HOW TO MAKE (ALMOST) ANYTHING

MAS.863 / FALL 2011

KELLY SHAW

M.ARCH LEVEL III

03 / PCB DESIGN, FABRICATION, AND ASSEMBLY

04 / WATERJET CUTTER AND CNC MILLING

11 / INTERFACE AND APPLICATION PROGRAMMING

12 / MECHANICAL AND MACHINE DESIGN

13 / NETWORKING AND COMMUNICATIONS

WEEK 12 / MECHANICAL AND MACHINE DESIGN

This week I played catch-up to my Final Project Proposal. Check Week 14 for the updates. I spent most of my

time battling with Charlieplexing in Eagle but each section was also tasked with making the MTM Snap-Fit

Machine. SUPER FUN to put together. Unfortunately I only have documentation of the CNC-milled components

coming together:

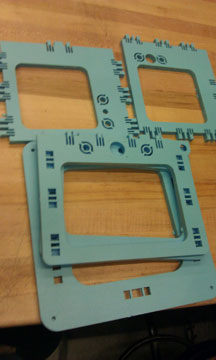

[all the milled pieces]

[enclosure pieces]

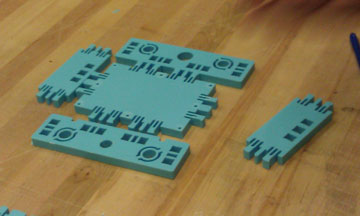

[laying the pieces out for assembly, orientation is important!]

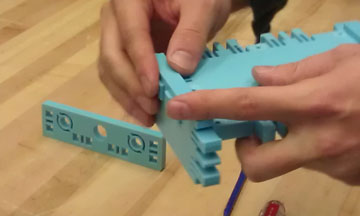

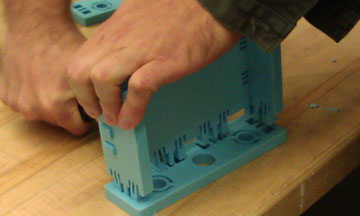

[Jonathan demoing how the pieces snap together]

[using a screwdriver to push the flextures to fit each piece into its slot]

*Note that each notched leg has a channel to give the plastic more flexibility. It was also conveniently a slot

you could wedge the screwdriver into.

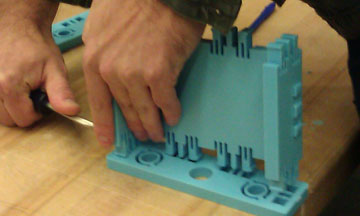

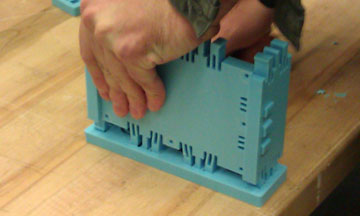

[adjusting each piece on one face just a little before applying a ton of downwards pressure]

[SNAP]

[assembling the body]