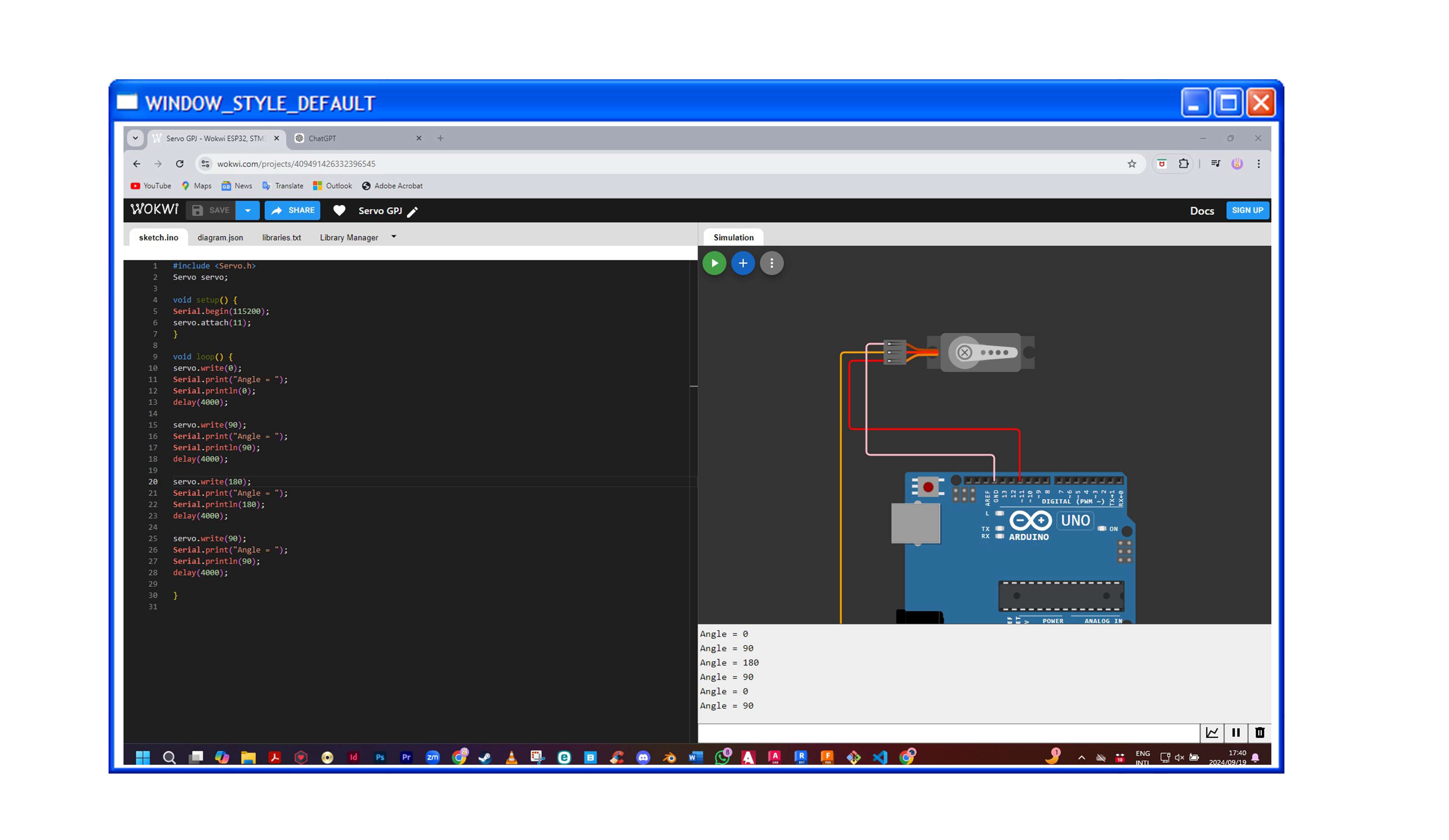

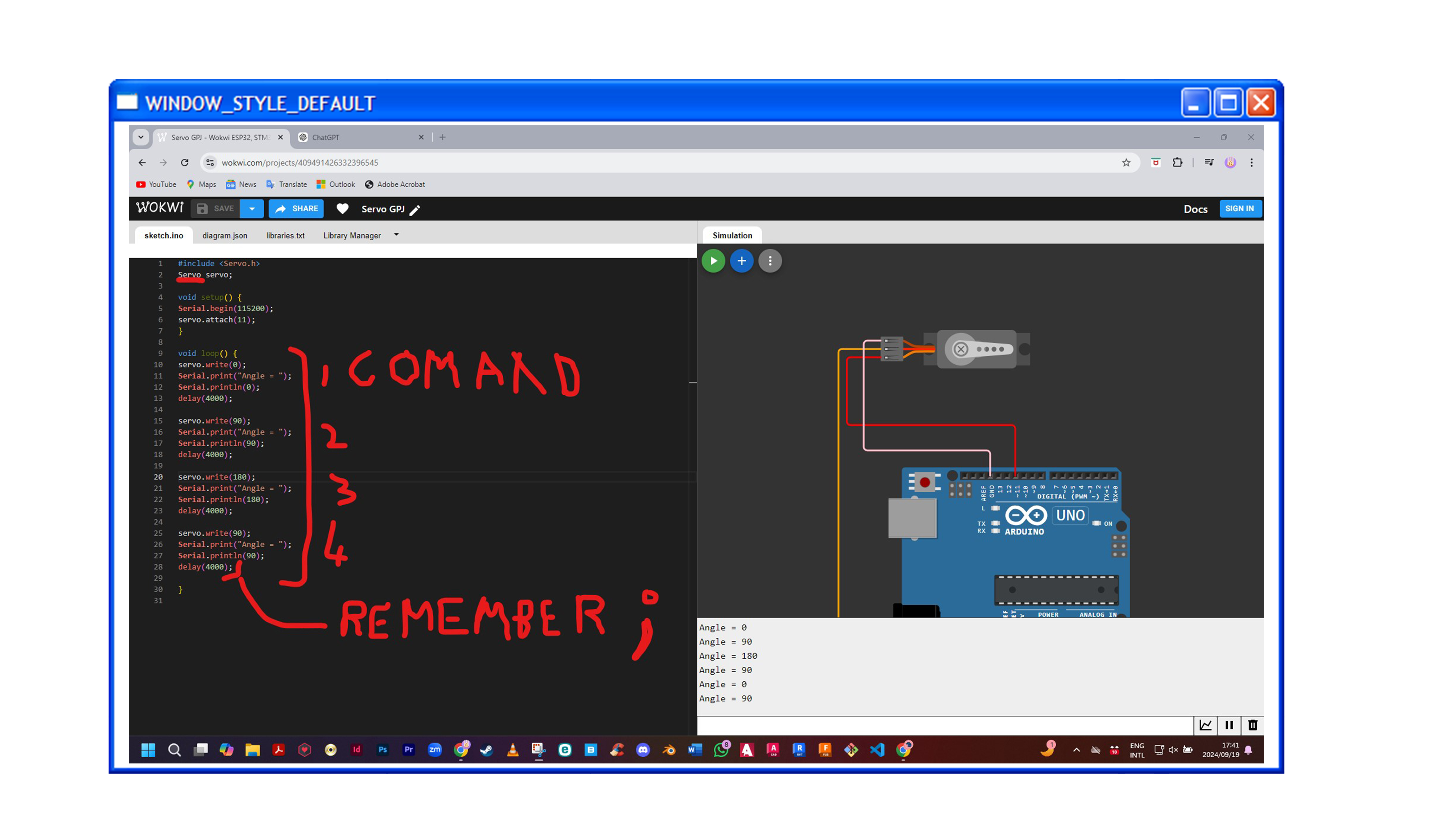

This week we were tasked to design a layout of electronic components. I have to warn the reader that my knowledge of this topic is quite limited so forgive me if I use the wrong terminologies. I started by experimenting with an online software called WOKWI. Here the program allows you to simulate electronic circuit boards and their interaction with electrical devices. I started by following a tutorial which operated a servo motor. Here I discovered a few things. Firstly, I now know why semicolons are important as I neglected to add all of them precisely as in the tutorial and that caused my build to fail. Secondly, I learnt that I had some misconceptions about electronics. Initially, I thought that each item (like for example a servo motor) would work independent of programming which dictates its behavior. For example, if you attach a battery to a computer fan it would no doubt run. I thought this was a similar situation to what you would find in other types of electronics – but now I understand that the programming element is there to give commands to the hardware which then follows through on the orders.

As I delved deeper into the software, I began to appreciate the importance of component selection in circuit design. Each component not only serves a specific function but also influences the overall performance and efficiency of the project. Understanding the specifications of various components, such as voltage ratings and current requirements, became crucial. This awareness will guide my future projects and help me avoid common pitfalls associated with incompatible parts.

By tinkering with the code a bit, I realized that I could adjust the speed of the intervals of the rotation by changing the delay. Each paragraph of the code is an individual input or command which tells the system which operation to complete. I also discovered the limitations of the motor itself. It cannot do a full rotation of only about 180 degrees, but I can tell it where to stop by adjusting the angle and the delay. There is another type of servo motor, which is called the continuous rotation servo motor which allows you to do a full rotation, and for the moment might serve my possible interests more. Furthermore, I learnt that each of the microprocessors (controllers) like the Arduino, Raspberry Pi, and SEEED each have their strengths and weaknesses.

Workflow

Embedded Electronics Images

I installed the libraries to the servo motor.

I realized that I could influence the machine with each paragraph of code, where each line is a unique command.

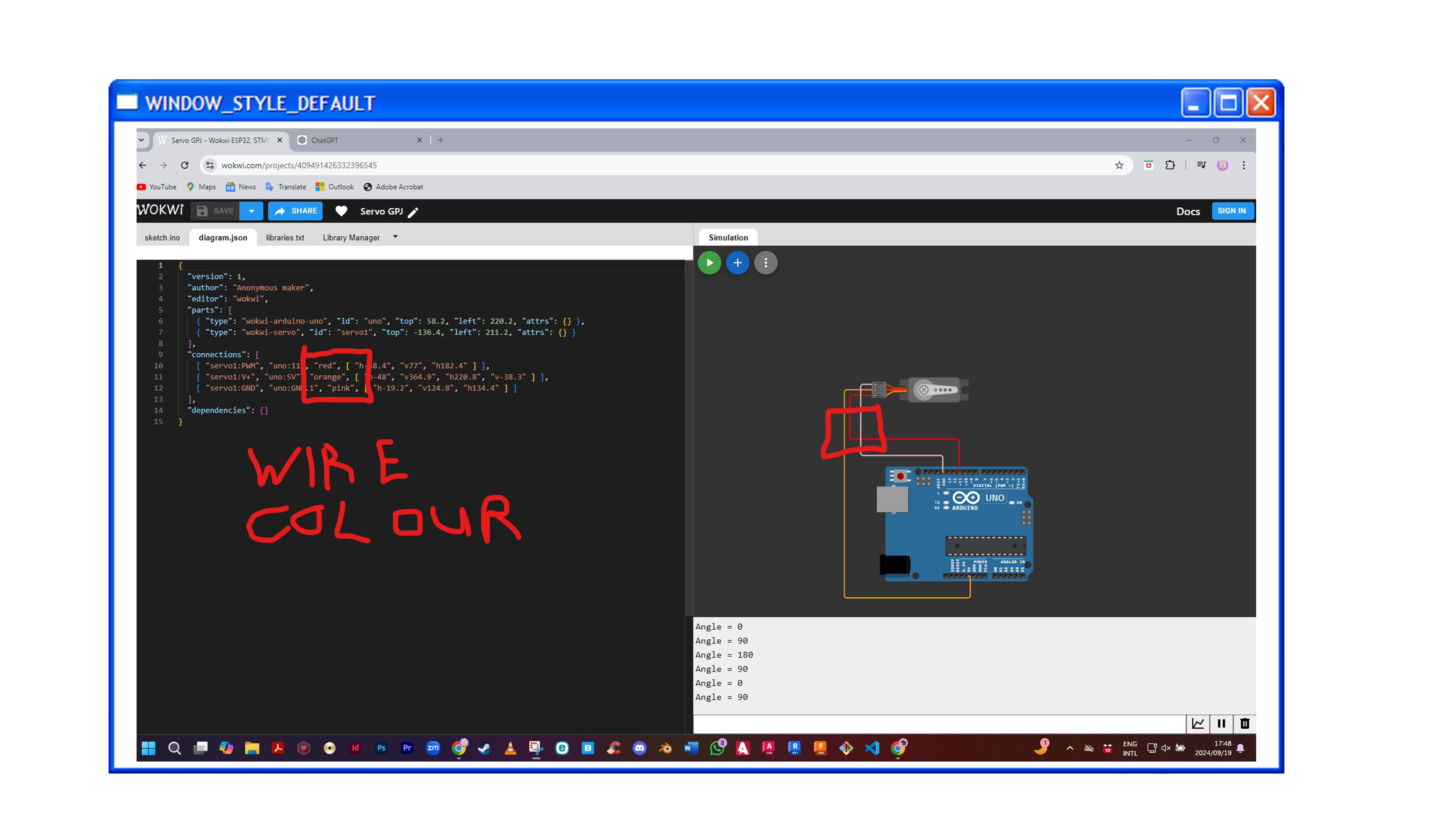

You can change the wire colour in the code and on the interface.

Each command line is a unique command which influences the speed and the directionality of the servo motor.

I installed the Arduino program.

A comparative analysis of the 3 systems which I am looking at for possible use in my final project.

At this stage of the project, I had to start understanding what was necessary in terms of the final project I was working on. Being a complete novice in terms of all the technology required to design and build an optical device like a thermal camera, I was going to require some assistance (if I was going to approach this on my own). I found a tutorial online which details the components and processes required to build a cheap thermal camera for around $50.

This was going to be a massive help. There were several tutorials detailing these cameras and which microcontrollers they were using. These included the Arduino UNO, the Raspberry Pi, and the ESP32 -which were all the processors used in these tutorials and devices.

I had difficulty trying to understand the different and intricate components detailed in the process, so I decided to experiment further on WOKWI. I did this to try and understand some of the innerworkings of the components of a camera. It is here where I tried to project a small 128 x 64 images on the OLED screen.

The code which I used to program the OLED screen. The ocean of green code is the converted image information which was translated into code to be displayed on the screen.

I downloaded an LCD – image converted which translated the image into blocks of greyscale colour.

Sketch diagram of electronic components of OLED screen and Servo Motor