HOW TO MAKE (ALMOST) ANYTHING

MAS.863 / FALL 2011

KELLY SHAW

M.ARCH LEVEL III

03 / PCB DESIGN, FABRICATION, AND ASSEMBLY

04 / WATERJET CUTTER AND CNC MILLING

11 / INTERFACE AND APPLICATION PROGRAMMING

12 / MECHANICAL AND MACHINE DESIGN

13 / NETWORKING AND COMMUNICATIONS

WEEK 07 / EMBEDDED MICROCONTROLLER PROGRAMMING

This week we programed an ATtiny44 microcontroller using the FabISP Programmer we

created from Week 03. We were asked to add a push button and LED to a modified PCB

layout from Eagle.

01. Designing the PCB

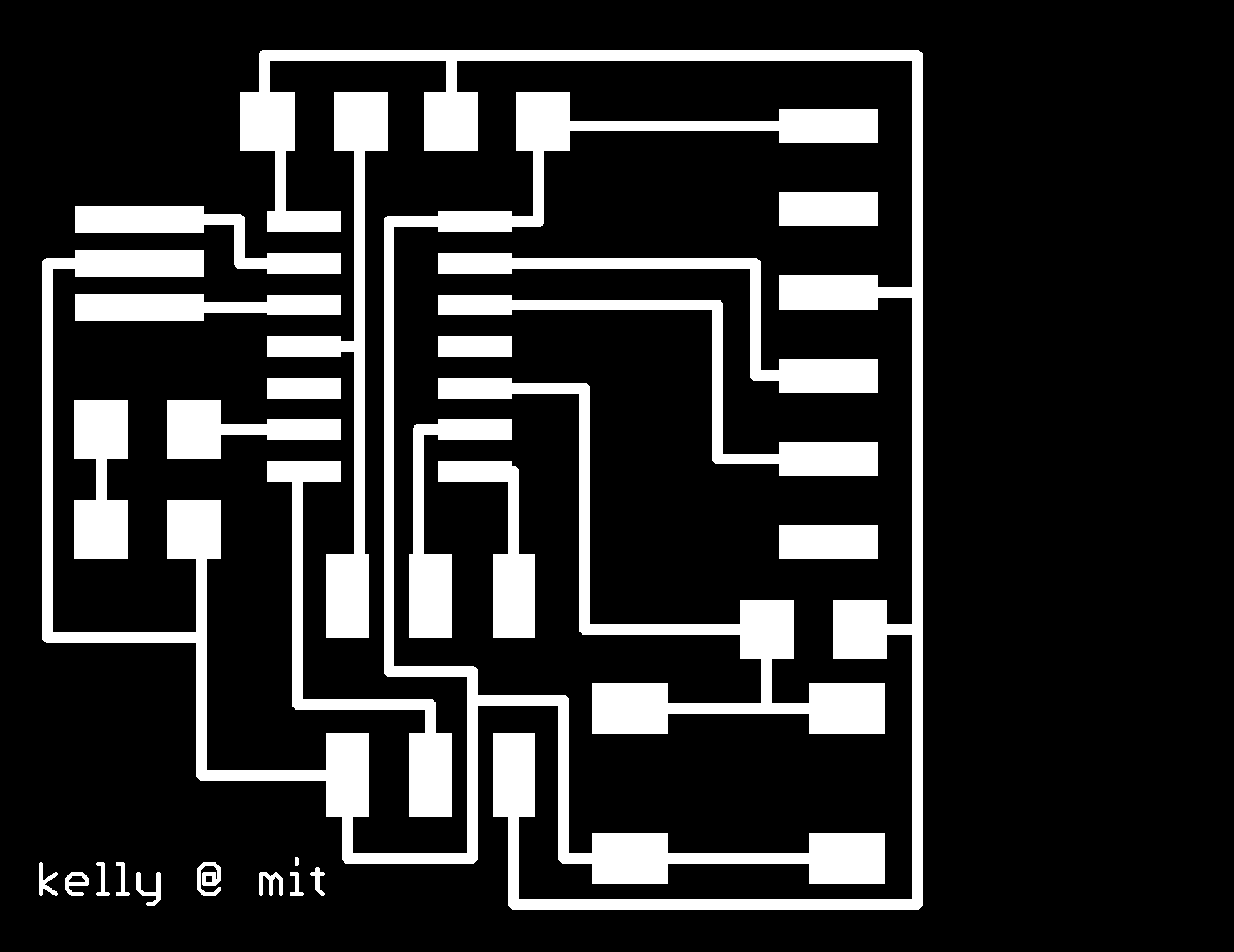

We used Eagle to add our button and a LED to the schematic. I missed the tutorial but Neil

was nice enough to take some notes which I've included here. I found that the best way to

learn the UI for Eagle was to look at some existing schematics from previous years and

try to replicate them, while switching to the layout view to better understand how the traces

and components are laid out.

[schematic view]

[exported .png of traces from layout view]

02. Milling and Stuffing the PCB

I used the default settings for a 1/64'' bit for milling the traces. For the depth of cut, the default

value was 0.1 mm but after one pass, my traces appeared to only be partially milled.

[partially cut copper traces]

On the second attempt I successfully re-cut my traces with a depth of 0.2 mm. To do the cut-

out with the 1/32'' bit you have to remember to double check the 3D settings. The min Z-cut

should be 0 mm, but the maximum depth of cut should be about -1.8 mm to ensure you cut

completely through the board. The Z-step should be at 0.5 mm.

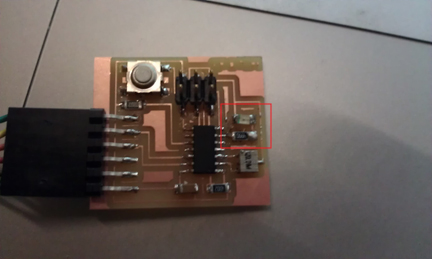

[milled board]Stuffing the boards was pretty straight forward but it was important to check the orientation of

the LED and the ATtiny44 microcontroller. On my first attempt I had soldered my LED in the

wrong direction. The green line on the LED should be pointing away from the resistor and

the resistor should be limiting the current going into the LED. I was able to check if my LED

was working properly by using the FTDI cable and running the Blink program example from

Arduino.

David Mellis ran a good session on programming the ATtiny with Arduino and most of the

steps can be found on the high-low tech site.

[problem area on fabricated board]

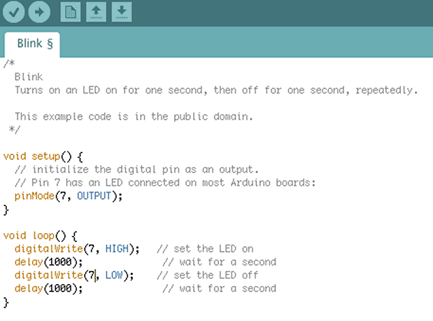

I edited the Blink.c example to work for my board. In my case, the LED was located on Pin 6,

which in the Arduino environment referred to Pin 7.

[Arduino Blink example]

[LED working]

03. Programming the ATtiny44 in C

Programming the board to turn the LED on when the button was pushed seemed like an easy

task in theory...until I realized that I didn't know much about C libraries, bits, bytes, registers, the

difference between WinAVR and CrossPack , or what a .c, .make. or .hex file was.

The debugging session David held became my opportunity to ask as many questions as possible

and here's what I learned [thanks David!]:> It's good to understand the syntax for the language. Some good places for understanding

the basics include:AVR Libc

HLT Wiki

> The .c, .make, and .hex business. The code you write is saved as a .c file. I used TextEditor

to write and edit my code. With the .c file you need to create a .make, file which includes a

compilation of program commands that translate your code (.c files) into machine code

(.hex files) for the microcontroller.

>Once you have your .c and .make file you can run the following commands in Terminal to

program the microcontroller from the FabISP:make -f somefilename.c.make // this generates the hex file

make -f somefilename.c.make program-usbtiny // this loads the program to your microcontroller

My steps to learning how to program in C included getting the LED to turn on, getting it to blink,

getting the button to control the LED, and finally getting the LED to turn on and stay blinking

when the button was pressed. Here's the final code:

// LED Button Blink Program

#include <avr/io.h>

#define F_CPU 1e6

#include <avr/delay.h>#define TRUE 1

#define FALSE 0int main()

{

//SETUP

//Button is on PA3

//LED is PA7PORTA= _BV(PA3); //Turn button pullup resistor on

DDRA = _BV(PA7); //Enable output on the LED pin

PORTA = _BV(PA7); //Turns LED on//LOOP

while (TRUE)

{

if ((PINA & _BV(PA3))) //button is not pushed

{

PORTA = 0; //turn LED off

}

else

{

PORTA = _BV(PA7); //turn LED on

_delay_ms(1000);

PORTA = 0;

_delay_ms(1000);

}

}

}

[FabISP programming the ATtiny44]To see everything in action:

LED BLINKY BUTTON VIDEO