HOW TO MAKE (ALMOST) ANYTHING

MAS.863 / FALL 2011

KELLY SHAW

M.ARCH LEVEL III

03 / PCB DESIGN, FABRICATION, AND ASSEMBLY

04 / WATERJET CUTTER AND CNC MILLING

11 / INTERFACE AND APPLICATION PROGRAMMING

12 / MECHANICAL AND MACHINE DESIGN

13 / NETWORKING AND COMMUNICATIONS

WEEK 02 / LASER AND VINYL CUTTER

INSPIRATION FOR KIT-OF-PARTS: Bucky Fuller's Geodesic Dome

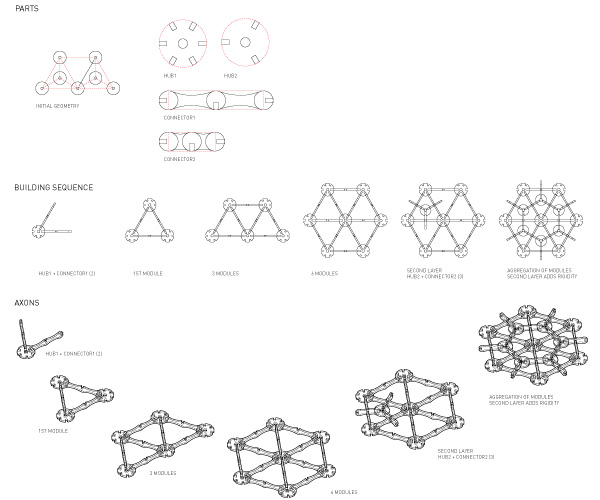

DESIGN AND CONSTRUCTION OF HUBS AND CONNECTORS

LASER CUTTING1,

Testing the material (SPEED / POWER)

2.

Material testing: The connector ends had a very small chamfer but what really made

a difference was the grain of the cardboard when I cut the material. There was

more rigidity in one direction vs. the other. In the images below, the one on the left

was weaker in its length and the corrugation crushed more easily when being fitted

into notches. I chose to go with the grain on the right for strength but there was a

tradeoff as I would later experiment and find out that the right grain was better for

introducing curvature to the 6 module configurations.

3.

Testing the module and its crossbracing: I realized after this test that I had left out

6th notch in the connector hub and had to tweak some of the connector lengths.

4.

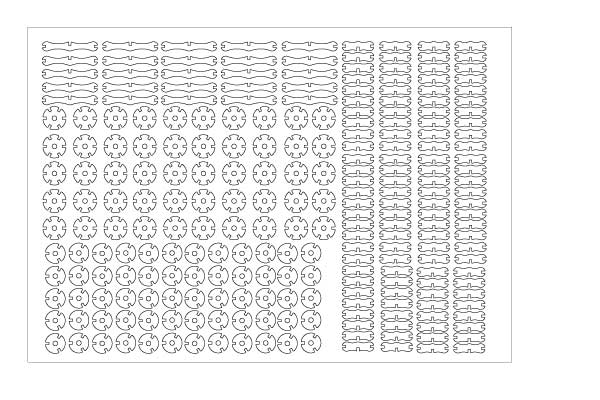

The whole test file being cut. For the DWG file click here.

5.

Laying out the pieces and putting it all together,

6.

Finished pieces put together. I was hoping to actually make a whole geodesic dome

or sphere but I ran out of time. In the end I might have been able to achieve it with

longer connectors and experimenting more with using the other grain. When you

lift the center of the construction up, there starts to be a bend but I think it would have

taken ALOT more time to keep going with the existing pieces!