Week 10 — Computer Controlled Machining

Making Something Big

This week, our assignment was to make (design+mill+assemble) something big. Thinking large, I graviated towards some sort of furniture piece to add to my home.

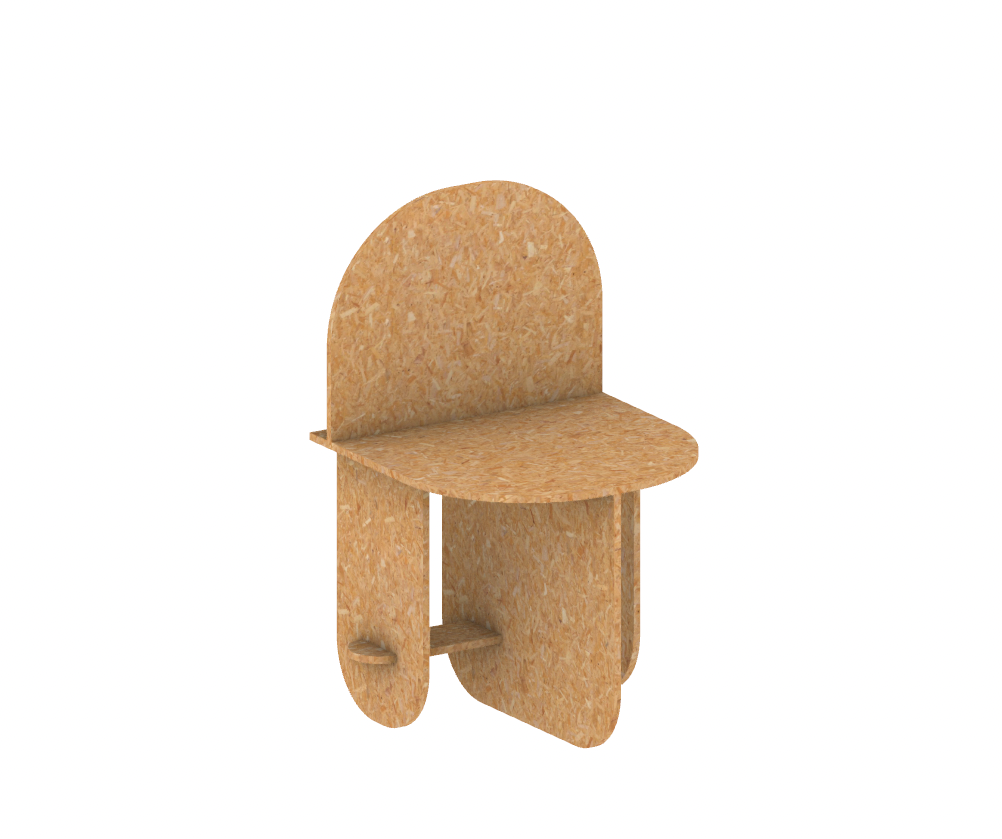

My thought was a dining chair as I currently am using folding chairs from IKEA. However, after further thinking, I decided I wanted a chair for my pile of clothes.

You know that one? Where you have not dirty but still worn clothes? I needed one of those.

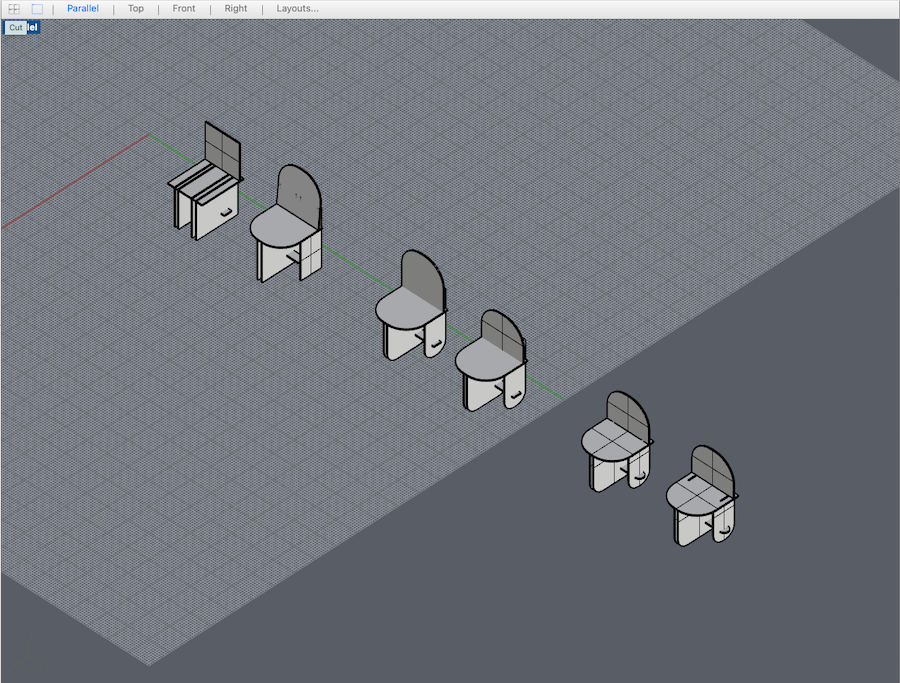

I wanted something with curves, something with large surface area (due to the fragility of the OSB), but still standarded size. After working on a few iterations, I landed on a design.

The support in the middle hopefully will allow the slides to be smaller, with filets on every planar surface.

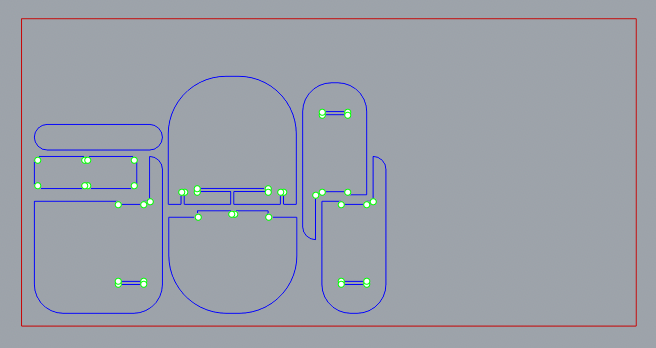

In the shop, the material was measured at .488" thick (usually its marketed as .5" thick so its always good to measure beforehand for the joints.)

During the group assignment, we had a test cut to check for joint spacing.

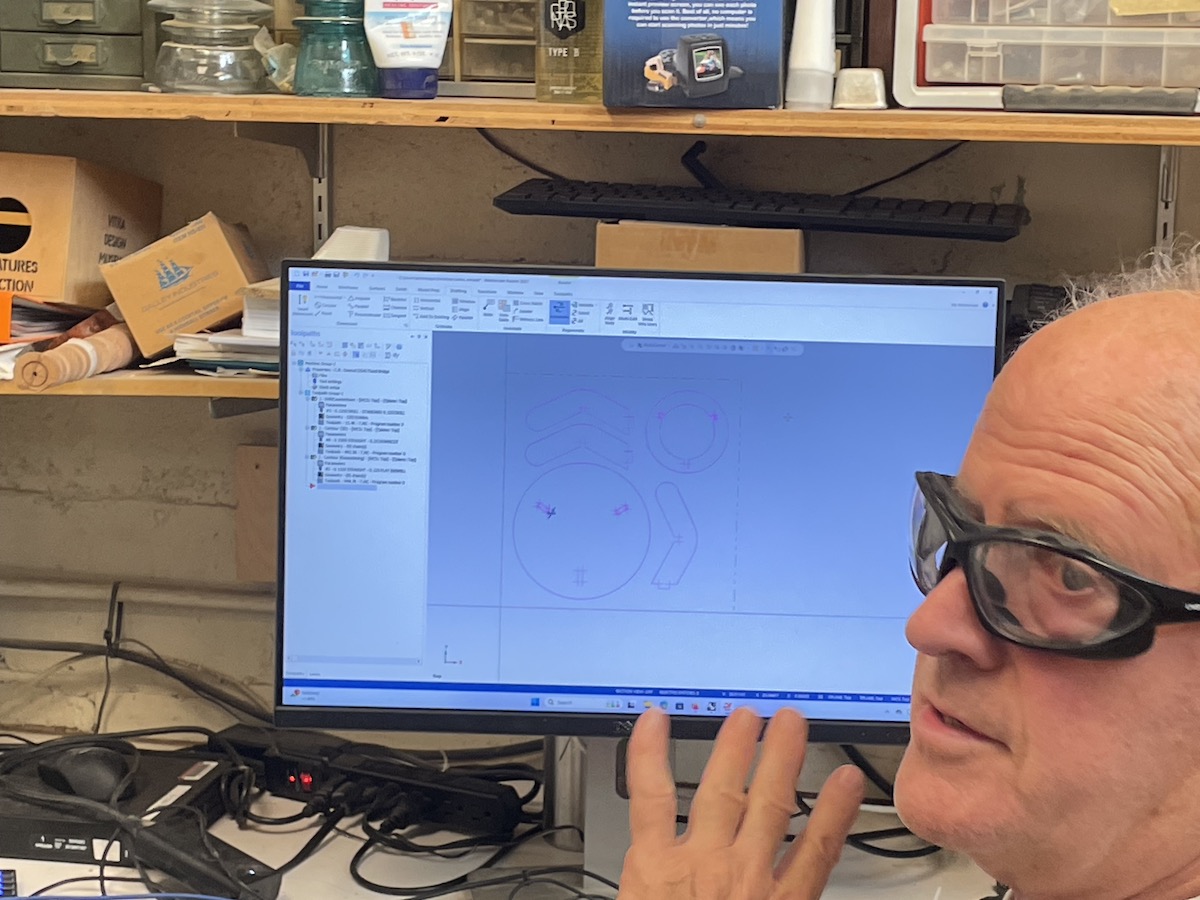

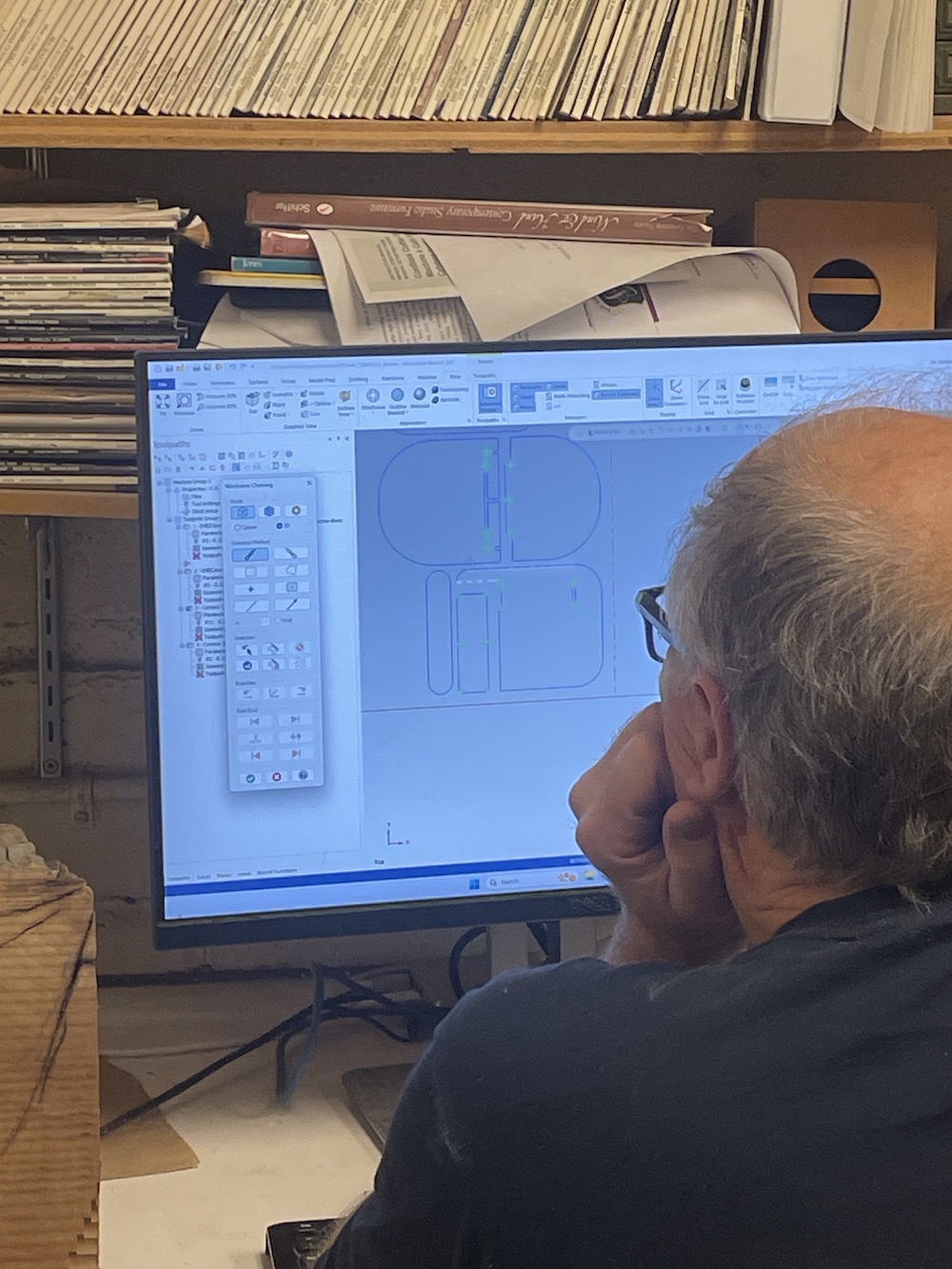

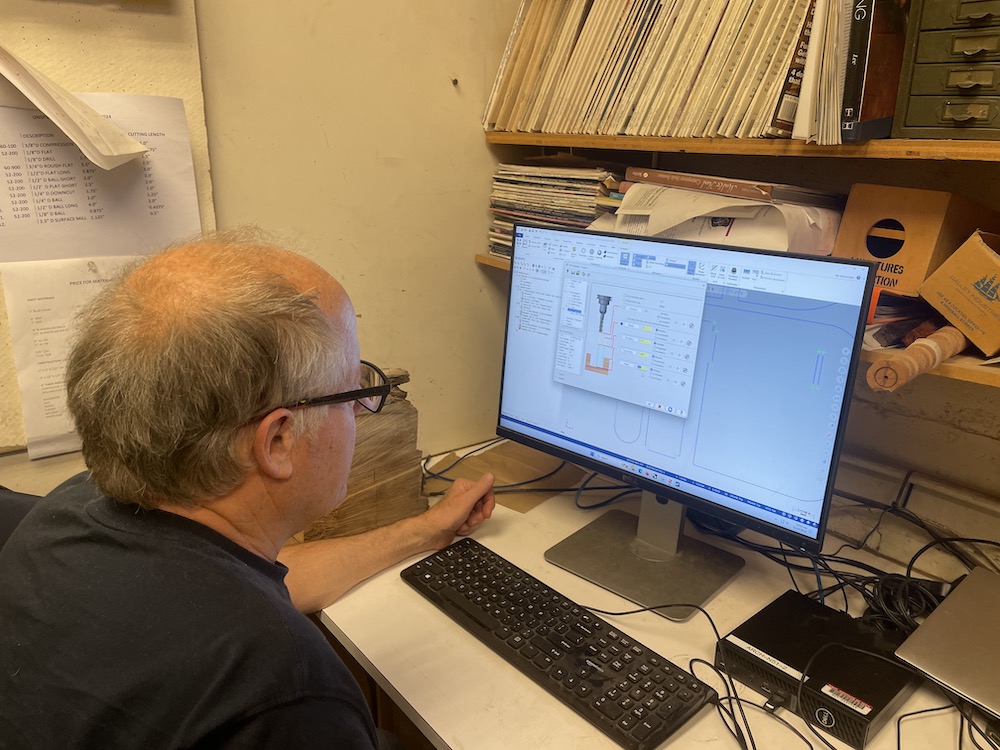

I prepped the file in Rhino, including points for the interior corners, to send over to be worked for the CNC Mastercam software.

Milling and Assembling

I sent over my files to Chris but unfortuately the machine broke. During Machine week I was able to squeeze in a time to cut.

Chris helped me set up the Mastercam file and off we went to go cut. The overall cut time was only 8 minutes. He ran another cut cycle through because the "onion" layer was not fully cut enough to use an exacto knife to get through the rest.

I knew that sanding and using the router to clean the edges were going to take a while, so I settled into the shop and got started.

Overall, I took around 2 hours to clean up everything.

Assembly went OK, the "chair" is wobbly and shears one way. It can stand up on its own but I would not recommend anyone sitting on it.

The scale of it is also off-- roughly 2-3" shorter then standard height chairs. Oh well~

Group Assignment

For the group assignment, we did our lab's safety training. Chris went over the steps of preparing for and using the CNC (test runout, alignment, fixturing,

speeds, feeds, and toolpaths for the machine).

He also talked about how to design with the OSB material in mind, mentioning how easy it was to break when it's cut thin.