Week 06: Computer-Controlled Machining

"Make something big" — designing and machining furniture for my new home

"Make something big" — designing and machining furniture for my new home

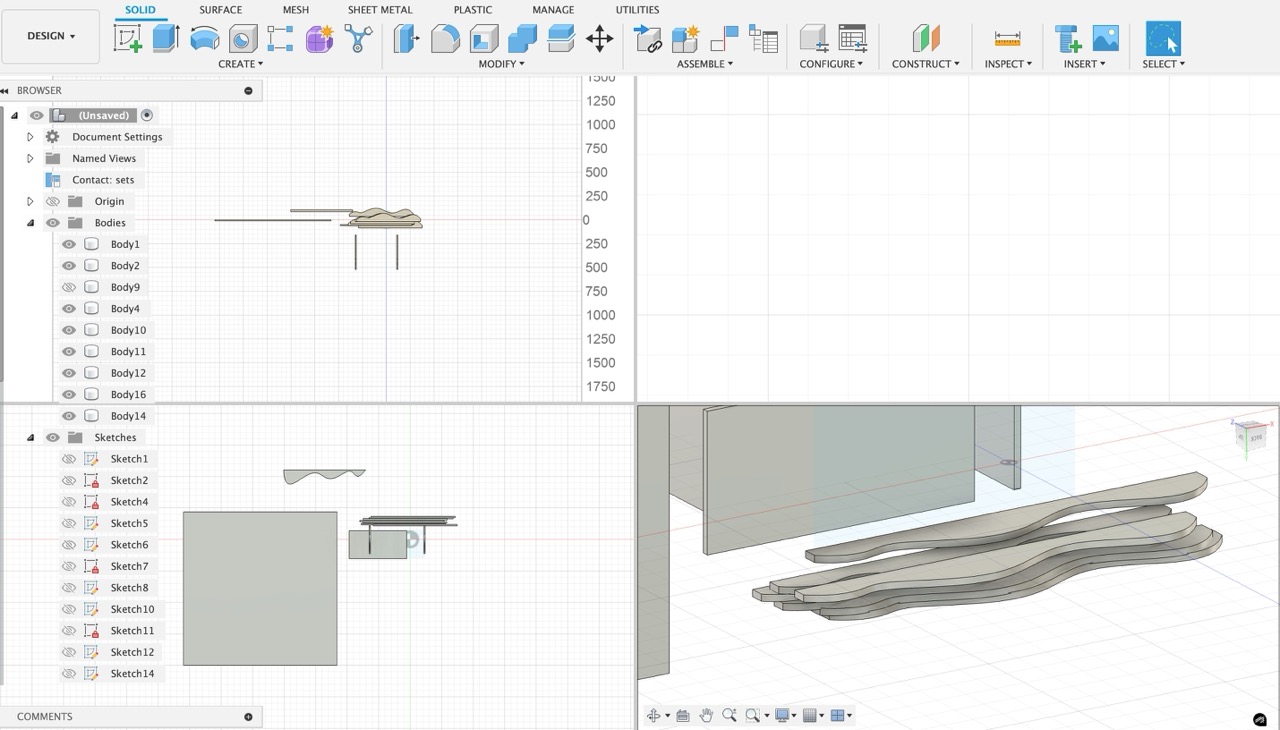

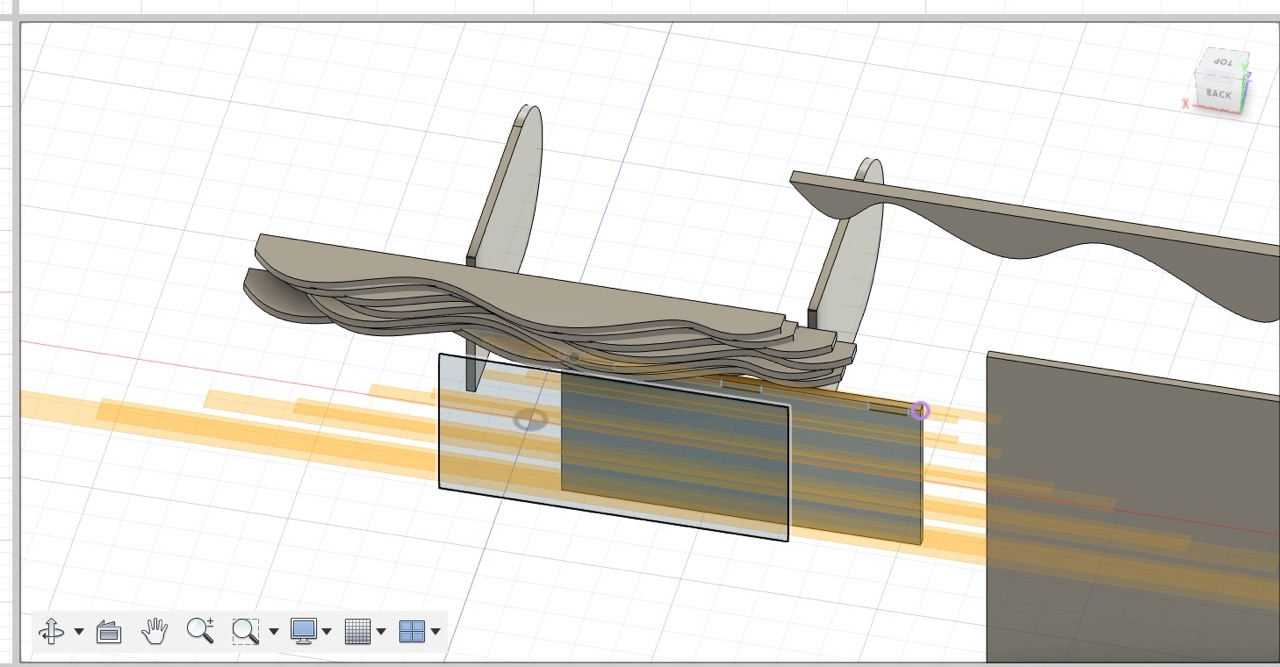

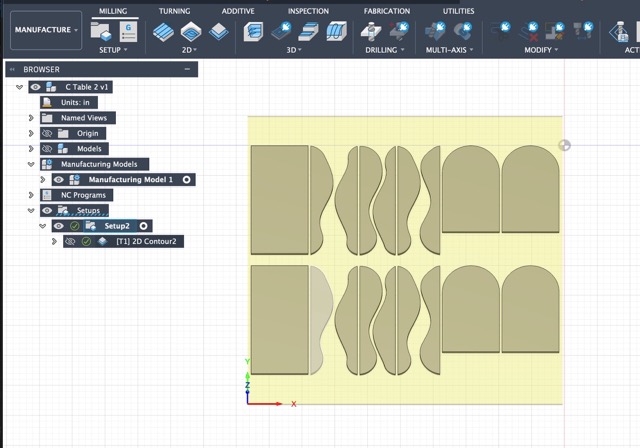

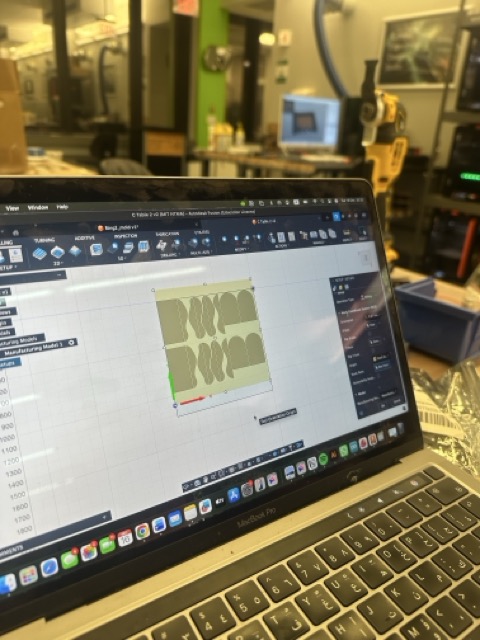

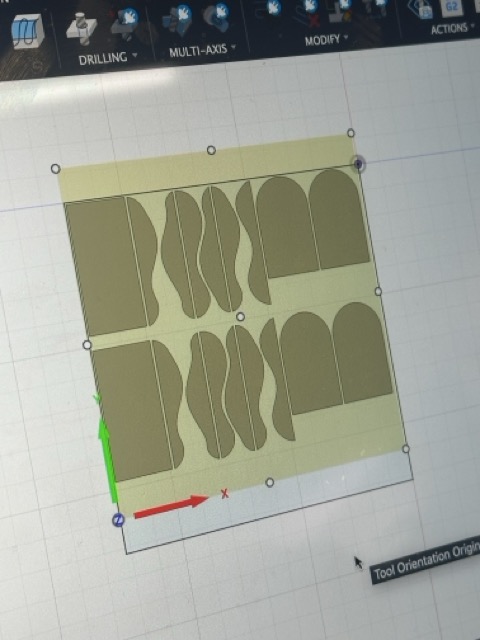

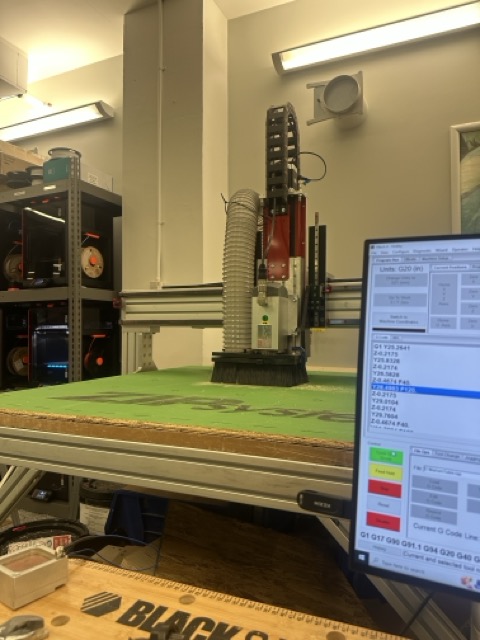

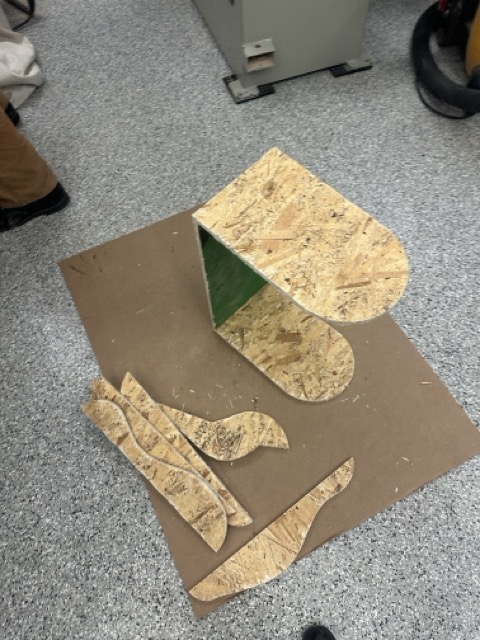

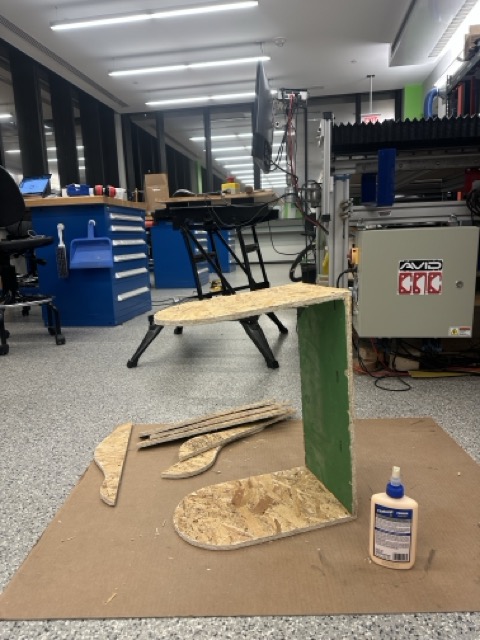

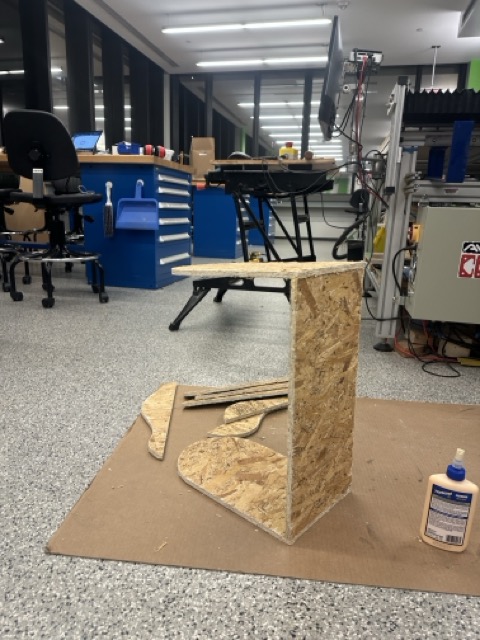

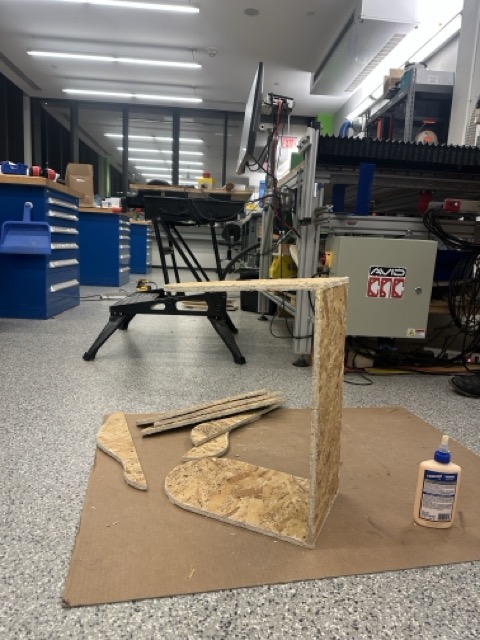

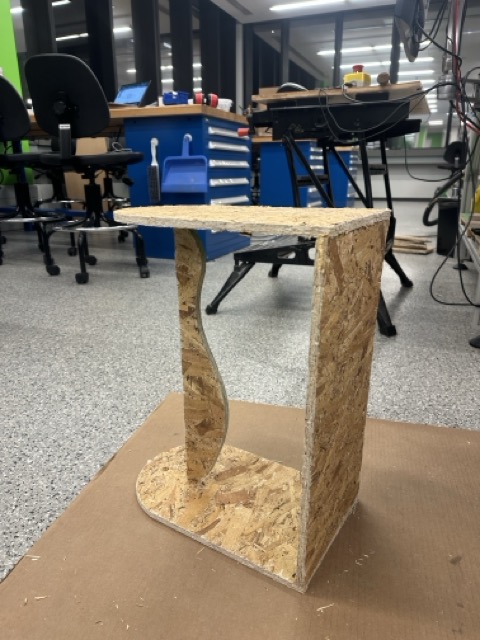

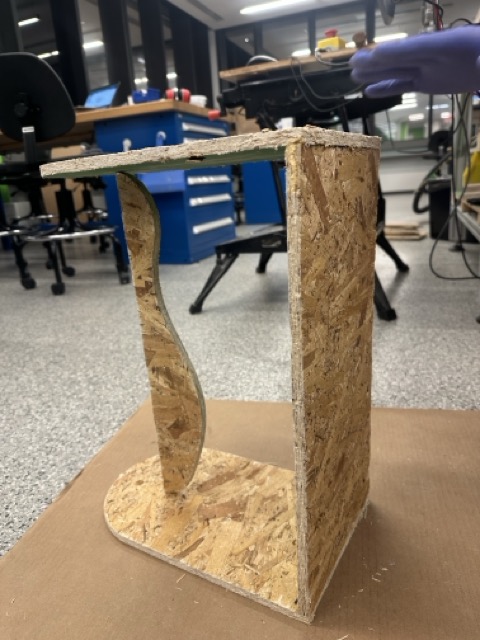

For this week, I used the CNC router to fabricate a C-shaped side table out of OSB as a full-scale prototype.

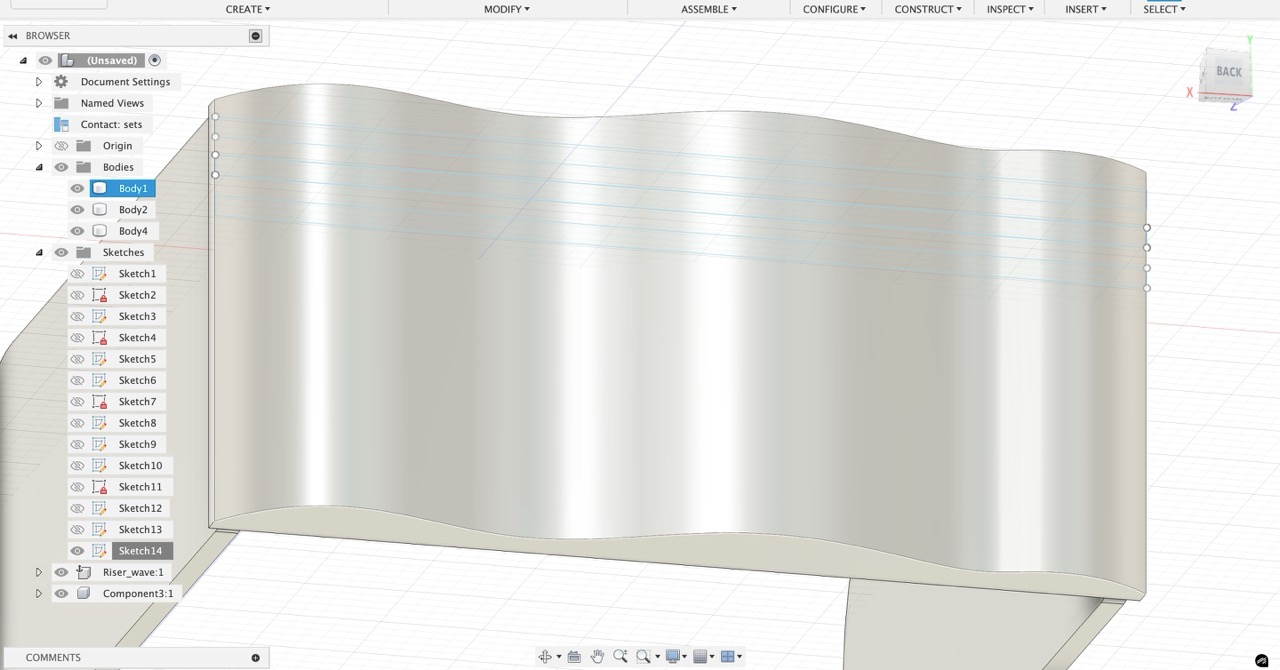

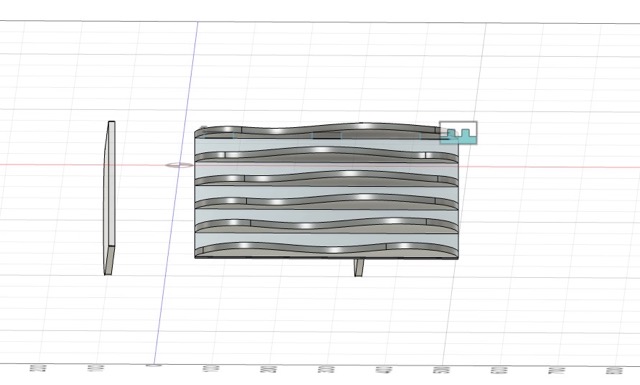

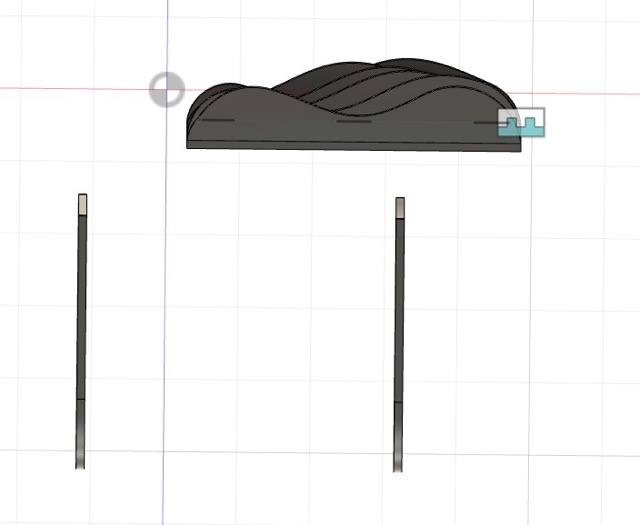

I designed the table as a C-table that can slide partially under a couch, with a soft wave motif running through the profile. The waves were intentional - I wanted the piece to feel light and fluid despite being made from a relatively heavy, rough material like OSB. Before finalizing the dimensions, I measured my couch to make sure the height, depth, and clearance would work in a real domestic setting. This directly informed the final scale of the piece.

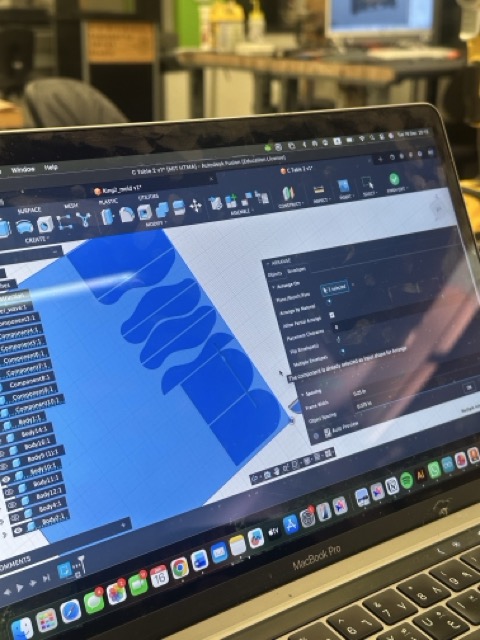

I ended up making two design versions:

This first CNC cut was very much treated as a prototype, not a final object.

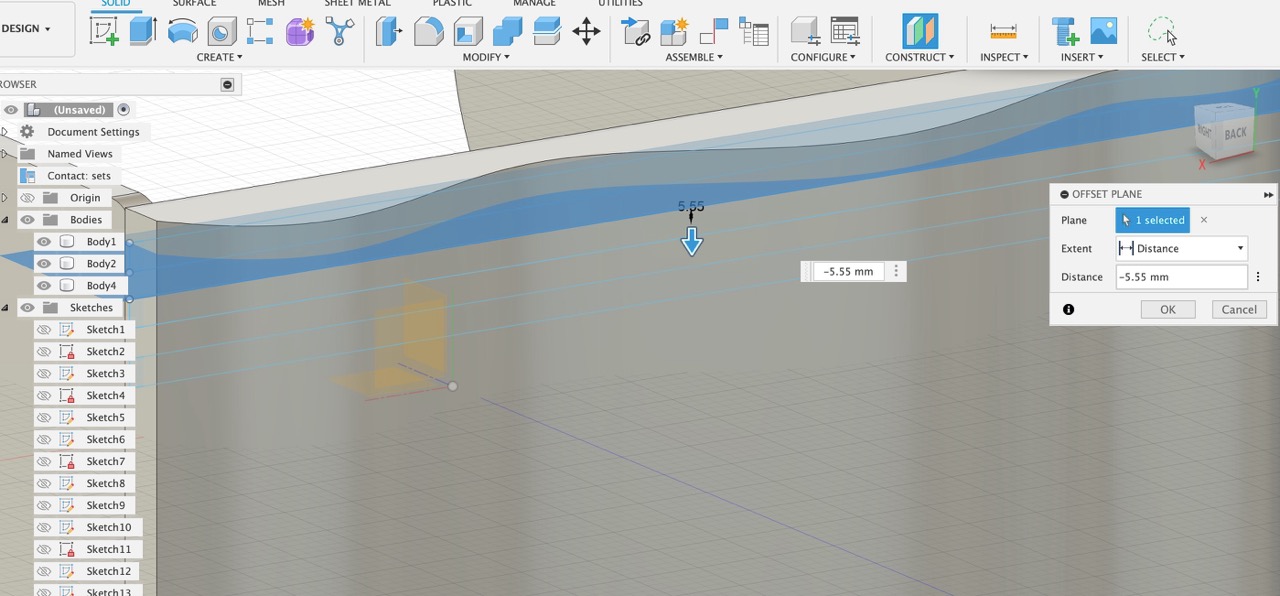

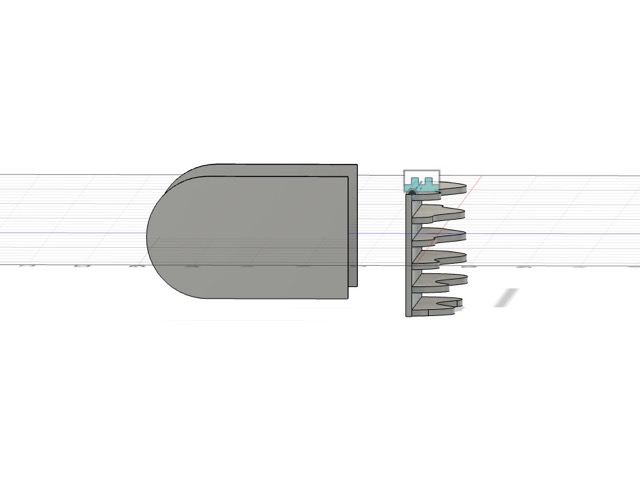

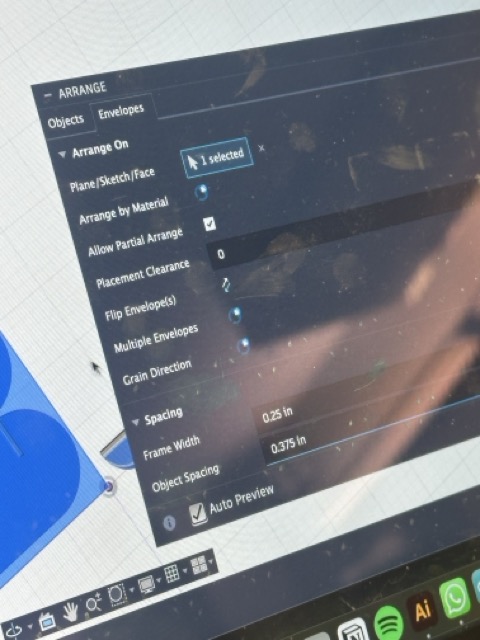

Moving from sketch to 3D model in Fusion 360, considering material constraints, joinery, and CNC machining capabilities.

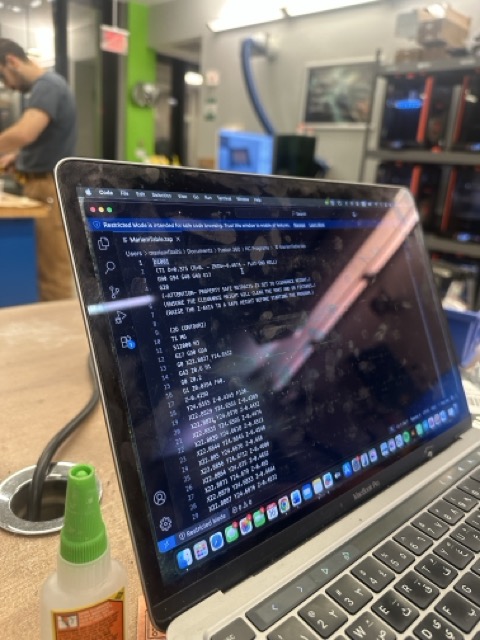

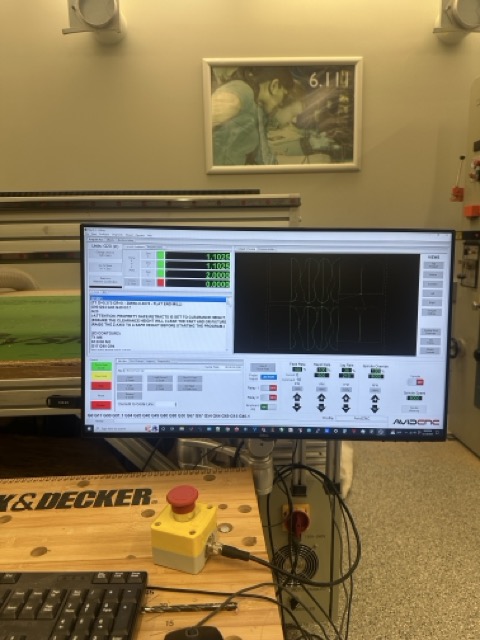

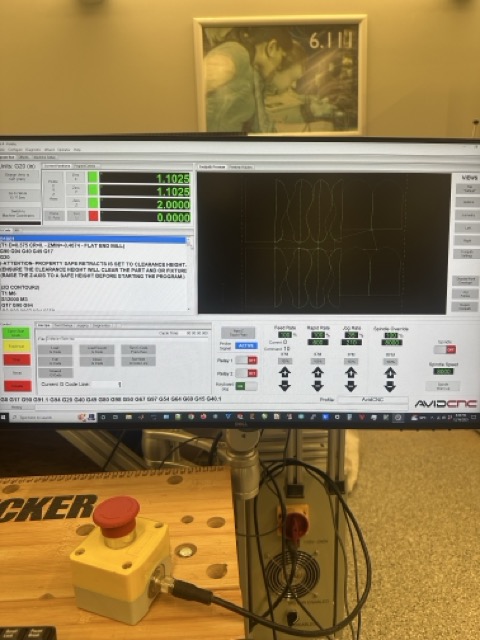

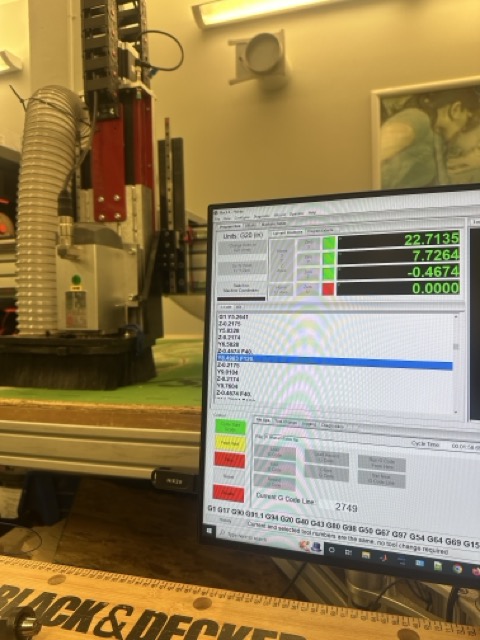

Feed Rate Override: Controls cutting speed while actively machining. Set to ~50% initially for safety. Can be adjusted in real time.

Rapid Rate: Controls how fast the machine moves when not cutting.

Jog Rate: Controls movement speed when jogging the machine using the keyboard.

Spindle Override: Controls spindle speed. Can be adjusted while running if needed.

For this cut, I intentionally did not create tabs in the CAM setup. This was a conscious decision - I didn't want to overcomplicate the process on my first iteration and instead wanted to see how the design behaved when milled at full scale. The goal here was learning through making, not perfection.

The OSB board was milled successfully, and the overall geometry held up better than expected, especially along the curved wave edges.

I had to remove remaining material carefully after the cut. To do this, I used an oscillating saw (the type commonly used for removing casts) to cleanly separate and free the parts. There is a short video documenting this process, showing the removal and cleanup step.

Once the pieces were free, I assembled the table and tested it in context next to and partially under the couch. Seeing it in use was critical - it helped me evaluate:

This assembled piece will remain a working prototype, which I'm using to decide whether I want to:

Huge thanks to Anthony for staying back with me and helping me through this process out of schedule - especially with the CNC setup and decision-making along the way.

Also thank you to Jesse for helping me think through different ways the parts could be assembled and held together, which directly informed how I approached this prototype.