Zijun Wei - How to Make Almost Anything

Week 3.

Computer Controlled Machining

This week we learned to use the ShopBot router for cutting large material. The Shaper cutter, which allows one to cut/carve wood by driving the tool along the intended trace, was also shown as an alternative. These tools are useful for rapid prototyping large cuttable material.

To get familiar with the ShopBot, I made something with the OSB provided. I have been looking forward to having a high chair for my kitchen table at home, and therefore drew some sketches with Fusion 360.

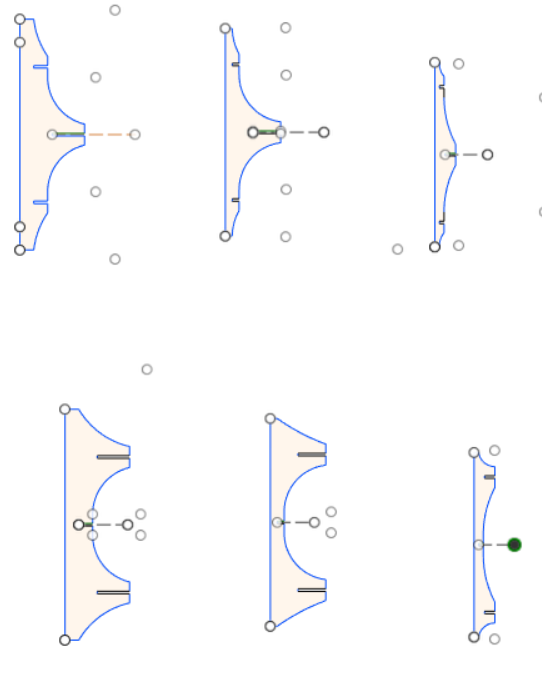

Initially, I only made three legs for the table, each is an arc bending from one side to the other. By have the arcs facing opposite directions, I secured the stablity of table in one direction. But since the board is only half an inch thick, and the legs are 29 inches high, there is high chance that they bend, or even break, in the direction orthogonal to their orientation.

To secure the orthogonal direction, I initially thought of cutting several leg parts of same size and glue them together. But by comparing the sketch dimension and the OSB sheet dimension, it seems I will need way more material than I was provided. Therefore, I added six mounts instead, which the three legs can snap into.

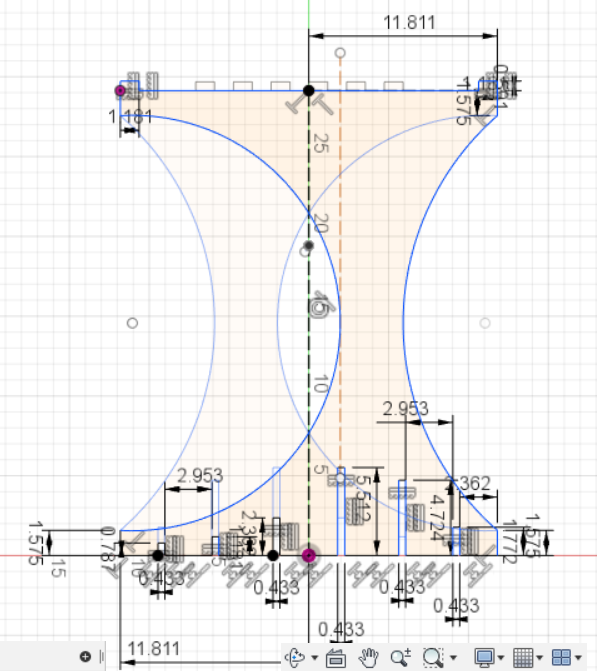

I was also concered with the joint tolerance. In the training, Tom suggested using 0.43 inch as the designed slot size, to tightly fit the bolt cut out from the 0.5-inch-thick sheet. But I was concerned that for some of the slots, this will be too tight. I used 11mm (0.4331) as the slot size in the end.

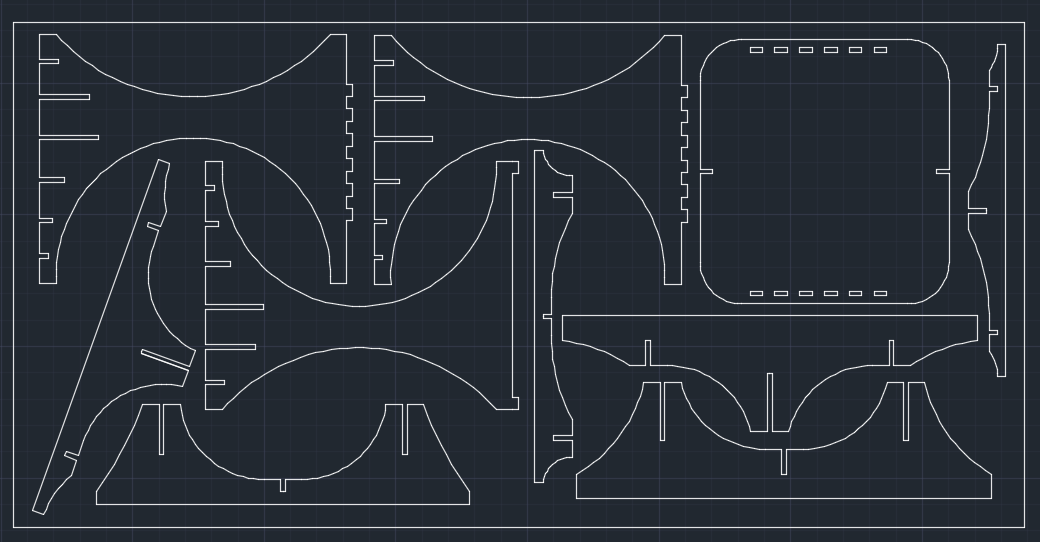

After some efforts, I was finally able to fit in all the cut parts vectors(dxf) into the 4'x8' sheet template. But when I measure the minimal distance from the parts to the edge, it was barely more than 1 inch. For a small tilted angle (say 1 degree), the 8' sheet can produce 1.8" offset, which the cuthead can run off the sheet edge. In the end, I decided to use one full sheet, and "recycle" some of the used sheet.

Click here for the design sketch in dxf format.

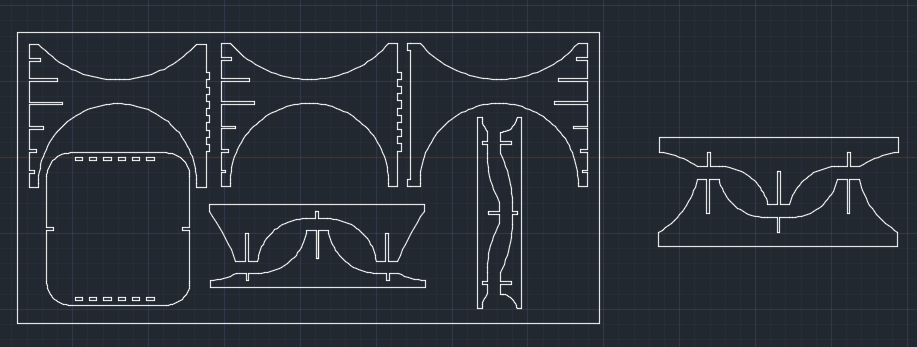

Thanks to John's great help, the cut was nice and smooth.

Putting the parts together, I found that the 11mm is still too tight for small joint, and I had to use sand paper and filler to reduce the size. And it worked perfectly.

The final assembly gave me a much larger chair than I expected. I think I can even use it as a small bedside table. It is able to sustain my weight with no problem, even when I try to swing along the weaker side.