My goal is to cast a heat-resistance container that could recycle waste PLA into sustainable iPhone cases with customizable patterns on its surface.

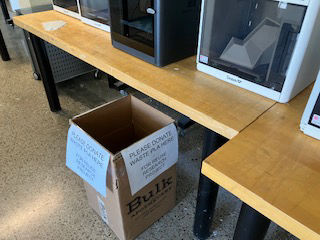

I started collecting waste PLA prints by placing recycle bins next to the arch shop's 3D printers. (This is the most productive place for waste materials!)

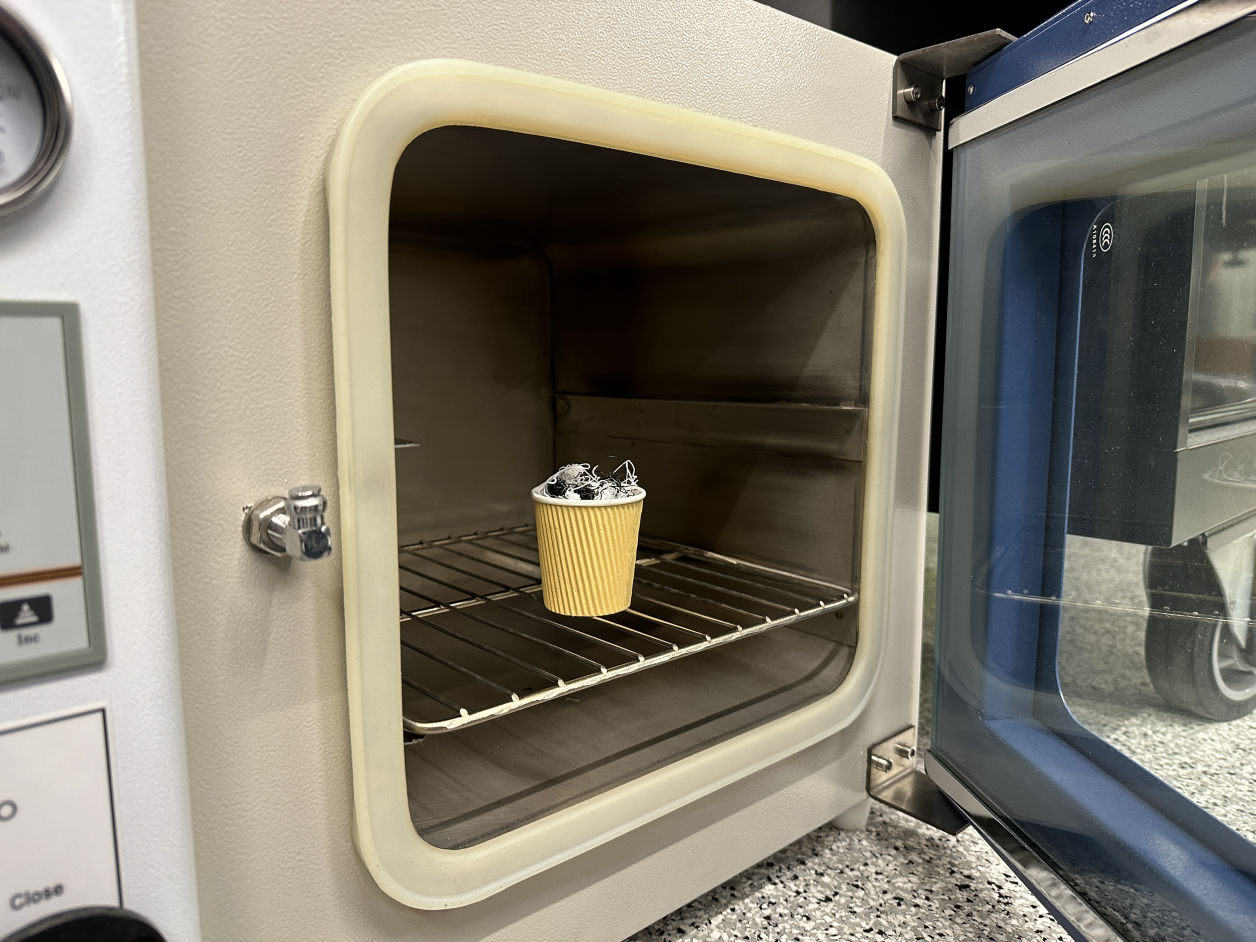

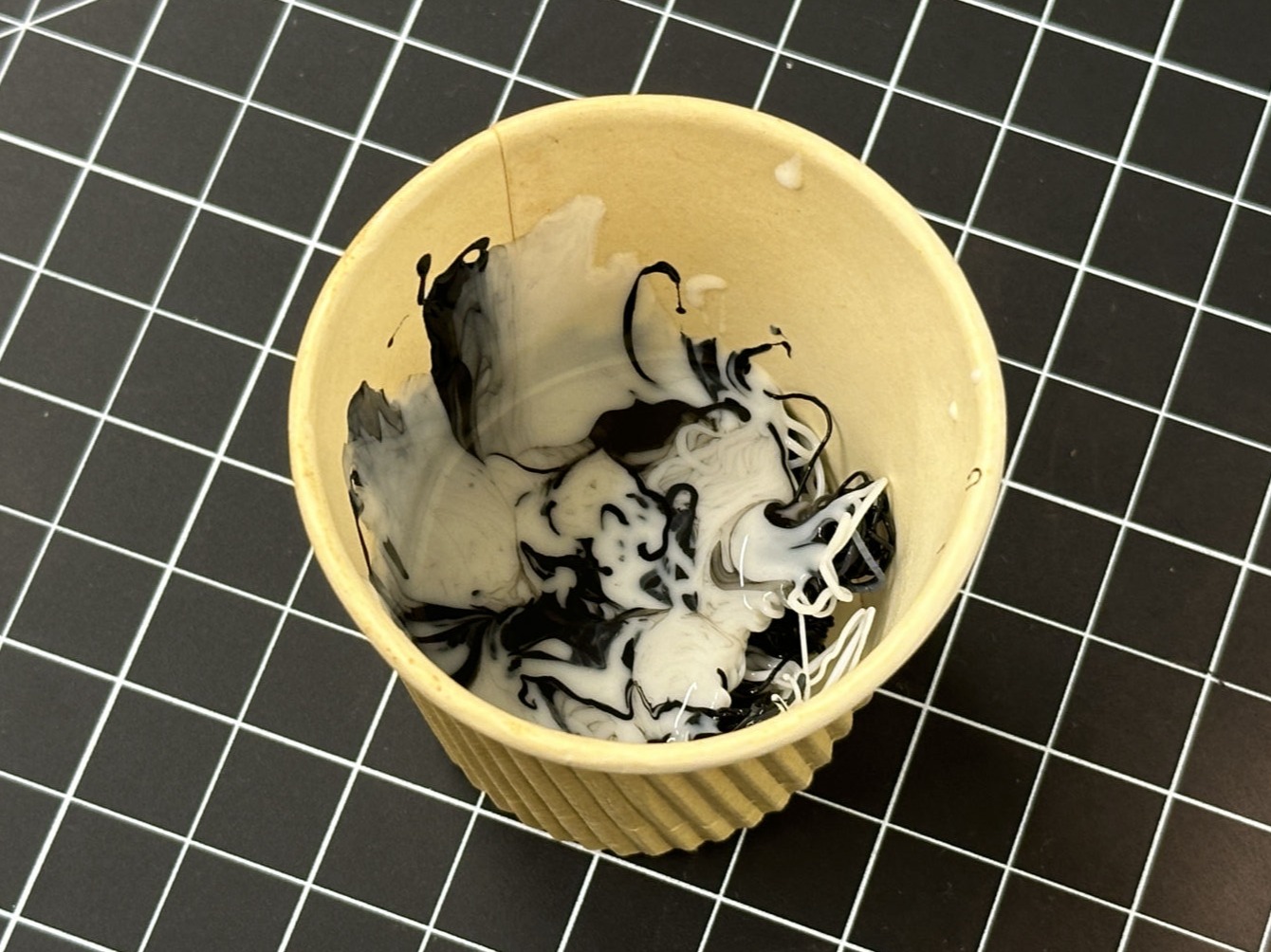

In the first experiment, I used a paper espresso cup to contain some PLA materials. To observe the blending of geometries, I found this fantastic black-and-white waste initially from another print of Neil's high-res portrait.

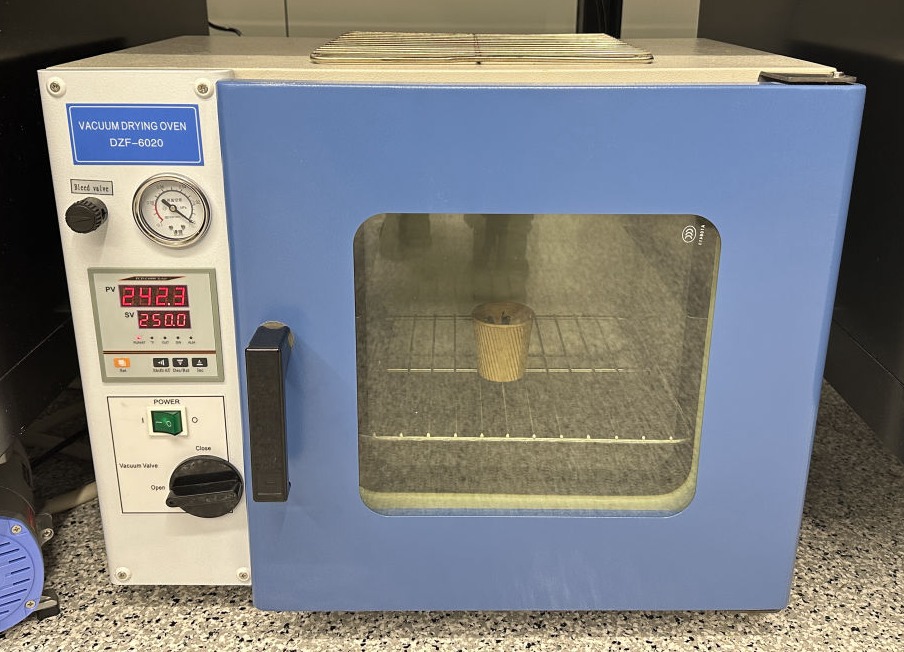

I borrowed TJ Rogers Lab's vacuum drying oven as a test bed of this material experiment.

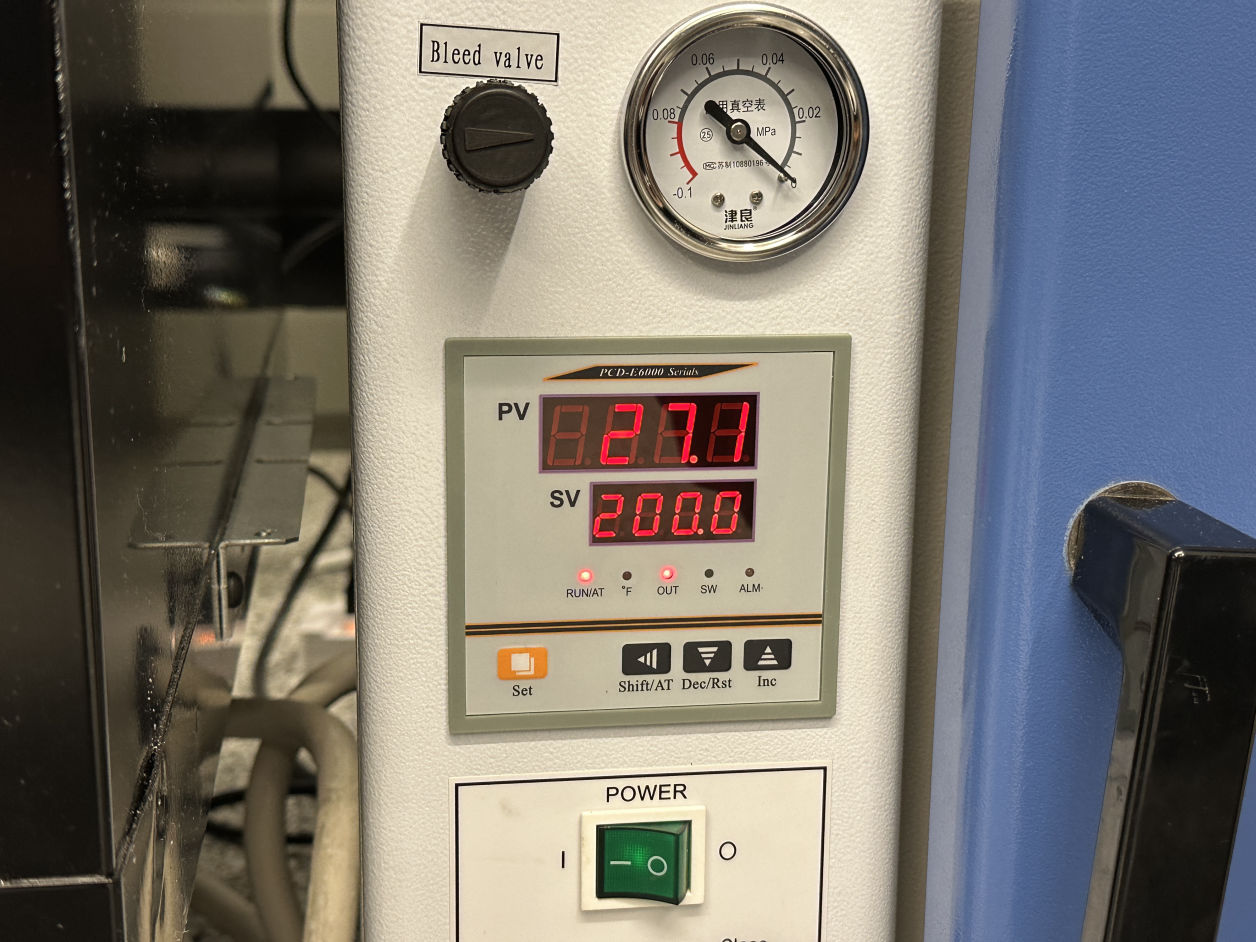

The first round was set at 200 degrees Celcius, roughly the PLA materials' melting point.

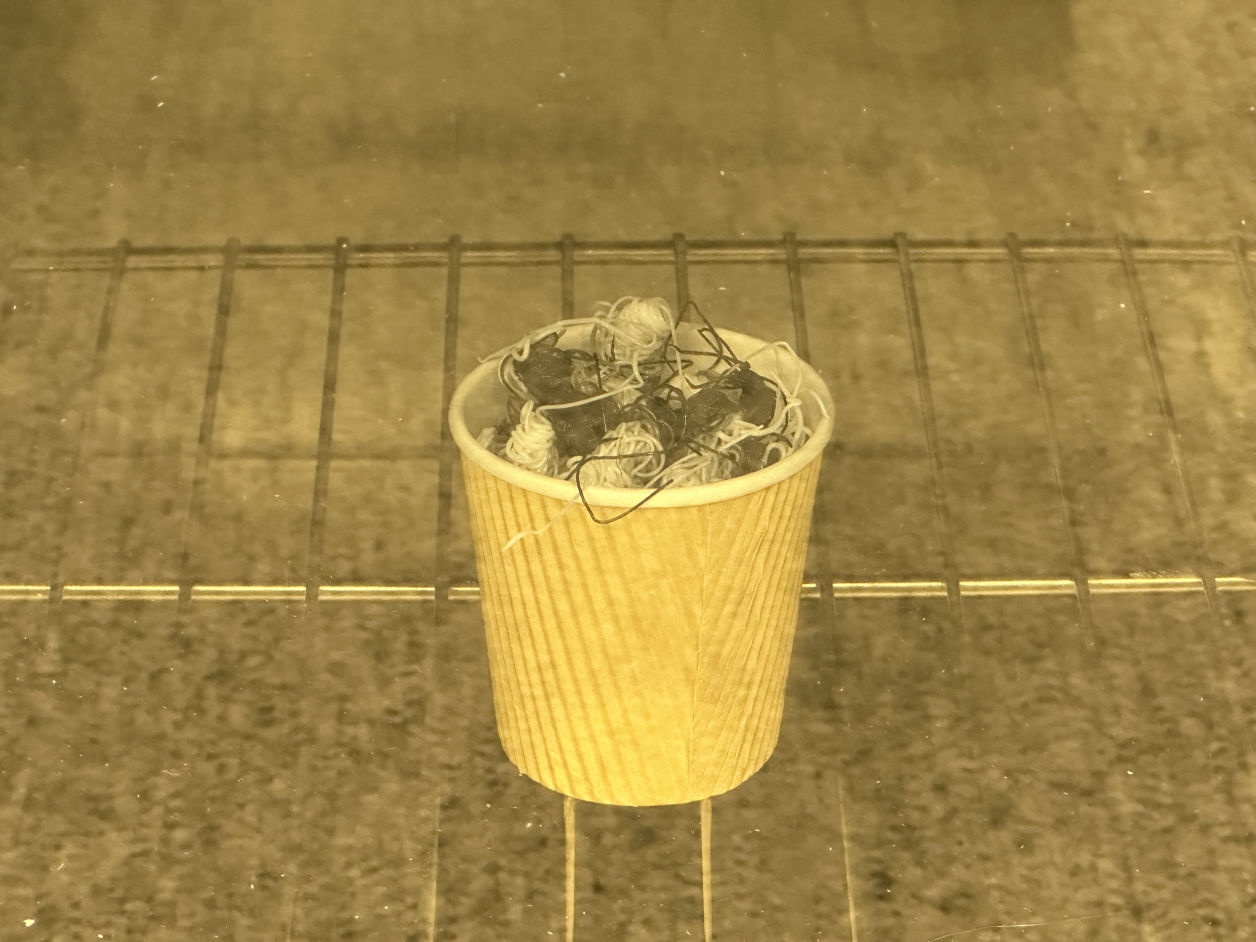

After around half an hour, since the machine's temperature rises a bit slowly, we can observe that some of the materials were not thoroughly melted.

Setting the temperature to 250 degrees Celcius, the melting process was much better, and the PLA could flow smoother to fit in the cup's shape with gravity.

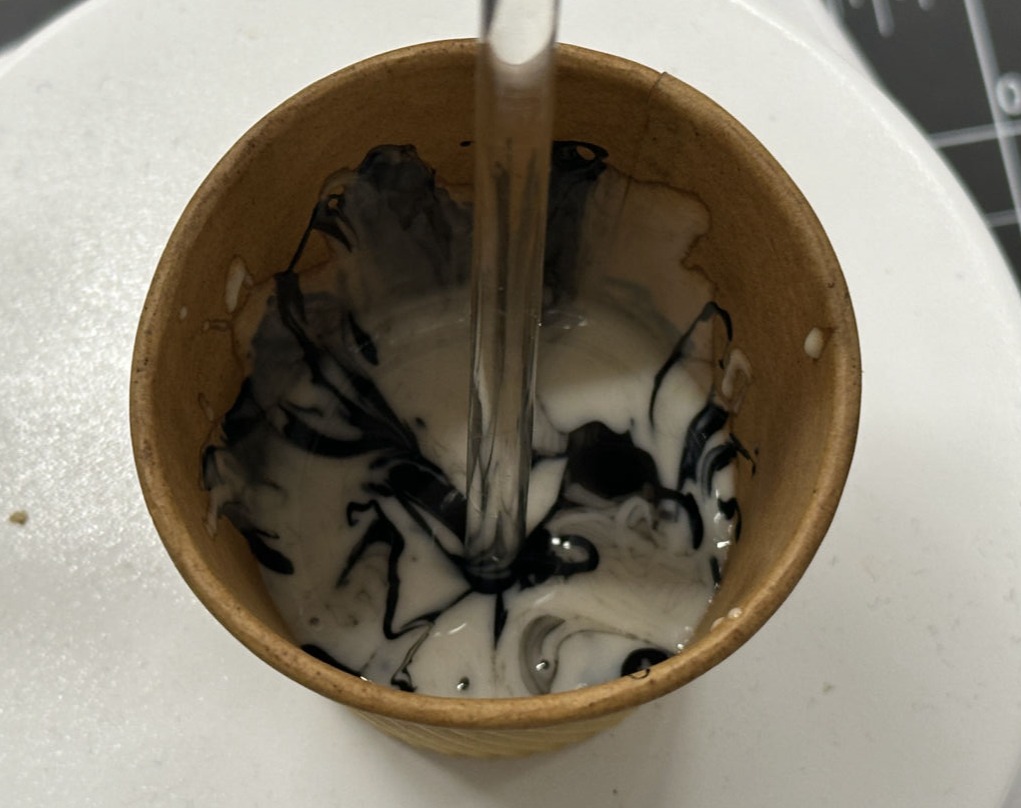

After removing it from the oven, I also tested the flexibility of the liquid material by poking it with a glass tube. Since the plastic colds extremely fast, everything comes to solid again within only half a minute.

The experiment successfully melted all the waste materials into a condensed espresso!

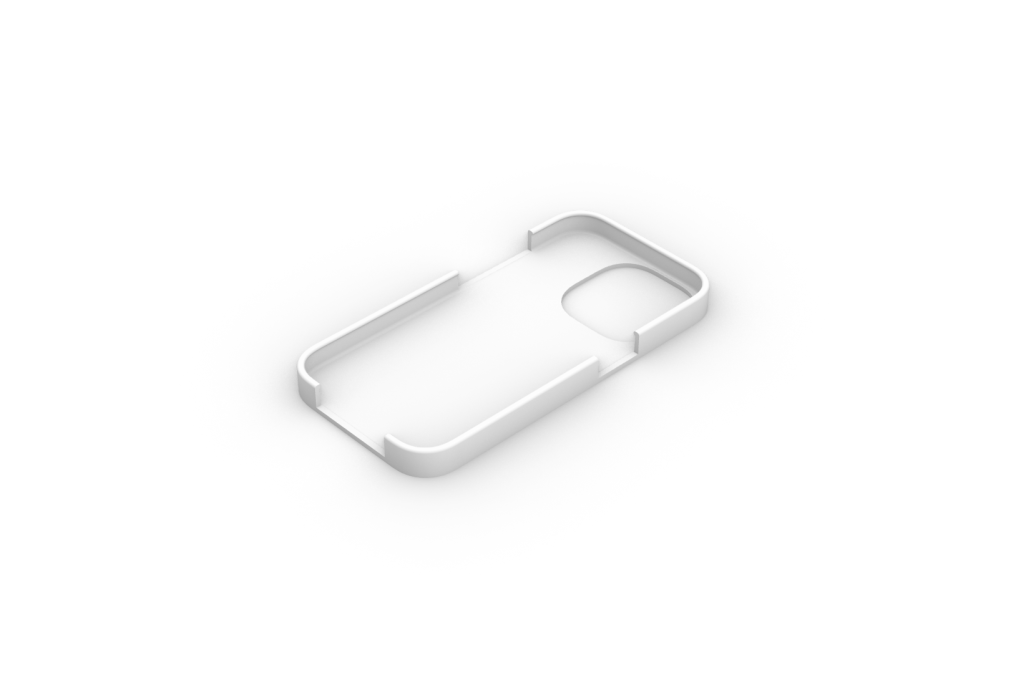

I found this iPhone case's STL file on the open source websites.

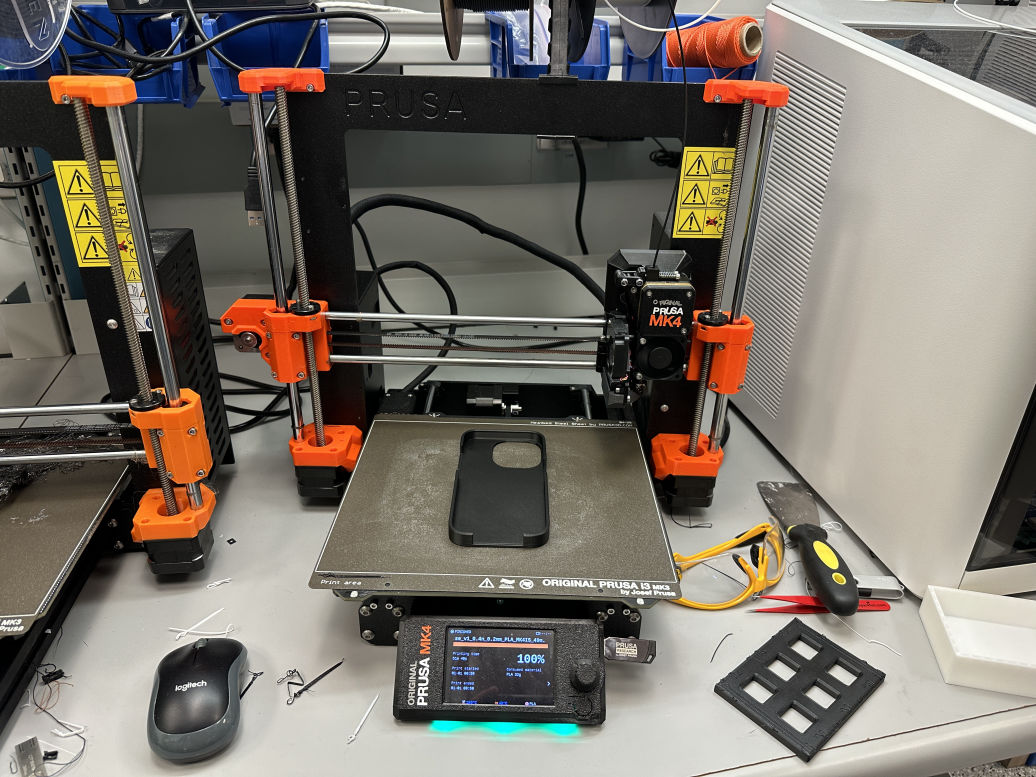

To cast a mold for repeatable fabrications of iPhone cases, I 3D printed this iPhone case as the geometry for reference.

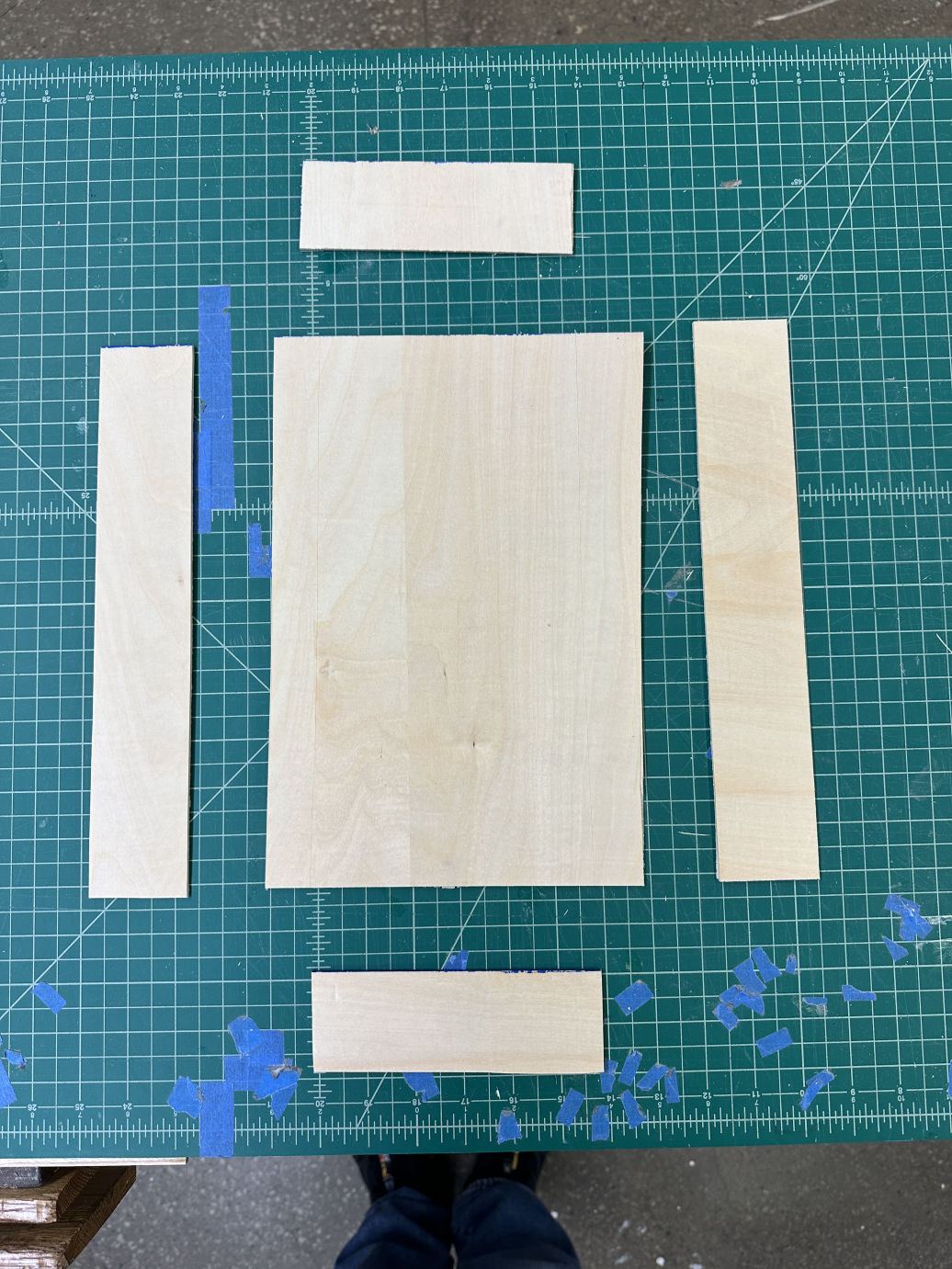

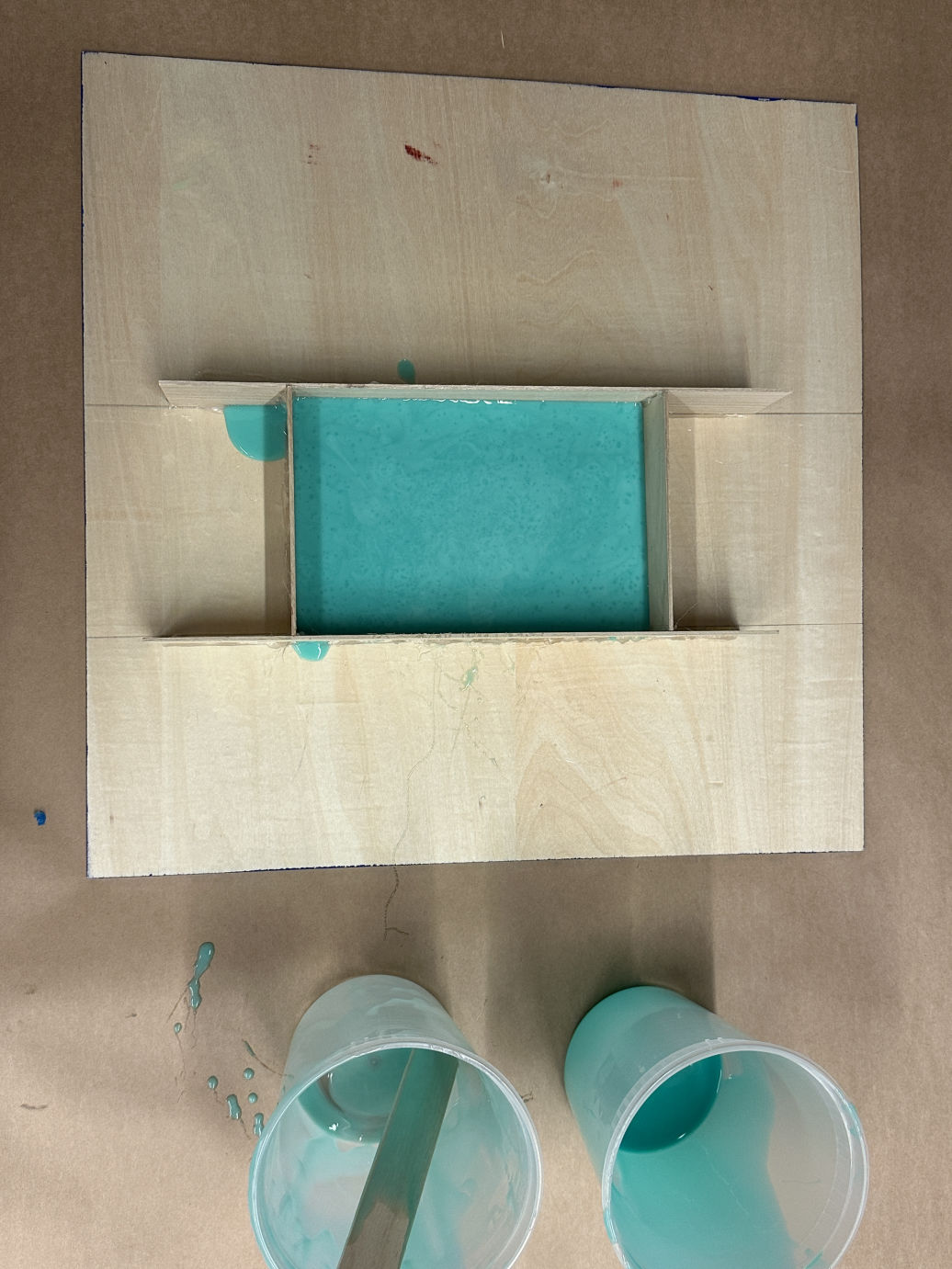

The outline of the container was made of some wooden pieces and formed a small box for casting the silicone.

Spraying some oil or mold-release spray on the wood box to make life easier when removing it in the future.

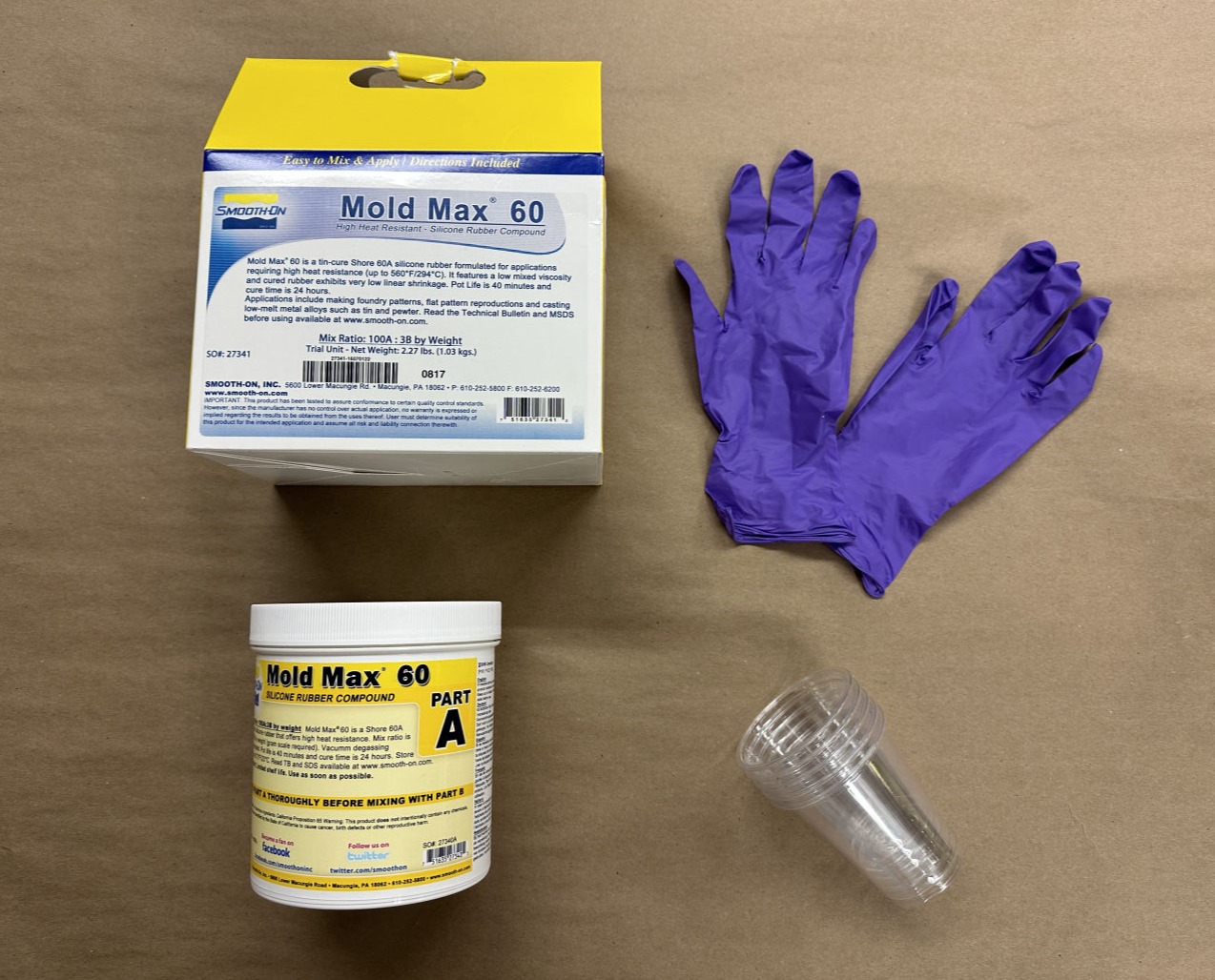

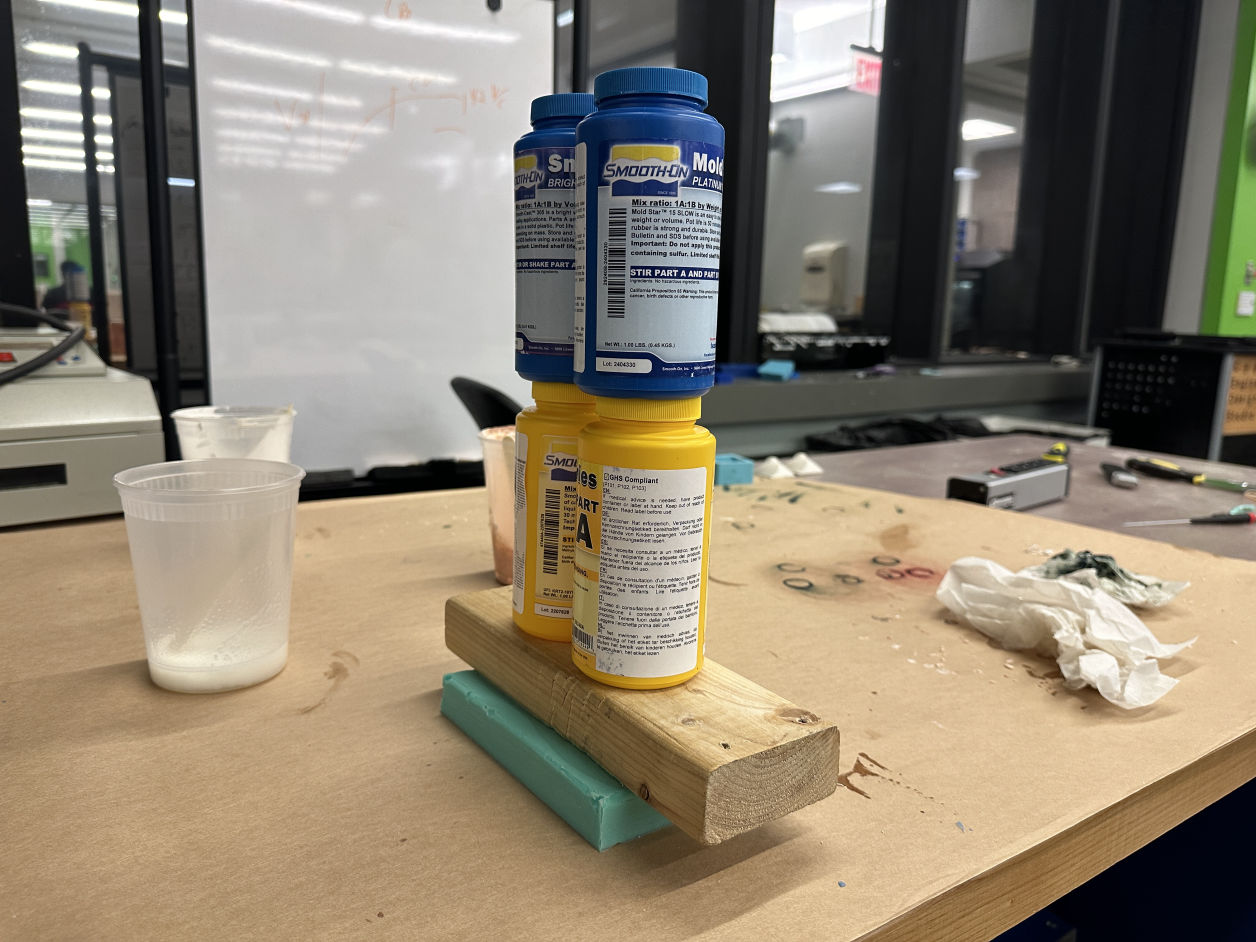

Because the molding process requires high temperatures in the oven, I am using Mold Max 60, a high-temperature silicone that can withstand under 294°C.

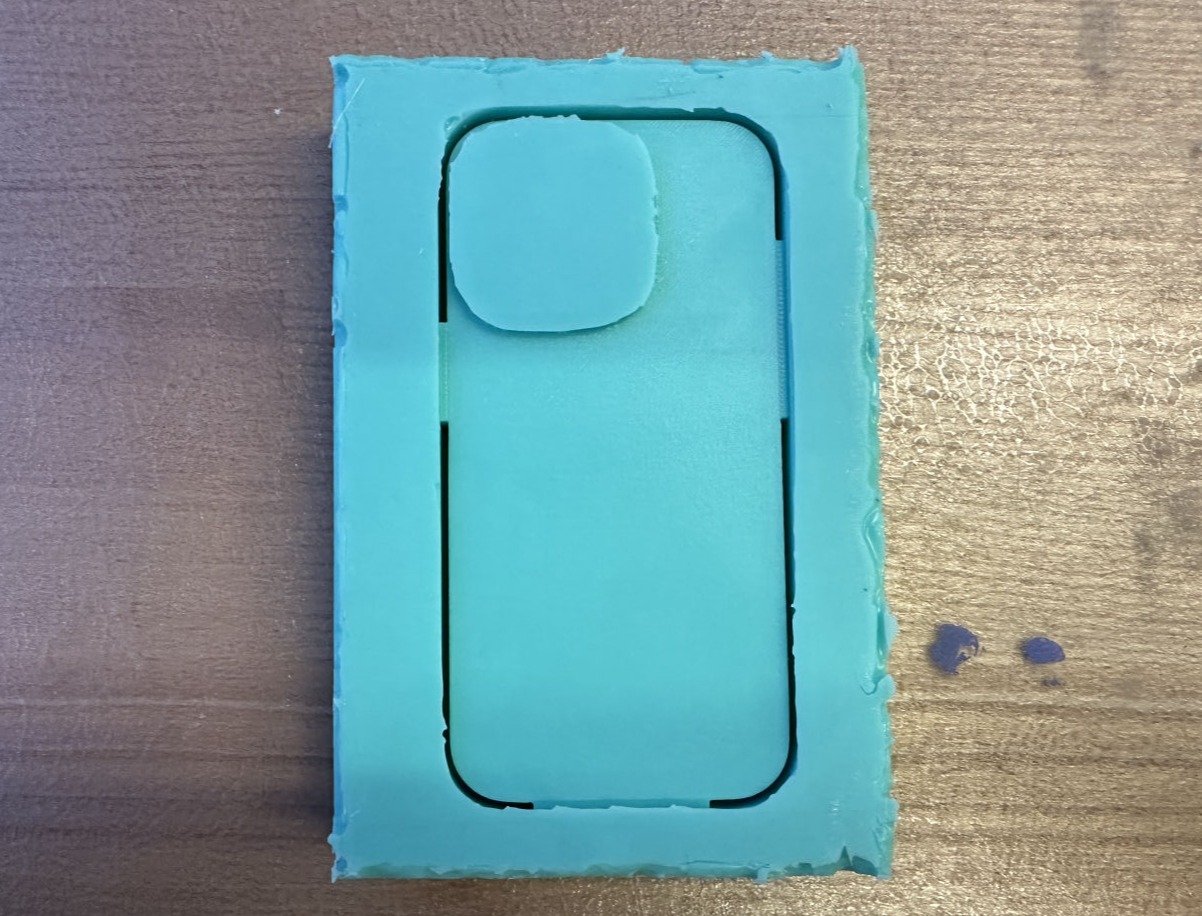

Because it was not mixed with an exact portion, the first experiment failed to form the geometry.

Good news: the iPhone case's mold finally formed successfully!

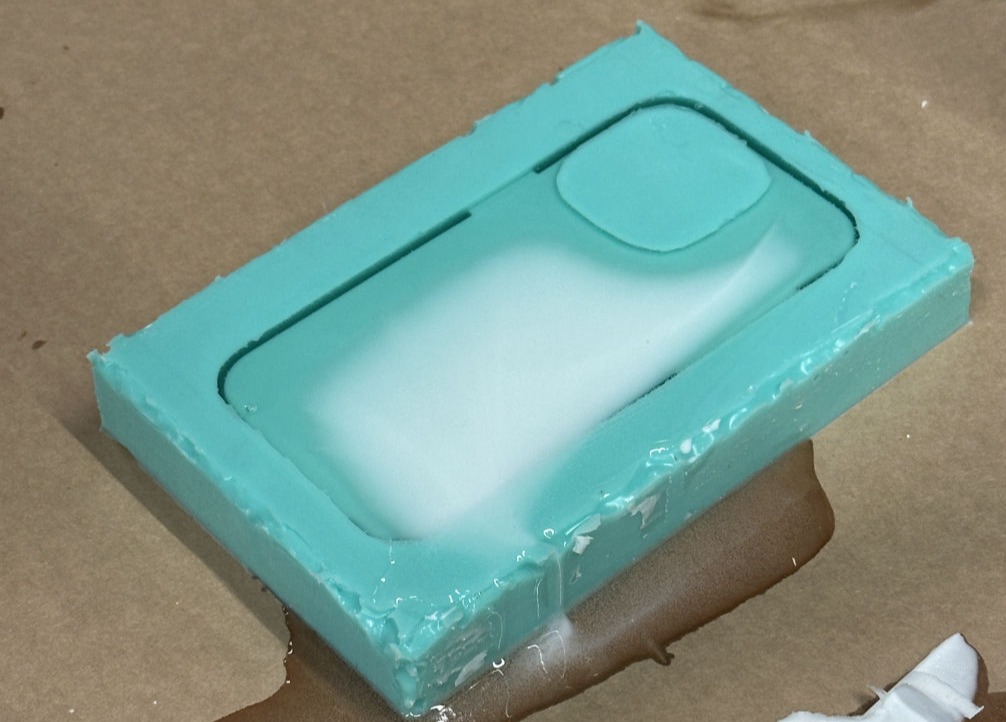

Using the "smooth-cast" plastic in this test, it was easy to pour and cured fast and gradually became solid within 30 minutes.

The iPhone case was done! With the same mold, from now on there's no need to buy cases, and I can fabricate a plastic iPhone case per 30 minutes!

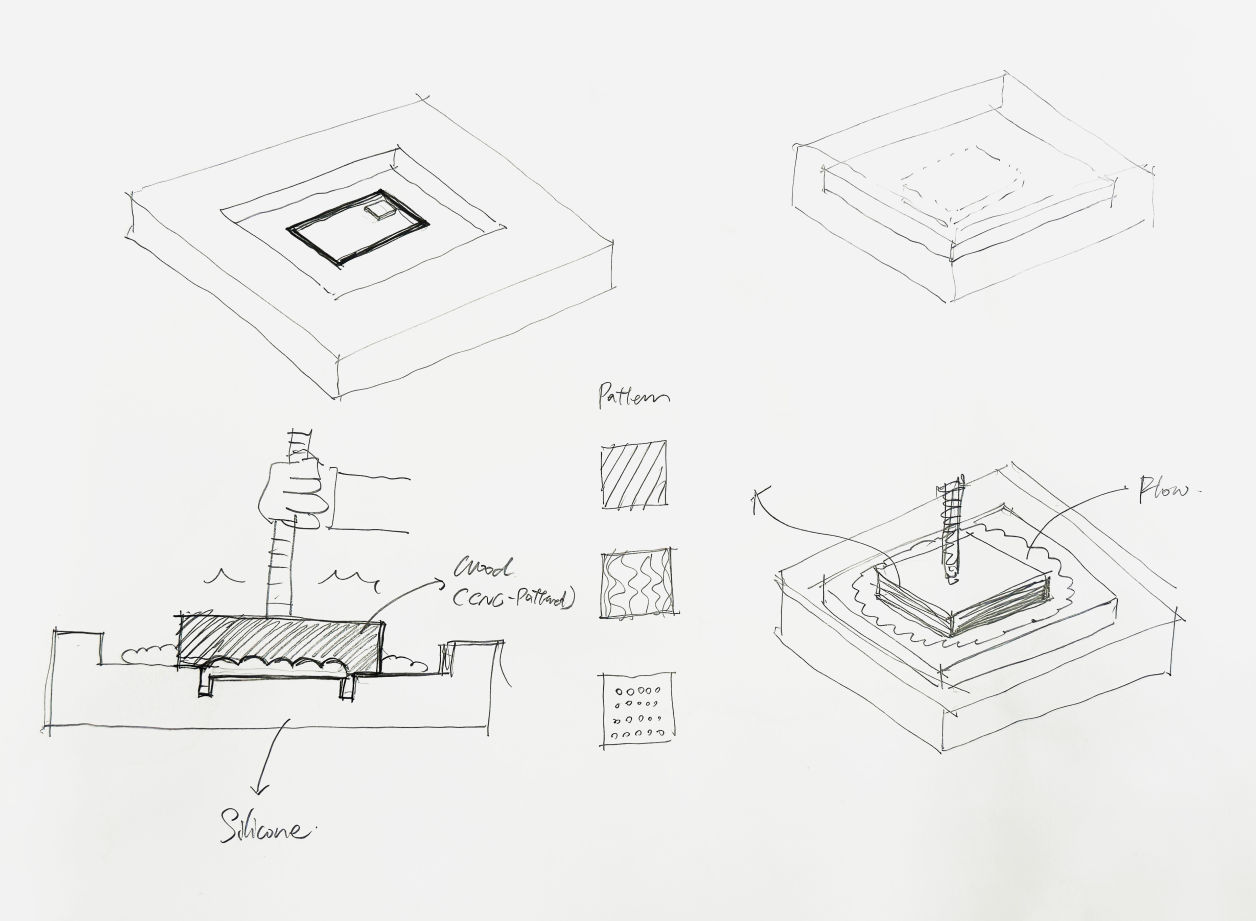

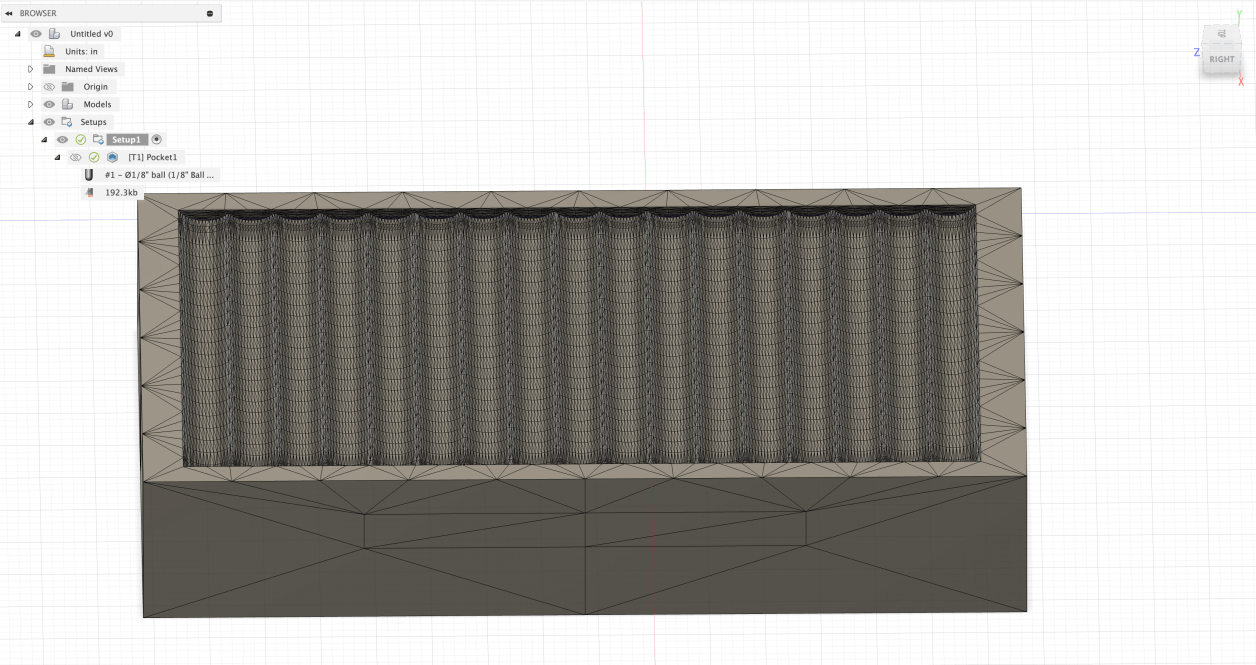

Design a simple pattern in Rhino and insert it into Fusion. Generating the tool path file afterward.

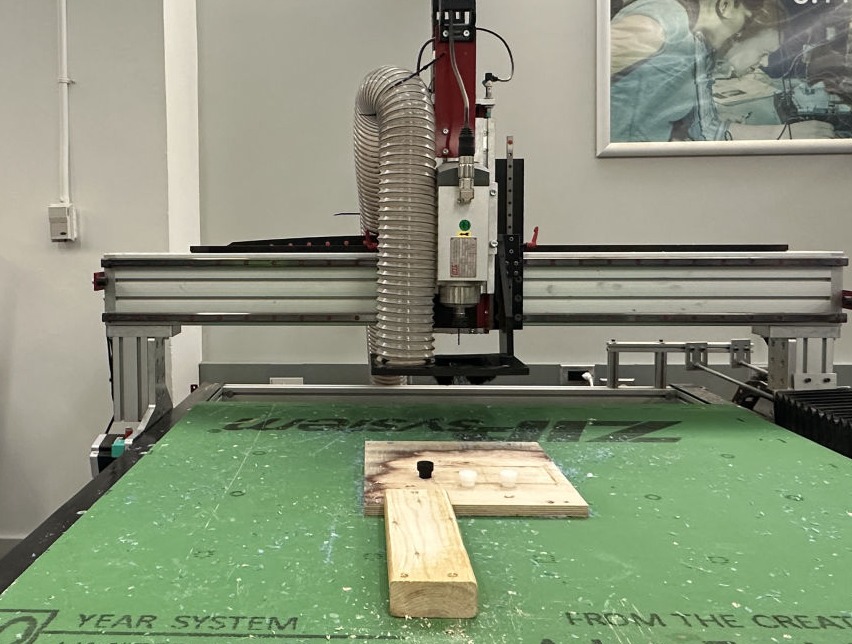

We took a piece of two-by-four wood crap and placed it on the table for CNC milling.

The texture got a bit rougher than we originally thought and built in the 3D model, Since the texture's resolution was based on the 1/8'' tool that we used.

My intention was to create an easy workflow to customize your own desired pattern on the back of the iPhone case by creating these CNC stamps rather than pairing another silicone.

I poured a bit more plastic than usual in order to fill in the stamp's patterns. However, something happened after pressing for a long time.

Guess what? The wood patterns merged perfectly with the plastic, and we couldn't remove it without breaking it. Thus becomes a bigger iPhone case lol......

Next time, I will try to CNC some smoother materials (like wax) and remove it earlier after the stamp.

Mobirise.com