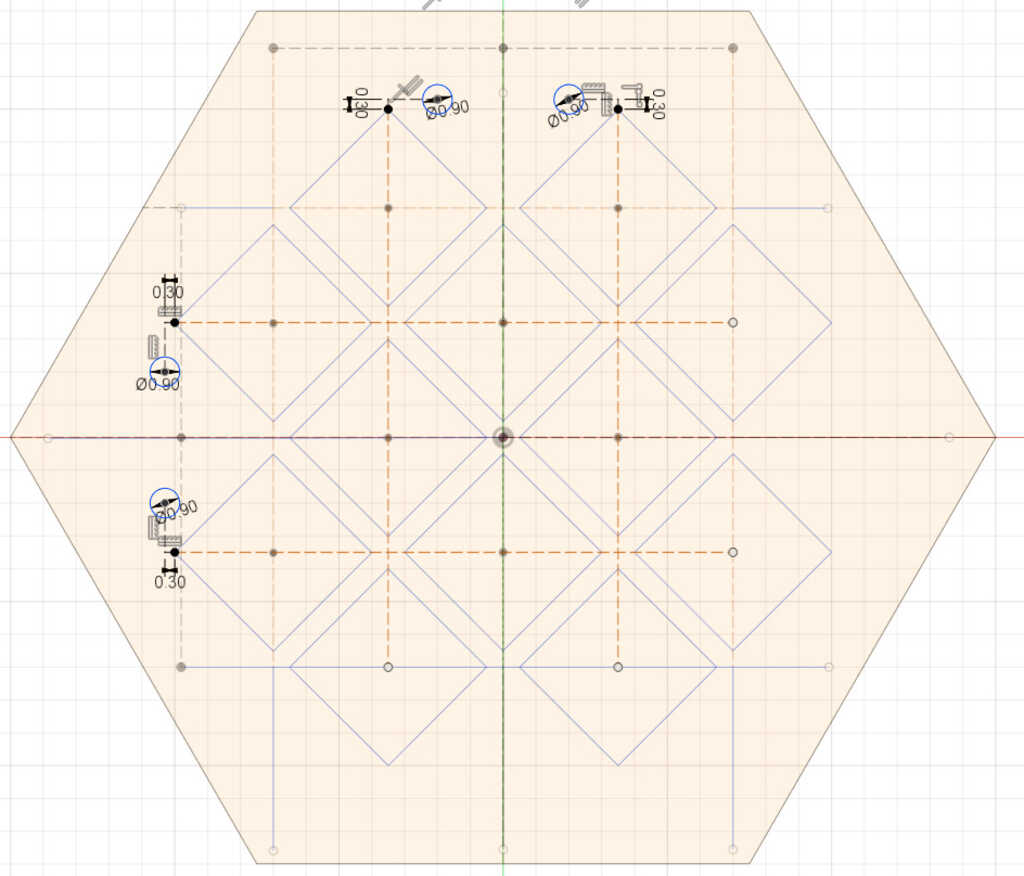

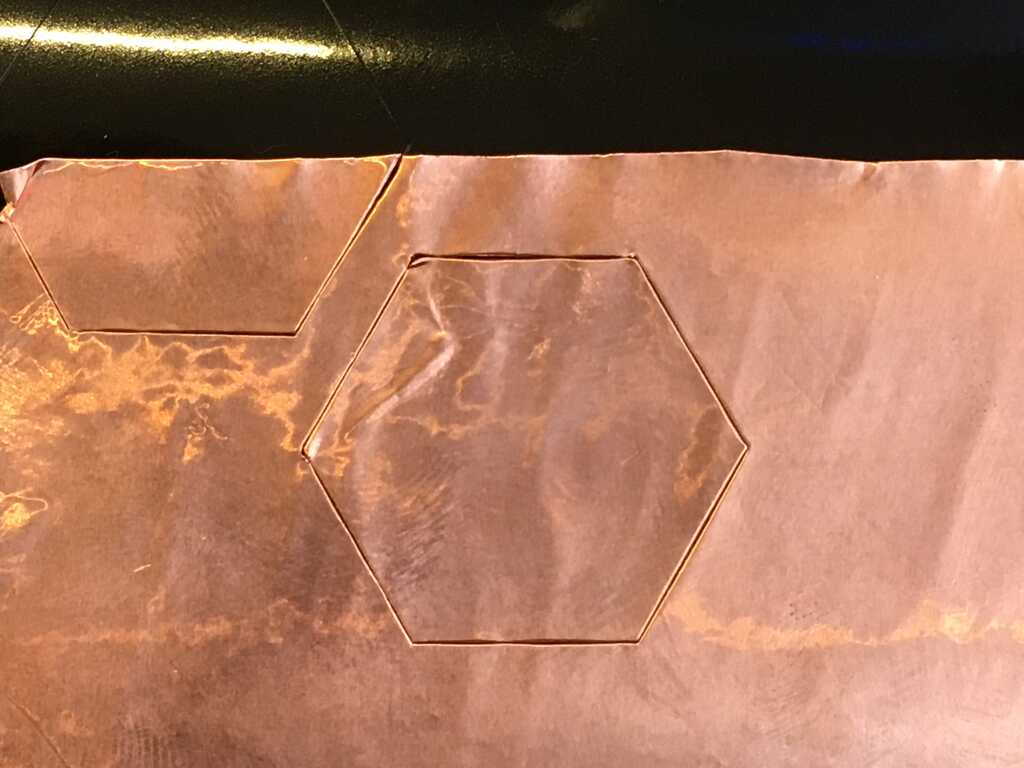

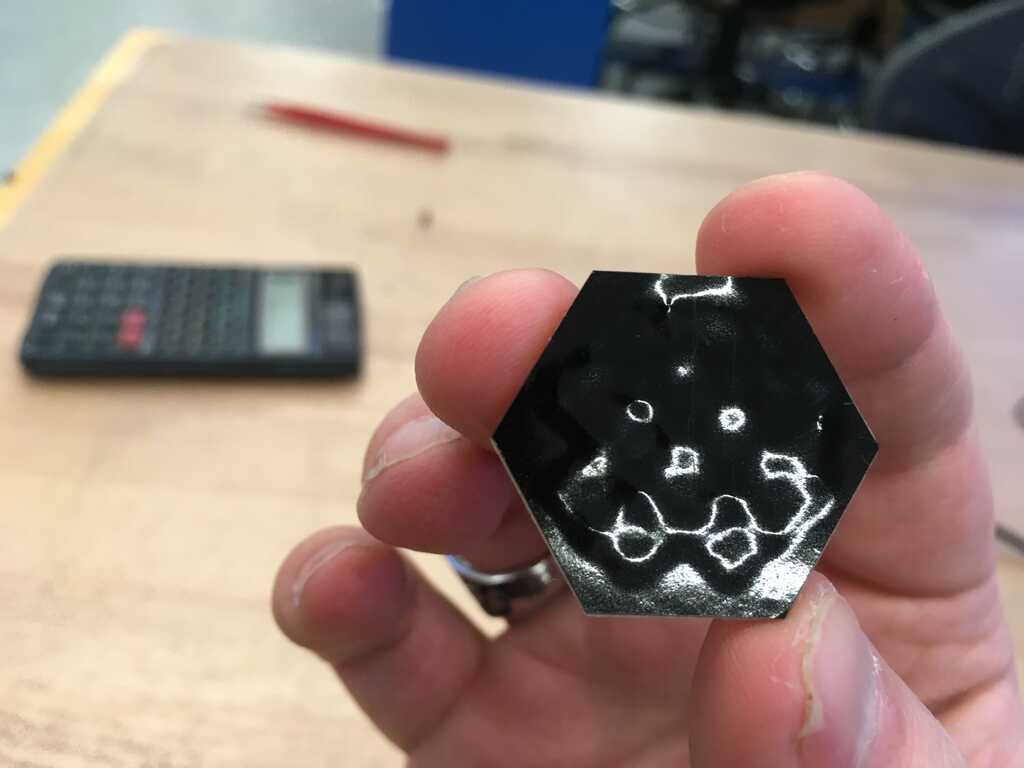

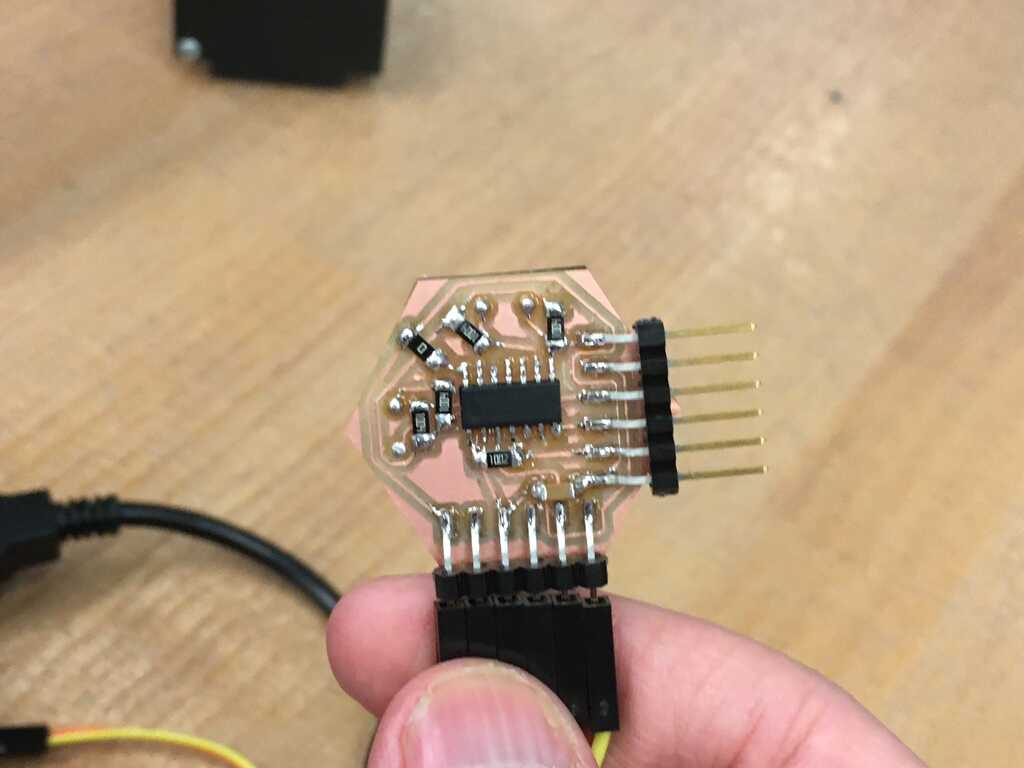

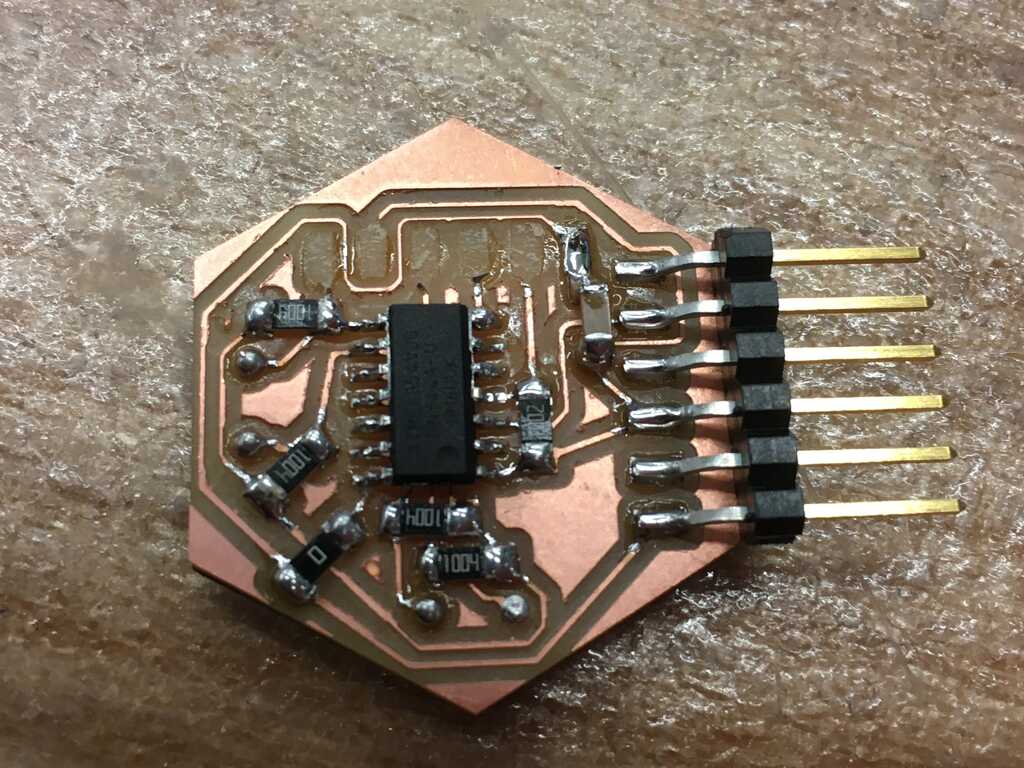

I already knew that vinyl cutting was going to be tricky for me this week. I didn't know I'd need it when I first did way back in Week 2, so I just made something neat and moved on. However, this week really needed it. So, to warm myself up, I did a test cut on vinyl with that hexagon from before. It fit perfectly on the board, so I knew I had my dimensions right! (Whoops, spoiler, I already milled my board)

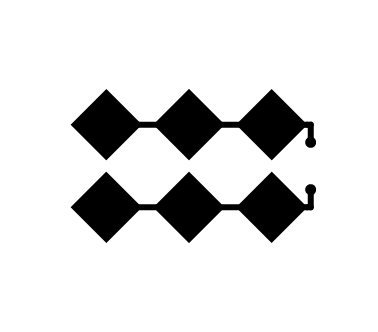

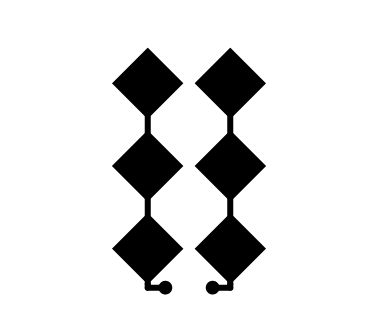

Now, the array needed a conductive material with an adhesive layer, so what better material than copper tape?

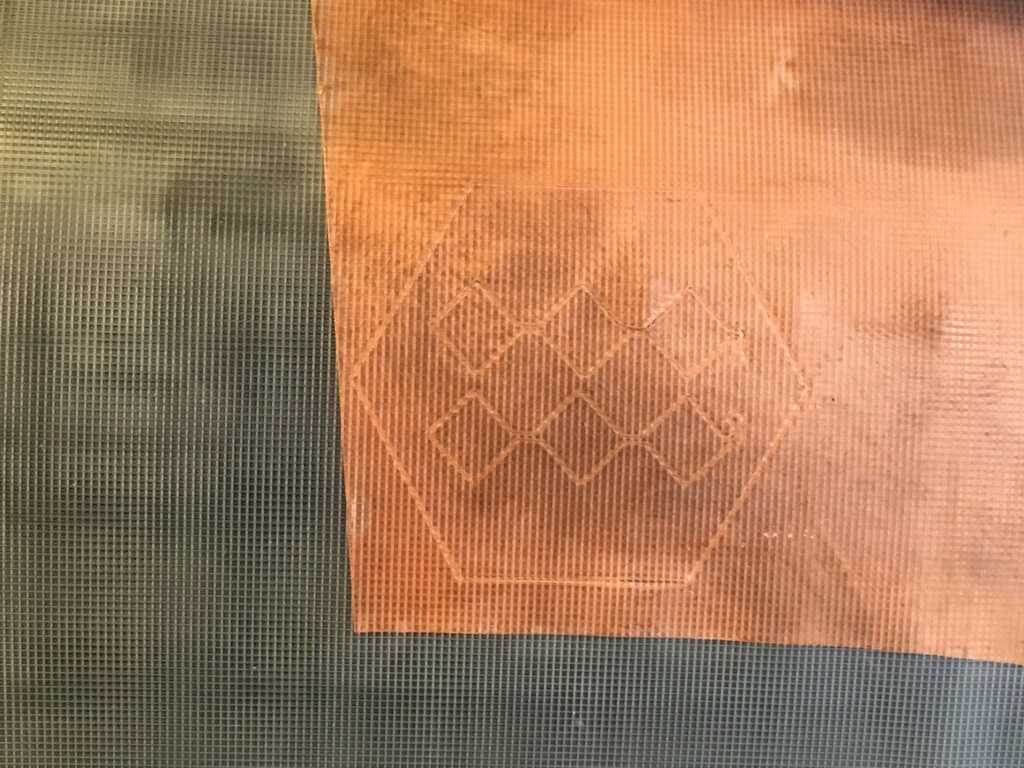

The first thing I tried was to directly adhere the copper tape to the vinyl and cut it from there. I cut it out with 80g of force at 2cm/s, but that didn't quite cut through the vinyl like I had wanted. However, it went much smoother than I had expected. (This was due to both the simple nature of the cut I was making, as well as the strong adhesion to the vinyl.)

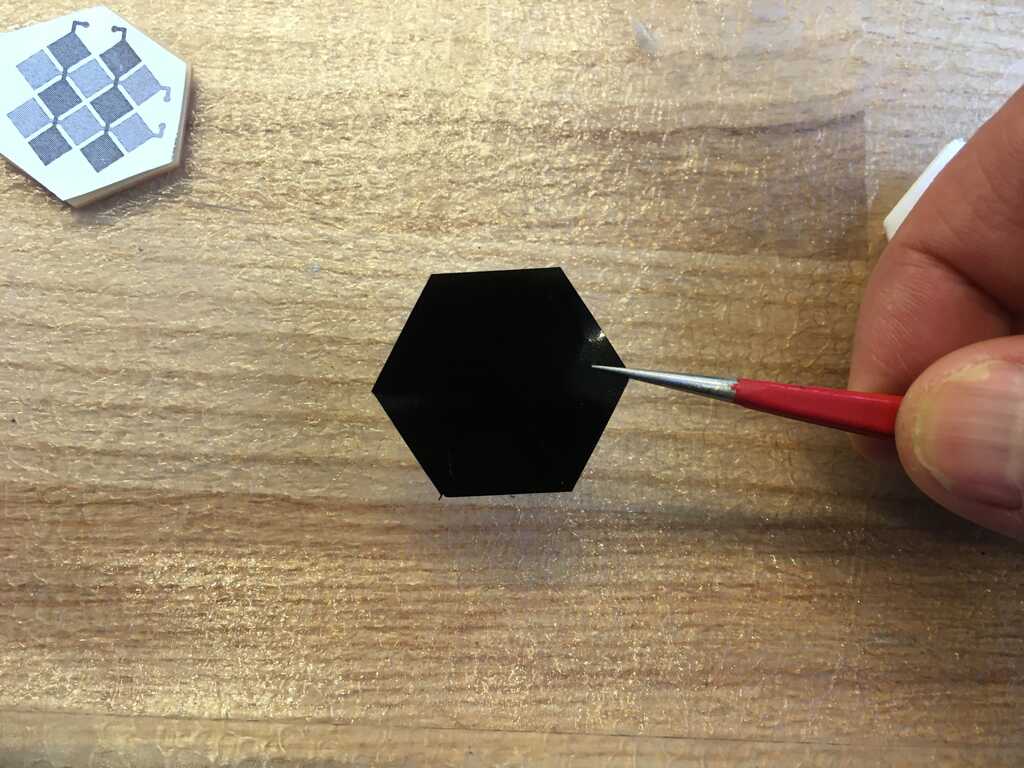

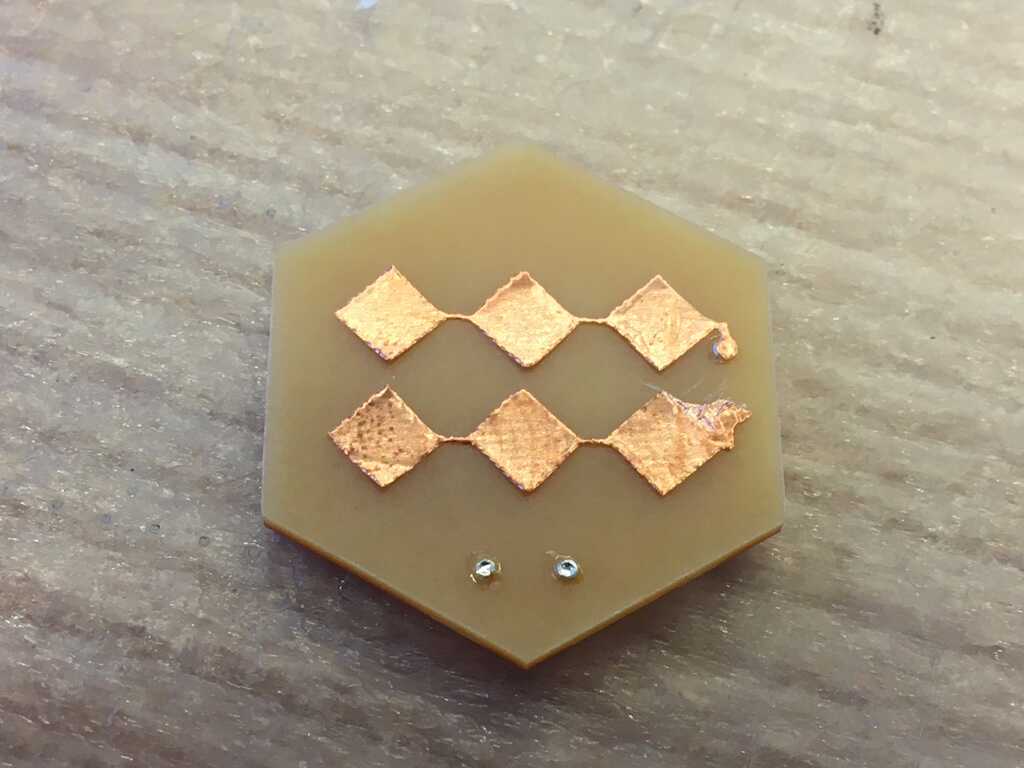

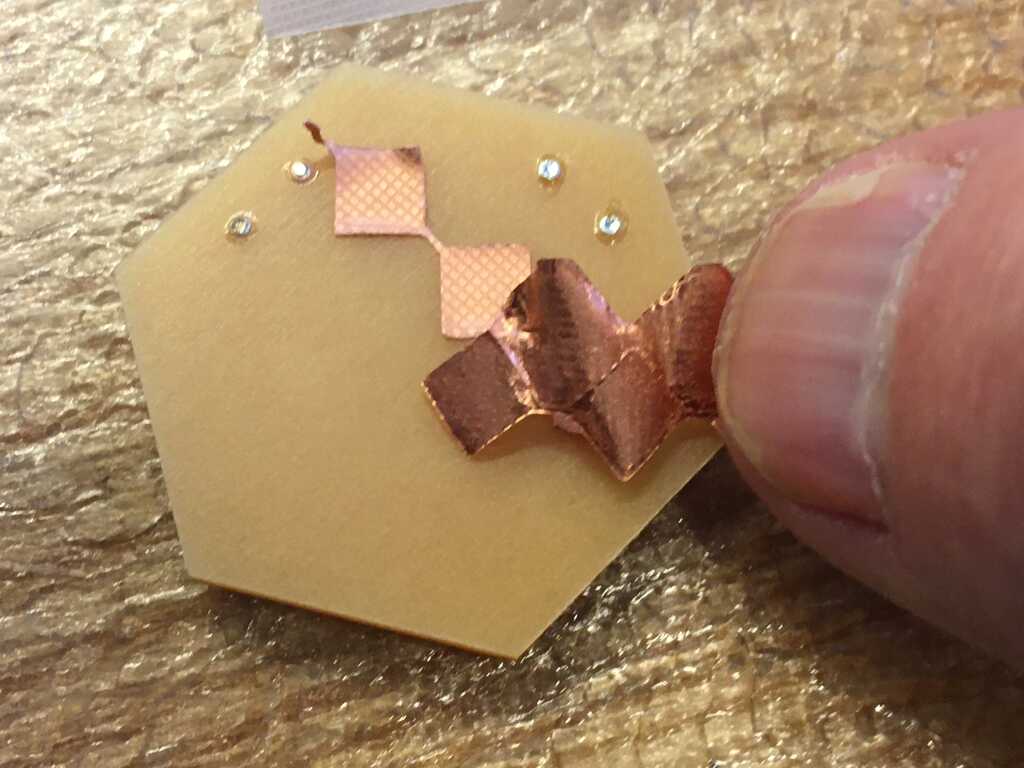

To get through the vinyl, I tried just a little more force at 100g. Other than setting my origin incorrectly, I cut exactly what I wanted! Looking at the actual tape, on the other hand, adhering it to the vinyl and then removing it took off a ton of adhesive, as you might be able to see in the second picture.

Alright, now it's time for a new approach. This time, I left the copper tape on its original backing, and taped down all of the sides with masking tape. Since I wasn't convinced that this was going to scale down to my tinier features, I jumped right in and started cutting those out instead. I tried a large variety of forces, and reduced the speed, but I just couldn't get good results. (I believe this was due to the weak adhesion of the copper tape to the original backing, leading to the knife dragging the tape behind it.)

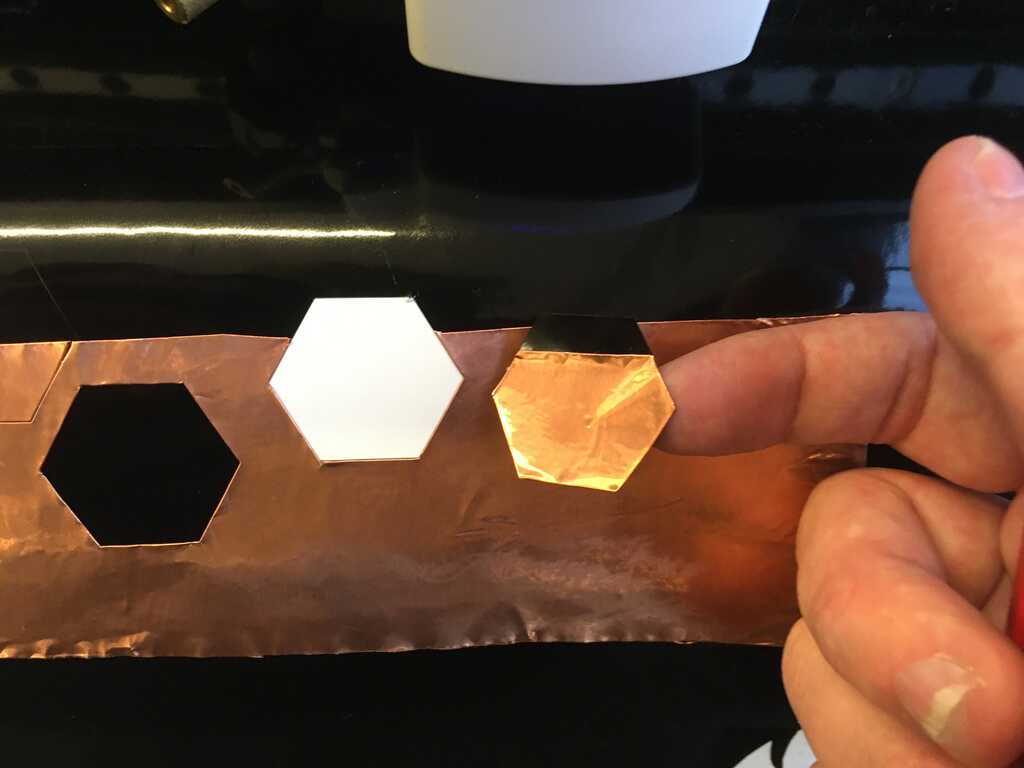

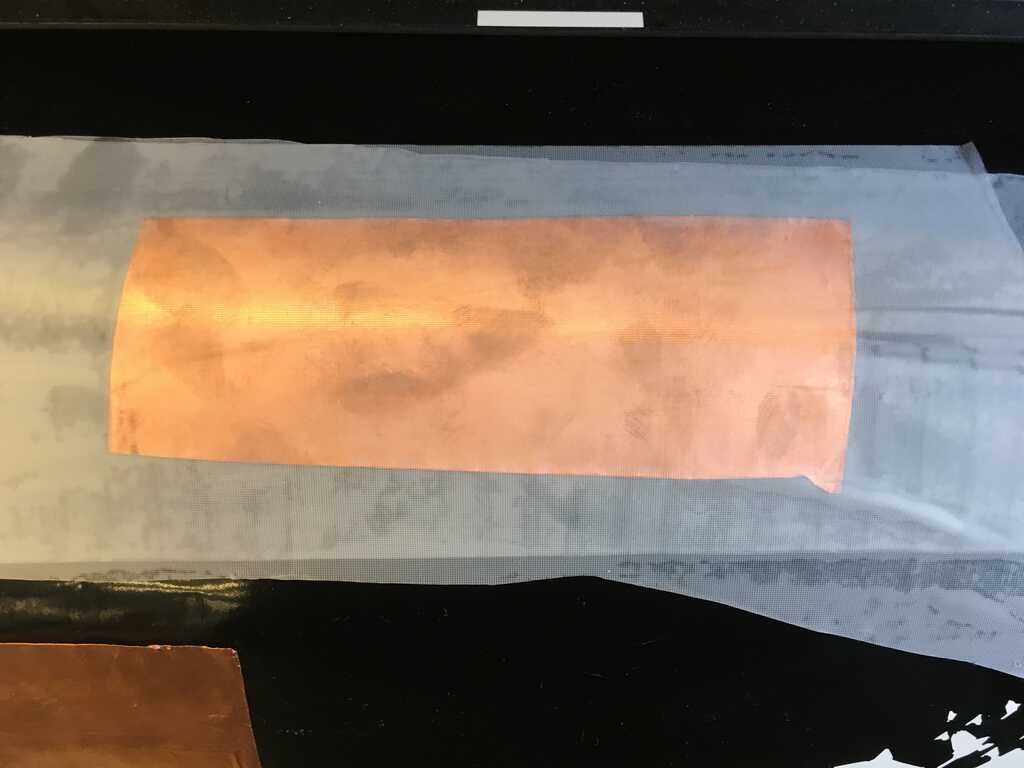

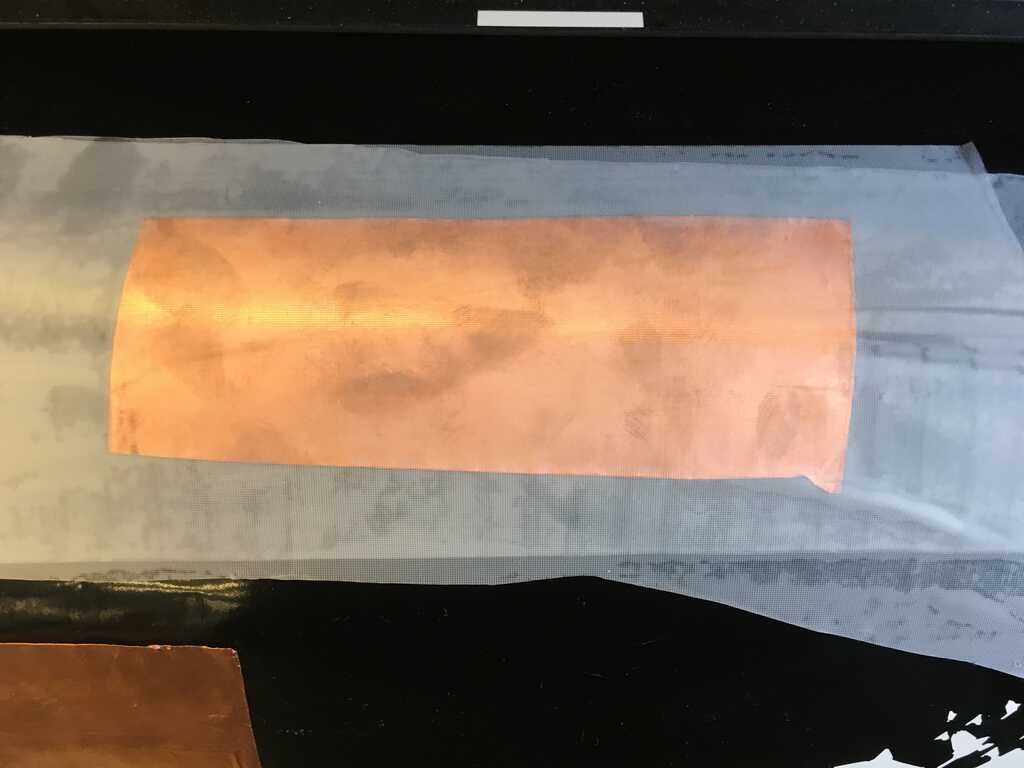

Frustrated, I looked at previous years' students' work. While I'm not exactly sure what Honghao Deng did, it put me on the right track. First, I peeled the copper tape. Next, I adhered the copper tape to the non-sticky side of some transfer tape. Finally, I adhered another piece of transfer tape on top of the back sides of the other two, making a transfer tape/copper tape sandwich, with all of the adhesive sides facing the same direction. I then adhered that sandwich to the vinyl roll.

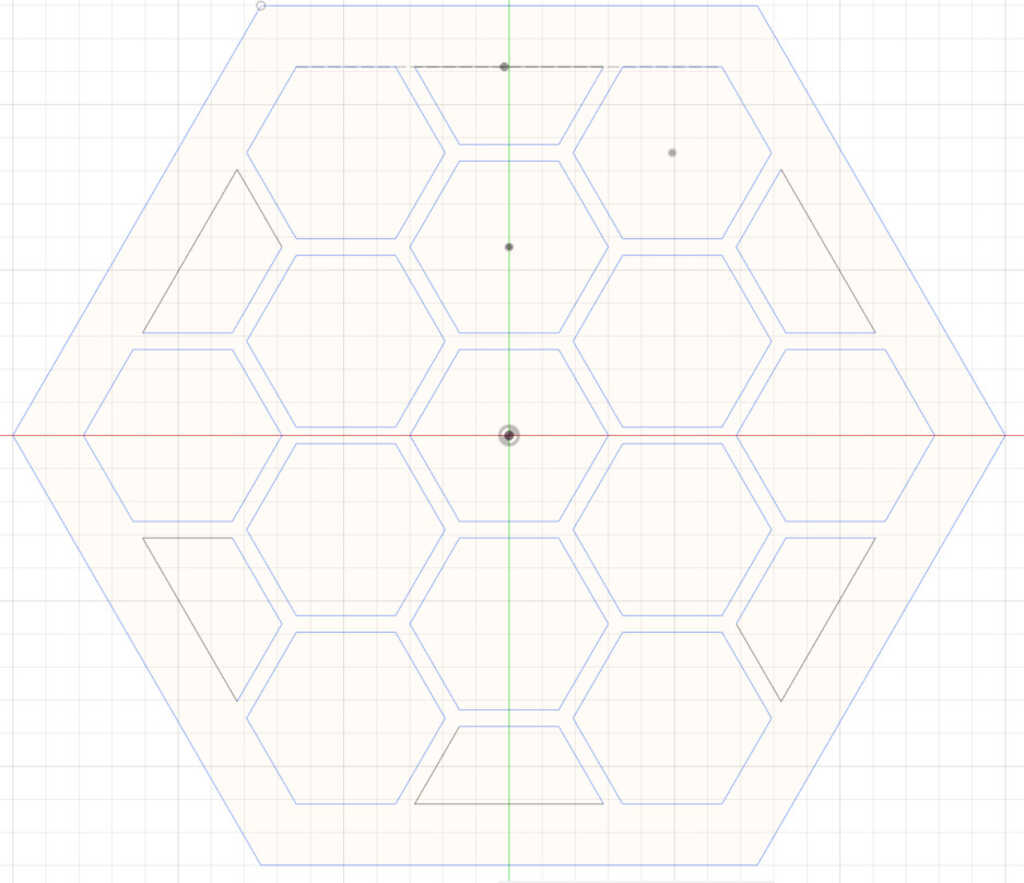

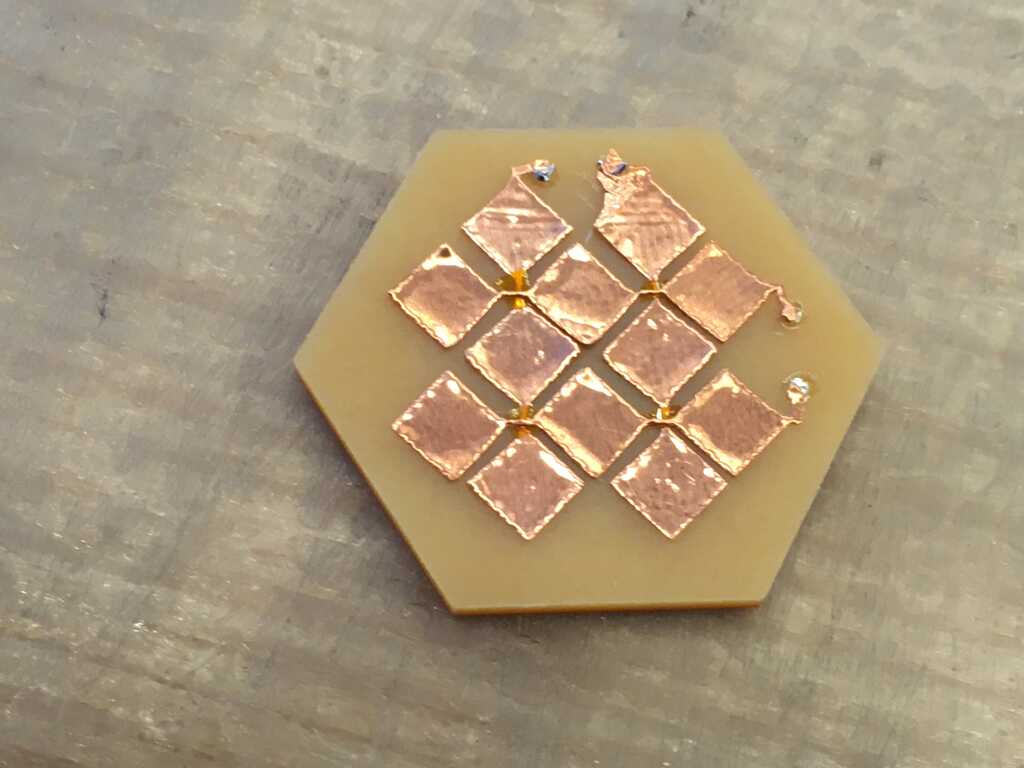

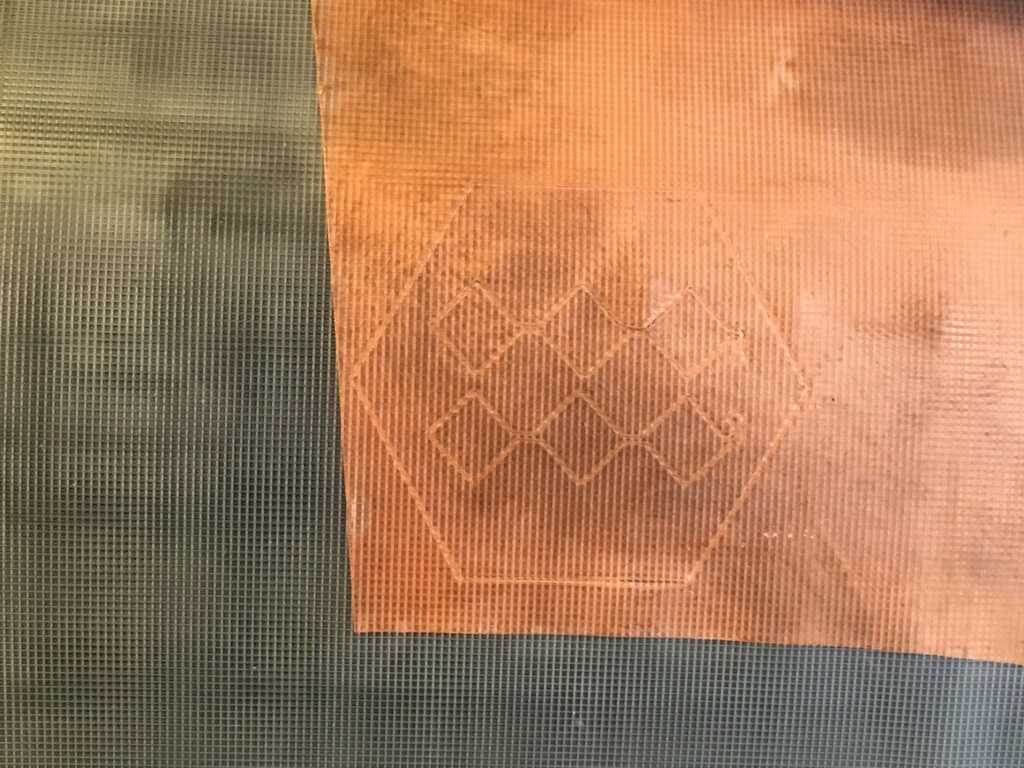

Since I was going to be cutting through so many layers, I tried 100g and 1cm/s at first, but that cut through all 3 layers. Lowering it to 80g, I seemed to get what I wanted! Once I cut it out, I cut around the rows with scissors. I peeled off the bottom layer, and smoothed it onto the hexagon module using a plastic card.

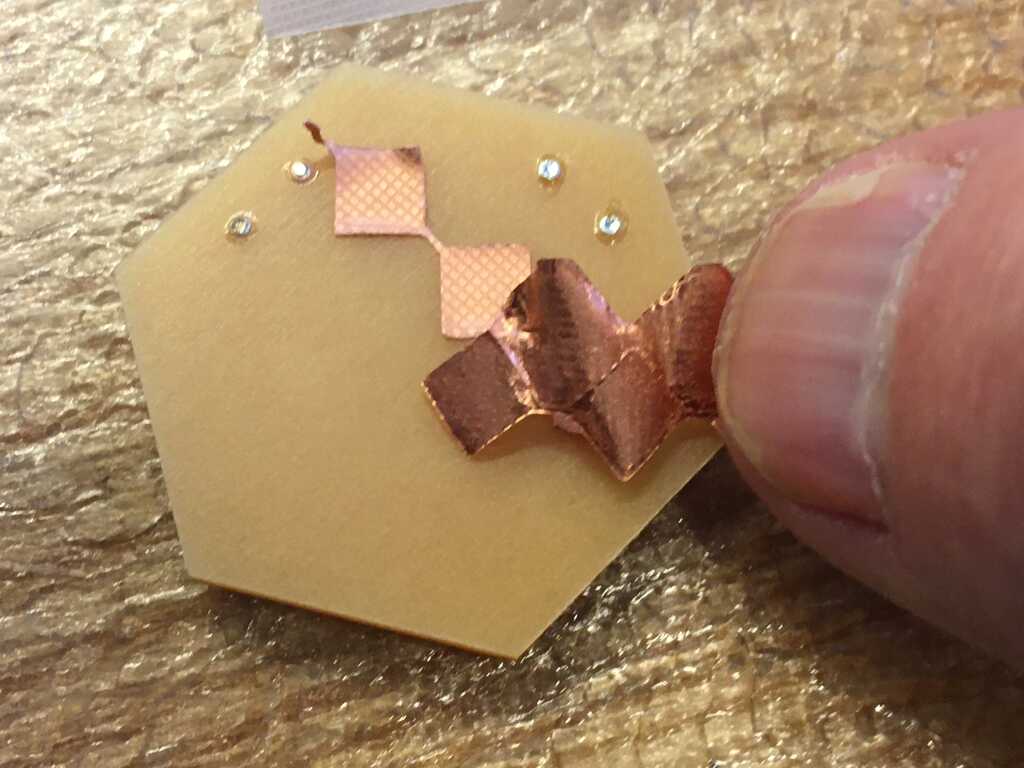

When I went to peel it, I unfortunately discovered that the vinyl cutter hadn't gone all the way through.

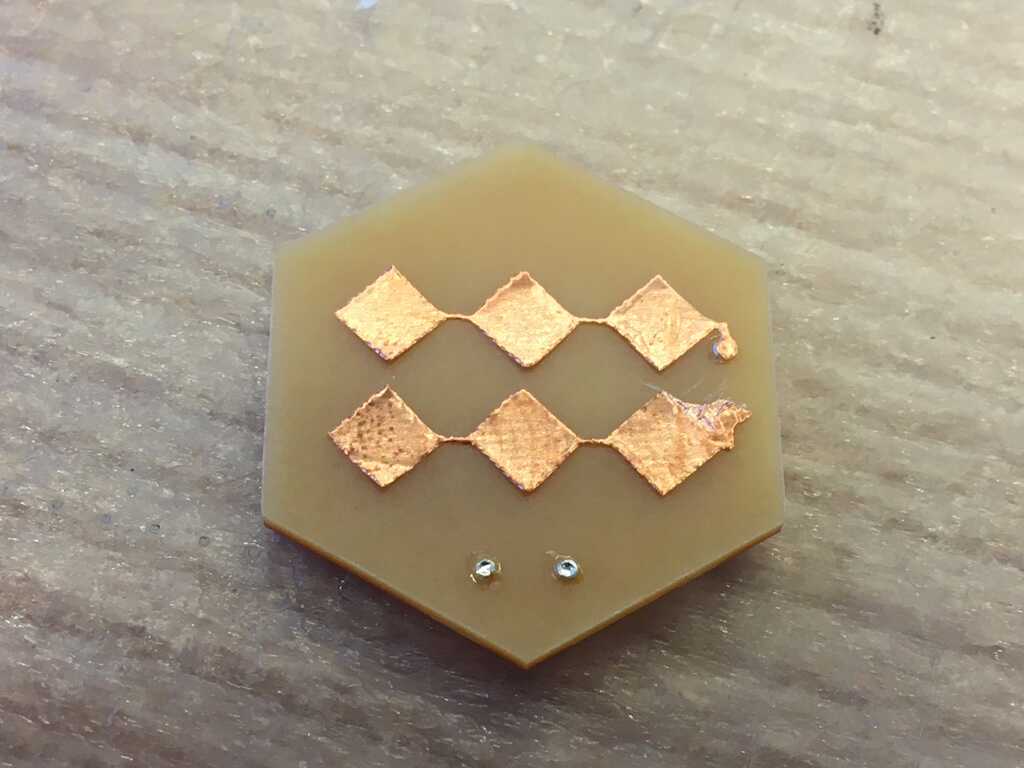

Not cutting through wasn't my only problem, I also had a hard time placing the square exactly right on the hexagon! Fortunately, when I exported the images from Illustrator, I gave them all the same dimensions, so if you stacked them on top of each other, they'd perfectly match up. So that meant that I could cut out a set of rows, and then cut out a hexagon on the same origin, and it would match up exactly. The other, major issue was not cutting all the way through. What I ultimately discovered was that two passes at 40g and 1cm/s gave me exactly what I was looking for.

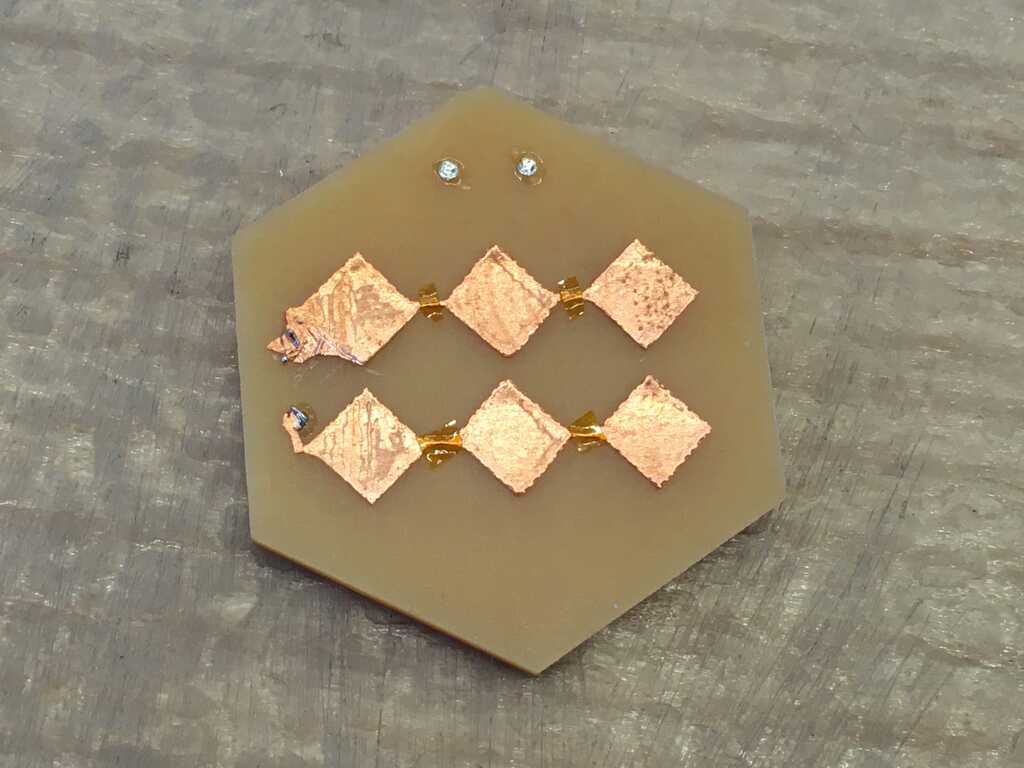

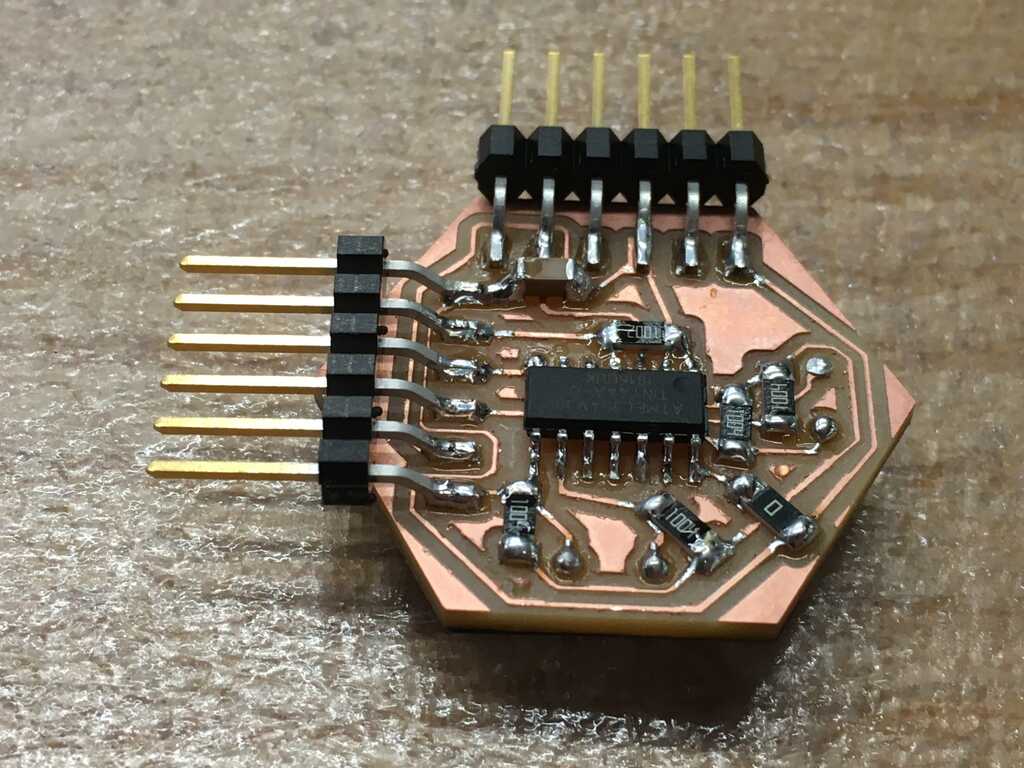

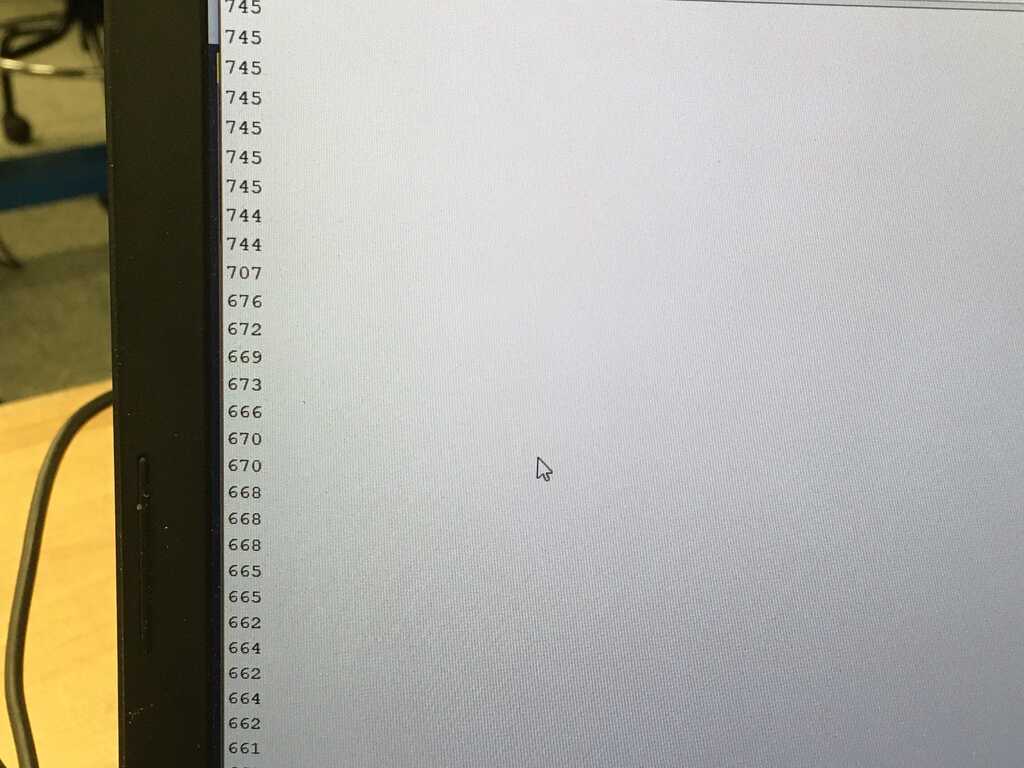

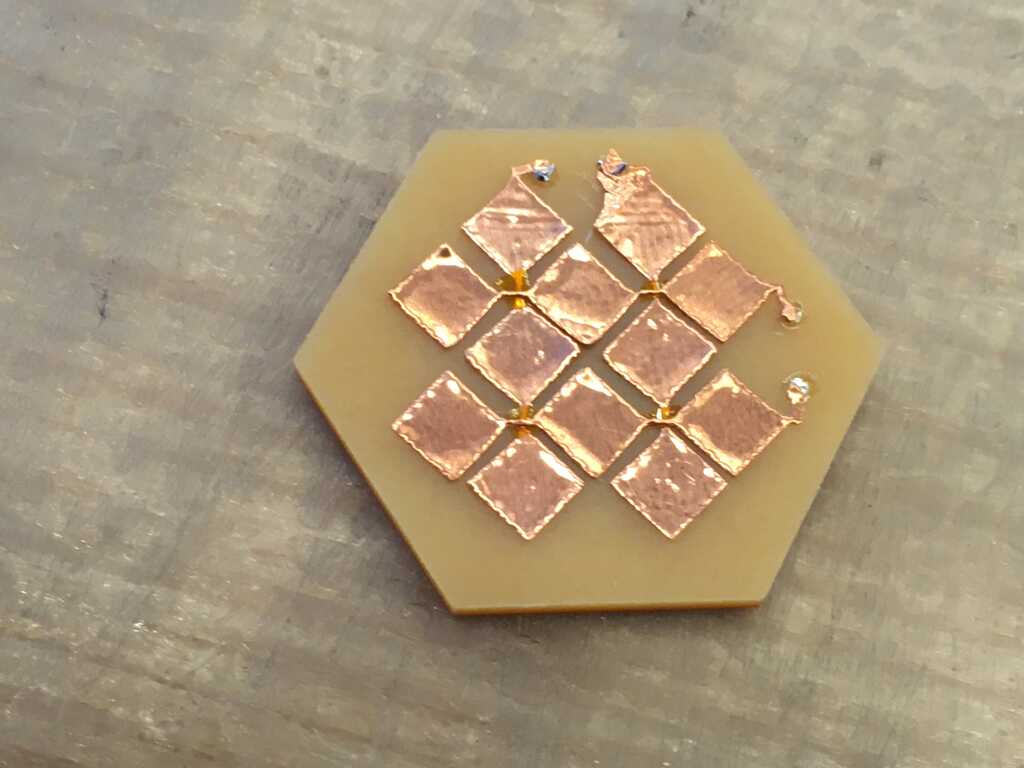

With a good cut, I was able to easily place and peel. I double checked my connections, and I wasn't getting any connection between the two rows and the other side of the board. There was already solder in the rivets, but that was placed before the copper tape. I then went and flowed a bit more solder through the rivets, and briefly touched the iron to the tape contacts to secure a connection. It worked beautifully.

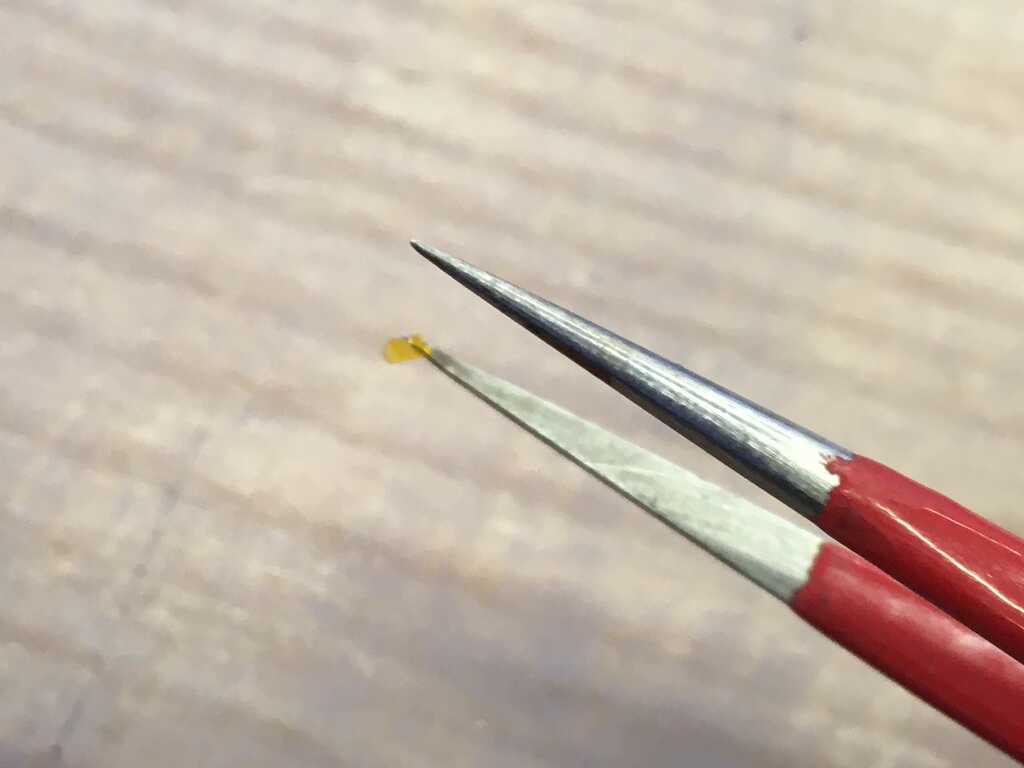

Now, the next part isn't as easy as slapping the other rows onto the board. I have to make sure the two layers are insulated from each other. Otherwise, I'd essentially just have a large chunk of copper on one side of the board. To get that insulation, I used Kapton tape. It can apparently withstand high temperatures, but I'm not using it to its full potential here.

Taking very tiny pieces, I placed them over the junctions of the rows. I had to use two tweezers to manipulate these miniscule chunks.

The second set of rows went on even smoother! Slightly misaligned (my fault), but there weren't any shorts and a bit of solder connected everything back, so no problem at all.

To top everything off and give it a smooth finish, I cut out another hexagon out of vinyl and slid it on. Check out how thin the actual capacitive layer is!