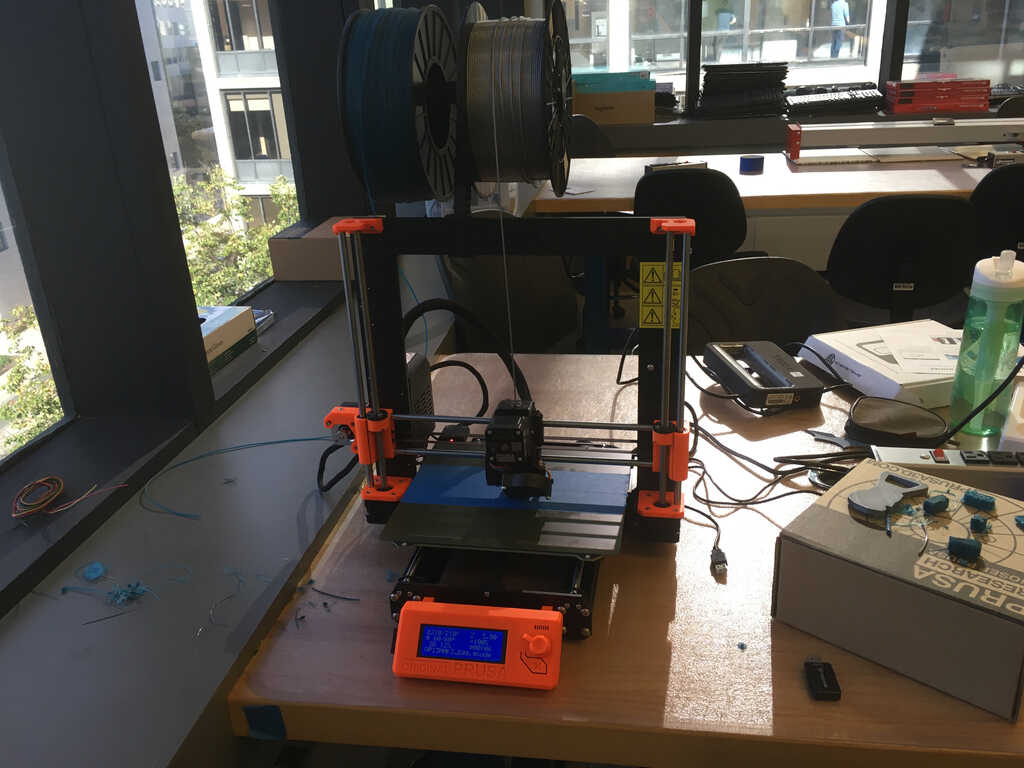

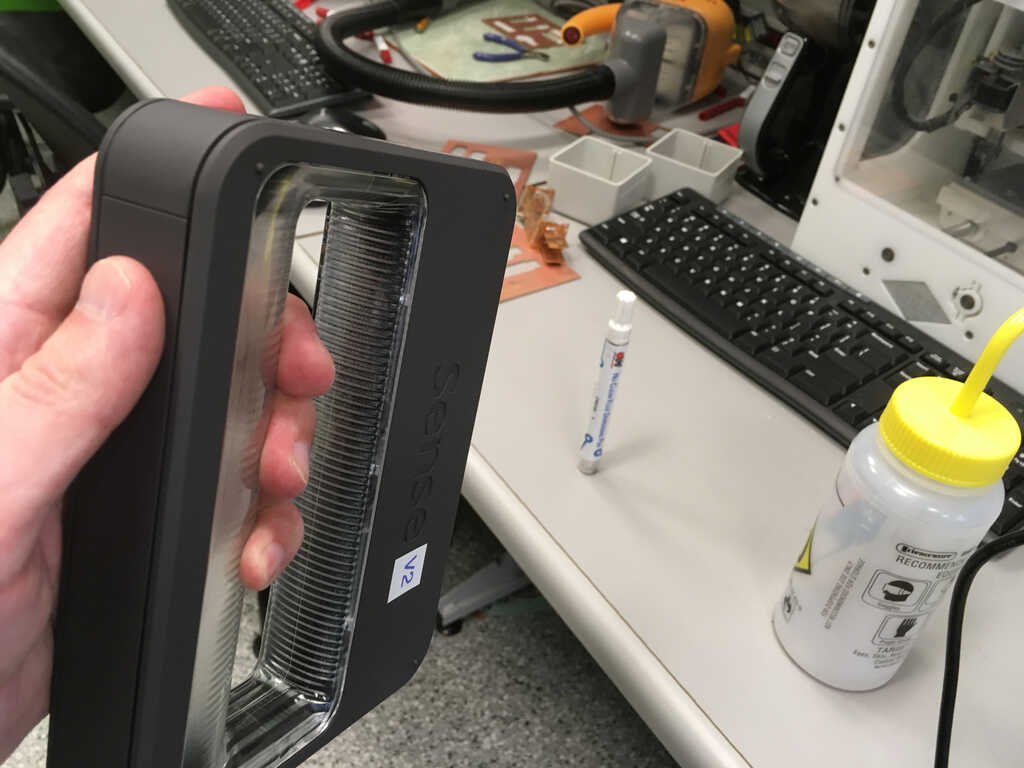

This week was about 3D tech, and I started it off with 3D scanning. In the EDS, we used the Sense scanners.

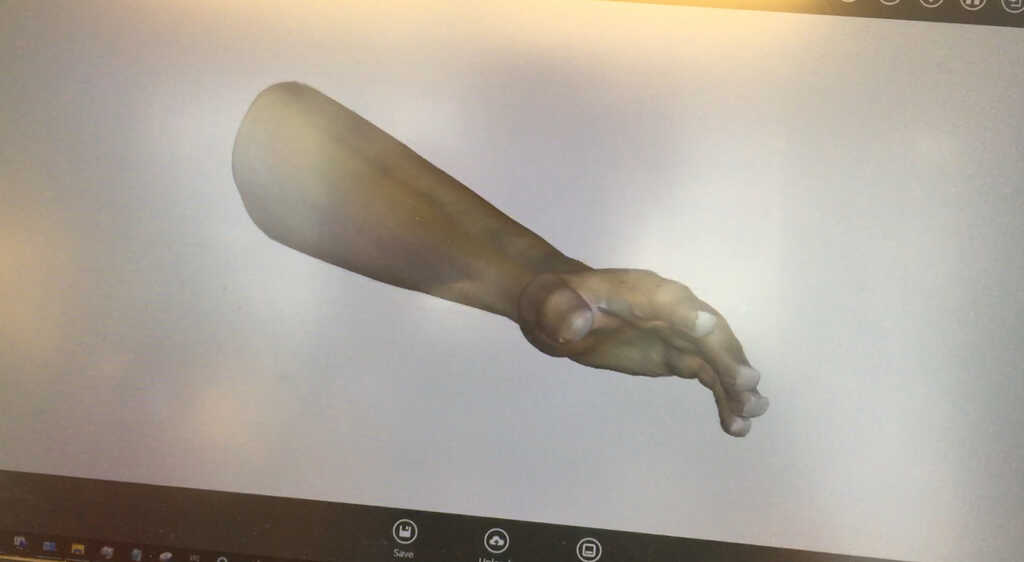

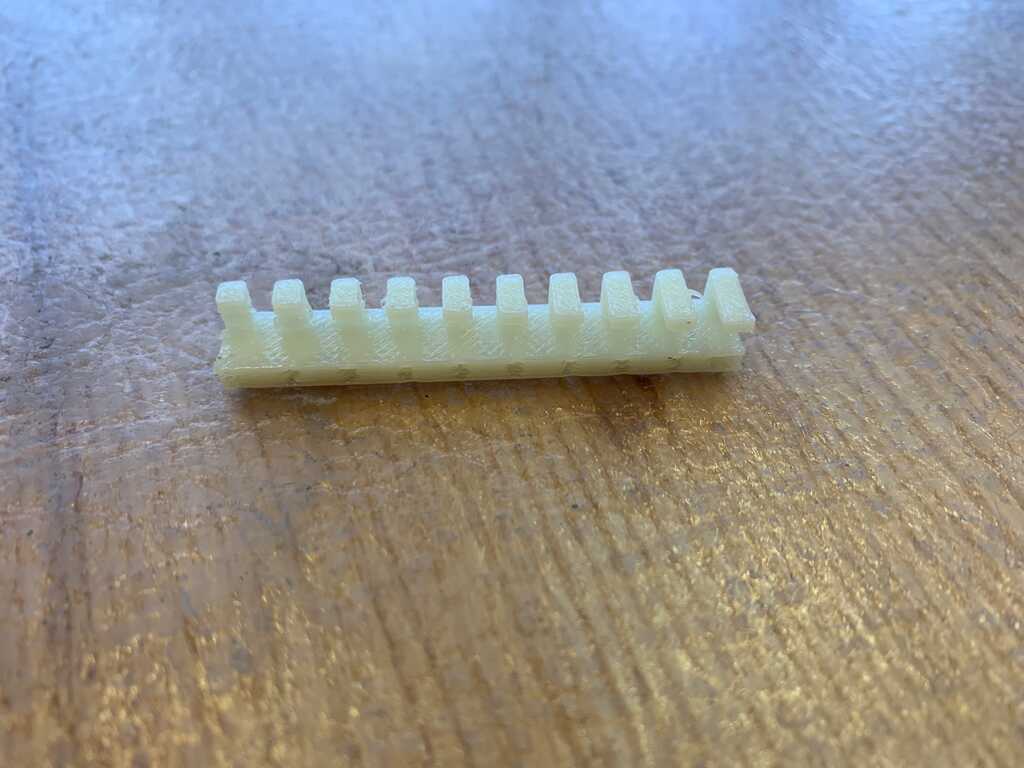

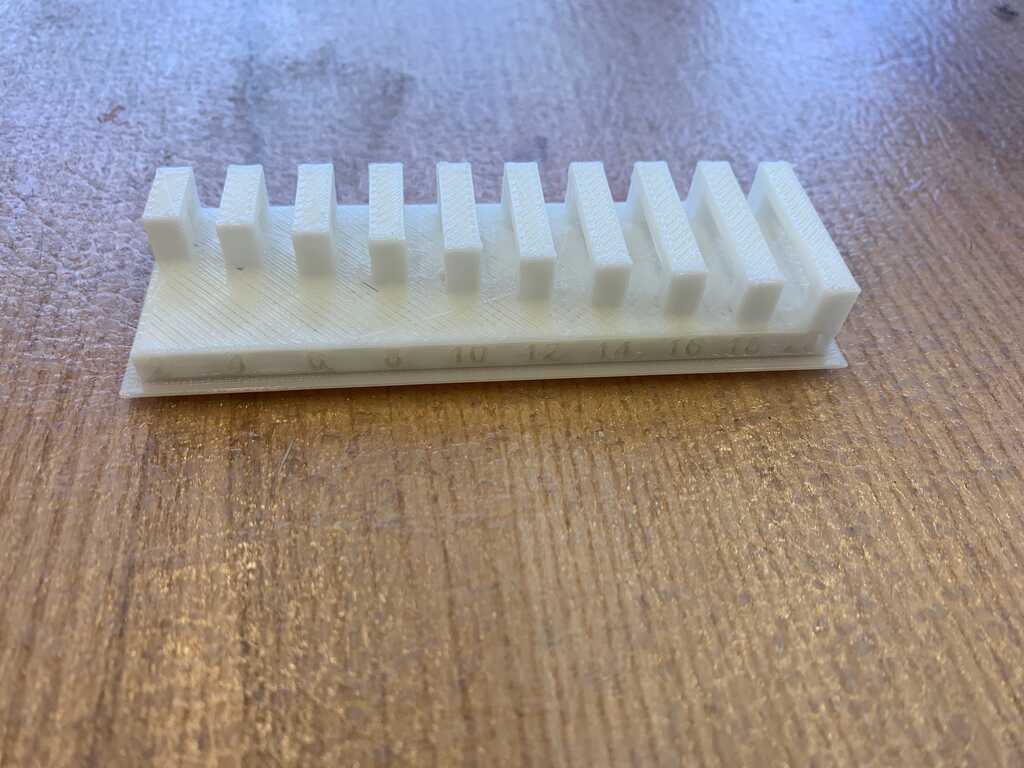

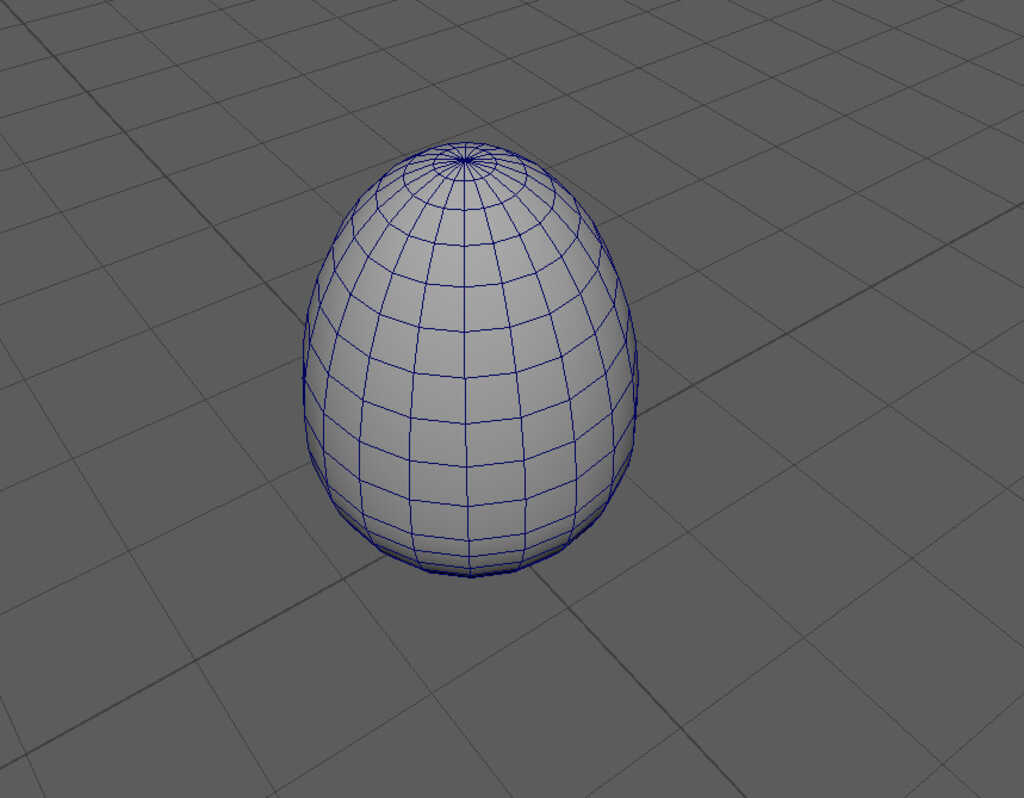

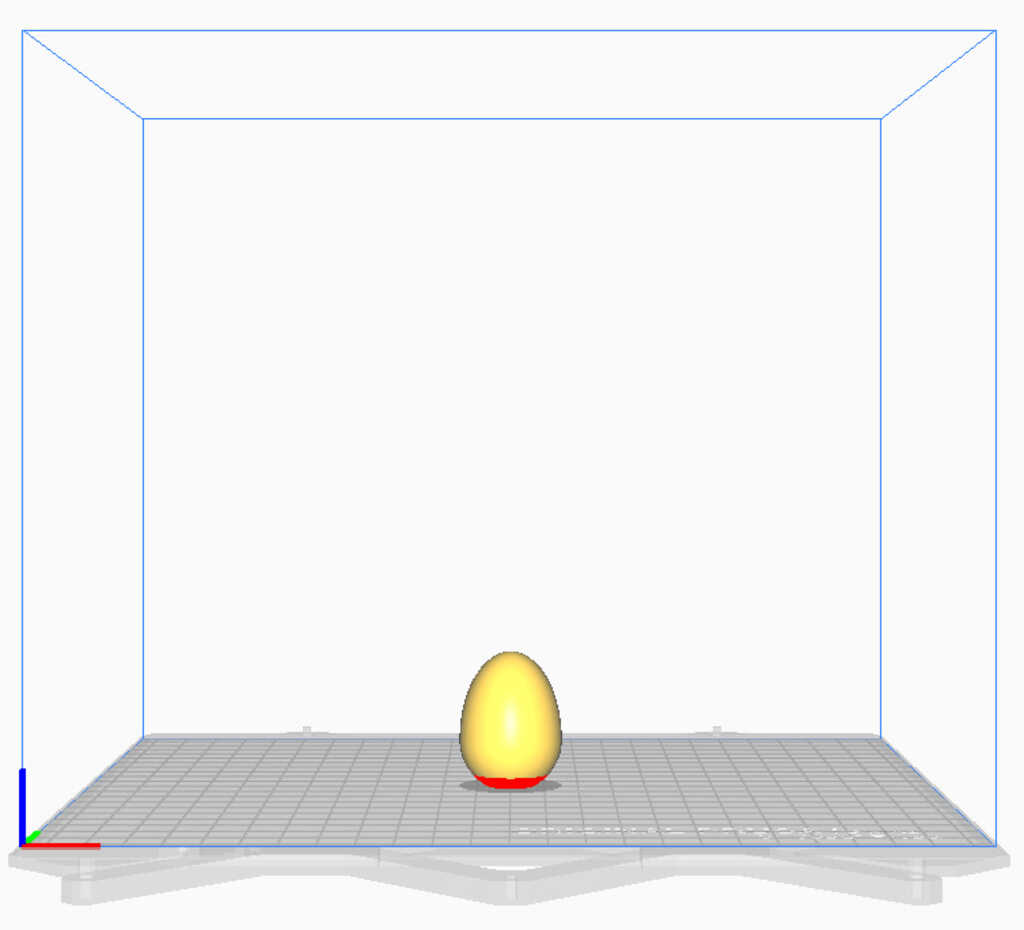

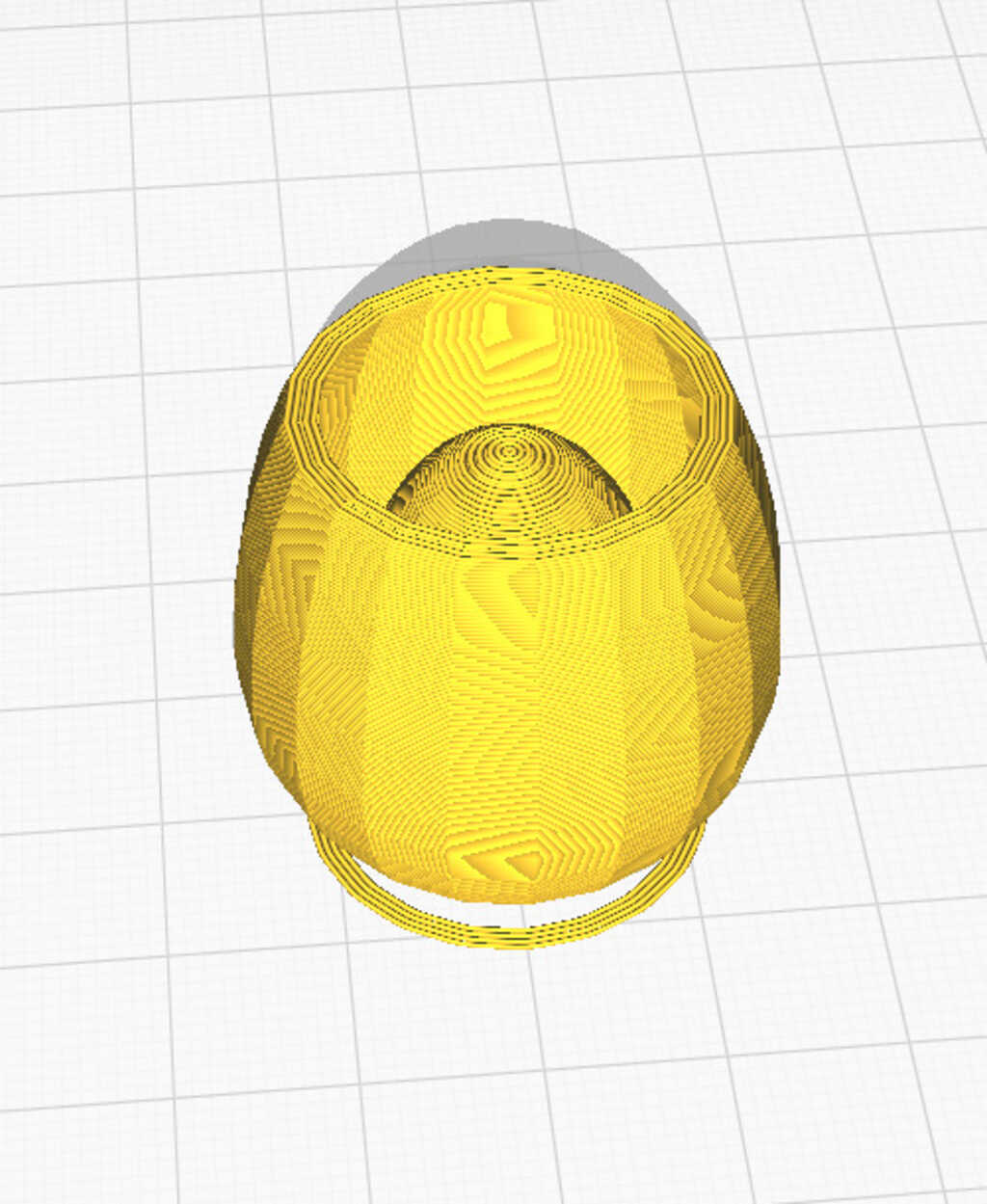

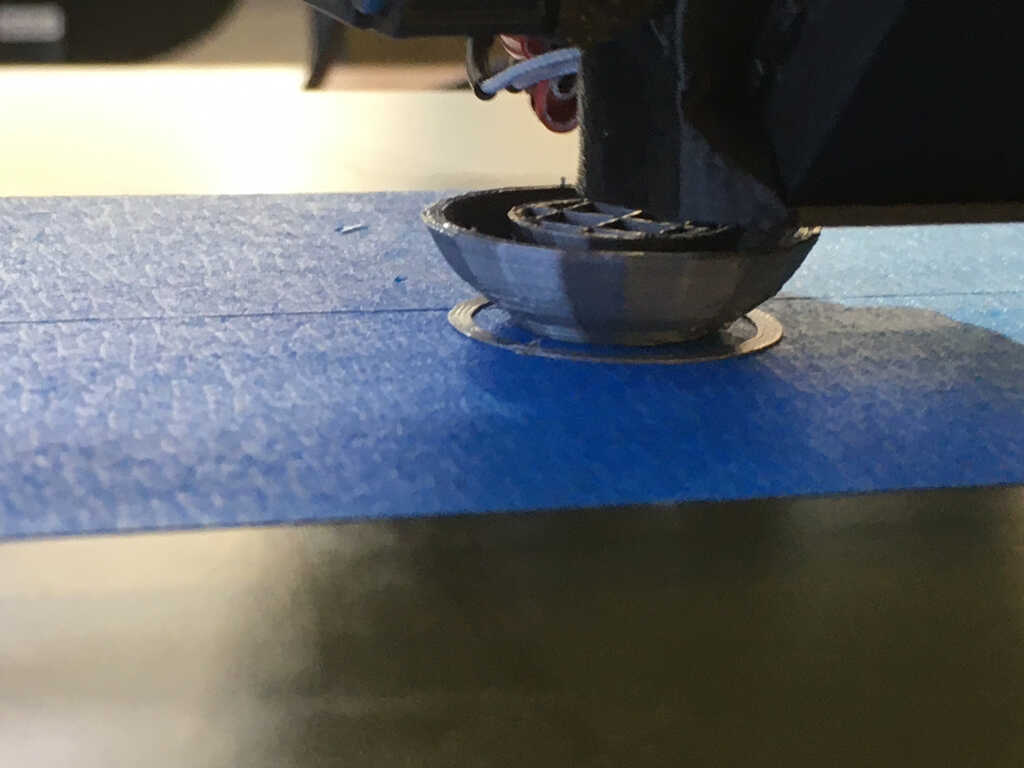

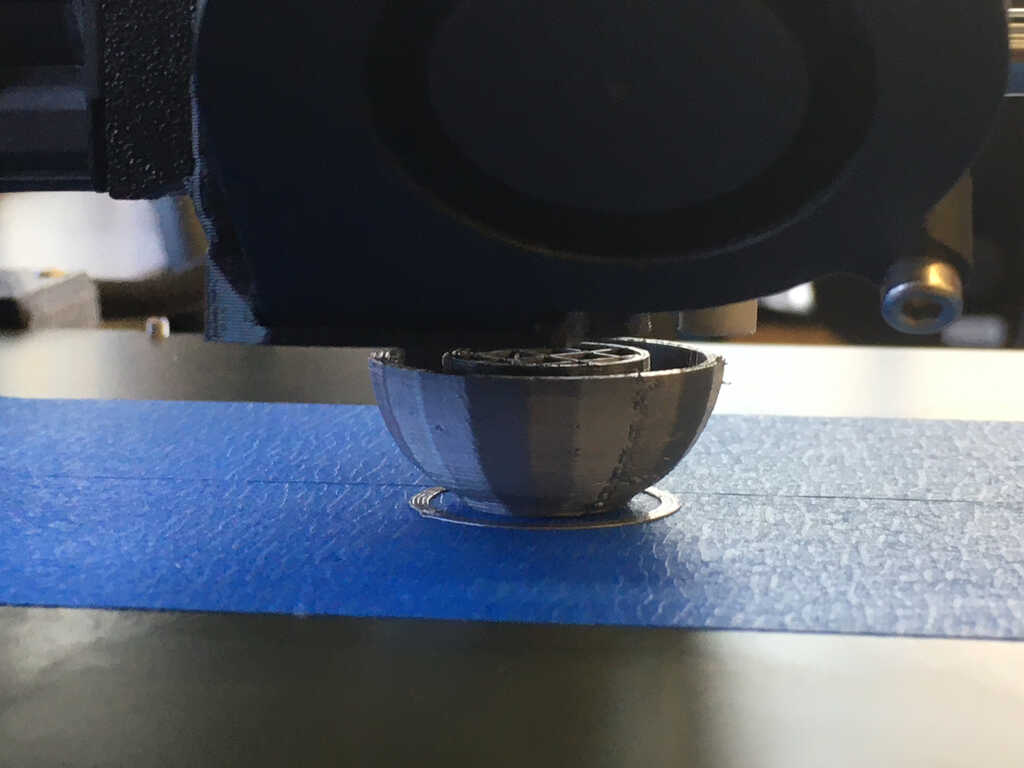

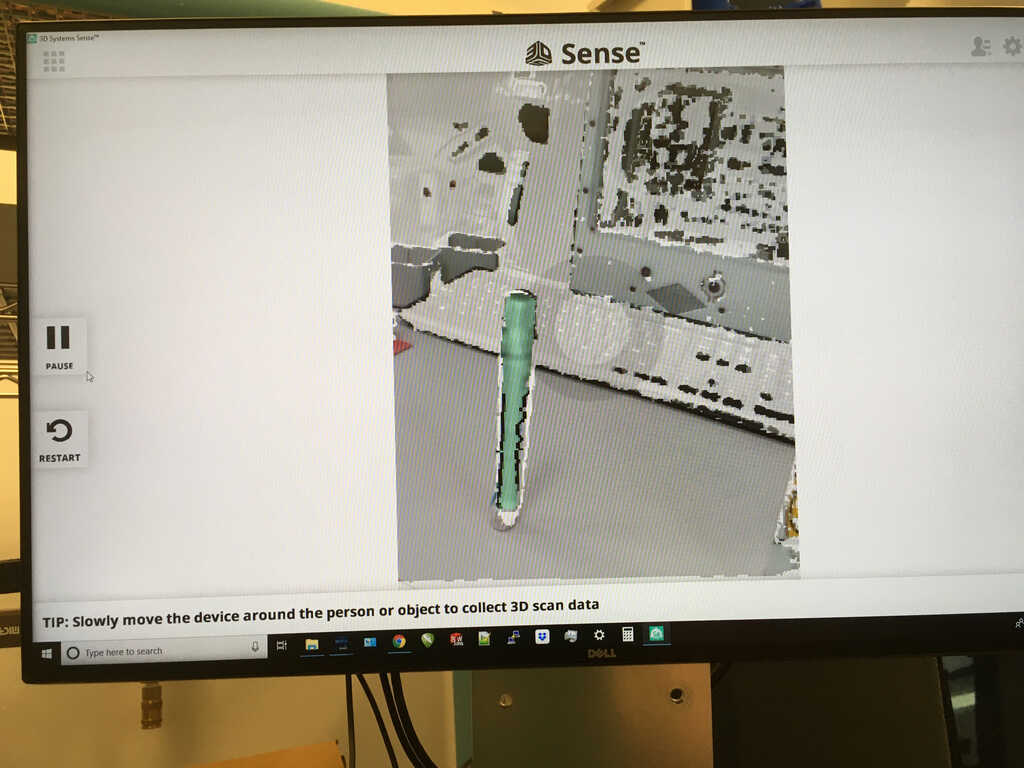

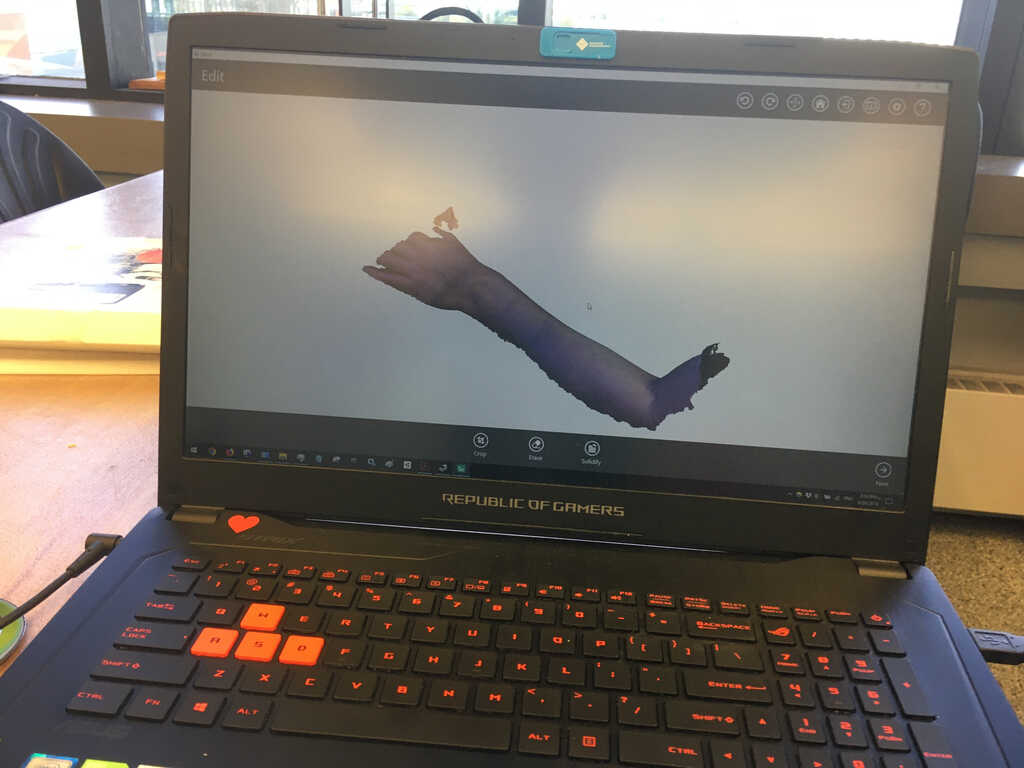

There were two options available: the V1 and the V2. To start off, I tried the V2 because newer obviously had to mean better, right? Well, unfortunately that wasn't the case. Right off the bat I couldn't get the V2 to work with the Sense software on my computer. I tried to use one of the computers in the lab, where it worked... sort of. This is what the V2 software looks like mid-scan:

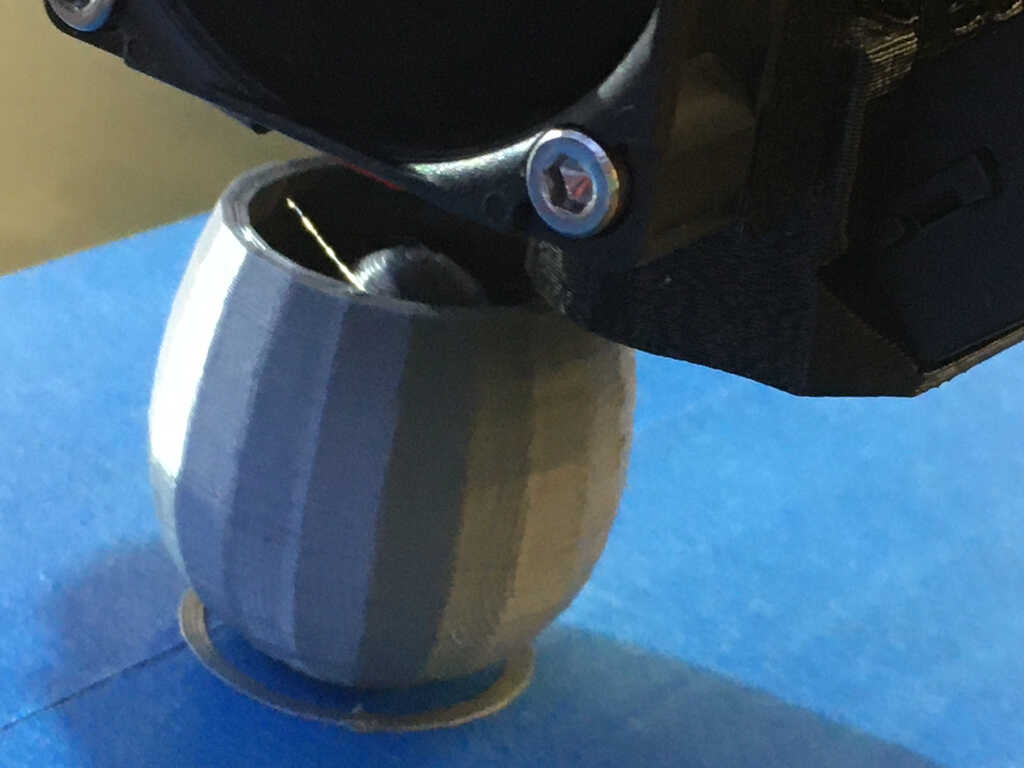

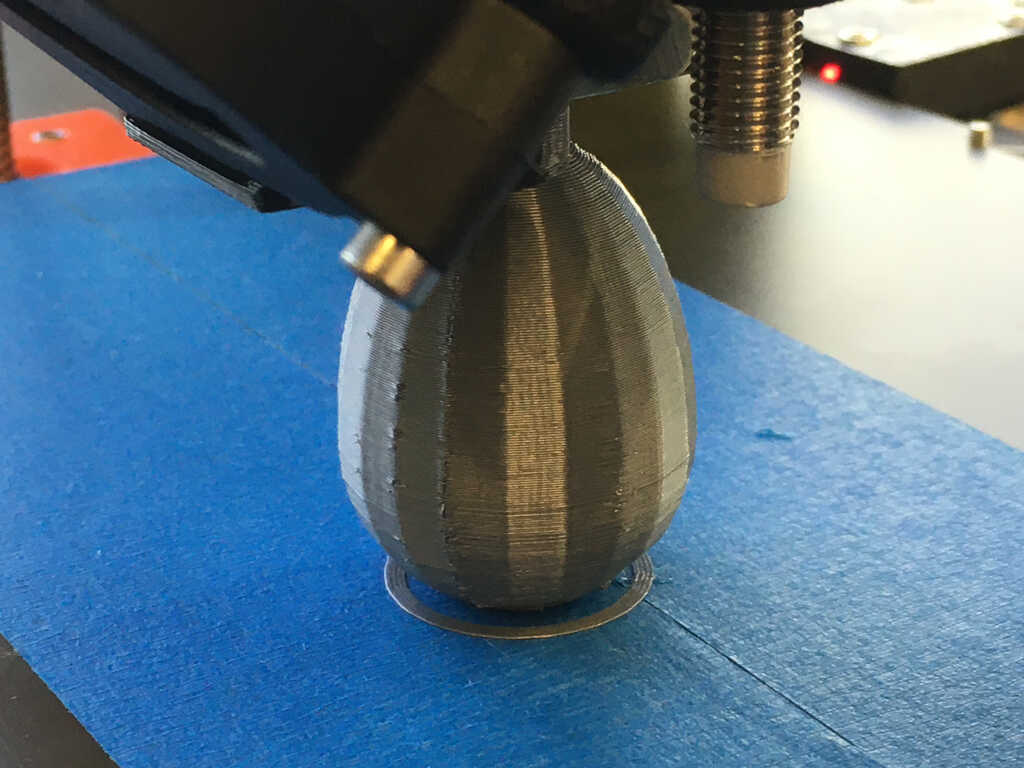

Here, you can see it's working. However, there were major issues with it losing tracking after maybe 15°, and while backtracking would temporarily get the tracking back, we could never get it to go beyond that point. So we decided to try out the V1 instead. It ended up working much smoother, and we were able to get full scans!

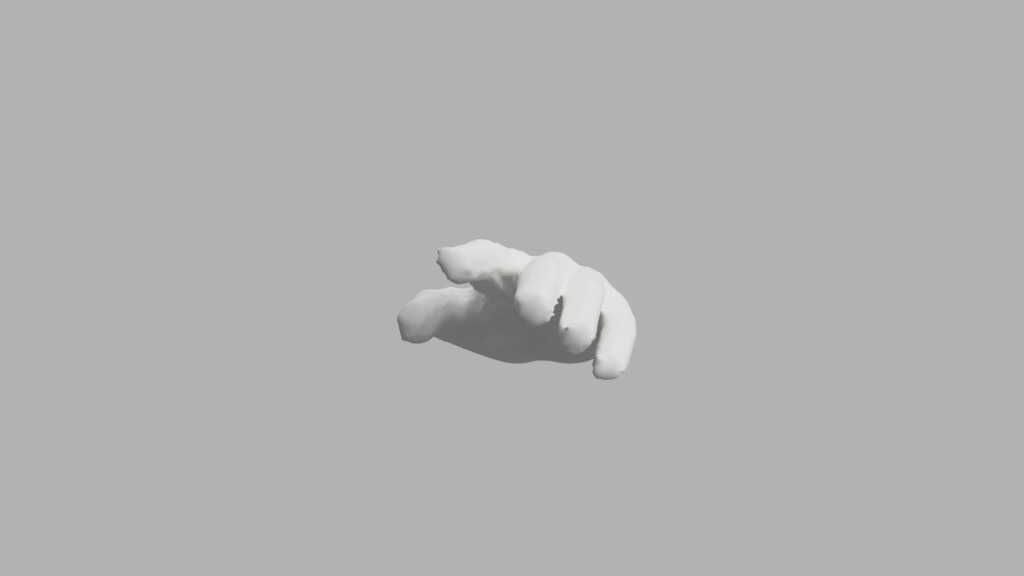

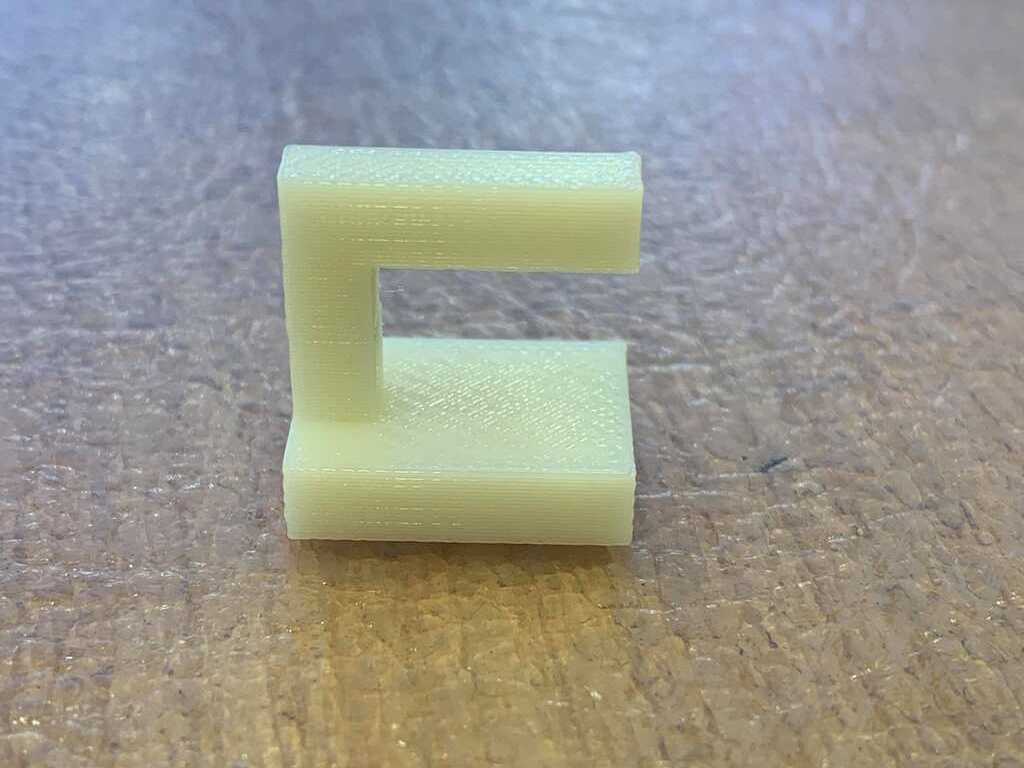

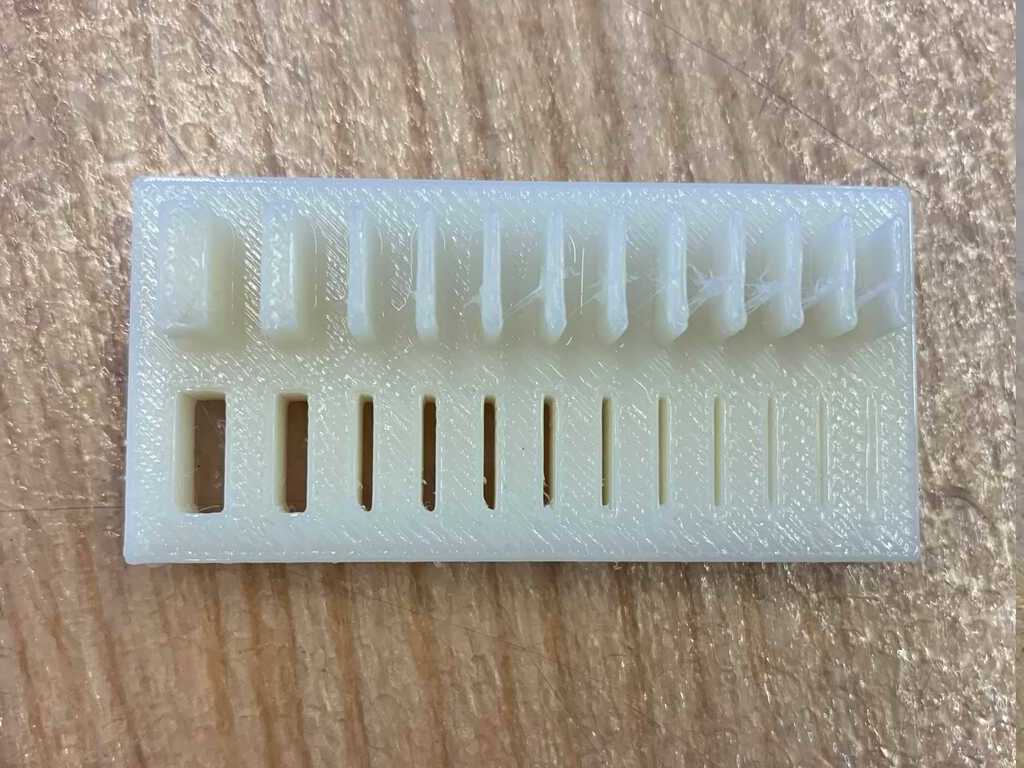

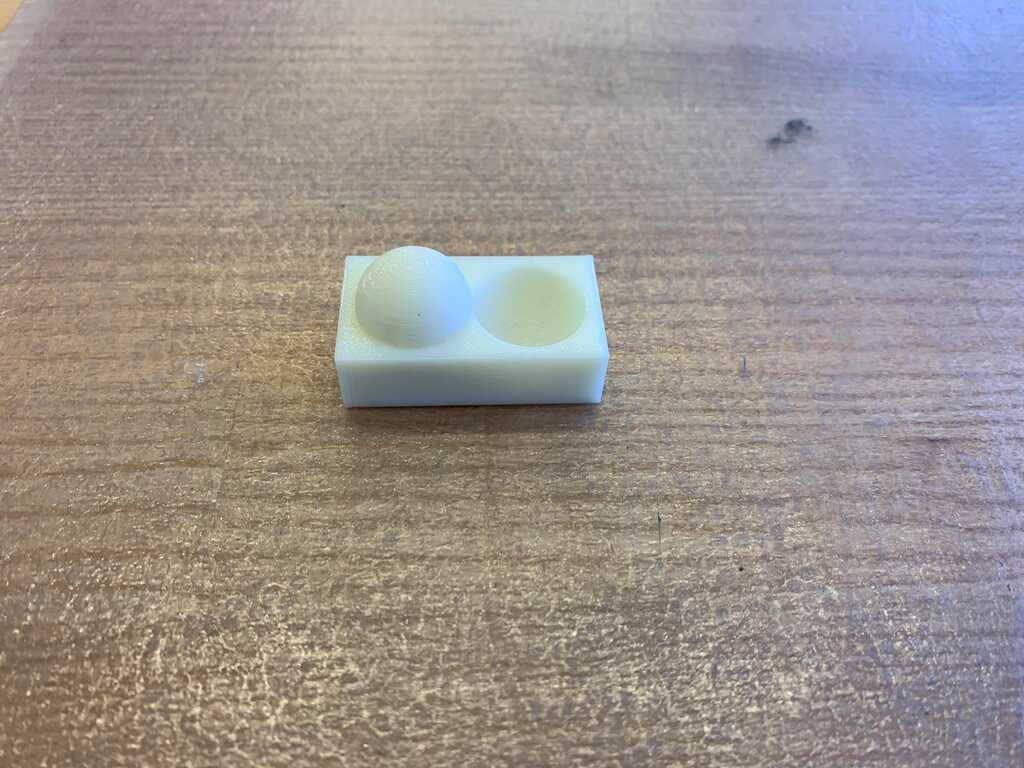

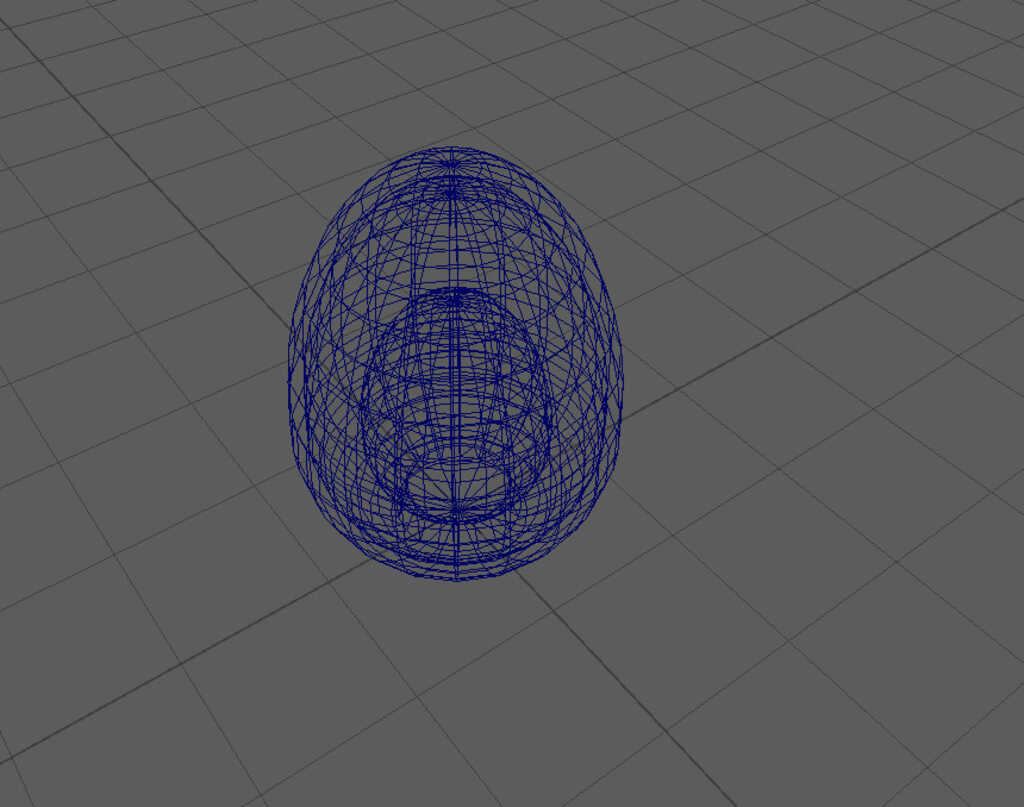

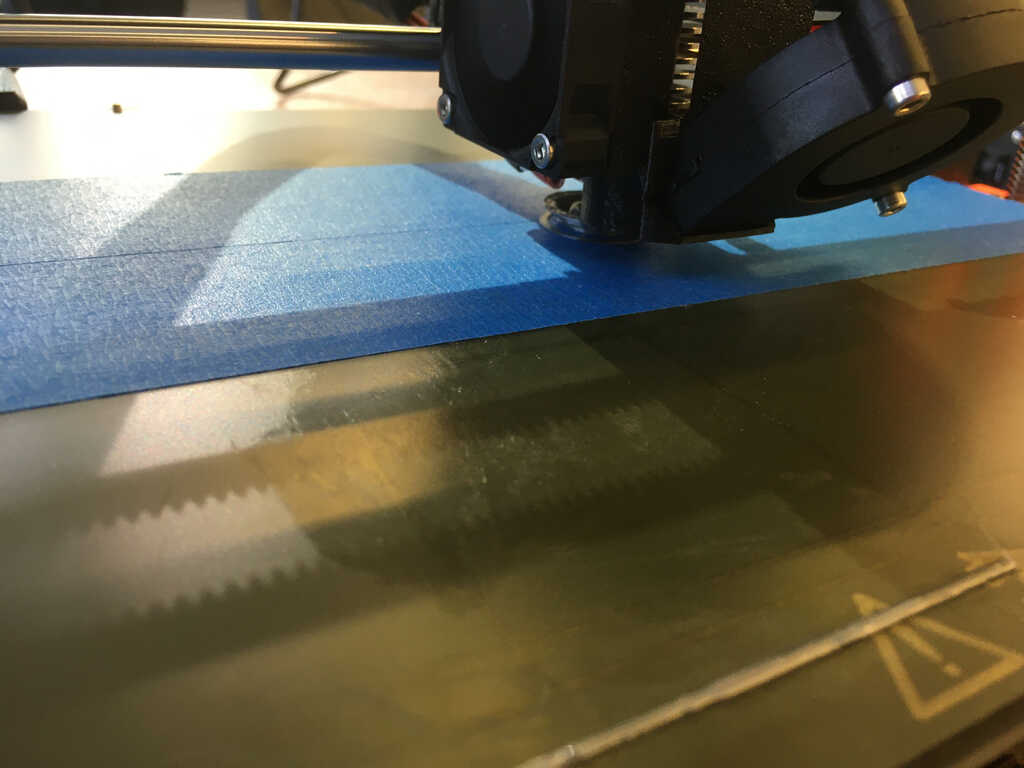

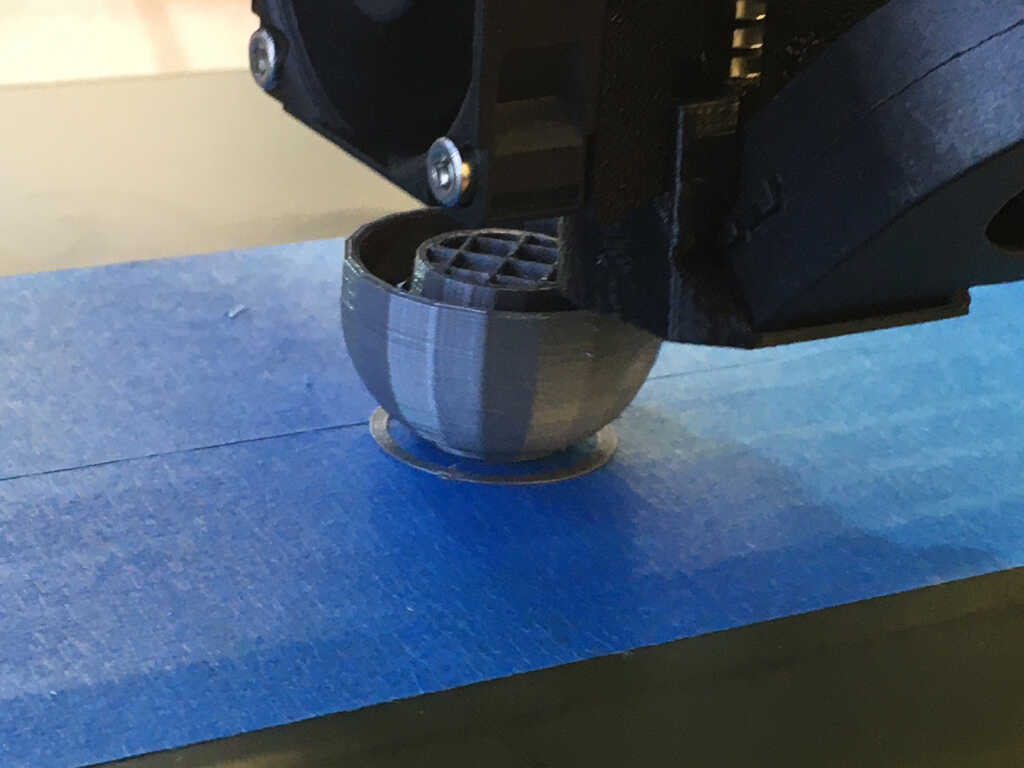

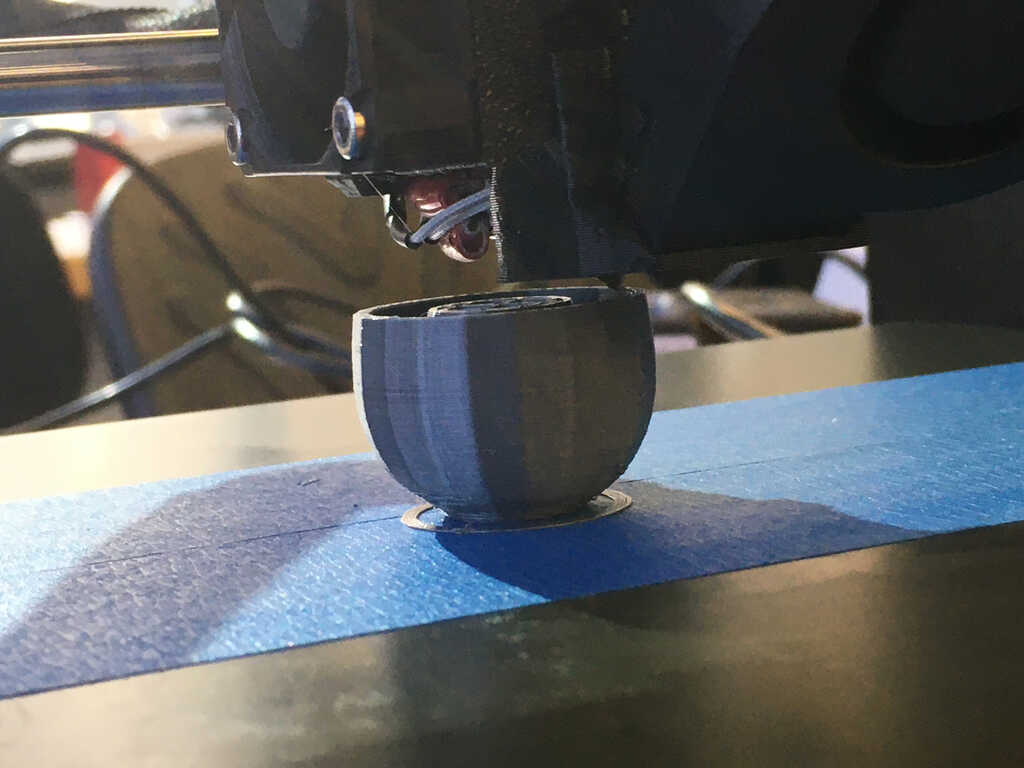

To tie in with my final project, a modular wearable device, I wanted a model of my arm. I tried to do this by myself, but got this cursed result:

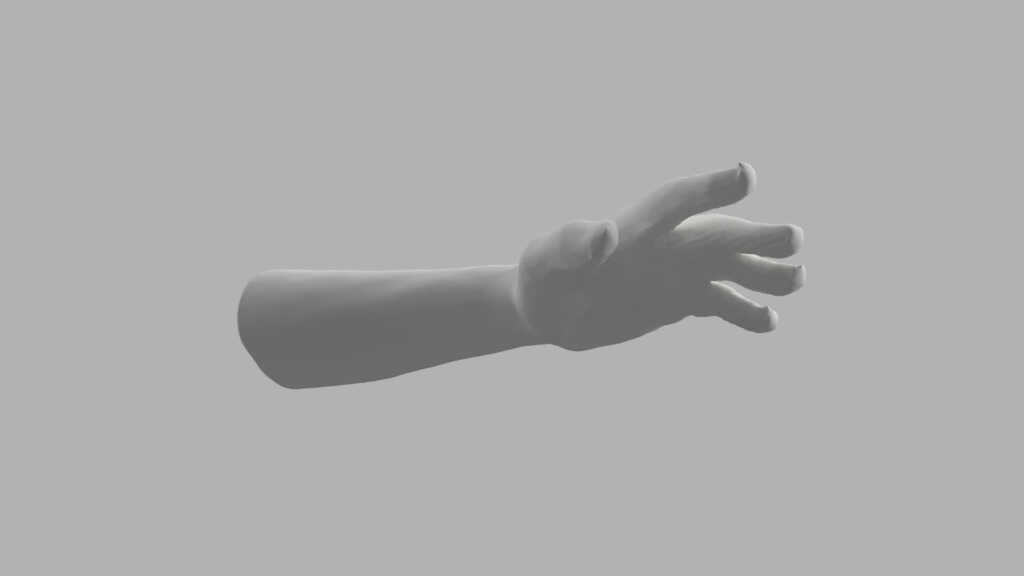

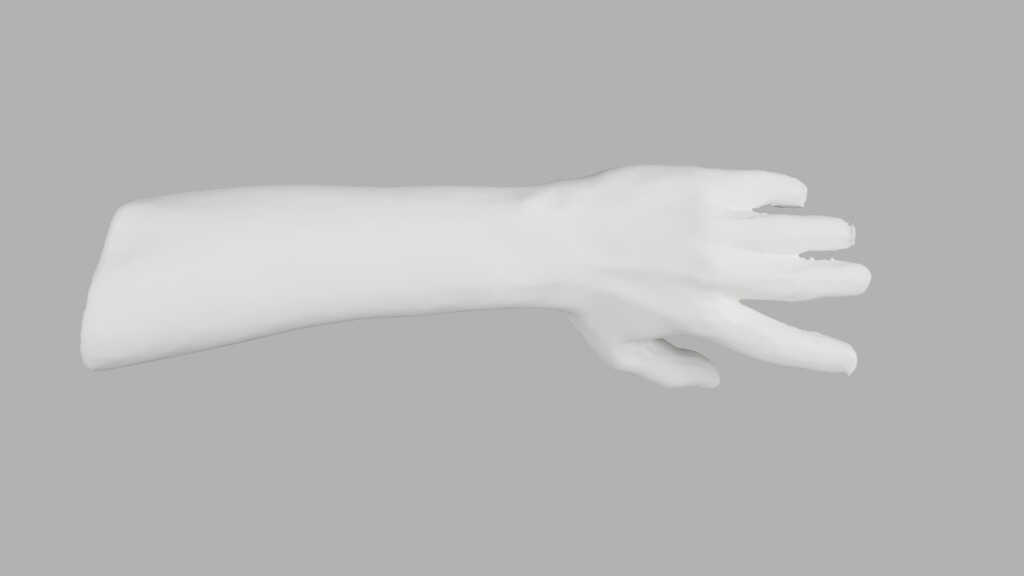

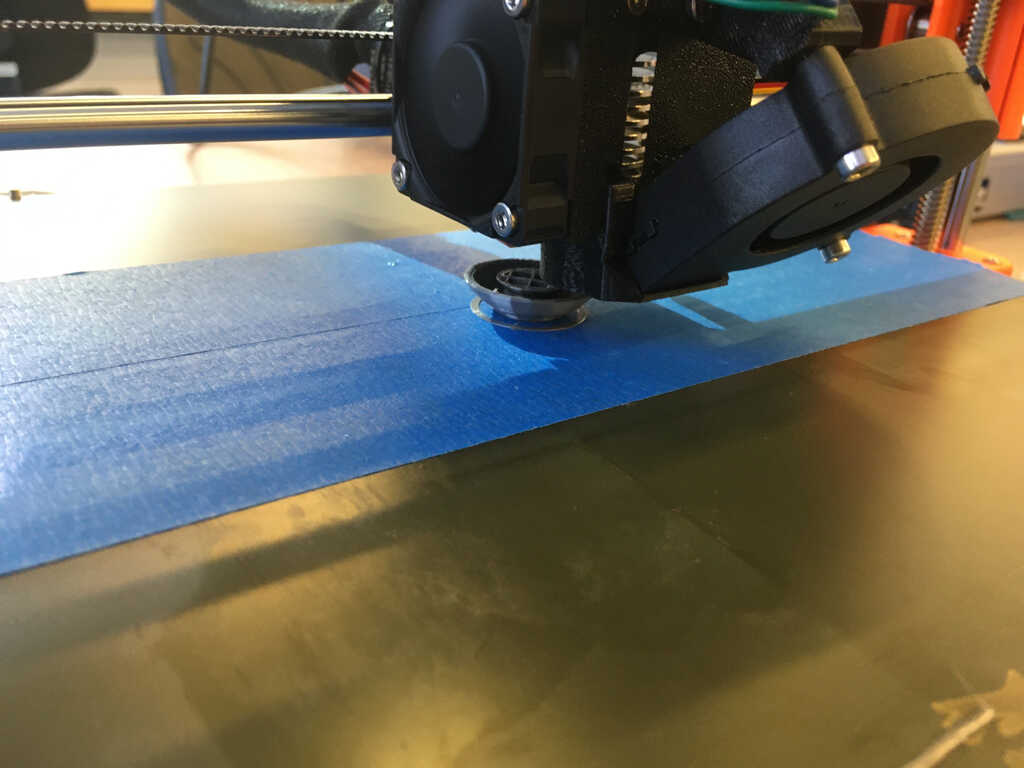

I asked for help from Prashanth, the TA on duty, and together we got a very decent scan of my arm. I stuck my hand in the air as though I was waiting to ask a question, and he walked around with the sense. The result turned out surprisingly good!