H-PCB2_W+PCB2_HOLE_DY,PCB2_HOLE_DX));

oo.push(rect_xywh(CHAMBER_H+WOOD_THICK+10,BOX_D-5,MEZZ_H-20,5));

oo.push(rect_xywh(CHAMBER_H+WOOD_THICK+MEZZ_H+WOOD_THICK+CHAMBER_H+WOOD_THICK+3,BOX_D-8,8,8));

let y = CHAMBER_H+WOOD_THICK+MEZZ_H+WOOD_THICK+CHAMBER_H+WOOD_THICK+MEZZ_H;

let wh = [MEZZ_SIDE_SLOT_W,WOOD_THICK];

oo.push([

[y,BOX_D],

[y,BOX_D-wh[0]],

[y+wh[1],BOX_D-wh[0]],

[y+wh[1],BOX_D],

]);

export_outline("part_box_right.svg",oo);

let part0 = extrude(oo, WOOD_THICK);

export_model("part_box_right.stl",part0);

}

function base_front(){

let o = [];

o.push(...finger_edge(BASE_W,BASE_X_FINGER_CNT));

o.push(...trsl_poly([rot_path_2d(finger_edge(BASE_H,BASE_Y_FINGER_CNT),PI/2)],BASE_W,0)[0]);

o.push(...trsl_poly([rot_path_2d(finger_edge(BASE_W,BASE_X_FINGER_CNT),PI)],BASE_W,BASE_H)[0]);

o.push(...trsl_poly([rot_path_2d(finger_edge(BASE_H,BASE_Y_FINGER_CNT),PI/2+PI)],0,BASE_H)[0]);

let oo = [o];

// oo.push([

// [BOX_W/2-20,BOX_H/2-20],[BOX_W,BOX_H/2-20],

// [BOX_W,BOX_H/2+20],[BOX_W/2-20,BOX_H/2+20]

// ]);

oo.push(m3_hole(BASE_W/2-BEARING_BRACK_HOLE_DX,BASE_H/2-BEARING_BRACK_HOLE_DY));

oo.push(m3_hole(BASE_W/2+BEARING_BRACK_HOLE_DX,BASE_H/2-BEARING_BRACK_HOLE_DY));

oo.push(m3_hole(BASE_W/2-BEARING_BRACK_HOLE_DX,BASE_H/2+BEARING_BRACK_HOLE_DY));

oo.push(m3_hole(BASE_W/2+BEARING_BRACK_HOLE_DX,BASE_H/2+BEARING_BRACK_HOLE_DY));

oo.push(m3_hole(10,10));

oo.push(m3_hole(BASE_W-10,10));

oo.push(m3_hole(BASE_W-10,BASE_H-10));

oo.push(m3_hole(10,BASE_H-10));

oo.push(...trsl_poly([[

[-MG995_W_GAP,0],[MG995_W+MG995_W_GAP,0],[MG995_W+MG995_W_GAP,MG995_D],[-MG995_W_GAP,MG995_D]

],

hole(-MG995_HOLE_DX,MG995_HOLE_DY,MG995_HOLE_R),

hole(-MG995_HOLE_DX,MG995_D-MG995_HOLE_DY,MG995_HOLE_R),

hole(MG995_W+MG995_HOLE_DX,MG995_HOLE_DY,MG995_HOLE_R),

hole(MG995_W+MG995_HOLE_DX,MG995_D-MG995_HOLE_DY,MG995_HOLE_R),

],BASE_W/2+BEARING_GEAR_R+MG995_GEAR_R-MG995_AXIS_LX,BASE_H/2-MG995_D/2));

export_outline("part_base_front.svg",oo);

let part0 = extrude(oo, WOOD_THICK);

export_model("part_base_front.stl",part0);

}

// function base_front_test_mount(){

// let o = [

// [BOX_W/2-30,BOX_H/2-20],[BOX_W,BOX_H/2-20],

// [BOX_W,BOX_H/2+20],[BOX_W/2-30,BOX_H/2+20]

// ];

// let oo = [o];

// oo.push(m3_hole(BOX_W/2-BEARING_BRACK_HOLE_DY,BOX_H/2-BEARING_BRACK_HOLE_DX));

// oo.push(m3_hole(BOX_W/2+BEARING_BRACK_HOLE_DY,BOX_H/2-BEARING_BRACK_HOLE_DX));

// oo.push(m3_hole(BOX_W/2-BEARING_BRACK_HOLE_DY,BOX_H/2+BEARING_BRACK_HOLE_DX));

// oo.push(m3_hole(BOX_W/2+BEARING_BRACK_HOLE_DY,BOX_H/2+BEARING_BRACK_HOLE_DX));

// oo.push(...trsl_poly([[

// [-MG995_W_GAP,0],[MG995_W+MG995_W_GAP,0],[MG995_W+MG995_W_GAP,MG995_D],[-MG995_W_GAP,MG995_D]

// ],

// hole(-MG995_HOLE_DX,MG995_HOLE_DY,MG995_HOLE_R),

// hole(-MG995_HOLE_DX,MG995_D-MG995_HOLE_DY,MG995_HOLE_R),

// hole(MG995_W+MG995_HOLE_DX,MG995_HOLE_DY,MG995_HOLE_R),

// hole(MG995_W+MG995_HOLE_DX,MG995_D-MG995_HOLE_DY,MG995_HOLE_R),

// ],BOX_W/2+BEARING_GEAR_R+MG995_GEAR_R-MG995_AXIS_LX,BOX_H/2-MG995_D/2));

// export_outline("part_base_front_test_mount.svg",oo);

// let part0 = extrude(oo, WOOD_THICK);

// export_model("part_base_front_test_mount.stl",part0);

// }

function base_front2(){

let o = [[0,0],[BASE_W,0],[BASE_W,BASE_H],[0,BASE_H],

[0,BASE_H-BASE2_SLOT_DX],

[BASE2_SLOT_LEN,BASE_H-BASE2_SLOT_DX],

[BASE2_SLOT_LEN,BASE_H-BASE2_SLOT_DX-WOOD_THICK],

[0,BASE_H-BASE2_SLOT_DX-WOOD_THICK],

[0,BASE2_SLOT_DX+WOOD_THICK],

[BASE2_SLOT_LEN,BASE2_SLOT_DX+WOOD_THICK],

[BASE2_SLOT_LEN,BASE2_SLOT_DX],

[0,BASE2_SLOT_DX]

];

// o.push(...finger_edge(BASE_W,BASE_X_FINGER_CNT));

// o.push(...trsl_poly([rot_path_2d(finger_edge(BASE_H,BASE_Y_FINGER_CNT),PI/2)],BASE_W,0)[0]);

// o.push(...trsl_poly([rot_path_2d(finger_edge(BASE_W,BASE_X_FINGER_CNT),PI)],BASE_W,BASE_H)[0]);

// o.push(...trsl_poly([rot_path_2d(finger_edge(BASE_H,BASE_Y_FINGER_CNT),PI/2+PI)],0,BASE_H)[0]);

let oo = [o];

// oo.push([

// [BOX_W/2-20,BOX_H/2-20],[BOX_W,BOX_H/2-20],

// [BOX_W,BOX_H/2+20],[BOX_W/2-20,BOX_H/2+20]

// ]);

oo.push(m3_hole(BASE_W/2-BEARING_BRACK_HOLE_DX,BASE_H/2-BEARING_BRACK_HOLE_DY));

oo.push(m3_hole(BASE_W/2+BEARING_BRACK_HOLE_DX,BASE_H/2-BEARING_BRACK_HOLE_DY));

oo.push(m3_hole(BASE_W/2-BEARING_BRACK_HOLE_DX,BASE_H/2+BEARING_BRACK_HOLE_DY));

oo.push(m3_hole(BASE_W/2+BEARING_BRACK_HOLE_DX,BASE_H/2+BEARING_BRACK_HOLE_DY));

// oo.push(m3_hole(10,10));

// oo.push(m3_hole(BASE_W-10,10));

// oo.push(m3_hole(BASE_W-10,BASE_H-10));

// oo.push(m3_hole(10,BASE_H-10));

let rail = [];

let n = 100;

for (let i = 0; i < n; i++){

let a = PI/3 + (i/(n-1))*(PI);

rail.push([

BASE_W/2+cos(a)*(BASE_RAIL_R+BASE_RAIL_W/2),

BASE_H/2+sin(a)*(BASE_RAIL_R+BASE_RAIL_W/2),

])

}

for (let j = 0; j < n; j++){

let i = n - j-1;

let a = PI/3 + (i/(n-1))*(PI);

rail.push([

BASE_W/2+cos(a)*(BASE_RAIL_R-BASE_RAIL_W/2),

BASE_H/2+sin(a)*(BASE_RAIL_R-BASE_RAIL_W/2),

])

}

oo.push(rail);

oo.push(...trsl_poly([[

[-MG995_W_GAP,0],[MG995_W+MG995_W_GAP,0],[MG995_W+MG995_W_GAP,MG995_D],[-MG995_W_GAP,MG995_D]

],

hole(-MG995_HOLE_DX,MG995_HOLE_DY,MG995_HOLE_R),

hole(-MG995_HOLE_DX,MG995_D-MG995_HOLE_DY,MG995_HOLE_R),

hole(MG995_W+MG995_HOLE_DX,MG995_HOLE_DY,MG995_HOLE_R),

hole(MG995_W+MG995_HOLE_DX,MG995_D-MG995_HOLE_DY,MG995_HOLE_R),

],BASE_W/2+BEARING_GEAR_R+MG995_GEAR_R-MG995_AXIS_LX,BASE_H/2-MG995_D/2));

export_outline("part_base_front2.svg",oo);

let part0 = extrude(oo, WOOD_THICK);

export_model("part_base_front2.stl",part0);

}

function base_left2(){

let a = BASE_DEG*PI/180;

let w = cos(a)*BASE_W;

let h = sin(a)*BASE_W;

let w0 = cos(a)*BASE2_SLOT_LEN;

let h0 = sin(a)*BASE2_SLOT_LEN;

let h1 = WOOD_THICK/cos(a);

let o = [[0,0],[w-w0,h-h0],[w-w0,h-h0-h1],[w-w0-w0,h-h0-h0-h1],[w-w0-w0,h-h0-h0-h1-BASE2_SLOT_DY],[w,h-h1-BASE2_SLOT_DY],[w,h+BASE_ELEV_H],

[BASE_BACK_DX+WOOD_THICK,h+BASE_ELEV_H],

[BASE_BACK_DX+WOOD_THICK,h+BASE_ELEV_H-BASE_BACK_H/2],

[BASE_BACK_DX,h+BASE_ELEV_H-BASE_BACK_H/2],

[BASE_BACK_DX,h+BASE_ELEV_H],

[0,h+BASE_ELEV_H]];

let oo = [o];

export_outline("part_base_left2.svg",oo);

let part0 = extrude(oo, WOOD_THICK);

export_model("part_base_left2.stl",part0);

}

function glass(){

let ys = [

CHAMBER_H,

CHAMBER_H+WOOD_THICK+MEZZ_H,

CHAMBER_H+WOOD_THICK+MEZZ_H+WOOD_THICK+CHAMBER_H,

CHAMBER_H+WOOD_THICK+MEZZ_H+WOOD_THICK+CHAMBER_H+WOOD_THICK+MEZZ_H,

]

let o = [

[0,0],[BOX_W,0],

[BOX_W,ys[0]],[BOX_W+WOOD_THICK,ys[0]],[BOX_W+WOOD_THICK,ys[0]+WOOD_THICK],[BOX_W,ys[0]+WOOD_THICK],

[BOX_W,ys[1]],[BOX_W+WOOD_THICK,ys[1]],[BOX_W+WOOD_THICK,ys[1]+WOOD_THICK],[BOX_W,ys[1]+WOOD_THICK],

[BOX_W,ys[2]],[BOX_W+WOOD_THICK,ys[2]],[BOX_W+WOOD_THICK,ys[2]+WOOD_THICK],[BOX_W,ys[2]+WOOD_THICK],

[BOX_W,BOX_H],

[0,BOX_H],

[0,ys[3]+WOOD_THICK],[-WOOD_THICK,ys[3]+WOOD_THICK],[-WOOD_THICK,ys[3]-WOOD_THICK],[0,ys[3]-WOOD_THICK],

[0,ys[2]+WOOD_THICK],[-WOOD_THICK,ys[2]+WOOD_THICK],[-WOOD_THICK,ys[2]],[0,ys[2]],

[0,ys[1]+WOOD_THICK],[-WOOD_THICK,ys[1]+WOOD_THICK],[-WOOD_THICK,ys[1]-WOOD_THICK],[0,ys[1]-WOOD_THICK],

[0,ys[0]+WOOD_THICK],[-WOOD_THICK,ys[0]+WOOD_THICK],[-WOOD_THICK,ys[0]],[0,ys[0]],

]

let oo = [o];

oo.push(m3_hole(BOX_W/2-OLED_HOLE_DIST/2,BOX_H-OLED_HOLE_DY));

oo.push(m3_hole(BOX_W/2+OLED_HOLE_DIST/2,BOX_H-OLED_HOLE_DY));

export_outline("part_glass.svg",oo);

let part0 = extrude(oo, WOOD_THICK);

export_model("part_glass.stl",part0);

}

function base_back2(){

let o = [

[0,0],

[BASE2_SLOT_DX,0],

[BASE2_SLOT_DX,BASE_BACK_H/2],

[BASE2_SLOT_DX+WOOD_THICK,BASE_BACK_H/2],

[BASE2_SLOT_DX+WOOD_THICK,0],

[BASE_H-BASE2_SLOT_DX-WOOD_THICK,0],

[BASE_H-BASE2_SLOT_DX-WOOD_THICK,BASE_BACK_H/2],

[BASE_H-BASE2_SLOT_DX,BASE_BACK_H/2],

[BASE_H-BASE2_SLOT_DX,0],

[BASE_H,0],

[BASE_H,BASE_BACK_H],

[0,BASE_BACK_H]

];

let oo = [o];

export_outline("part_base_back2.svg",oo);

let part0 = extrude(oo, WOOD_THICK);

export_model("part_base_back2.stl",part0);

}

function subtract_shapes(shapes,cuts){

let bb = get_bbox(shapes.flat());

bb.x -= 2;

bb.y -= 2;

bb.w += 4;

bb.h += 4;

shapes = shapes.map(xys=>xys.map(xy=>[xy[0]-bb.x,xy[1]-bb.y]));

cuts = cuts.map(xys=>xys.map(xy=>[xy[0]-bb.x,xy[1]-bb.y]));

let cnv = createCanvas(bb.w*20,bb.h*20);

let ctx = cnv.getContext('2d');

ctx.fillRect(0,0,cnv.width,cnv.height);

ctx.scale(20,20);

ctx.fillStyle = "white";

for (let i = 0; i < shapes.length; i++){

ctx.beginPath();

for (let j = 0; j < shapes[i].length; j++){

ctx[j?'lineTo':'moveTo'](...shapes[i][j]);

}

ctx.fill();

ctx.fillStyle = "black";

}

ctx.fillStyle = "black";

for (let i = 0; i < cuts.length; i++){

ctx.beginPath();

for (let j = 0; j < cuts[i].length; j++){

ctx[j?'lineTo':'moveTo'](...cuts[i][j]);

}

ctx.fill();

}

// fs.writeFileSync("test.png",cnv.toBuffer('image/png'));

let contours = trace(ctx,1);

return contours.map(xys=>xys.map(xy=>[xy[0]/20+bb.x,xy[1]/20+bb.y]));

}

function pattern1(w,h){

let SCALE = 1;

let cn0 = createCanvas(w*SCALE,h*SCALE);

let ct0 = cn0.getContext('2d');

ct0.scale(SCALE,SCALE);

ct0.fillStyle = 'black';

ct0.fillRect(0,0,w,h);

ct0.translate(-20,-5);

ct0.strokeStyle = 'white';

ct0.lineWidth = 10;

for (let i = 0; i < 10; i++){

for (let j = 0; j < 10; j++){

ct0.save();

if (i % 2) ct0.translate(-60,0);

ct0.beginPath();

ct0.arc(j*120-40,i*60-40,80,0,PI*2);

ct0.fill();

ct0.stroke();

ct0.beginPath();

ct0.arc(j*120-40,i*60-40,60,0,PI*2);

ct0.fill();

ct0.stroke();

ct0.beginPath();

ct0.arc(j*120-40,i*60-40,40,0,PI*2);

ct0.fill();

ct0.stroke();

ct0.beginPath();

ct0.arc(j*120-40,i*60-40,20,0,PI*2);

ct0.fill();

ct0.stroke();

ct0.restore();

}

}

return cn0;

}

function pattern2(w,h){

let cn0 = createCanvas(w,h);

let ct0 = cn0.getContext('2d');

ct0.fillStyle = 'black';

ct0.fillRect(0,0,w,h);

ct0.scale(1.5,1.5);

ct0.strokeStyle = 'white';

let N = 1000;

let N_CAND = 100;

let circs = [];

let dmax = 30;

for (let i = 0; i < N; i++){

let dmin = -Infinity;

let nx, ny;

for (let j = 0; j < N_CAND; j ++){

let x = rand()*w;

let y = rand()*h;

let d = Infinity;

for (let k = 0; k < circs.length; k++){

d = Math.min(d,Math.hypot(circs[k][0] - x,circs[k][1] - y)- circs[k][2]);

}

if (d > dmin){

dmin = d;

nx = x;

ny = y;

}

}

if (dmin < 8){

continue;

}

circs.push([nx,ny,dmin<0?dmax:Math.min(dmin,dmax)]);

}

let nbrs = [];

for (let i = 0; i < circs.length; i++){

let ds = circs.map((x,j)=>[j,dist(circs[i][0],circs[i][1],x[0],x[1])-circs[i][2]-x[2]]);

ds.sort((a,b)=>a[1]-b[1]).shift();

nbrs.push(ds.slice(0,3));

}

// console.log(nbrs);

ct0.fillStyle = 'white';

ct0.lineCap = 'round';

// ct0.filter='blur(3px)';

for (let i = 0; i < circs.length; i++){

// ct0.lineWidth = 1;

// ct0.beginPath();

// ct0.arc(...circs[i],0,PI*2);

// ct0.stroke();

let q = circs[nbrs[i][0][0]];

ct0.lineWidth = 7;

let a0 = Math.atan2(circs[i][1]-q[1],circs[i][0]-q[0])+PI;

ct0.beginPath();

// ct0.moveTo(circs[i][0]+cos(a0)*r0,circs[i][1]+sin(a0)*r0);

for (let j = 0; j < 100; j++){

let t = j/100;

let m = Math.max(1,(circs[i][2]/12));

let a = a0+t*PI*2*m;

let r = (circs[i][2]+6)*(1-t);

let x = circs[i][0] + cos(a)*r;

let y = circs[i][1] + sin(a)*r;

ct0[j?'lineTo':'moveTo'](x,y);

}

ct0.stroke();

}

// let imgdata = ct0.getImageData(0,0,cn0.width,cn0.height)

// for (let i = 0; i < imgdata.data.length; i++){

// imgdata.data[i] = imgdata.data[i] < 128 ? 0 : 255;

// }

// ct0.putImageData(imgdata,0,0);

// console.log('?');

let dat = ct0.getImageData(0,0,cn0.width,cn0.height).data;

let im = [];

for (let i = 0; i < dat.length; i+=4){

im.push(dat[i]>128?255:0);

}

let contours = findContours(im,cn0.width,cn0.height);

// console.log('?');

for (let i = 0; i < contours.length; i++){

contours[i] = approxPolyDP(contours[i].points,1.5);

}

contours = contours.filter(x=>x.length>=3);

// console.log('?');

let cn1 = createCanvas(w,h);

let ct1 = cn1.getContext('2d');

// ct1.filter='blur(4px)';

// ct1.scale(SCALE,SCALE)

ct1.fillStyle = 'white';

ct1.fillRect(0,0,w,h);

ct1.fillStyle = 'black';

ct1.strokeStyle="black";

ct1.lineWidth = 2;

ct1.beginPath();

for (let i = 0; i < contours.length; i++){

for (let j = 0; j < contours[i].length; j++){

ct1[j?'lineTo':'moveTo']((contours[i][j][0]-3)*1.1,(contours[i][j][1]-3)*1.1);

}

}

ct1.stroke();

ct1.fill();

// let imgdata = ct1.getImageData(0,0,cn1.width,cn1.height)

// for (let i = 0; i < imgdata.data.length; i++){

// imgdata.data[i] = imgdata.data[i] < 128 ? 0 : 255;

// }

// ct1.putImageData(imgdata,0,0);

// console.log('?');

return cn1;

}

function pattern4(w,h){

let cnv = createCanvas(w,h);

let ctx = cnv.getContext('2d');

ctx.fillRect(0,0,w,h);

ctx.strokeStyle = "white";

ctx.lineWidth = 3;

ctx.beginPath();

let dd = 6;

for (let i = -h; i < w; i+=40){

ctx.moveTo(i-dd,0);

ctx.lineTo(i+h-dd,h);

ctx.moveTo(i+dd,0);

ctx.lineTo(i+h+dd,h);

}

for (let i = 0; i < w+h; i+=40){

ctx.moveTo(i-dd,0);

ctx.lineTo(i-h-dd,h);

ctx.moveTo(i+dd,0);

ctx.lineTo(i-h+dd,h);

}

ctx.stroke();

ctx.save();

ctx.translate(4,-4);

ctx.fillStyle = "white";

ctx.beginPath();

for (let i = 0; i < h+40; i+=40){

for (let j = 0; j < w; j+=40){

ctx.moveTo(j,i-16);

ctx.lineTo(j+16,i);

ctx.lineTo(j,i+16);

ctx.lineTo(j-16,i);

}

}

ctx.fill();

ctx.restore();

return cnv;

}

function pattern3(w,h,bbs){

let cnv = createCanvas(w,h);

let ctx = cnv.getContext('2d');

function fillcircle(x,y,r,a0=0,a1=PI*2){

ctx.beginPath();

ctx.arc(x,y,r,a0,a1);

ctx.fill();

}

function drawgua(x,y,w,bb){

ctx.save();

ctx.fillStyle="white";

ctx.fillRect(x-w/2,y-w/2,w,w/5);

ctx.fillRect(x-w/2,y-w/2+w/5*2,w,w/5);

ctx.fillRect(x-w/2,y+w/2-w/5,w,w/5);

ctx.fillStyle="black";

if (!bb[0])ctx.fillRect(x-w/8,y-w/2,w/4,w/5);

if (!bb[1])ctx.fillRect(x-w/8,y-w/2+w/5*2,w/4,w/5);

if (!bb[2])ctx.fillRect(x-w/8,y+w/2-w/5,w/4,w/5);

ctx.restore();

}

ctx.fillRect(0,0,w,h);

ctx.strokeStyle = "white";

ctx.lineWidth = 3;

ctx.beginPath();

let dd = 6;

for (let i = -h; i < w; i+=40){

ctx.moveTo(i-dd,0);

ctx.lineTo(i+h-dd,h);

ctx.moveTo(i+dd,0);

ctx.lineTo(i+h+dd,h);

}

for (let i = 0; i < w+h; i+=40){

ctx.moveTo(i-dd,0);

ctx.lineTo(i-h-dd,h);

ctx.moveTo(i+dd,0);

ctx.lineTo(i-h+dd,h);

}

ctx.stroke();

ctx.fillStyle = "white";

ctx.beginPath();

for (let i = 0; i < h; i+=40/Math.sqrt(2)){

for (let j = 0; j < w; j+=40/Math.sqrt(2)){

ctx.moveTo(j,i-10);

ctx.lineTo(j+10,i);

ctx.lineTo(j,i+10);

ctx.lineTo(j-10,i);

}

}

ctx.fill();

fillcircle(w/5,h/2, 35);

fillcircle(w/5*2,h/2,35);

fillcircle(w/5*3,h/2,35);

fillcircle(w/5*4,h/2,35);

ctx.fillStyle = "black";

fillcircle(w/5,h/2,29);

fillcircle(w/5*2,h/2,29);

fillcircle(w/5*3,h/2,29);

fillcircle(w/5*4,h/2,29);

drawgua(w/5, h/2,30,bbs[0]);

drawgua(w/5*2,h/2,30,bbs[1]);

drawgua(w/5*3,h/2,30,bbs[2]);

drawgua(w/5*4,h/2,30,bbs[3]);

return cnv;

}

function poly_area(poly){

var n = poly.length;

var a = 0.0;

for(var p=n-1,q=0; q<n; p=q++) {

a += poly[p][0] * poly[q][1] - poly[q][0] * poly[p][1];

}

return a * 0.5;

}

function isect_circ_line(cx,cy,r,x0,y0,x1,y1){

//https://stackoverflow.com/a/1084899

let dx = x1-x0;

let dy = y1-y0;

let fx = x0-cx;

let fy = y0-cy;

let a = dx*dx+dy*dy;

let b = 2*(fx*dx+fy*dy);

let c = (fx*fx+fy*fy)-r*r;

let discriminant = b*b-4*a*c;

if (discriminant<0){

return null;

}

discriminant = Math.sqrt(discriminant);

let t0 = (-b - discriminant)/(2*a);

if (0 <= t0 && t0 <= 1){

return t0;

}

let t = (-b + discriminant)/(2*a);

if (t > 1 || t < 0){

return null;

}

return t;

}

function resample(polyline,step){

if (polyline.length <= 2){

return polyline.slice();

}

polyline = polyline.slice();

let out = [polyline[0].slice()];

let next = null;

let i = 0;

while(i < polyline.length-1){

let a = polyline[i];

let b = polyline[i+1];

let dx = b[0]-a[0];

let dy = b[1]-a[1];

let d = Math.sqrt(dx*dx+dy*dy);

if (d == 0){

i++;

continue;

}

let n = ~~(d/step);

let rest = (n*step)/d;

let rpx = a[0] * (1-rest) + b[0] * rest;