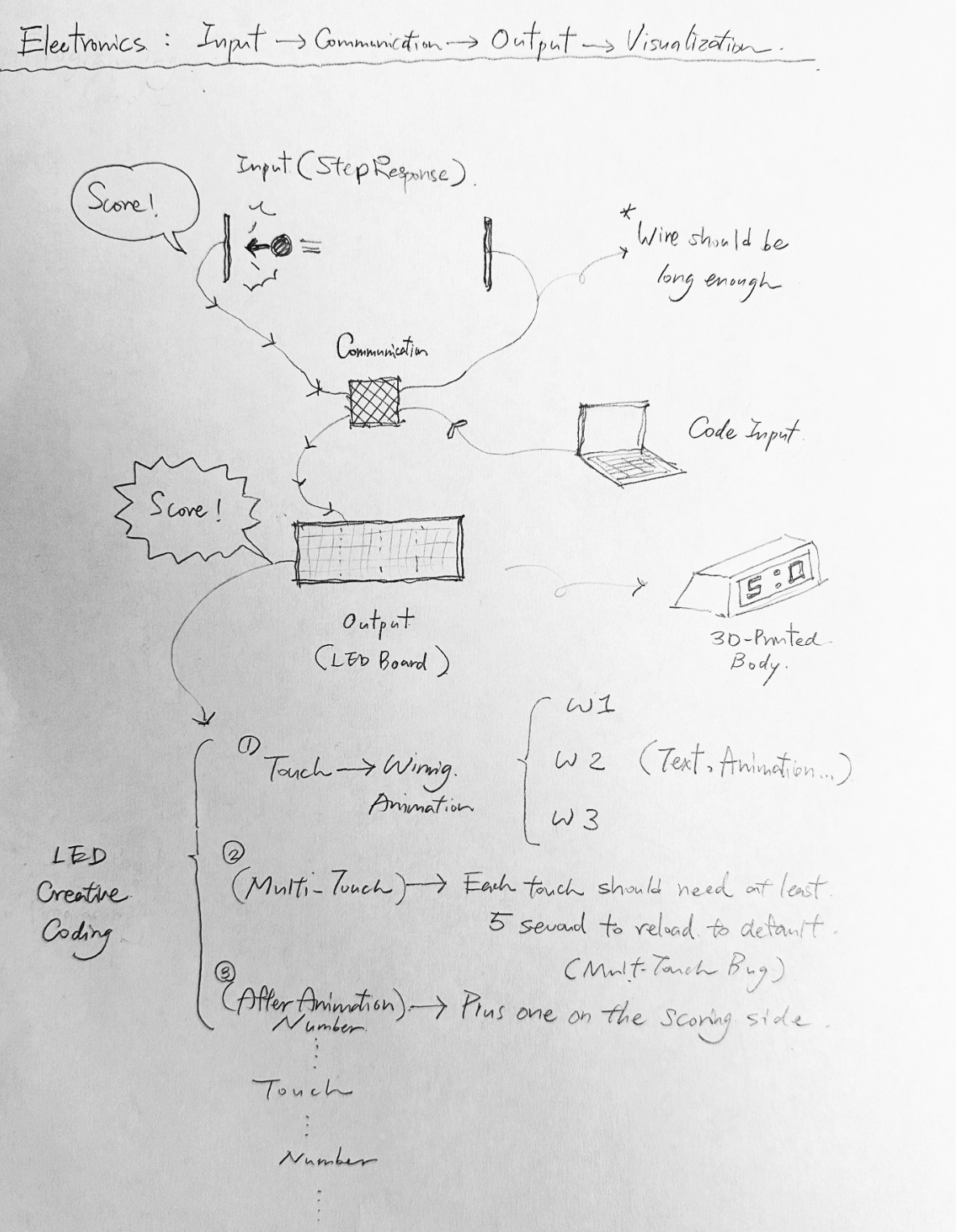

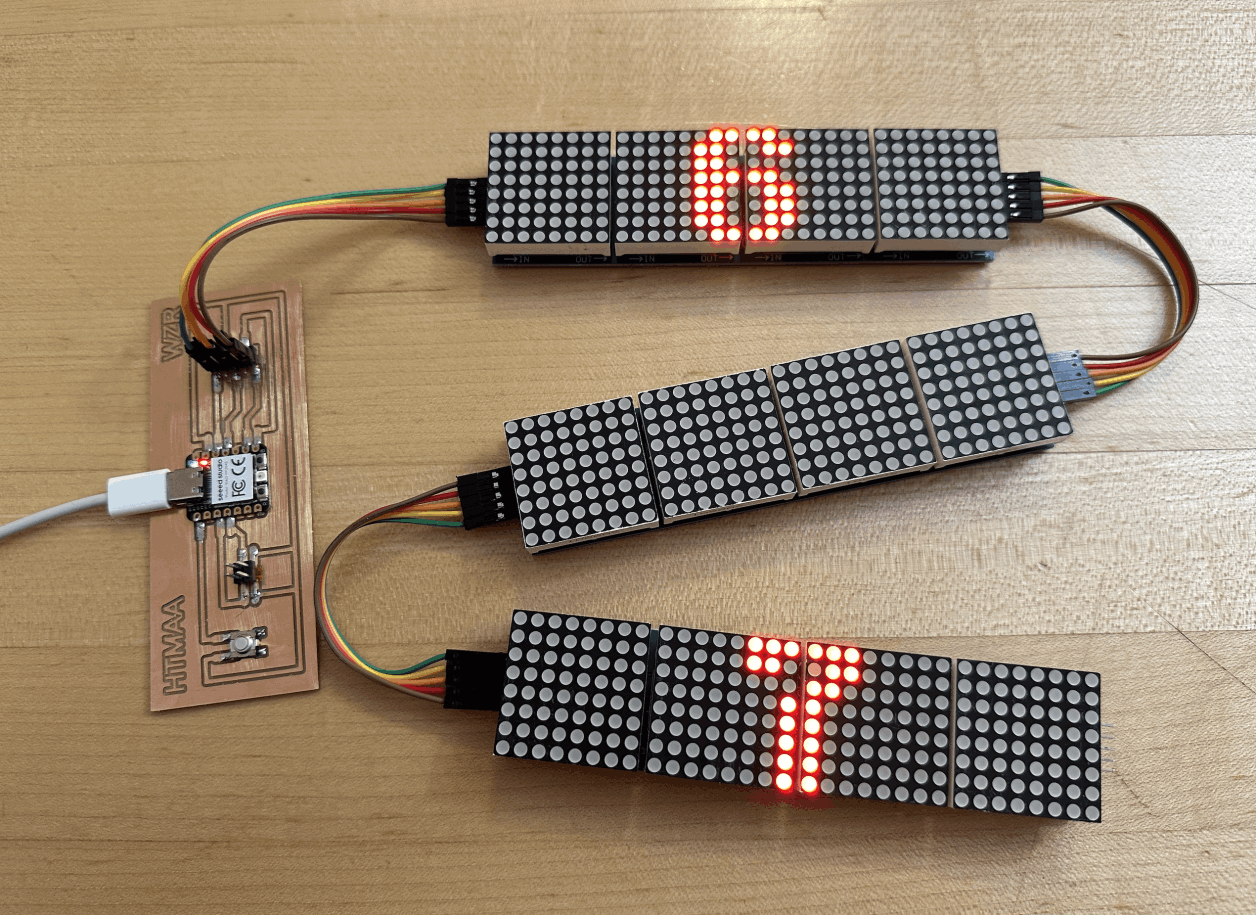

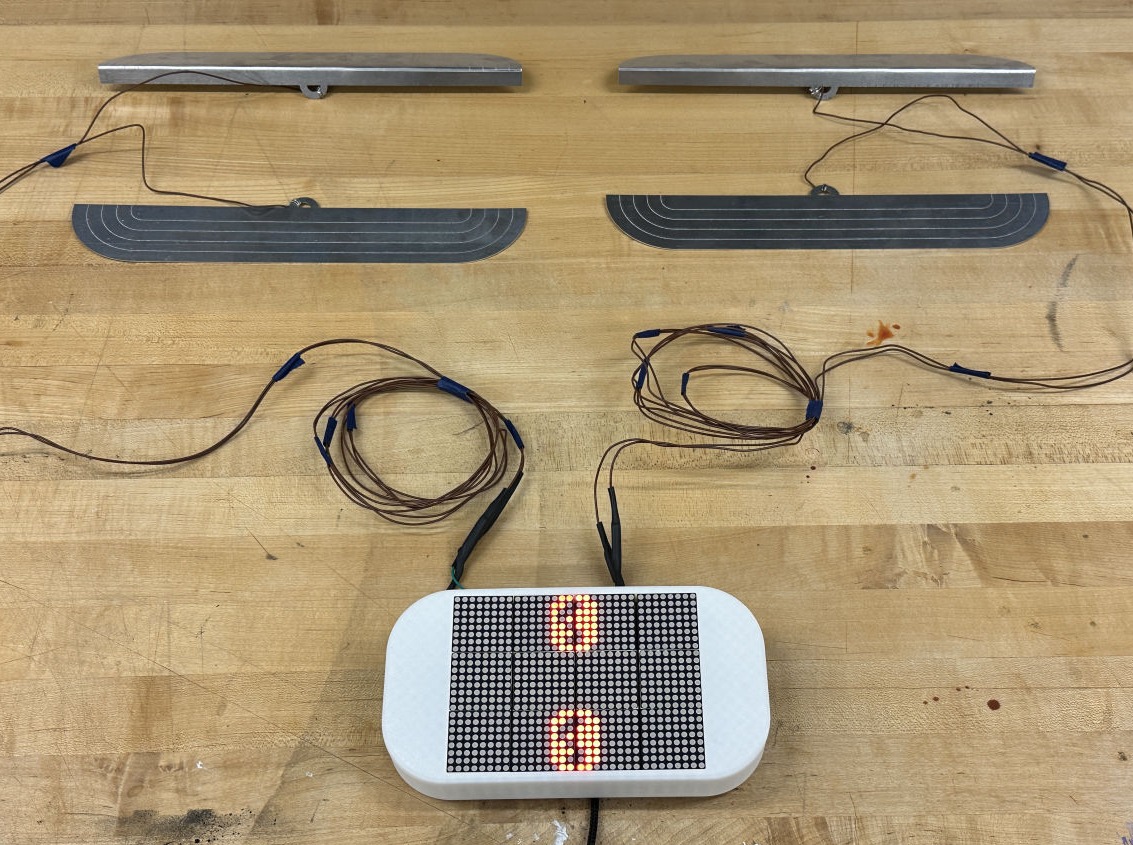

Code for interaction test

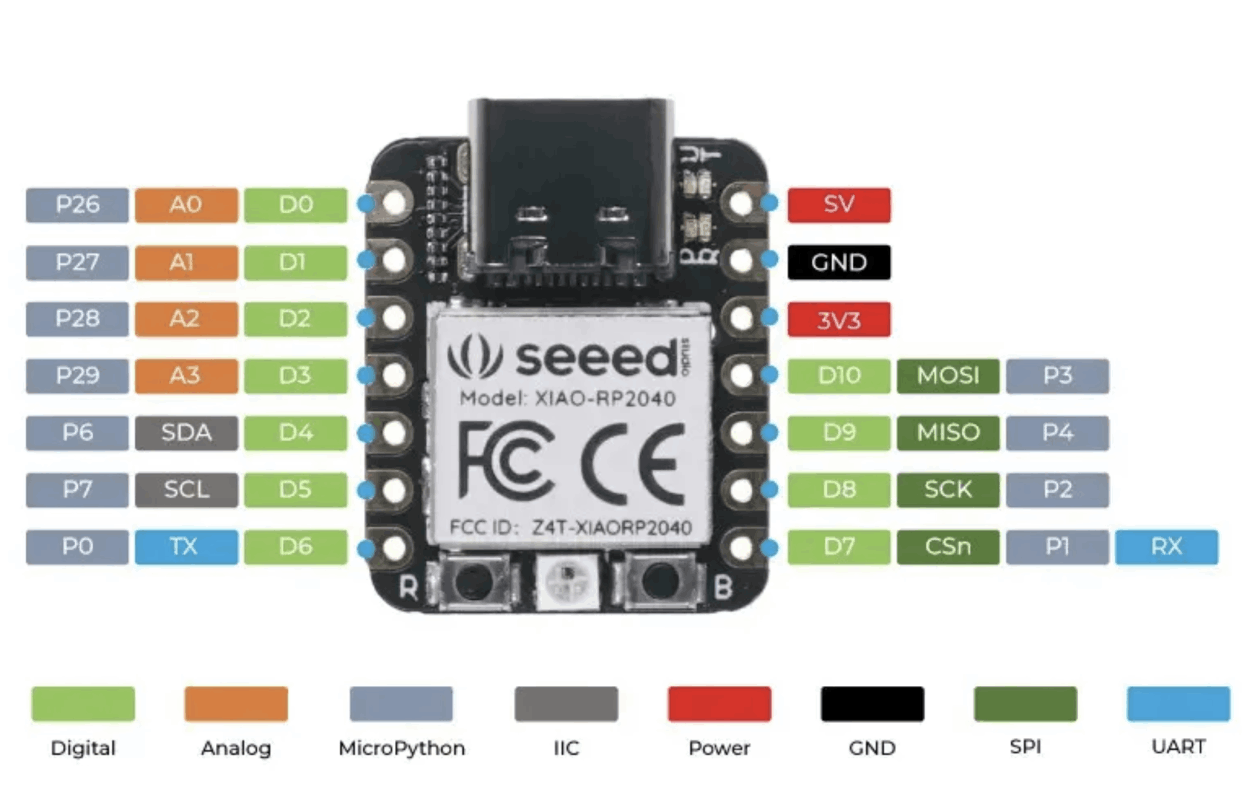

#define pin1 1 // Chip Select (CS)

#define pin2 2 // Clock (SCK)

#define pin3 3 // Data Input (MOSI)

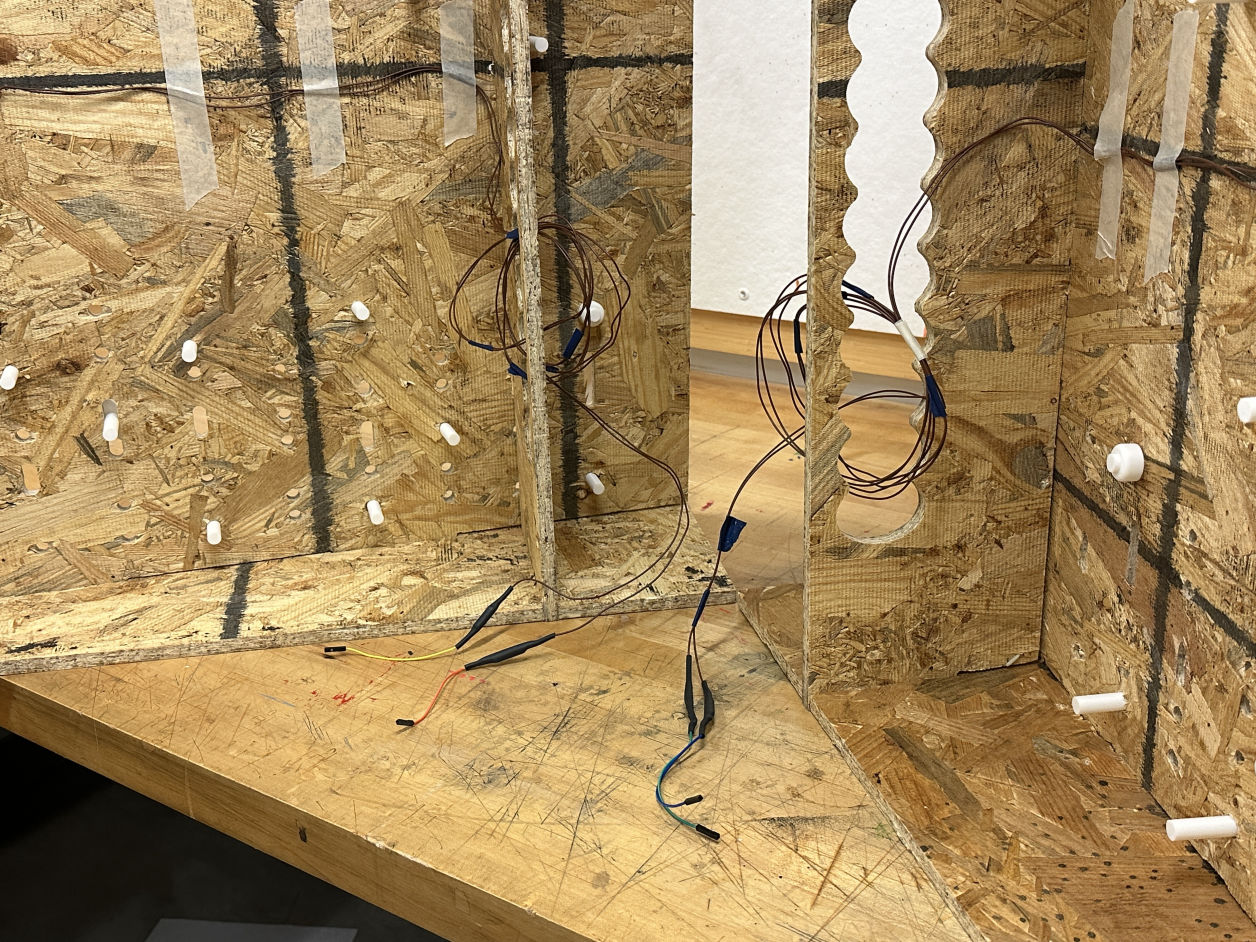

#define buttonPin1 28 // Button Input 1

#define buttonPin2 29 // Button Input 2

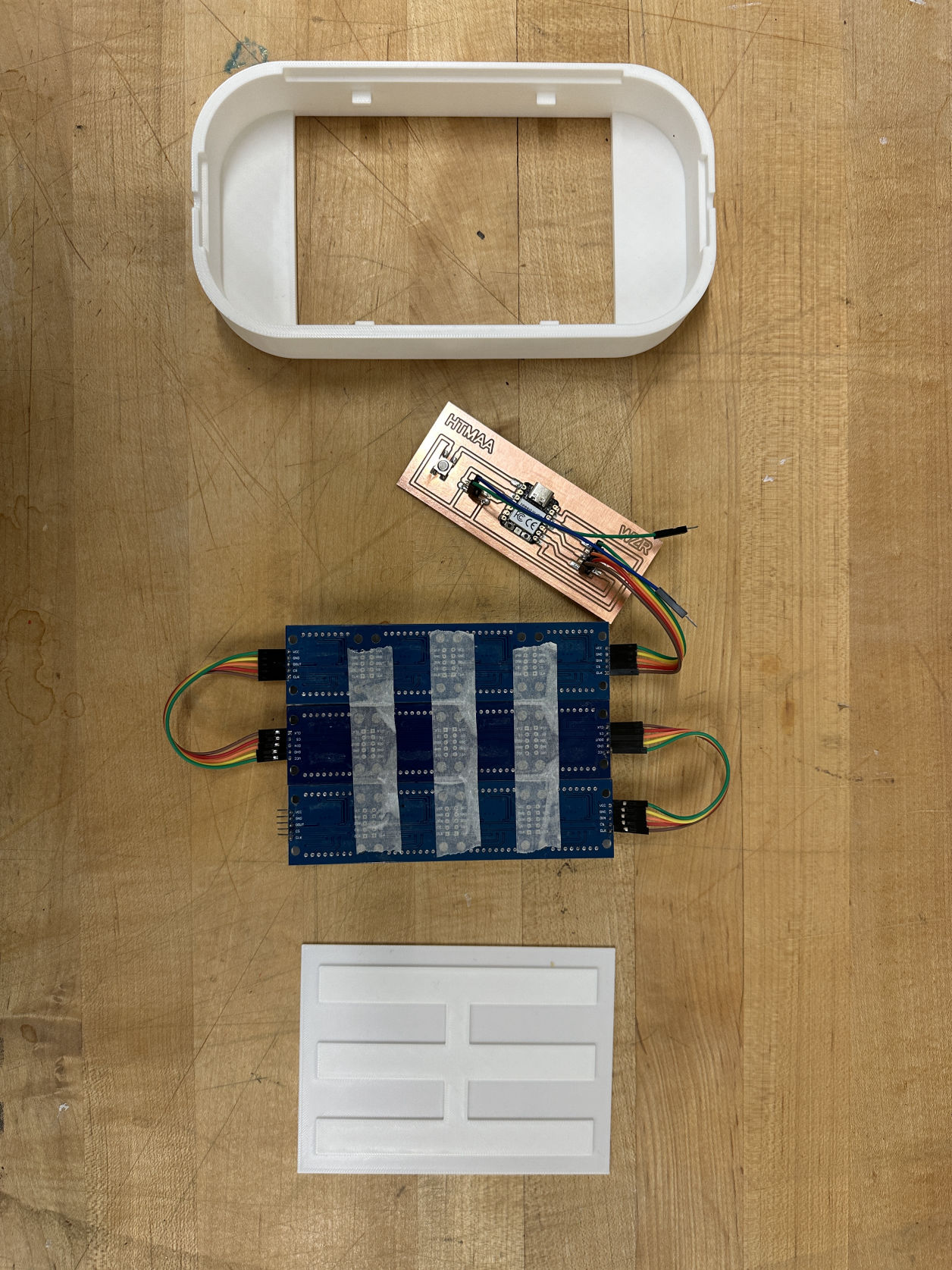

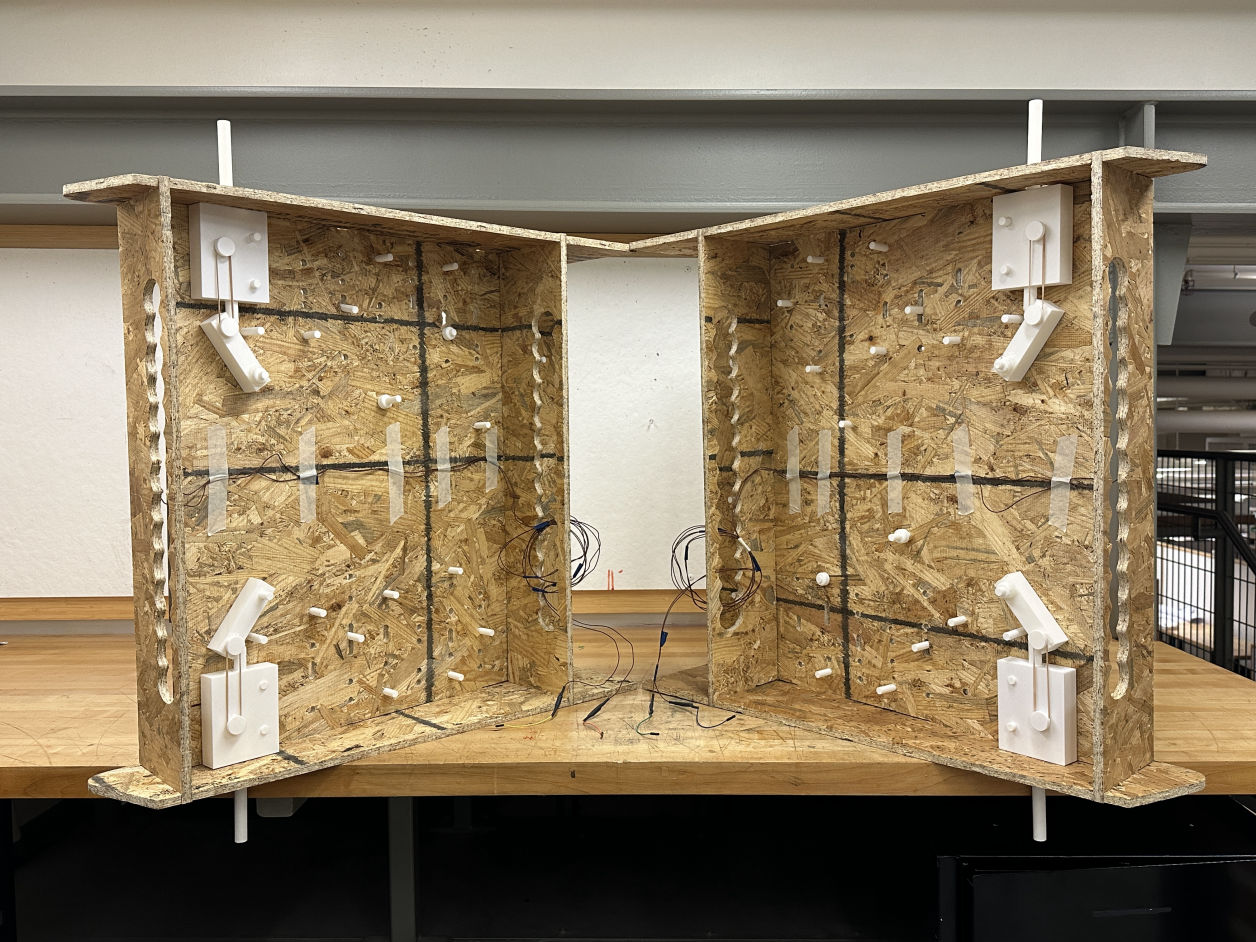

// LED Matrix Setup

#define X_SEGMENTS 4 // 4 LED matrix bars horizontally

#define Y_SEGMENTS 3 // 3 rows of matrices

#define NUM_SEGMENTS (X_SEGMENTS * Y_SEGMENTS)

// Framebuffer

byte fb[8 * NUM_SEGMENTS];

uint8_t number1 = 0; // Controlled by buttonPin1

uint8_t number2 = 0; // Controlled by buttonPin2

unsigned long lastPressTime1 = 0;

unsigned long lastPressTime2 = 0;

const unsigned long debounceDelay = 2500; // 2.5 seconds

// Function to Send Data to All MAX7219s

void shiftAll(byte address, byte data) {

digitalWrite(pin1, LOW); // Enable Chip Select

for (int i = 0; i < NUM_SEGMENTS; i++) {

shiftOut(pin3, pin2, MSBFIRST, address); // Send address

shiftOut(pin3, pin2, MSBFIRST, data); // Send data

}

digitalWrite(pin1, HIGH); // Disable Chip Select

}

void setup() {

Serial.begin(115200);

// Initialize SPI pins

pinMode(pin1, OUTPUT); // CS

pinMode(pin2, OUTPUT); // Clock

pinMode(pin3, OUTPUT); // Data Input

pinMode(buttonPin1, INPUT_PULLUP); // Button input 1

pinMode(buttonPin2, INPUT_PULLUP); // Button input 2

// Initialize Each MAX7219

shiftAll(0x0F, 0x00); // Display Test Register - Test Mode OFF

shiftAll(0x0B, 0x07); // Scan Limit: Display Digits 0-7

shiftAll(0x0C, 0x01); // Shutdown Register - Normal Operation

shiftAll(0x0A, 0x08); // Brightness: Medium

shiftAll(0x09, 0x00); // Decode Mode OFF

}

void loop() {

unsigned long currentTime = millis();

if (digitalRead(buttonPin1) == LOW && (currentTime - lastPressTime1 > debounceDelay)) {

lastPressTime1 = currentTime;

if (number1 < 99) {

number1++;

Serial.print("Button 1 touched! Number 1: ");

Serial.println(number1);

}

}

if (digitalRead(buttonPin2) == LOW && (currentTime - lastPressTime2 > debounceDelay)) {

lastPressTime2 = currentTime;

if (number2 < 99) {

number2++;

Serial.print("Button 2 touched! Number 2: ");

Serial.println(number2);

}

}

// Clear framebuffer

clear();

// Draw numbers on respective rows

draw_number(12, 0, number1); // Top row for number1

draw_number(12, 16, number2); // Bottom row for number2

// Show updated framebuffer

show();

}

void set_pixel(uint8_t x, uint8_t y, uint8_t mode) {

if (x >= X_SEGMENTS * 8 || y >= Y_SEGMENTS * 8) return;

byte *addr = &fb[(y * X_SEGMENTS) + (x / 8)];

byte mask = 128 >> (x % 8);

switch (mode) {

case 0: *addr &= ~mask; break; // Clear pixel

case 1: *addr |= mask; break; // Set pixel

case 2: *addr ^= mask; break; // Toggle pixel

}

}

void clear() {

memset(fb, 0, sizeof(fb));

}

void draw_number(uint8_t x, uint8_t y, uint8_t number) {

static const byte numbers[10][8] = {

{0b00111100, 0b01100110, 0b01101110, 0b01110110, 0b01111010, 0b01110010, 0b01100110, 0b00111100}, // 0

{0b00111100, 0b00111000, 0b00011000, 0b00011000, 0b00011000, 0b00011000, 0b00111000, 0b00111100}, // 1

{0b00111100, 0b01100110, 0b01100010, 0b00000110, 0b00001100, 0b00011000, 0b01100110, 0b00111100}, // Corrected 2

{0b00111100, 0b01100110, 0b00000110, 0b00011100, 0b00000110, 0b00000110, 0b01100110, 0b00111100}, // 3

{0b00001100, 0b00011100, 0b00101100, 0b01001100, 0b01111110, 0b00001100, 0b00001100, 0b00001100}, // 4

{0b01111110, 0b01100000, 0b01111100, 0b00000110, 0b00000110, 0b00000110, 0b01100110, 0b00111100}, // 5

{0b00111100, 0b01100110, 0b01100000, 0b01111100, 0b01100110, 0b01100110, 0b01100110, 0b00111100}, // 6

{0b01111110, 0b01100110, 0b00001100, 0b00011000, 0b00011000, 0b00011000, 0b00011000, 0b00011000}, // 7

{0b00111100, 0b01100110, 0b01100110, 0b00111100, 0b01100110, 0b01100110, 0b01100110, 0b00111100}, // 8

{0b00111100, 0b01100110, 0b01100110, 0b00111110, 0b00000110, 0b00000110, 0b01100110, 0b00111100} // 9

};

for (byte row = 0; row < 8; row++) {

for (byte col = 0; col < 8; col++) {

if (numbers[number][row] & (1 << col)) {

set_pixel(x + col, y + row, 1);

}

}

}

}

void show() {

for (byte row = 0; row < 8; row++) {

digitalWrite(pin1, LOW);

for (byte segment = 0; segment < NUM_SEGMENTS; segment++) {

byte x = segment % X_SEGMENTS;

byte y = segment / X_SEGMENTS * 8;

byte addr = (row + y) * X_SEGMENTS;

shiftOut(pin3, pin2, MSBFIRST, 8 - row);

shiftOut(pin3, pin2, MSBFIRST, fb[addr + x]);

}

digitalWrite(pin1, HIGH);

}

}