Week 11 — Machine Design

Block and Grabber Team

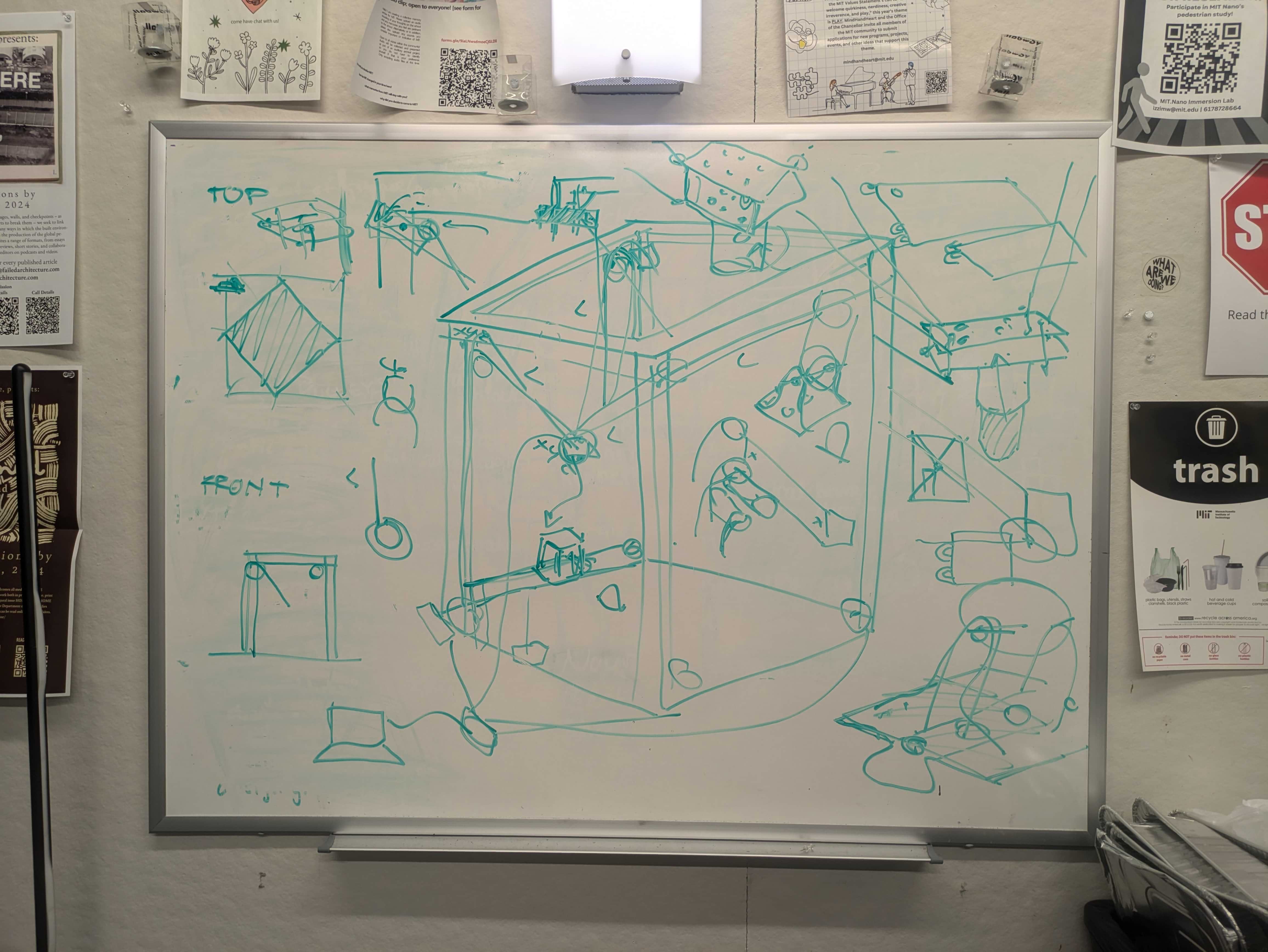

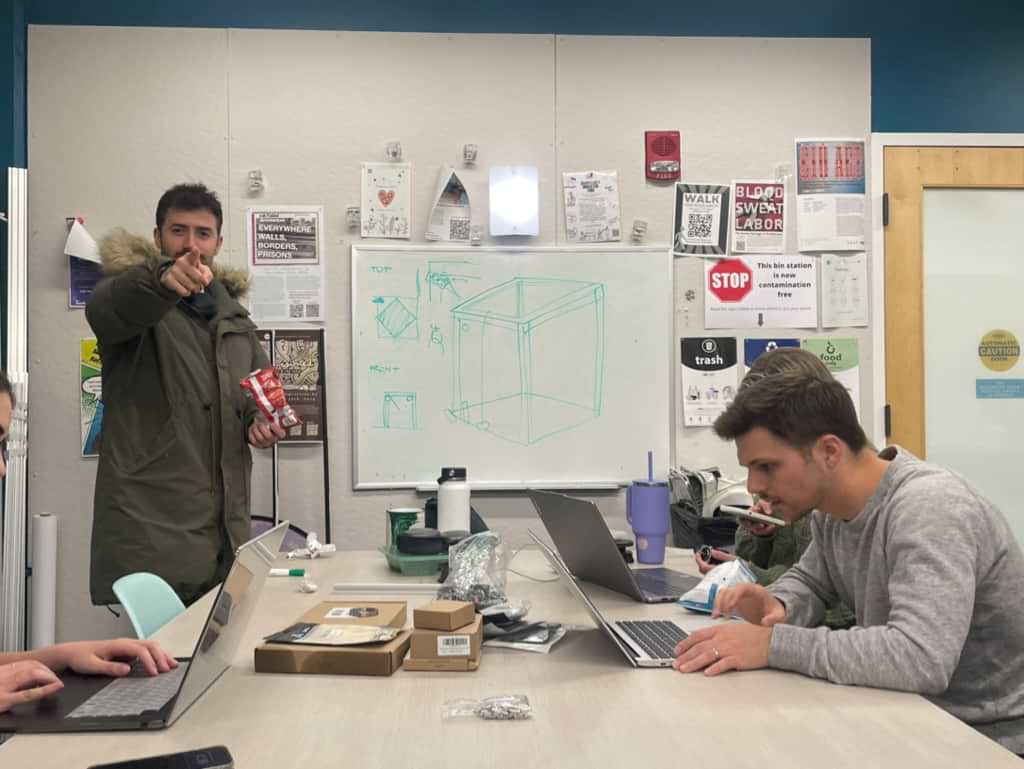

For this week, the whole Architecture section came together to create a machine! During our first stragety meeting 1.5 weeks before presentation day, we decided on on a concept.

I think our team settled on whomever had a cool idea first to execute and streamline the process. From there, our two team leads, Sergio and Jana broke everyone up into teams.

I ended up on the Block and Grabber team with Gert, Ahzin, and Nour.

For the final group project site: please go here.

Our team met as a group to discuss game plans and next steps before a full team meeting. See meeting notes below:

(PDF of meeting notes here)

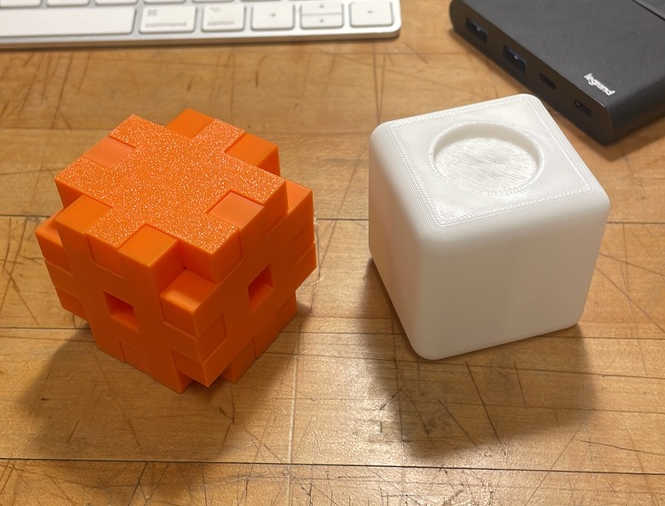

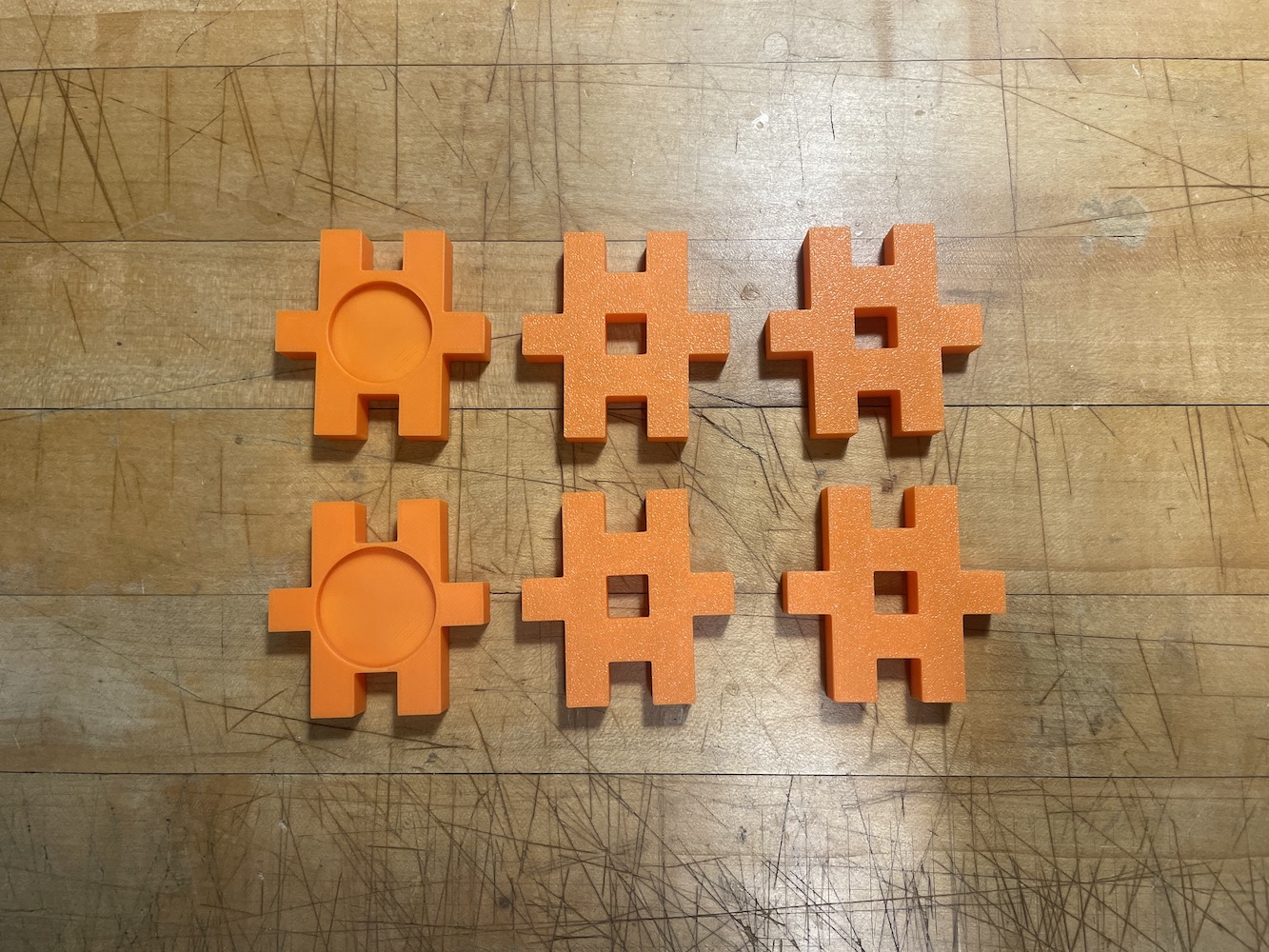

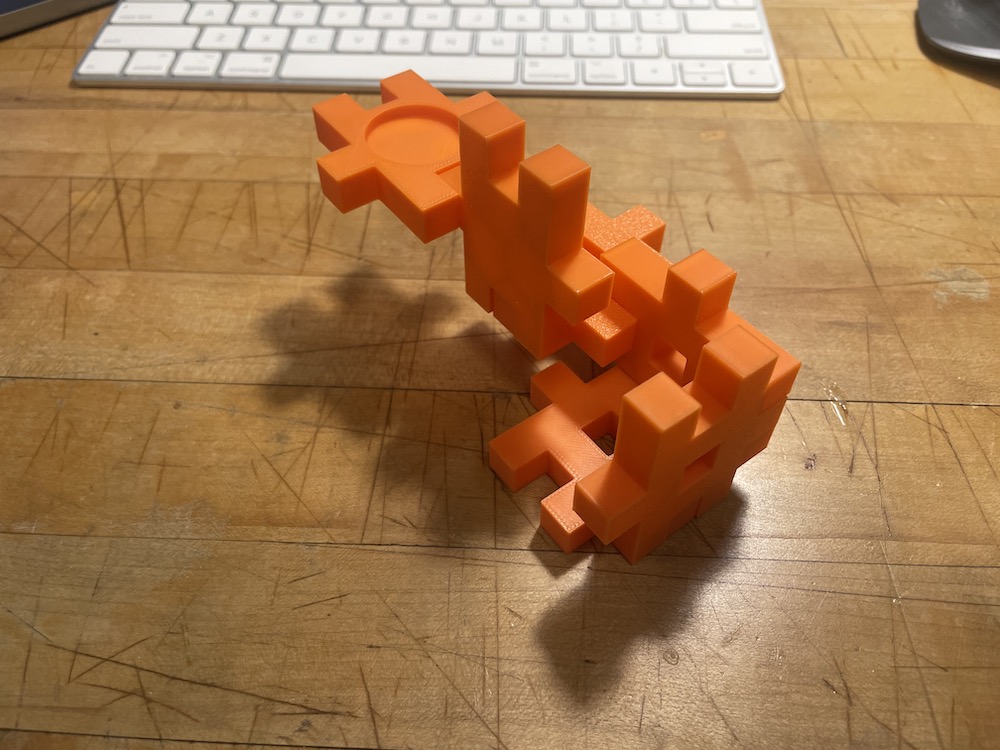

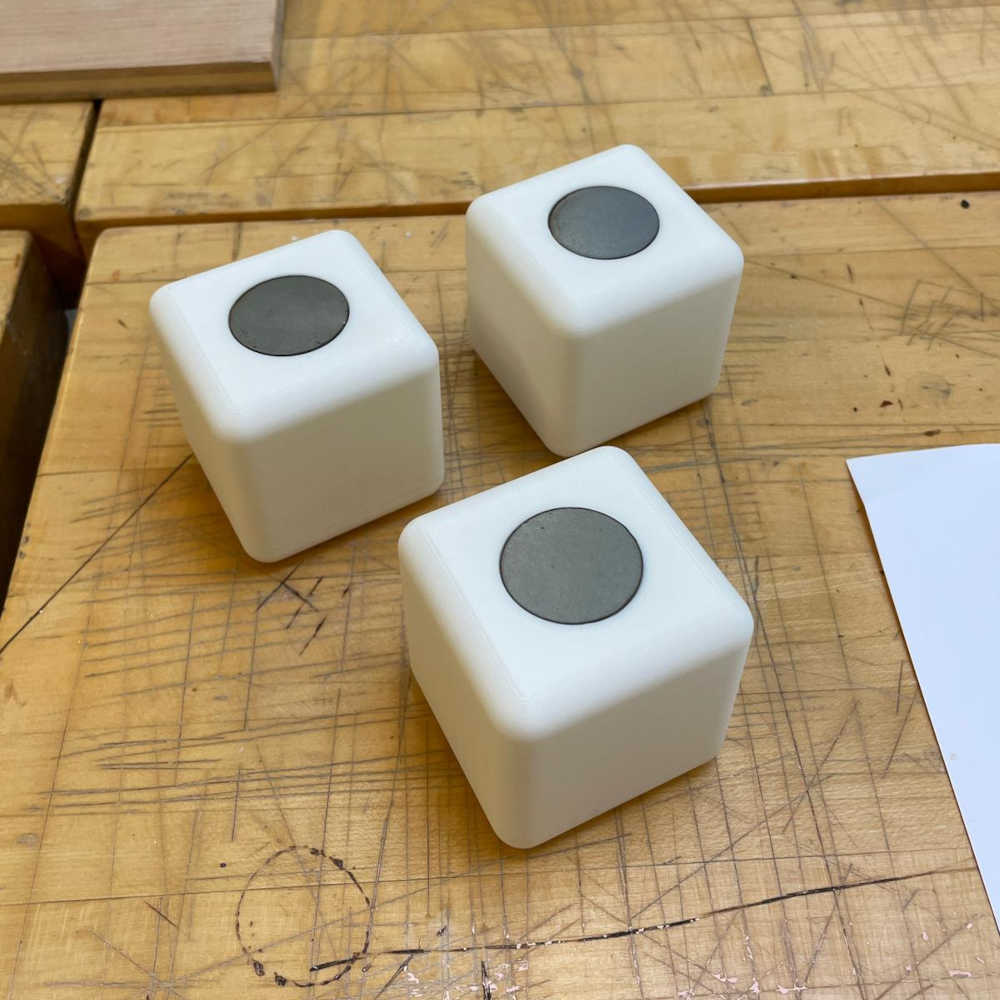

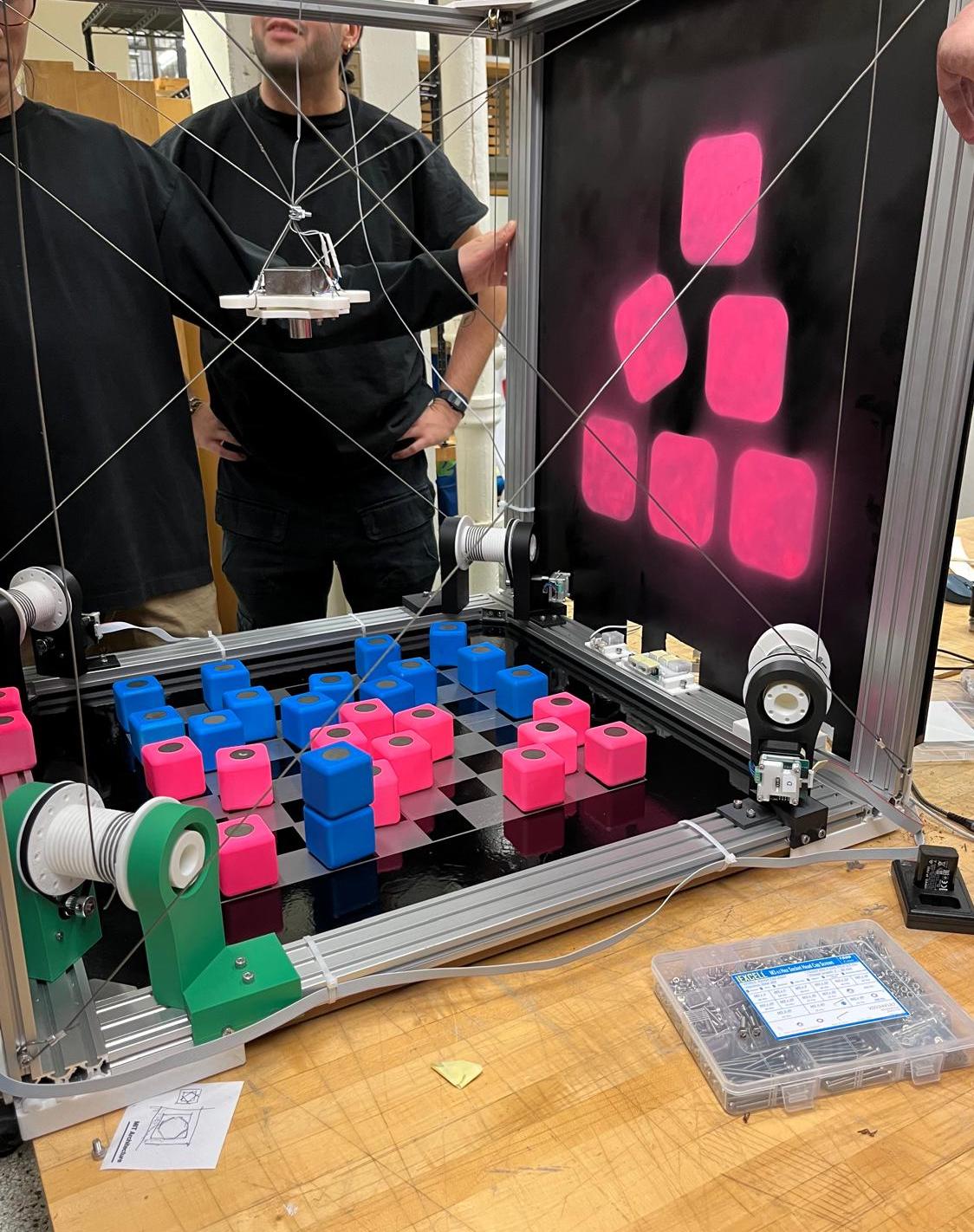

When designing the building blocks for our project, we aimed to mass-produce modular units that could connect using small magnets embedded in their faces.

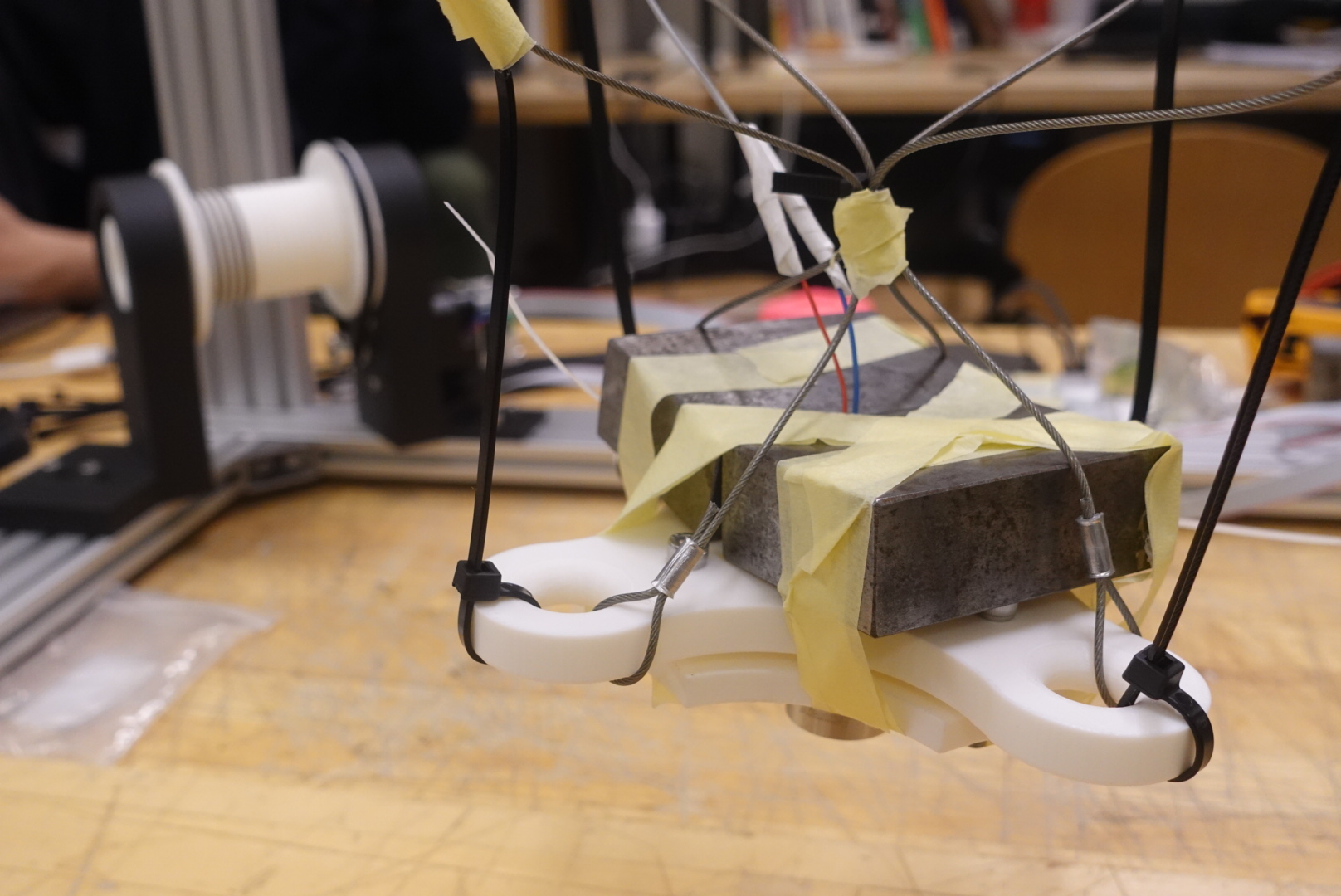

Alongside these, we developed a "grabber" mechanism—essentially a claw—powered by electromagnets.

The blocks would be 3D printed, with the magnets carefully integrated into their surfaces to be flush.

However, we soon encountered a problem we didn't first think through. Since we were using an electromagnet, we needed a steel element (not a magnet) to allow the blocks to be lifted.

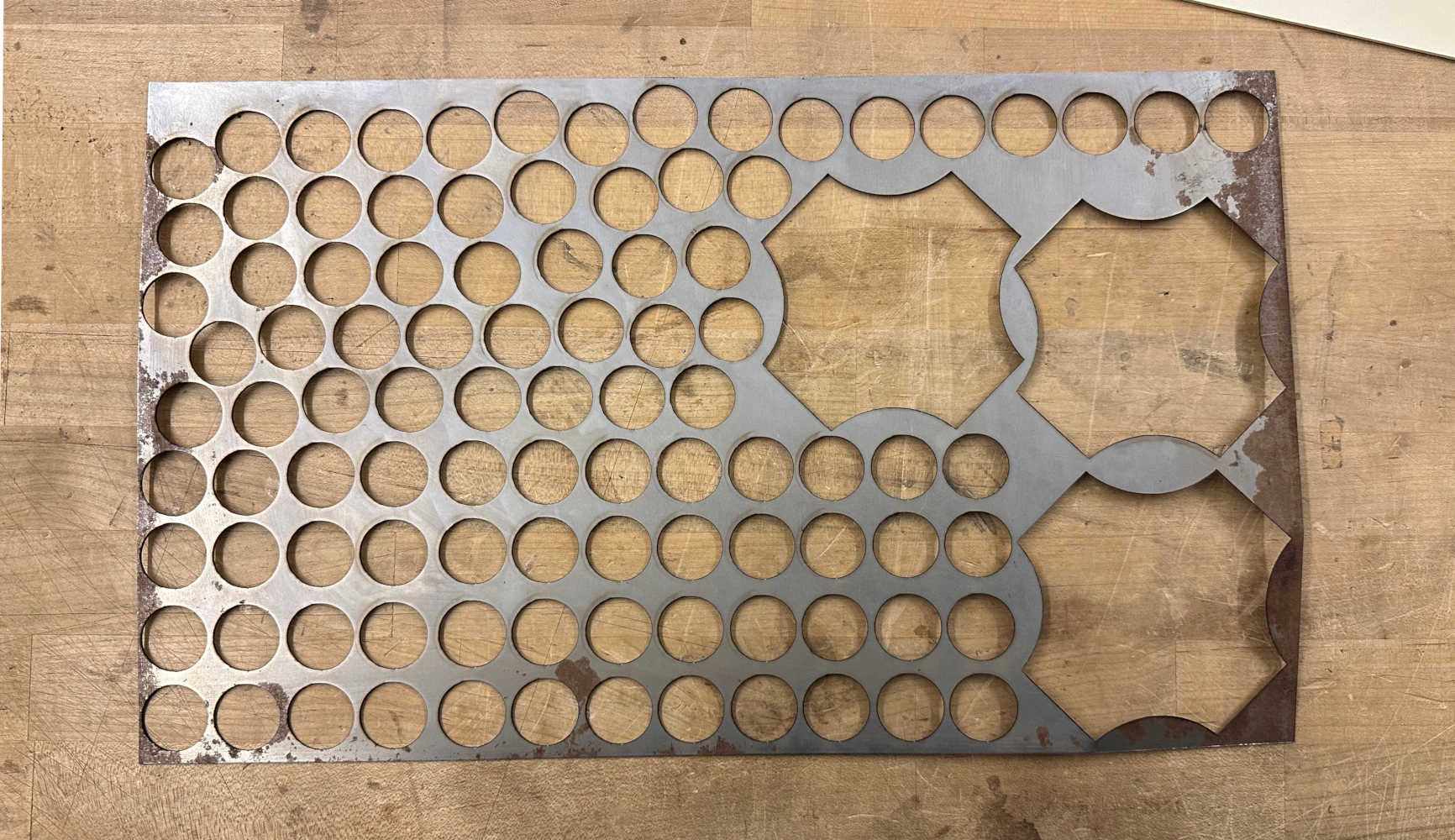

Our first thought was to make the full block metal, but that was expensive and we wouldn't be able to produce 50. We then decided to cut out 1" circle blocks and readjust our 3D print to have that sit on the top.

We were fortunate Nour had access to the Fablight metal cutter in n51 to cut the pieces. We used whatever scrap metal was around.

We also cut out metal plates to weight down the part that connected the pulley cable and electromagnet together, designed by Gert. More on this later.

I went through a few block options: the cube on the left was made of 6 interlocking pieces that were all press fit. The right had filets at the edges to soften everything. While the orange cube was a crowd favorite, the print time of the two were vastly different.

The left for all its pieces was at 1 hour, while two of the right were at 45 minutes, so we ended up printing the right.

Over the next few days, we were consistently printing out blocks in 12 to 16 increments across the BT lab and N51.

The Grabber

For the grabber, spearheaded by Gert, we were going to use the metal plates inbetween the two 3D print plates to weight it down.

Unfortunately, this was not heavy enough and Jacob offered his rectangle weights for holding down drawings to use.

We first tested with two metal pieces taped together... We then narrowed it down to just one weight with some double sided tape (thanks Ahzin!)

I spent a lot of time with XDD for the electromagnet portion of the grabbing. The first issue was that the grabber was having a hard time lifting the blocks. We double checked the weight requirements and everything seemed to be fine.

XDD checked the code and realized there was an error of some sort and was able to fix it. The second issue was that the grabber couldn't let go of the block once it was picked up.

We believe it was due to a too perfect seal between the steel plate and the electromagnet. We were troubleshooting and noticed having a piece of tape on the block helped.

We were at first concerned we'd need to tape every block but Jana had a great suggestion.

We fixed this with a piece of tape on the electromagnet itself. A bandaid fix for now...

Mass Fabrication and Painting

After chatting with the frame team, we were still inspired by arcade style visuals, including a game called stacker with NEON colors. Blake from the frame team picked up a bunch of spray paint colors to test out.

Our team all really liked the pink, and we added the blue for some contrast.

We began to spray everything over Monday and Tuesday, and glued in the metal disc once the paint dried.

Really thankful for the block/grabber team for all pulling their weight and showing up even when not needed! Thanks Nour/Ahzin/Gert for your hard work.

Misc

I also had a brief stint on the integretations team, making sure I took photos and videos of our team's progress, as well as sorting through all the images on our shared google drive.