What does it do?

It is a tool storage system composed of units that can be arranged with other units easily.

Who's done what beforehand?

Modular tool storage is pretty common but requires a lot of moving around of top units to get to the ones at the bottom. I mean, just take a look at Home Depot! None of them allow you to access all of the drawers in a stack without taking the other ones off! And the ones that do are proprietary, and must be used standalone— they can't be incorporated into a full tool chest and rearranged for convenience!

What sources did you use?

Anywhere on the Internet works— Amazon, Home Depot, Lowes, pretty much any tool supplier I looked at had nothing I wanted. And I asked Reddit and the best they had was talking about if modular toolboxes were a fad!

What did you design?

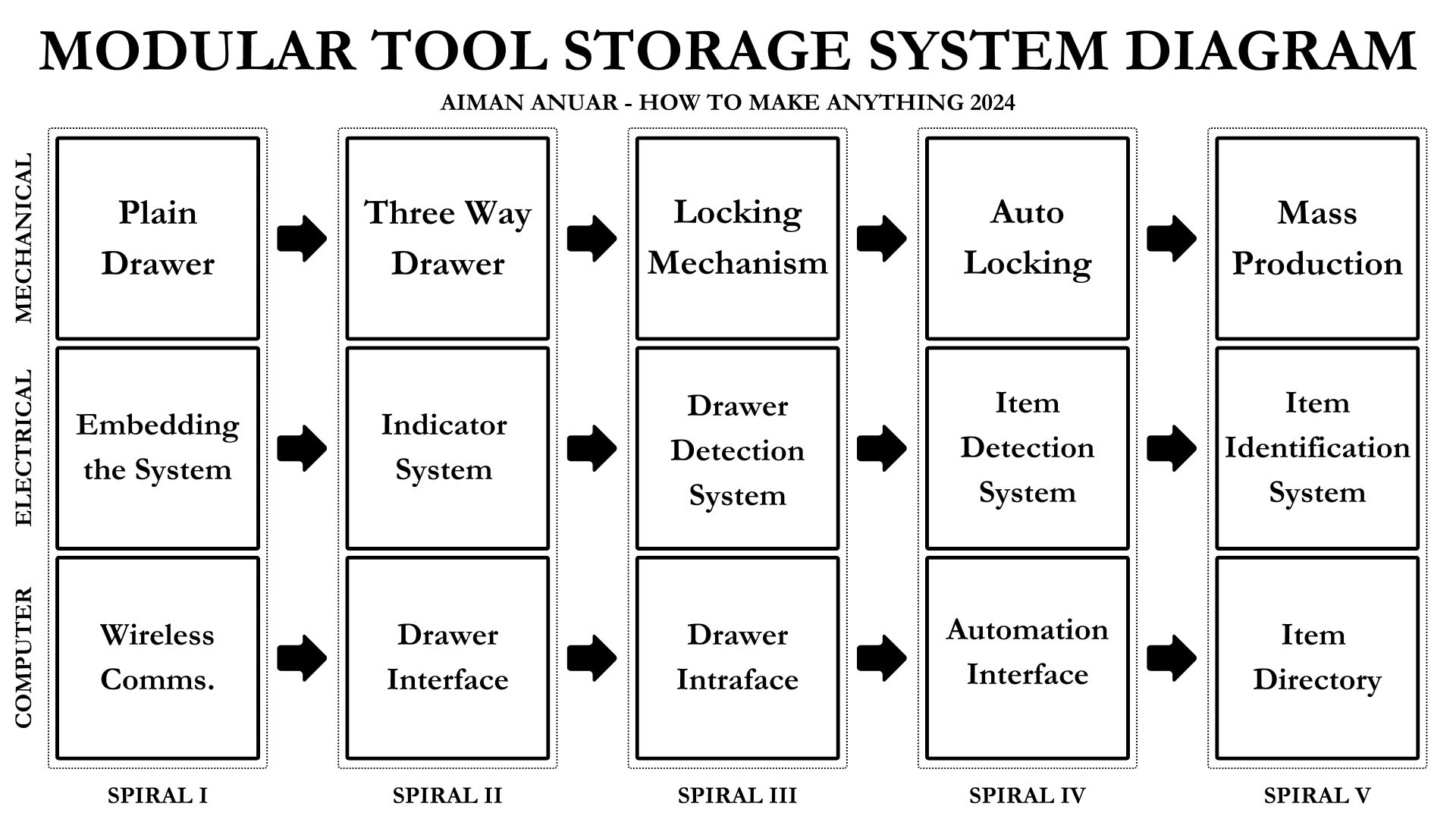

A novel three way drawer for a toolbox unit that could interlock with other units via magnetic sensing and actuation, read what was inside the toolbox, and communicate with an external device to tell what it had.

What materials and components were used?

Per toolbox unit:

1 24"x36" sheet of stock (cardboard or wood)

1 ESP32C3

2 LEDs

3 Motor Drivers

3 Electromagnets

3D printing filament

Ecoflex 50 Silicone

Miscellaneous wiring

Miscellaneous fastening hardware

Miscellaneous hot glue

Where did they come from?

Parts Cabinet

Makerspace Stock

Personal Inventory

How much did they cost?

I did not spend any of my own money as I pulled nearly everything from inventory and components I already had, like the electromagnets.

What parts and systems were made?

Mechanical Three-Way Drawer Unit with laser cut faces, 3D printed handles, and casted mat. (completed)

Electrical Drawer Interfacing and Interlocking System with programmed, designed, and milled PCBs, hall effect sensor inputs, and electromagnet outputs. (halfway completed)

Digital Interfacing System with External Device and Item Identification. (not completed)

What tools and processes were used?

See breakdown below.

What questions were answered?

Is a three-way drawer possible?

Is it possible to create a toolbox that can interface with and be hotswappable with another toolbox to create a modular tool chest?

Is it always better to start your design process early? Yes, yes it is.

What worked? What didn't?

I mostly failed on spiral development and not allocating time in a great way since I was busy nearly the entire semester.

How was it evaluated?

By even my own standards, it was not finished in time so I'm not satisified with that, but I am happy with the fact that it is designed to meet nearly all the components of the class.

What are the implications?

This project can definitely be picked up by a company that wants to mass manufacture modular toolboxes, so I could foresee a startup over this idea. I wonder if some tool enthusiasts would engage in it too. I know I would!

| Week | | | Topic | | | Aspect | | | Details |

|---|---|---|---|---|---|---|

| Week 1 | | | Computer-Aided Design | | | Mechanical | | | I used what I learned in Week 1 to 3D model what I wanted my toolbox to look like. |

| Week 2 | | | Computer-Controlled Cutting | | | Mechanical | | | I used what I learned in Week 2 to fabricate the toolbox out of laser cut sheets. |

| Week 3 | | | Embedded Programming | | | Digital | | | I used what I learned in Week 3 to code the general behavior for my toolbox. |

| Week 4 | | | 3D Scanning and Printing | | | Mechanical | | | I used what I learned in Week 4 to print out handles for the toolbox and the mold for casting. |

| Week 5 | | | Electronics Design | | | Electrical | | | I used what I learned in Week 5 to design the PCB that my toolbox would operate on. |

| Week 6 | | | Electronics Production | | | Electrical | | | I used what I learned in Week 6 to manufacture the PCB that my toolbox used by milling it. |

| Week 7 | | | Molding and Casting | | | Mechanical | | | I used what I learned in Week 7 to manufacture the mat that went inside the toolbox. |

| Week 8 | | | Input Devices | | | Electrical | | | I used what I learned in Week 8 to install and use the hall effect sensors in my toolbox. |

| Week 9 | | | Output Devices | | | Electrical | | | I used what I learned in Week 9 to install and use the electromagnets in my toolbox. |

| Week 10 | | | Computer-Controlled Machining | | | Unused | | | I did not use Week 10 for my project but I could have used it for mass production. |

| Week 11 | | | Mechanical and Machine Design | | | Unused | | | I did not use Week 11 for my project but I could have used it for the mechanical design of the drawers. |

| Week 12 | | | Networking and Communications | | | Digital | | | I used what I learned in Week 12 to allow the ESP32s used by different toolboxes to communicate with each other. |

| Week 13 | | | Interface and Application Programming | | | Digital | | | I used what I learned in Week 13 to allow the ESP32s to communicate with an external device and tell you their current status.. |

| Week 14 | | | Wildcard Week | | | Unused | | | I did not use Week 14 for my project but I could have used embroidery to create a logo for the toolbox. |