Parametric design feels very relaxing, since I generally enjoy sketching out skeletons for papers and the like...I spoke too soon. Learning Fusion 360 and the unintuitive ways that I reach constraint errors, it makes me appreciate my roommates (who are all architects).

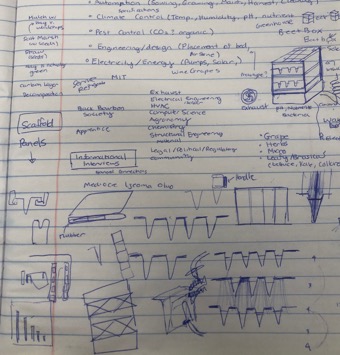

For this week, we were tasked with designing and modeling a potential final project. I enrolled in this course in order to prototype an indoor hydroponic system for community/commercial use. I began sketching out various structural features for the project, which included: a sowing bed, an irrigation system, and compartmentalized growing drawers.

Early sketch of my final project (hover to expand)

I intended for the prototype to eventually scale up to a refrigerator-sized system, but I do not believe my project will be as large.

I had no experience with CAD software, so I had to decide on which program to use. Most of the students in the Harvard section chose Fusion 360, so after unsuccessfully trying to learn FreeCAD, I went to Fusion. I spent several days (and nights) trying to understand Fusion 360 (through YouTube videos and the like). At a certain point, I grew comfortable enough to start.

Parametric modeling fits with a lot of the excel work that I have done. It really is beautiful when you get all the parameters rights and can just push a button (though that did not happen for me). At one point I had around 50 parameters.

The key takeaways from my time spent in Fusion are: 1) copy-and-paste is often too finicky to be used reliably, especially if you need to change dimensions later on; 2) learning the shortcuts (l for line, r for rectangle, d for dimensioning, t for trim) sped up my workflow; 3) when creating parameters to account for material size, I should make sure to clearly understand and visualize the conventions I am working with.

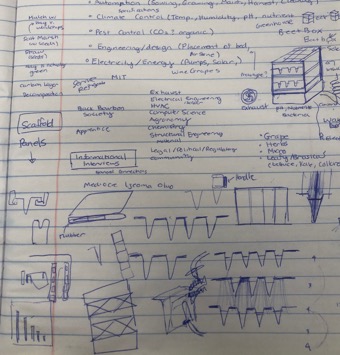

Building the roof of my final project in Fusion.

As for compressing pictures, I wasn’t sure how to use the process outlined in class, so I just found an online converter/compressor.