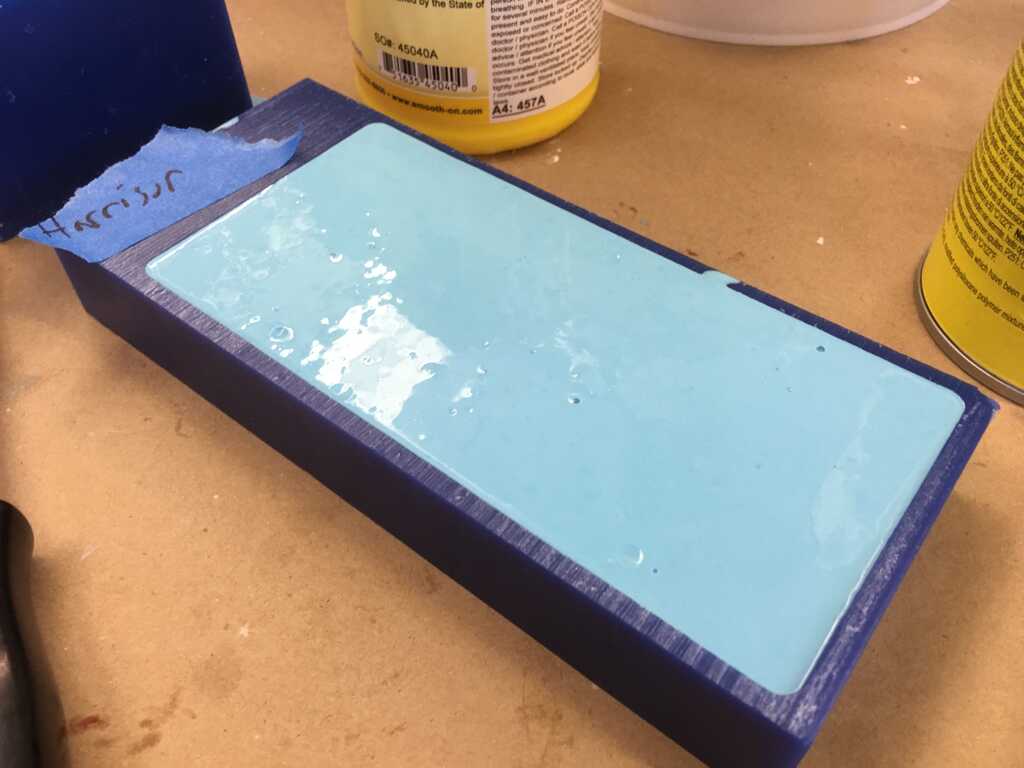

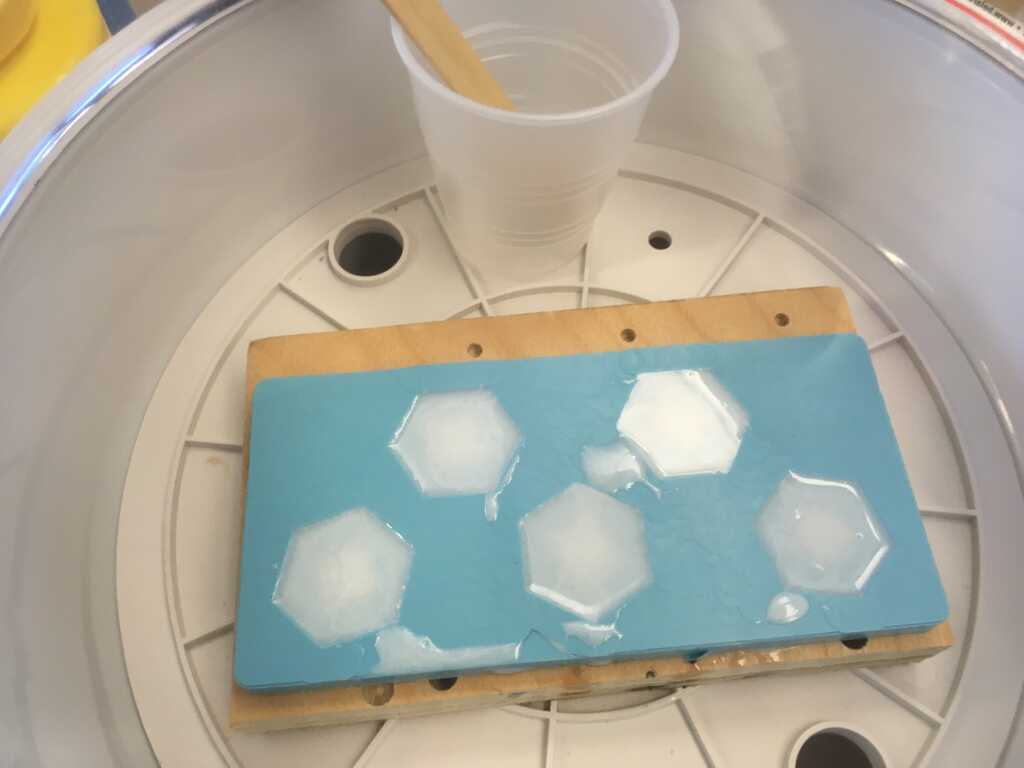

I planned on using Smooth-Cast 305 for many components (cures fast, solid color, plasticky), but I wanted to try the 326 first.

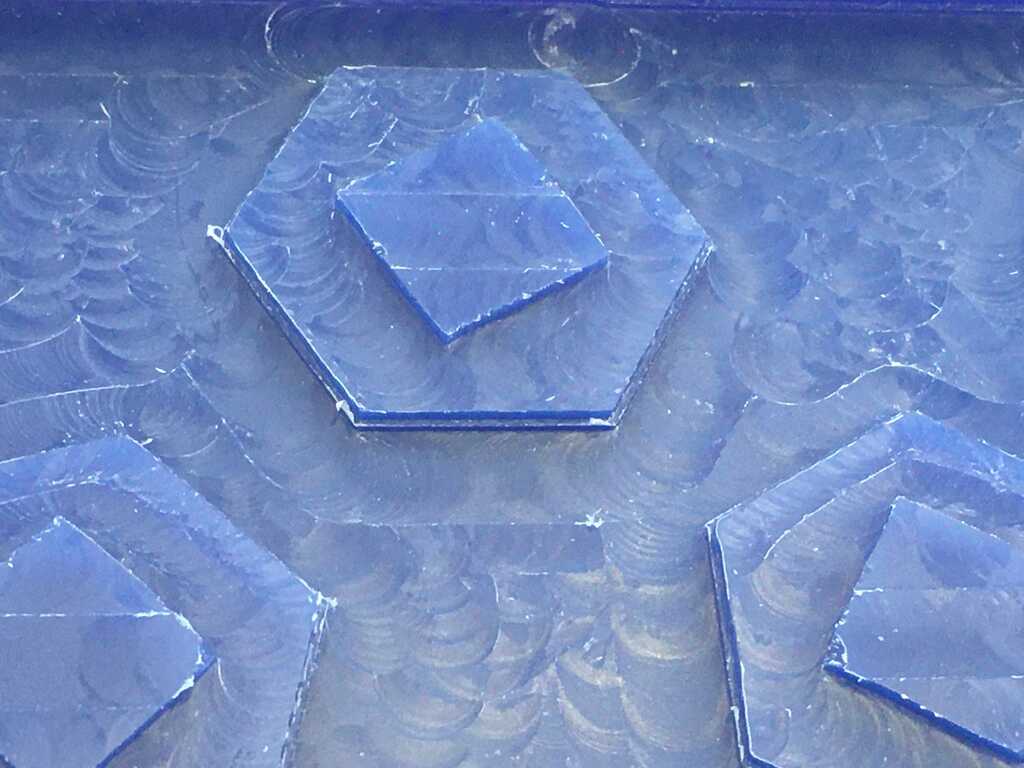

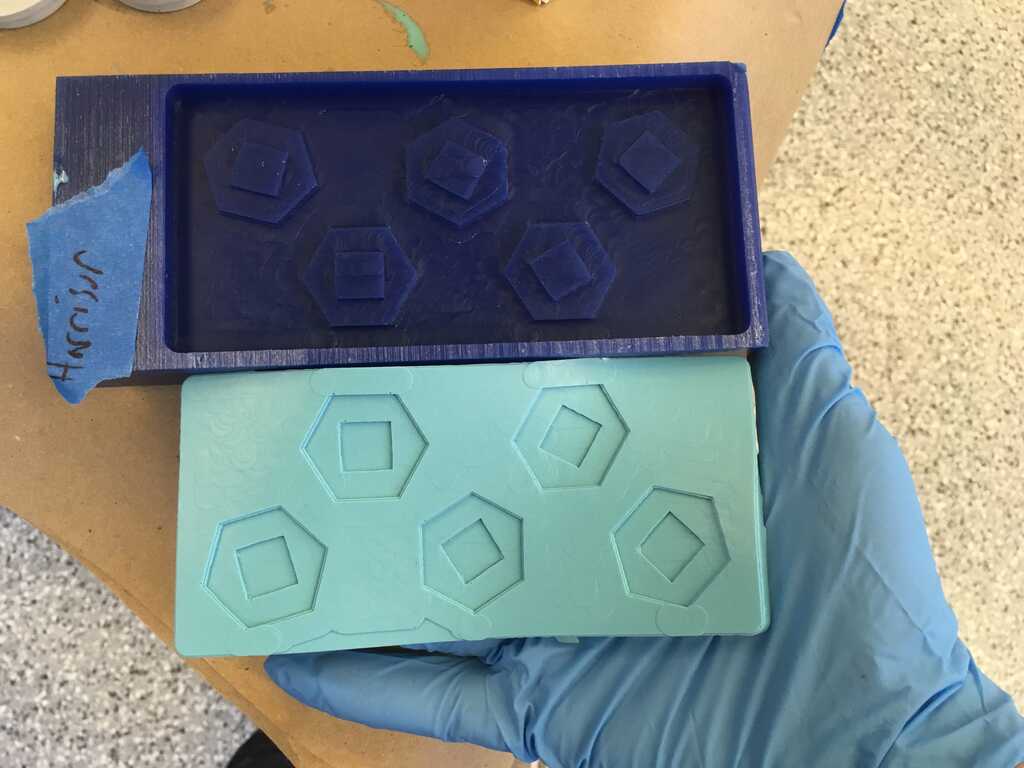

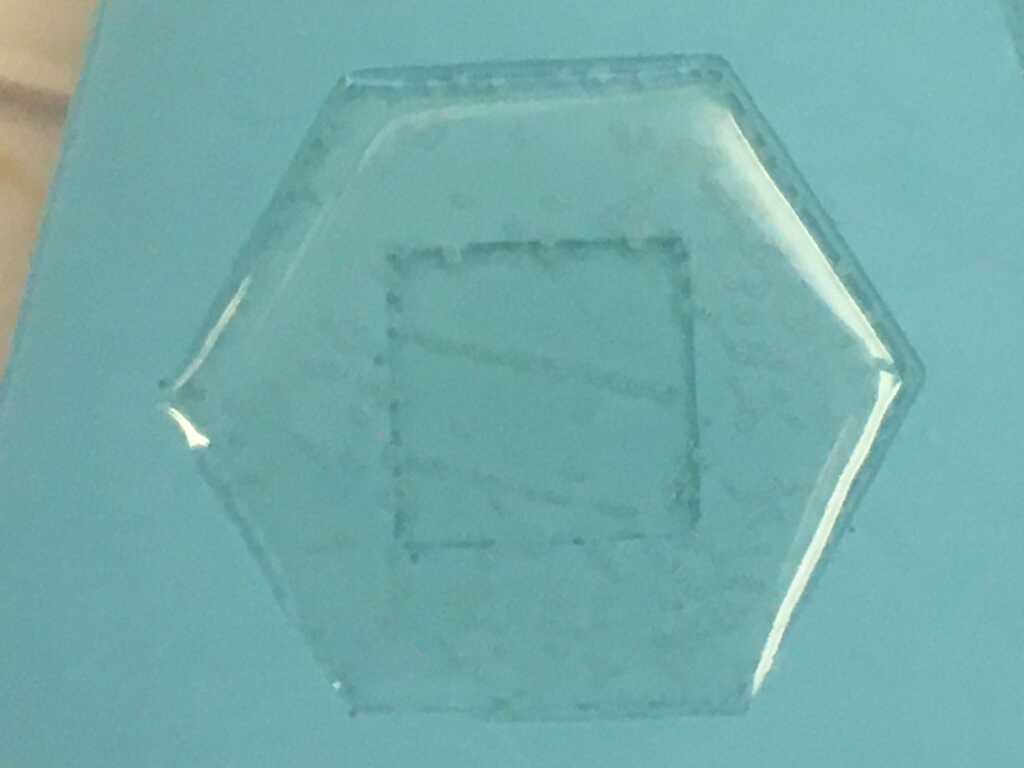

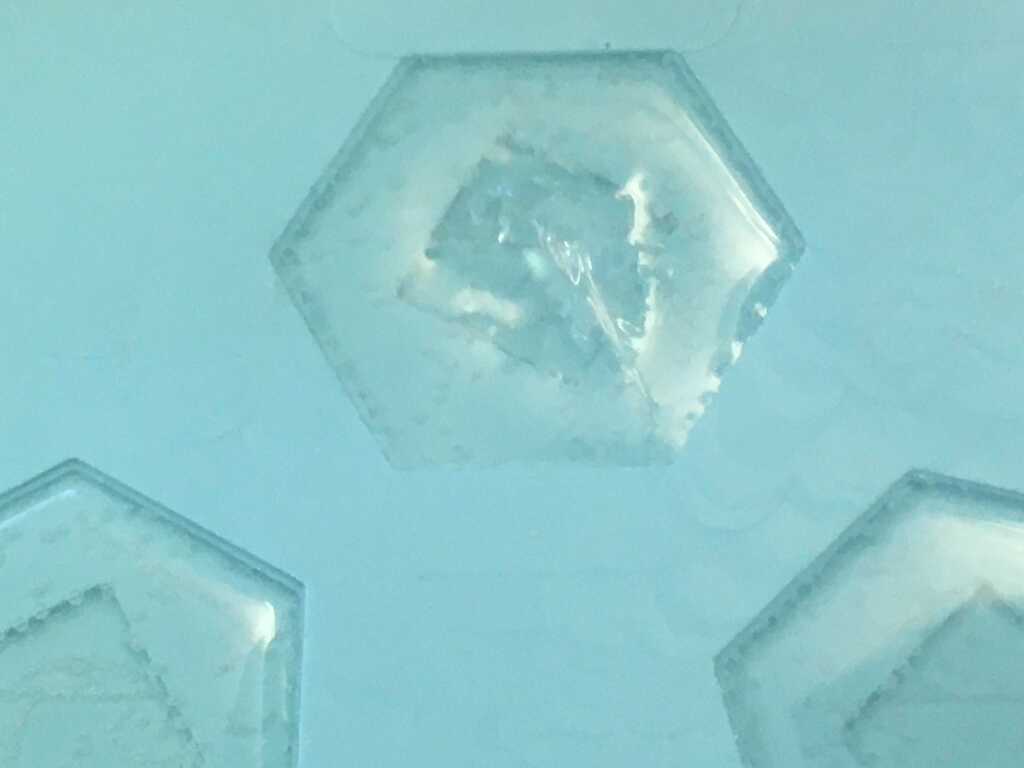

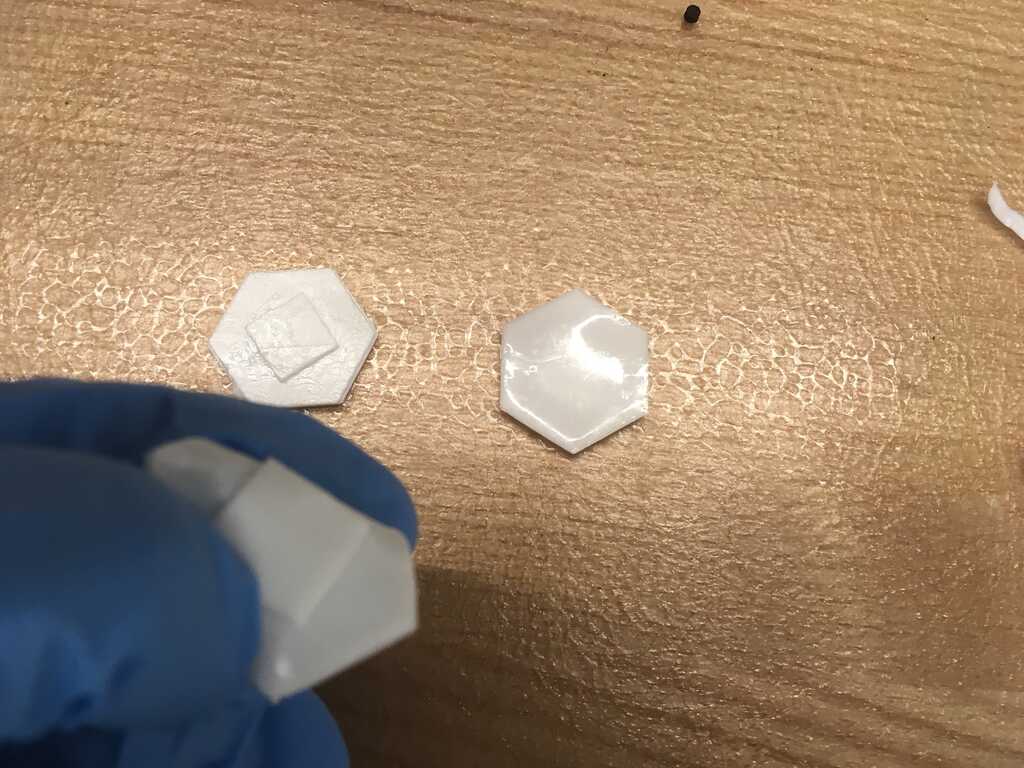

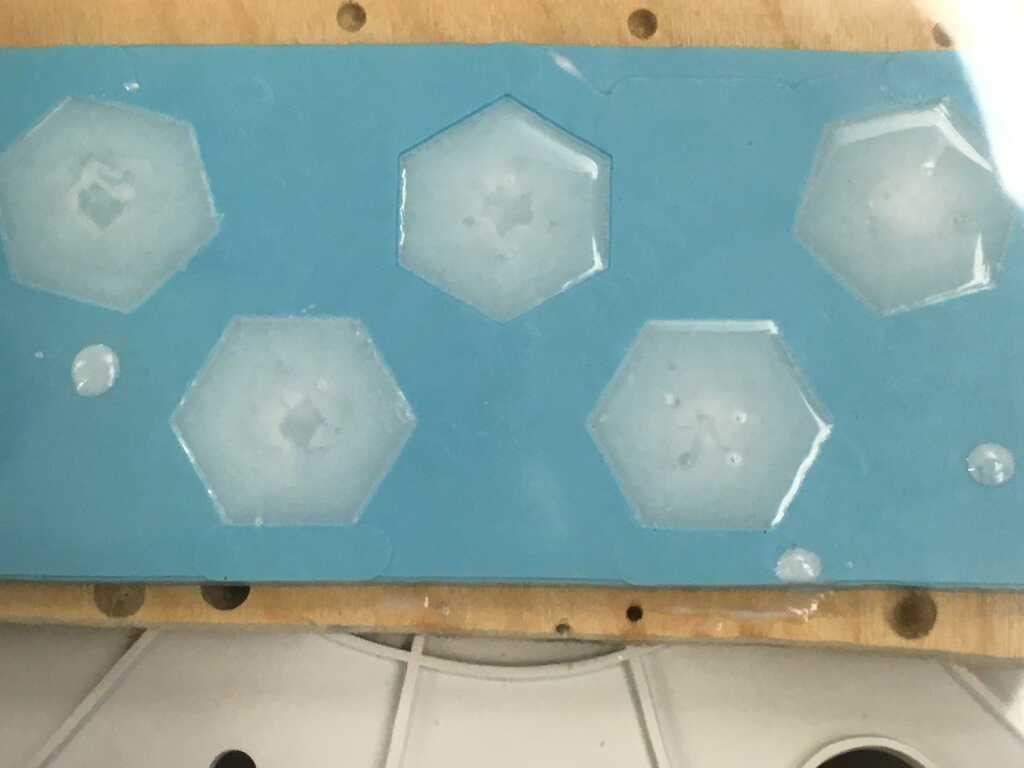

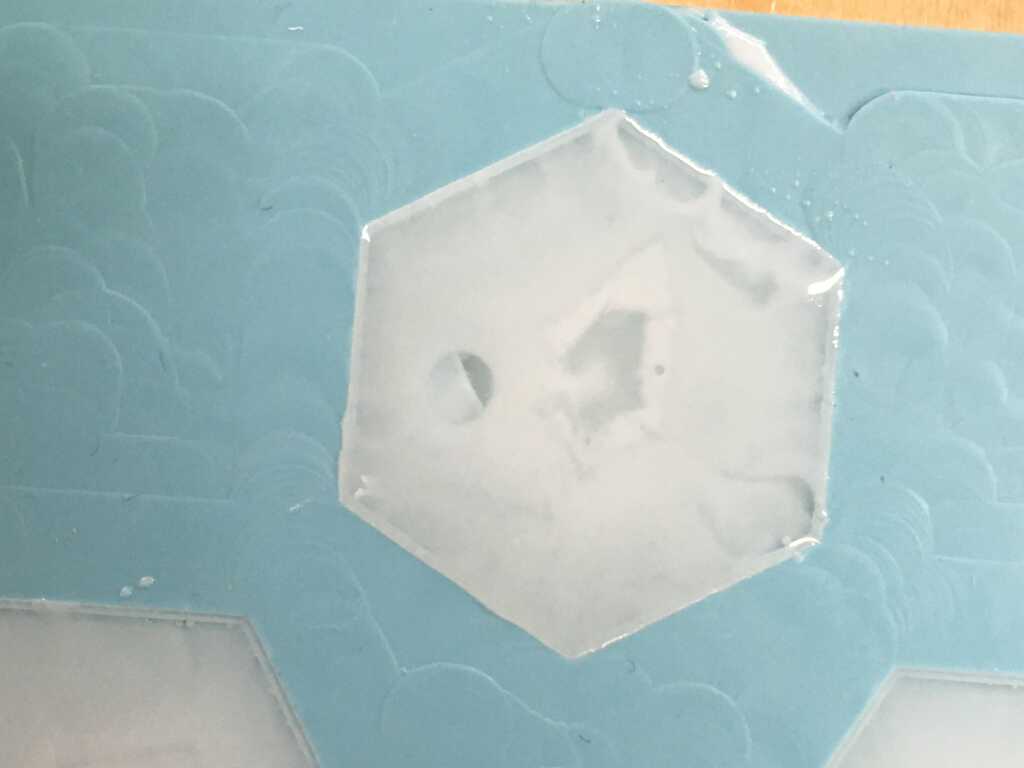

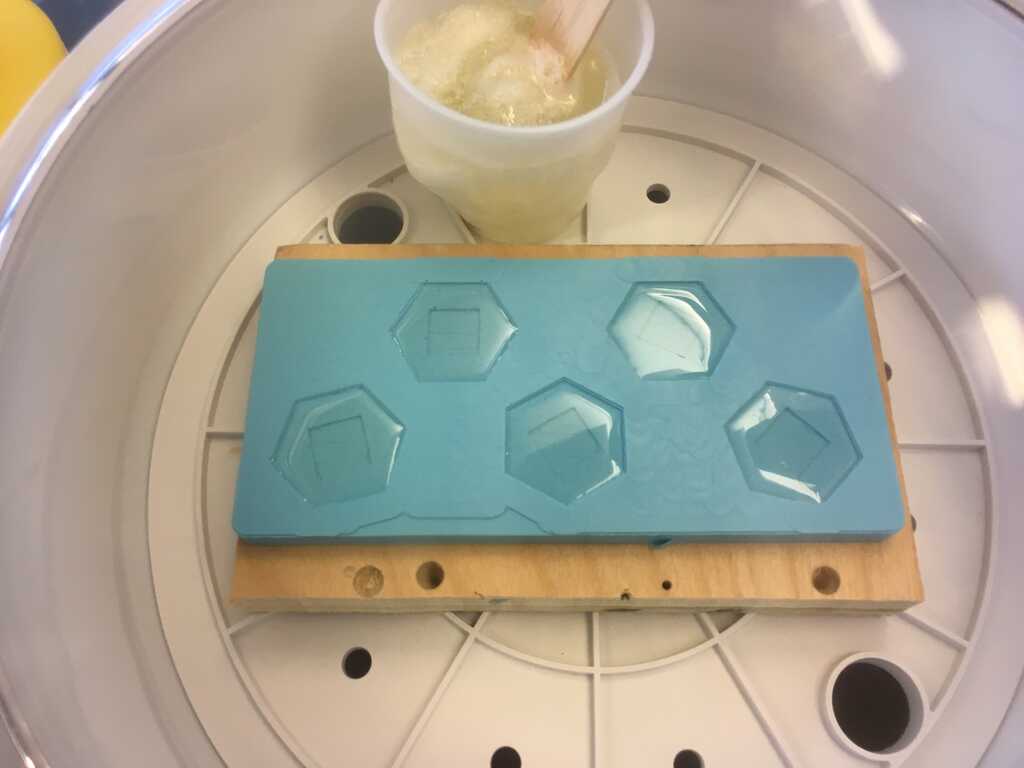

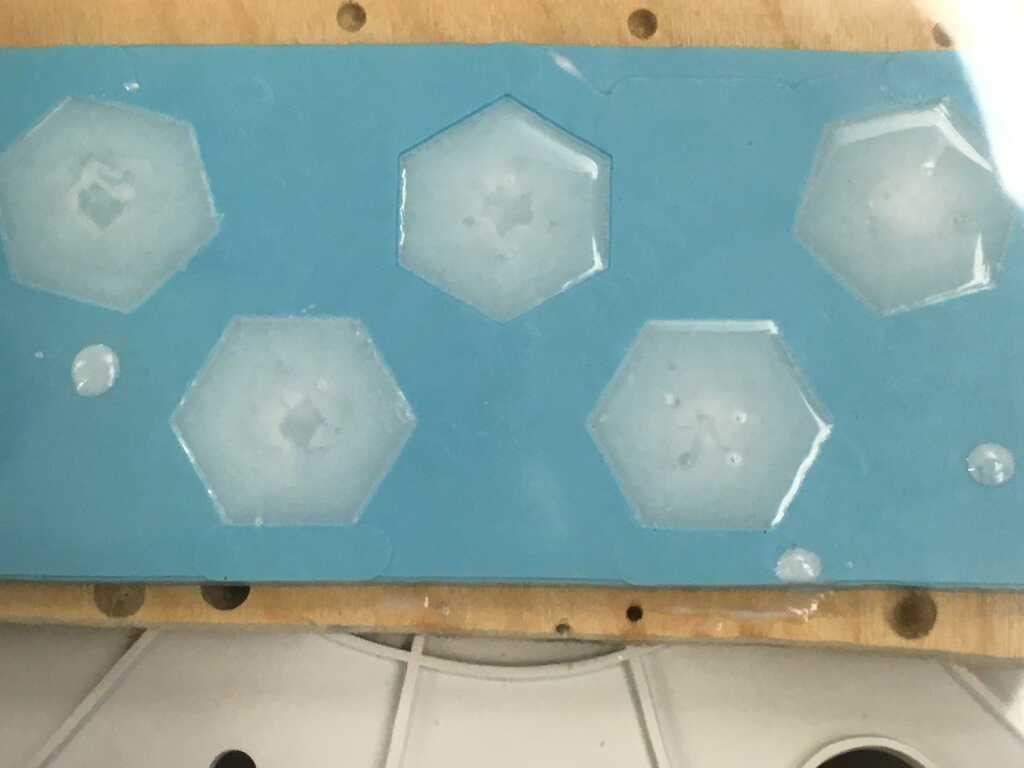

Even after using the vacuum, it still came out with a ton of bubbles. It also took a long time (> 1 hr) to cure, and my impatience yielded an imperfect cure on one of the hexagons.

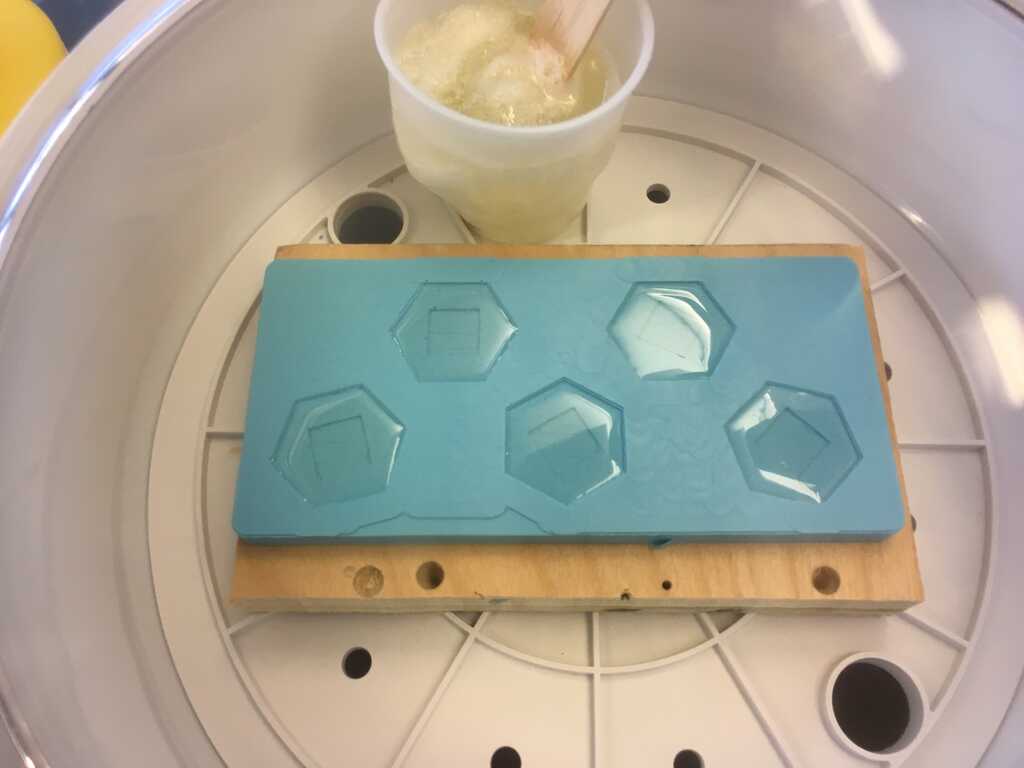

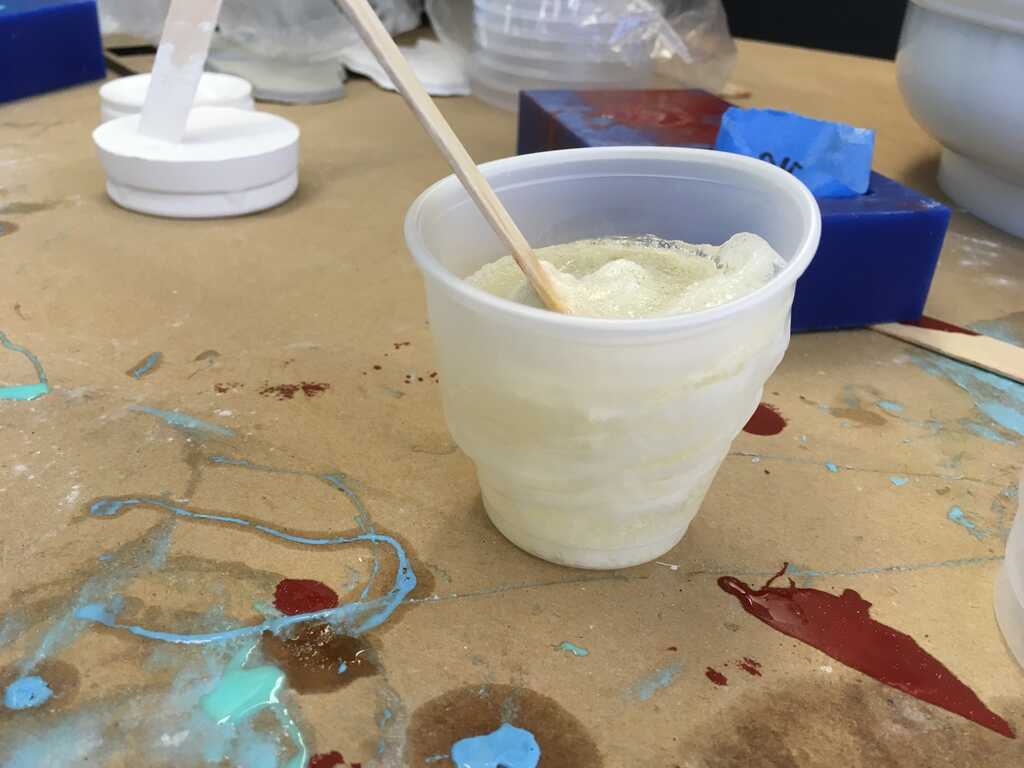

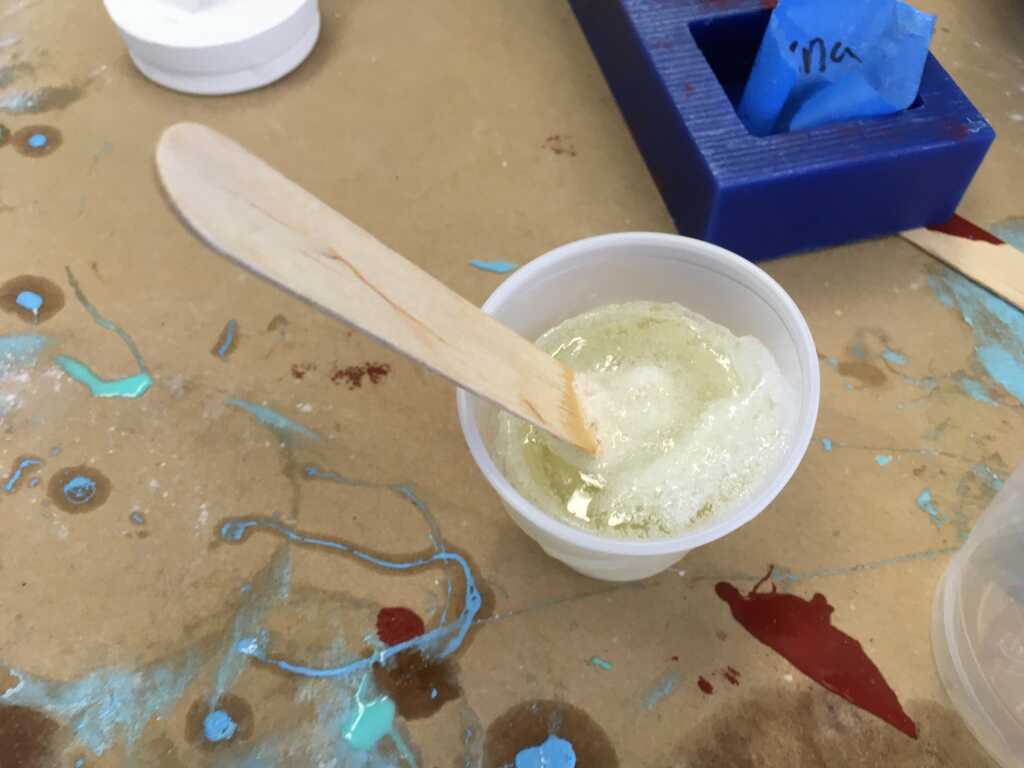

I also made a critical error with the 326. It poured much faster than the Oomoo, so I accidentally poured too much Part A into a cup. Once a liquid is poured, though, it's poured, and there's no going back. No one else needed the 326 at the time, so I poured enough Part B to get it to cure, filled in my mold, and let them sit. When I came back to it, the combined 326 in the cup had heated up so much it had melted part of the cup. I learned that the curing reaction is exothermic, and in large quantities, ramps up rapidly. Curing becomes much much faster. This can get much worse with materials such as Epoxy, which can smoke and even catch objects on fire.

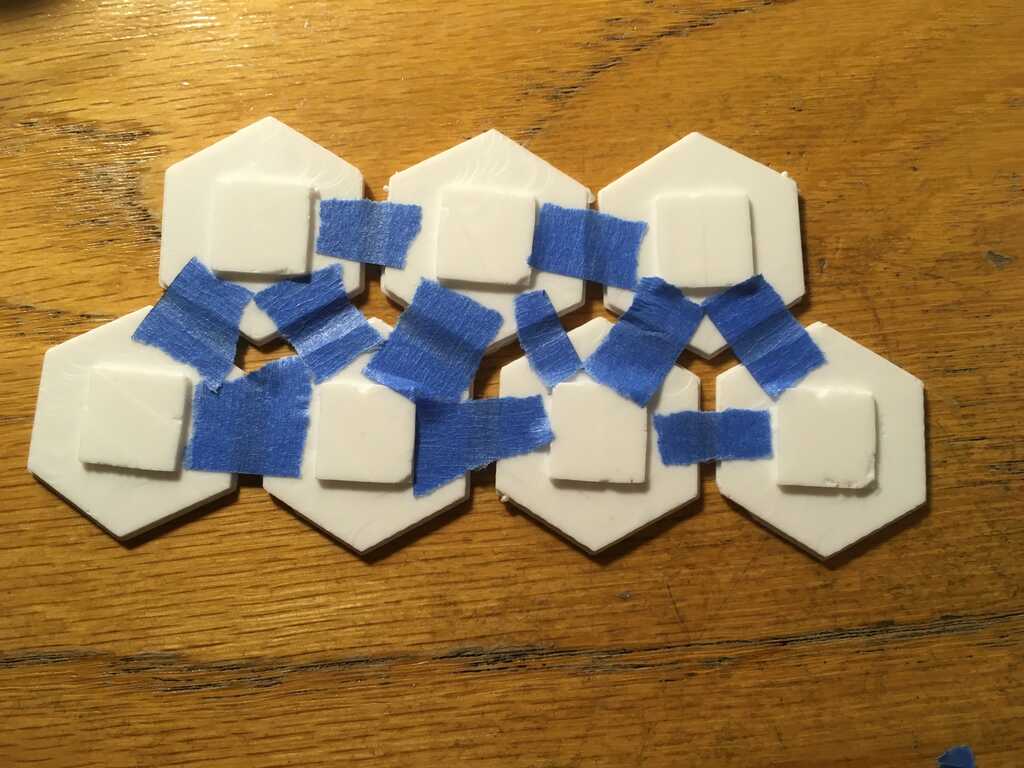

Another takeaway from this is that thinner objects don't heat up as much, and will cure much slower (hence why my hexagons take longer than average to cure). To avoid this with the 305, I combined just barely enough of each, and poured them into the mold. 5 hours later, none of them had cured. They were still very bendy, so something had to be wrong. I'm pretty sure that because I mixed such a low quantity, the amount of substrate that stuck to the inside of one of the cups was significant enough to get an incorrect ratio.

From then on out I used a scale, and poured both parts directly into the same cup, following the required 10:9 weight ratio. E.g. 10g of Part A, and 9g of Part B, leading to a total mass of 19g.

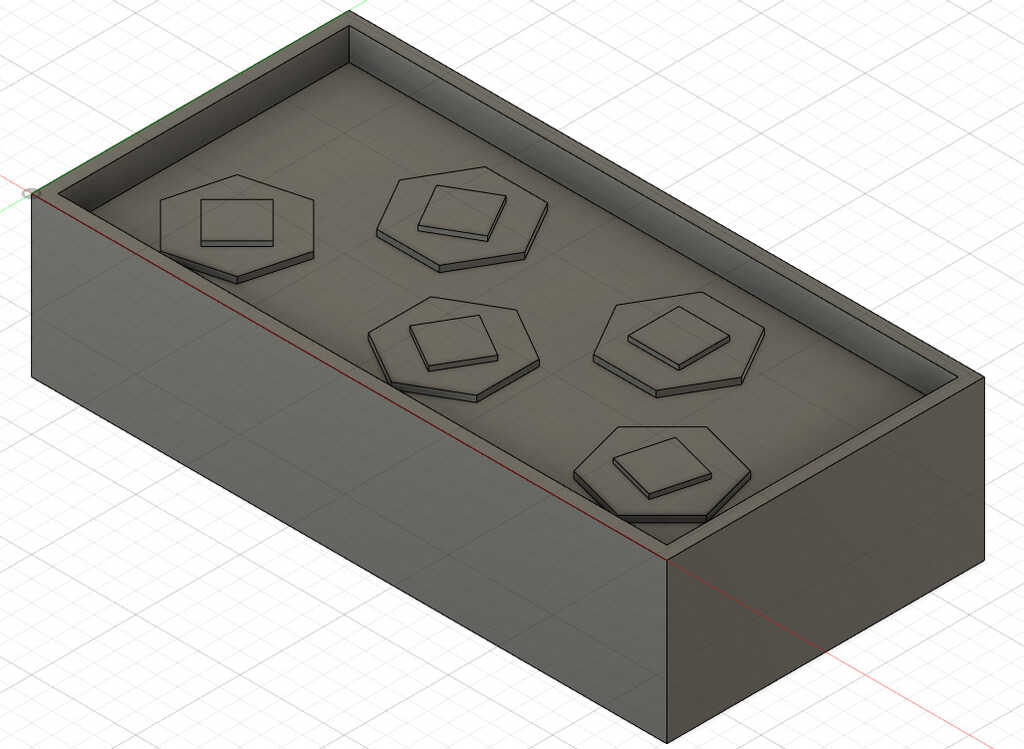

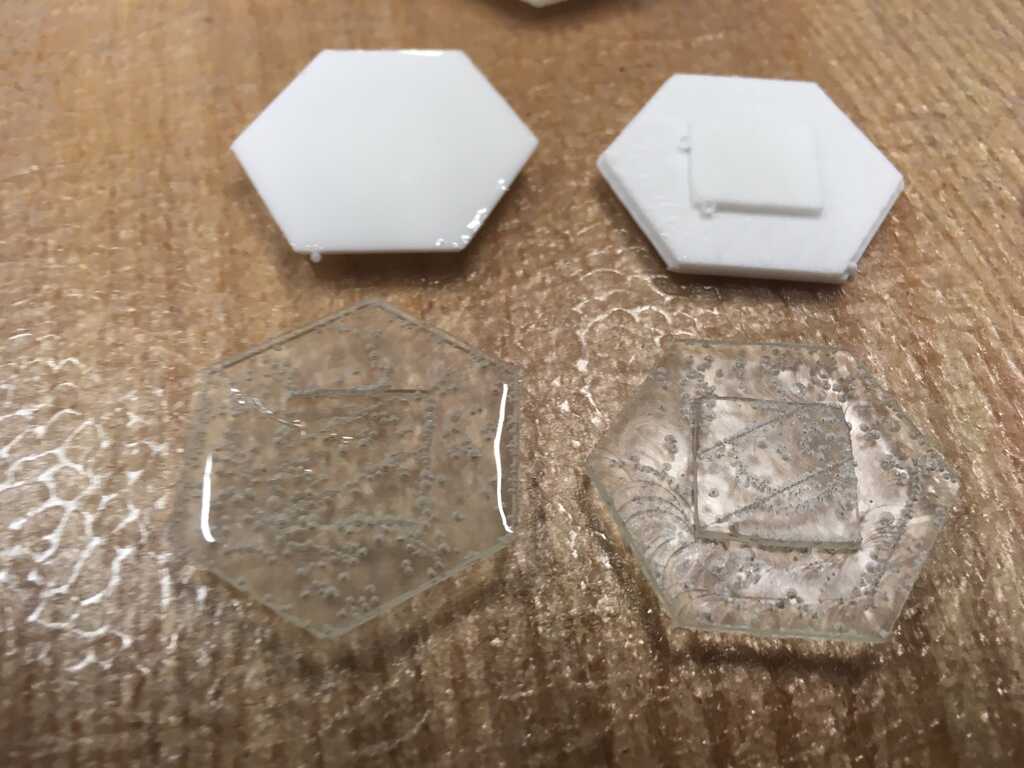

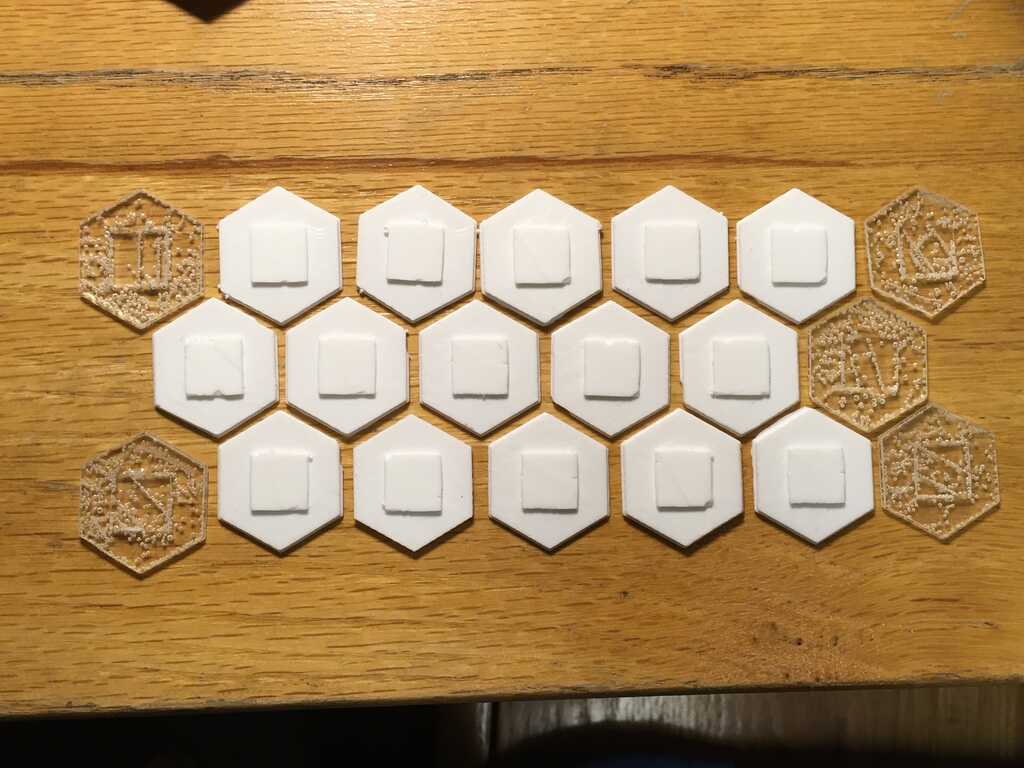

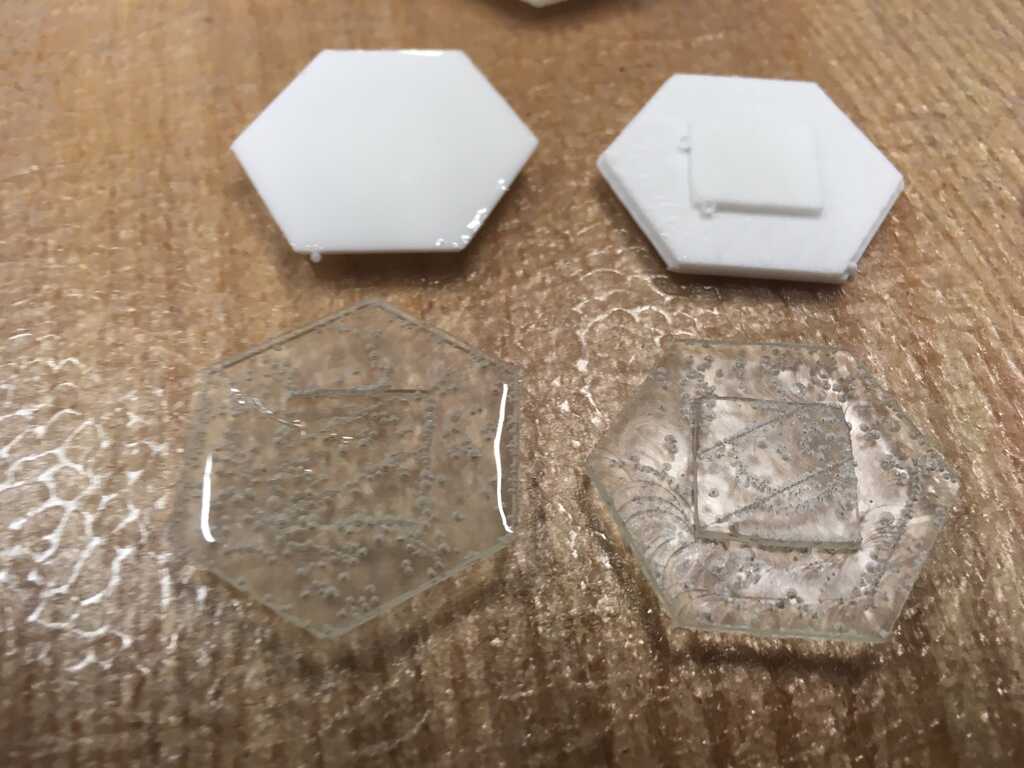

Here's the 326 and 305 side by side:

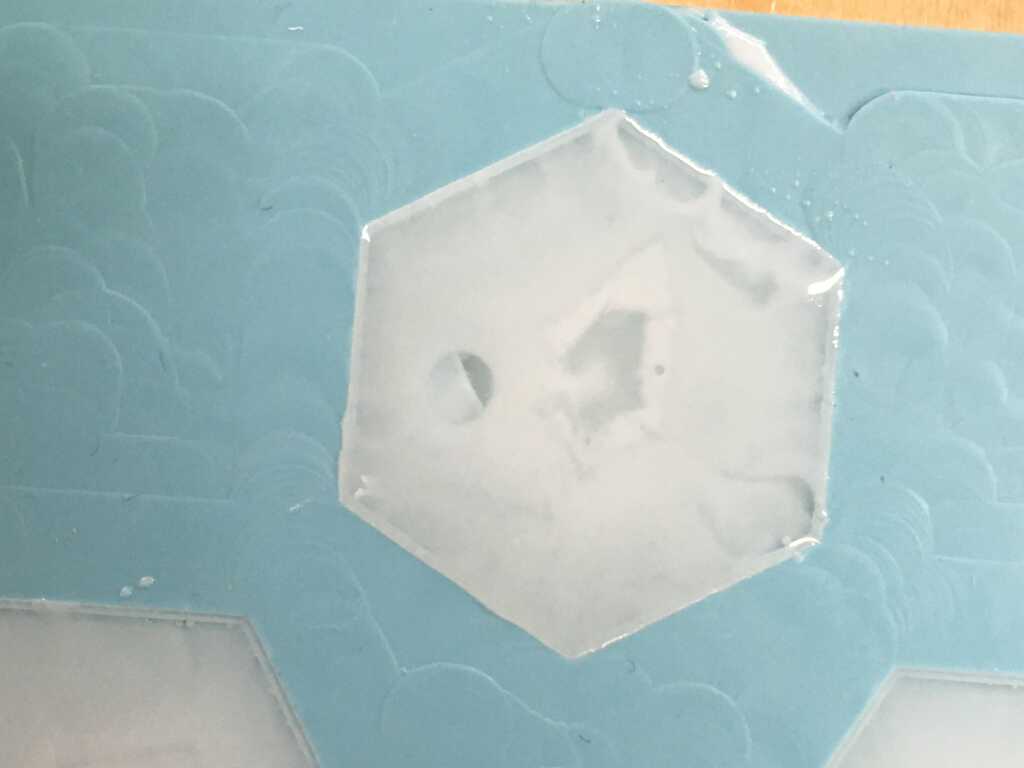

I also wanted to do a batch without the vacuum chamber, which looks like there may be a large bubble in one of the pieces, but I didn't notice it once it cured all the way.

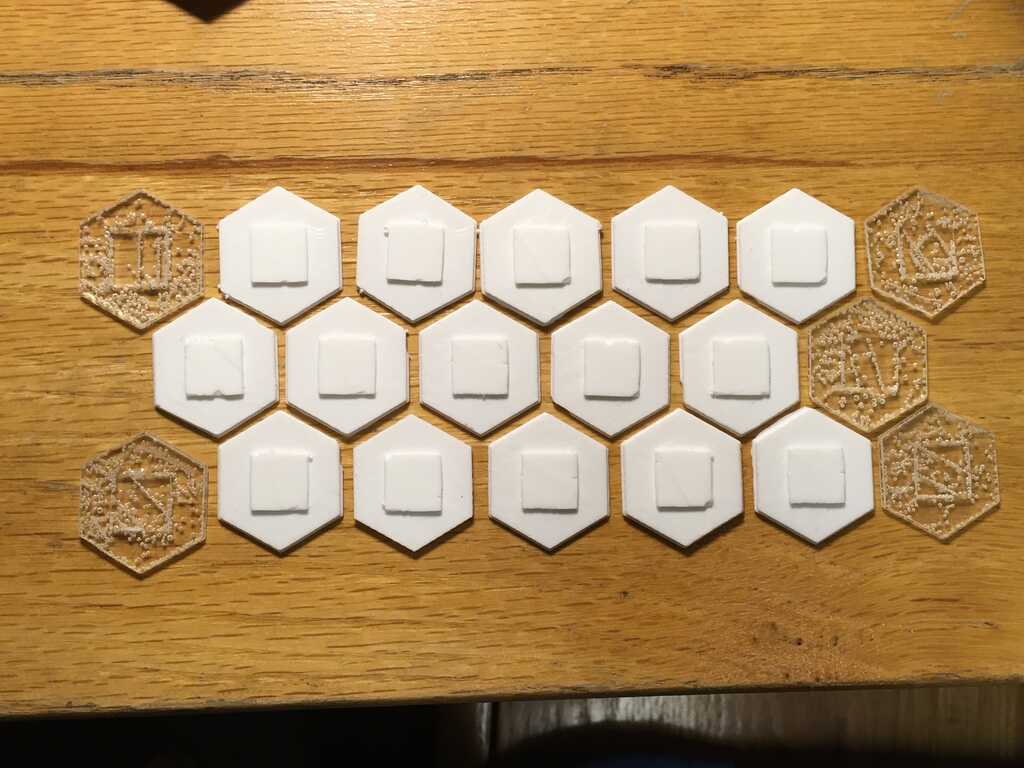

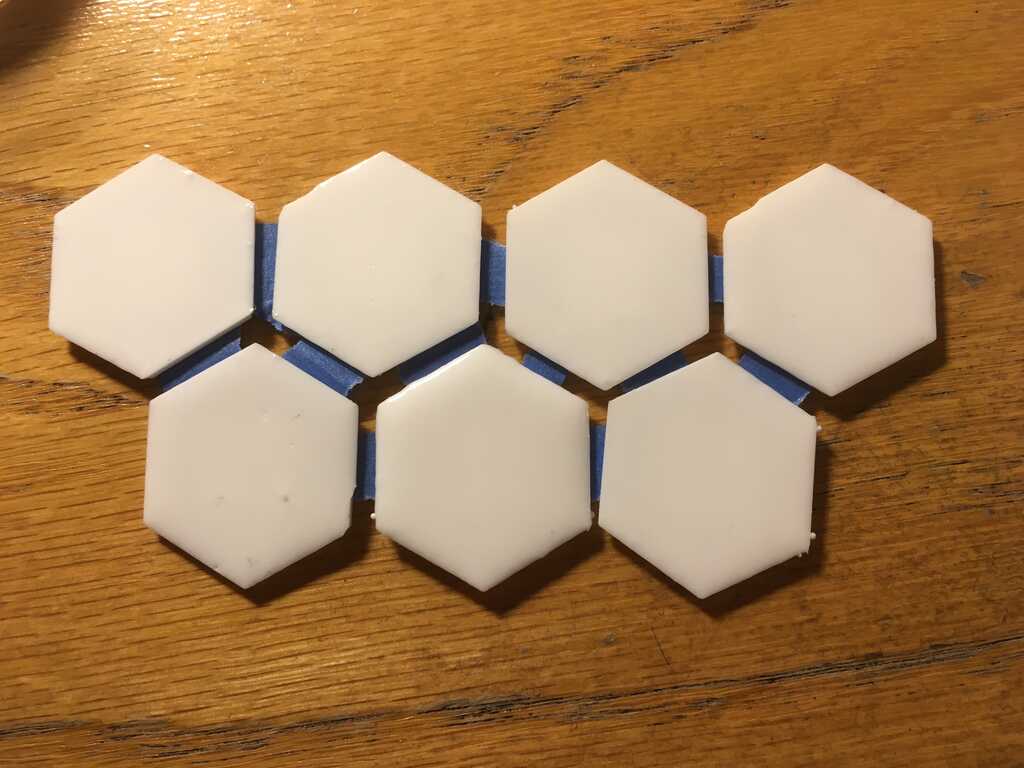

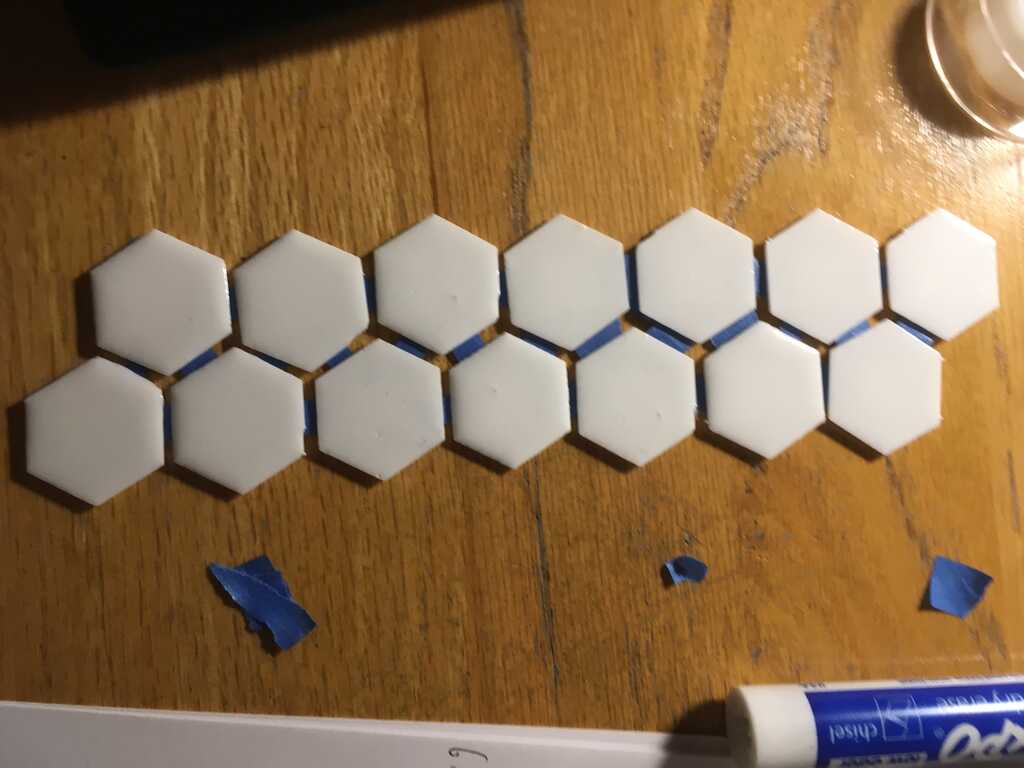

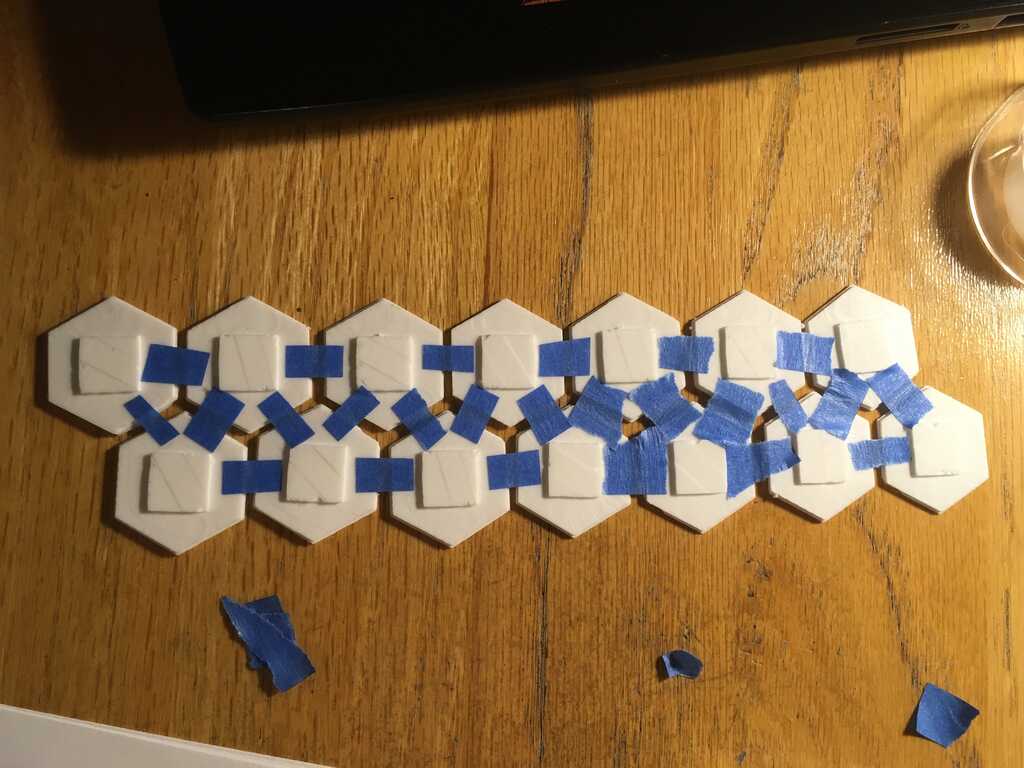

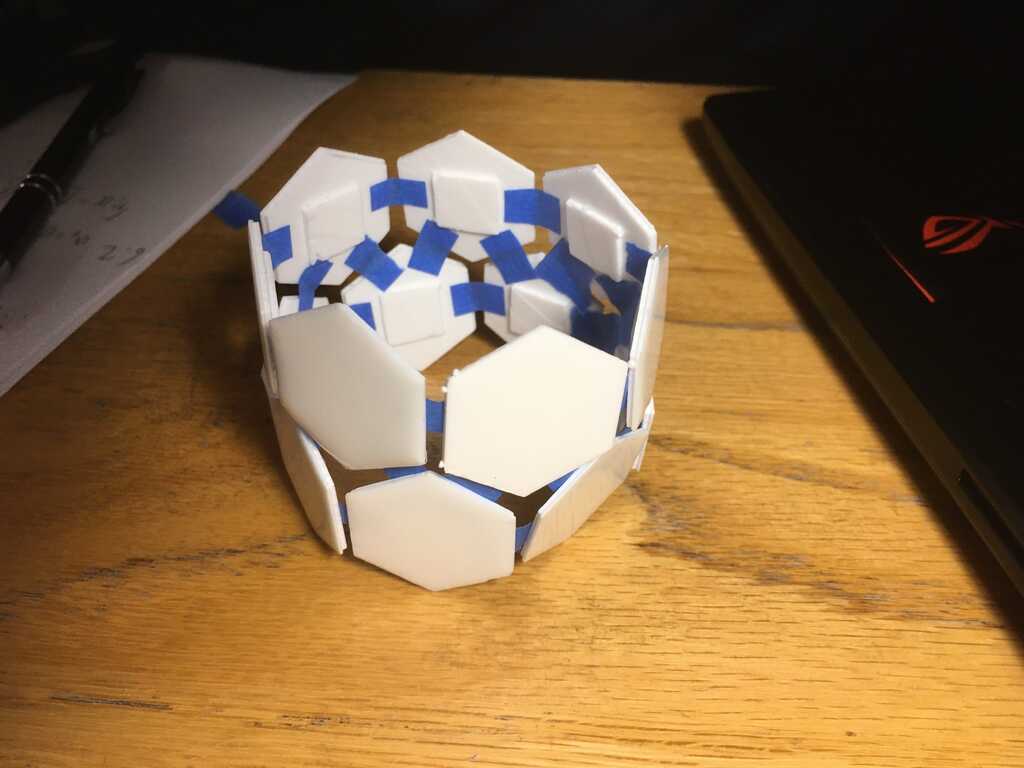

Here's all of the pieces laid out together: