This week we had to characterize our shop's lasercutter (focus, power, speed, rate, kerf, joint clearance), cut something on the vinylcutter, and then design and lasercut a construction kit.

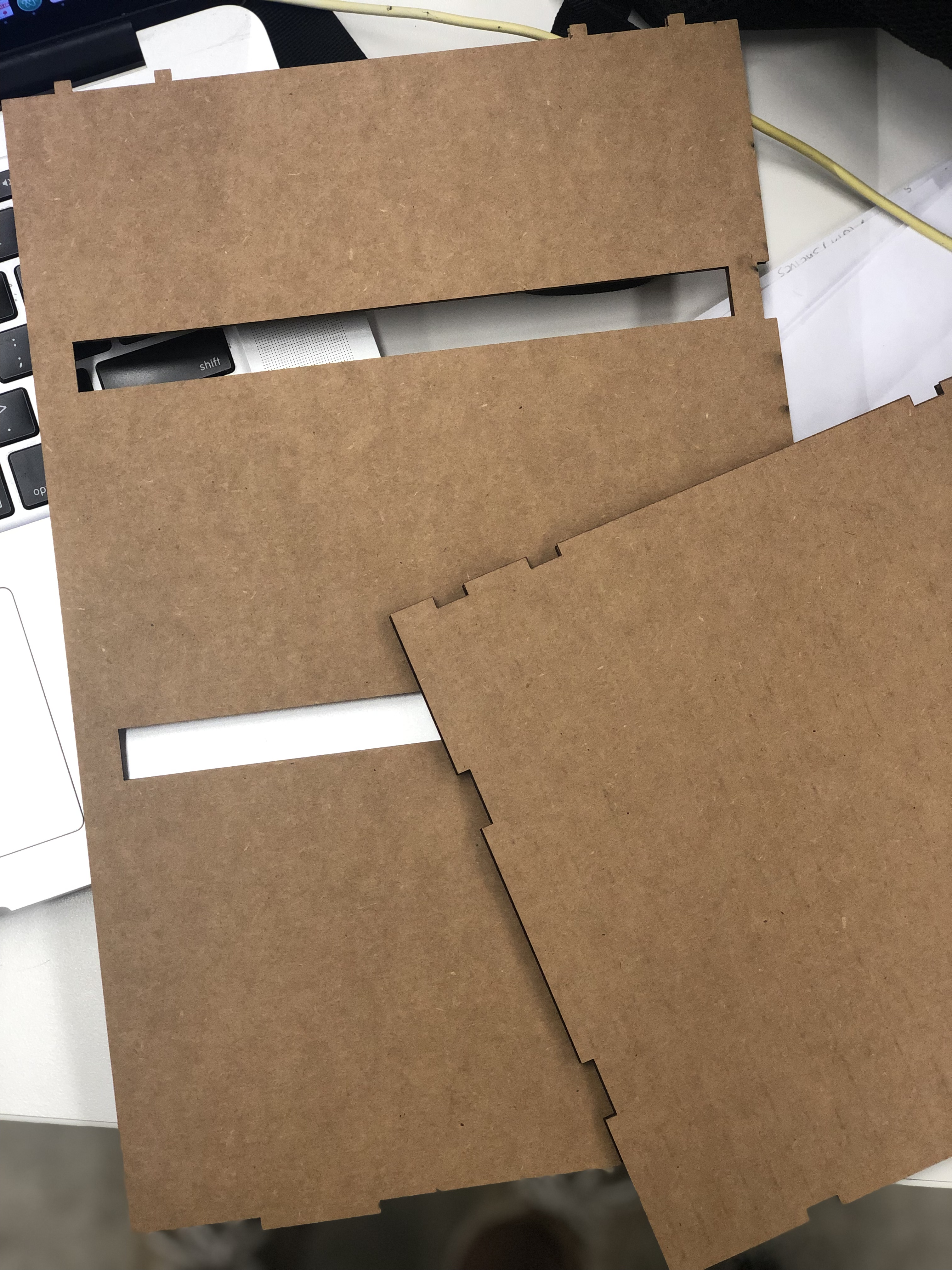

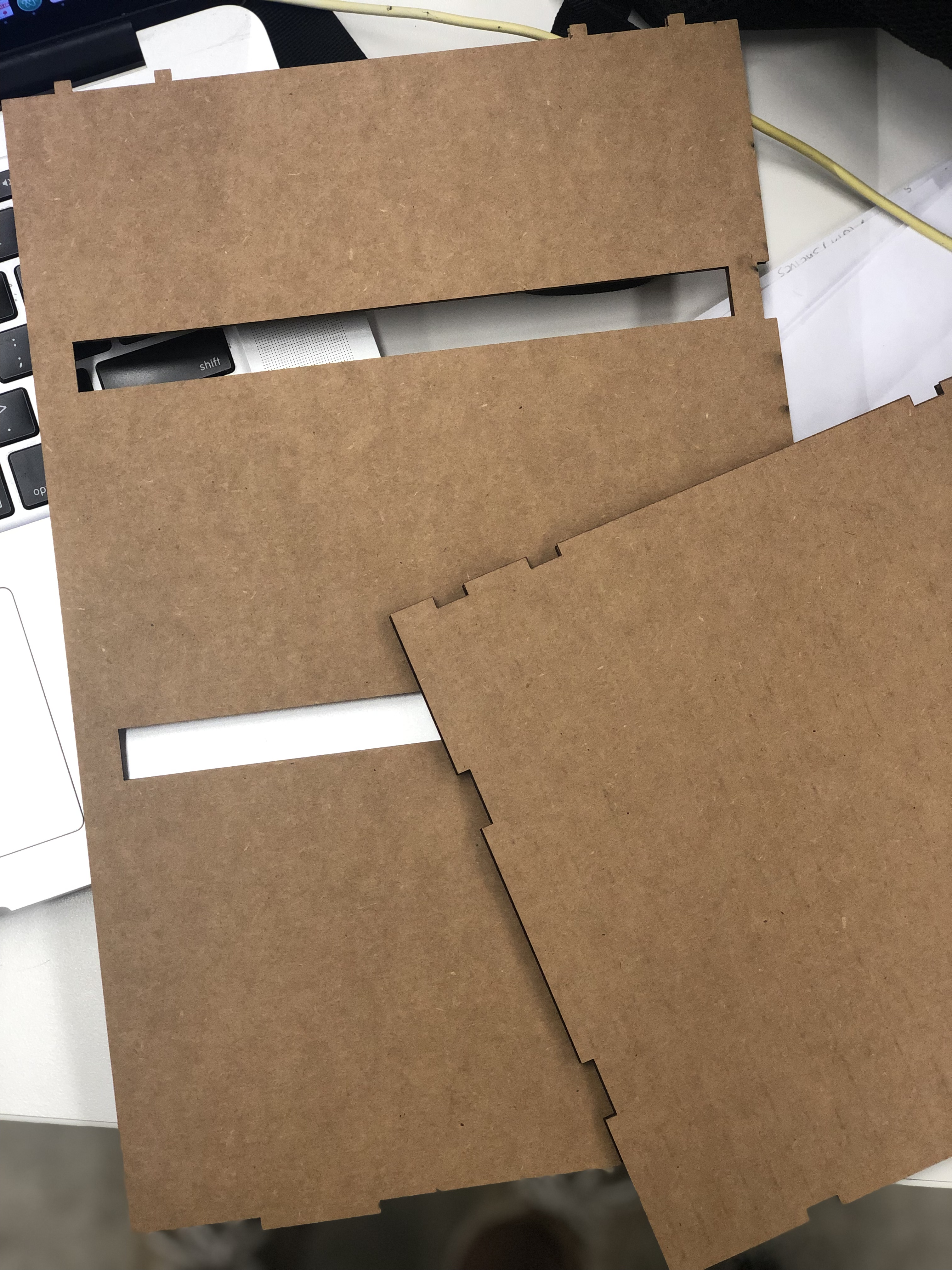

I decided to test out two connecting pieces from the parametric design week (which I included finger joints on). The two pieces I made didn't fit, but I was proud of them. It also helped to correct a prior design decision to try and "map" the pieces onto each other in Fusion. I think it accidentally led to certain shared constraints, because things became weird when I tried resizing shapes for the laser cutter dimensions. The vinyl pieces were created to be "pasted" inside the walls.

My missized pieces from the laser cutter

I thought kerf was a post-production issue, but it was actually something that has to be accounted for in the design and then checked with the cutter. Thankfully, I included a thickness parameter in the design.

Power settings (60 60 30) worked fine for .175 inch (4.5mm) cardboard on the lasercutter. I was confused as to how to chamfer the 2D projection sent to the printer.