HOW TO MAKE (ALMOST) ANYTHING

MAS.863 / FALL 2011

KELLY SHAW

M.ARCH LEVEL III

03 / PCB DESIGN, FABRICATION, AND ASSEMBLY

04 / WATERJET CUTTER AND CNC MILLING

11 / INTERFACE AND APPLICATION PROGRAMMING

12 / MECHANICAL AND MACHINE DESIGN

13 / NETWORKING AND COMMUNICATIONS

WEEK 08 / 3D SCANNING AND PRINTING

This week's assignment was to 3D scan an object and design and 3D print an object.

01. 3D SCANNINGWe used the 3D ZScanner to scan our objects this week. The scanner reminds me a bit of Wall-E.

Super cute and deceptively heavy.

[ZScanner]

For future reference I documented the workflow:

- After setting up the laptop with power and plugging in the firewall, open the ZScanner program.

- Go to ''Configure'' in the menu options and select ''Sensor Configuration''.

- Place your object on the black foam with positioning dots and hit ''Auto Adjust''. Hold the trigger

down while pointing the crosshairs at the object. Move towards and away from your object until

you have ''Reliable'' data.- Hit ''Apply'' and then ''Ok'' to apply your settings.

- Go to ''Configure'' and select ''Sensor Calibration''.

- Open the top secret wood box and pointing the laser at the white X, hit the ''Acquire'' button.

Hold the laser trigger down, focusing the crosshairs on the white X until the screen counts

from 1 to 10.- Put your object back on the black foam and make sure there are no other points lying nearby.

- Choose the ''Scan Surface'' button from the menu and choose ''Scan Positioning Features''.

Hit ''Record'' and scan the gun over all your white positioning dots. Once all the dots show up

on screen, hit the ''Stop Scan'' button.- Choose the ''Scan Surface'' button again and choose ''Scan Surface''. Hit ''Record'' and this time,

scan over your object slowly without moving the object's position on the black foam.

* You can move the black foam around but be sure your object's position relative to the white

dots remains constant.- When you are happy with the result, hit ''Stop Scan''.

- You can adjust the resolution and shrink the volume of the scan from the Surface Parameters

options and using the ''Fit Volume'' and ''Move Volume'' buttons.- To export your file, go to ''File'' and then ''Save Facets'' to save your file as an .stl file.

The first object I scanned was a wooden bracelet. I thought it would be interesting to try to capture

all of the edges and twists.

[wooden bracelet on positioning surface]

[SCANNING IN PROCESS]

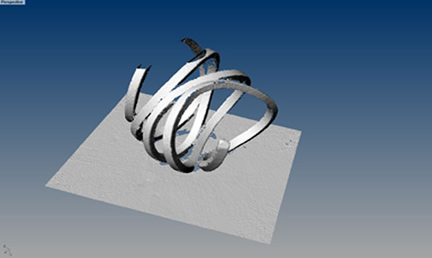

[bracelet.stl in Rhino]

[rendered scan in Rhino]

I tried the scan again by putting the positioning dots on the surface of the bracelet. But for some reason

the scanner would only scan the dots. At first I thought maybe it couldn't differentiate between the wood

table behind it and the wooden bracelet, but even with a black background, the scanner was still only

scanning the dots.

[positioning dots on the bracelet]

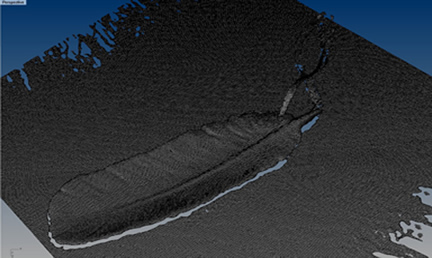

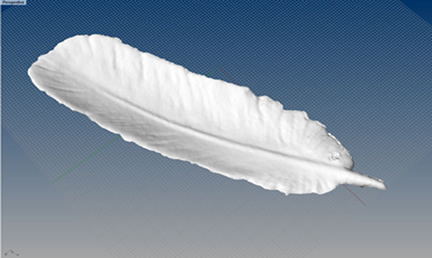

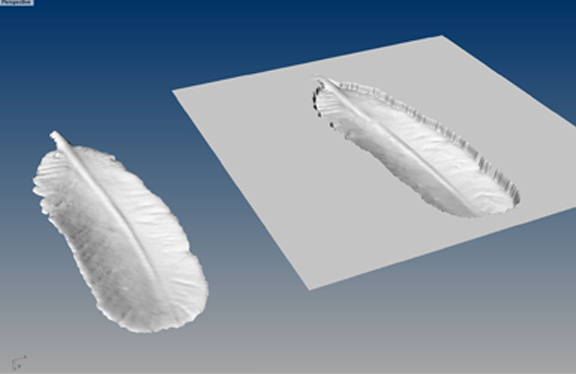

I had a little more time in the lab so I decided to try scanning an object with a detailed surface. I chose

a ceramic feather. I knew that it would be difficult to capture the underside of the feather and give it

the same thickness but I wanted to use the scan to more effectively render the real thinnesss of an

actual feather. These scans came out very well.

[feather placement on positioning surface]

[feather.stl in Rhino]

[feather after a little cleaning up]

[I have hopes to try to cast more copies of my feather...tbd]

02. 3D Printing

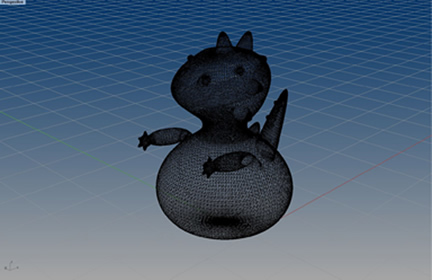

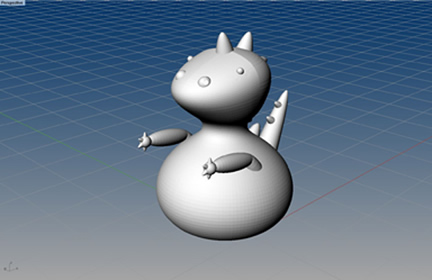

I was determined to give Dino [modeled in Rhino] a better twin this week via the ZCorp 3D printer.

[Dino wants a hug...using the 3D printer to get those undercuts]

[Dino.stl]

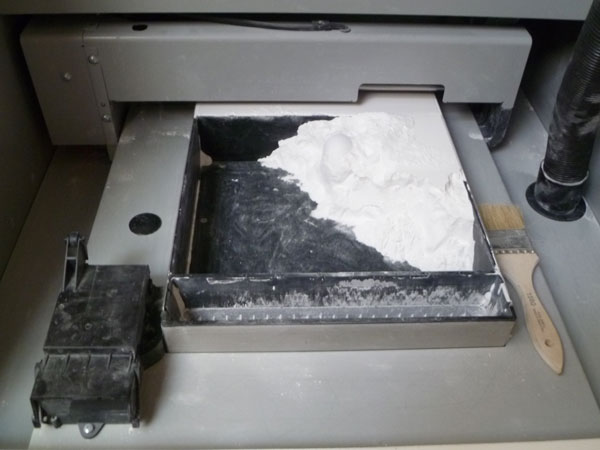

[excavating my dinosaur]

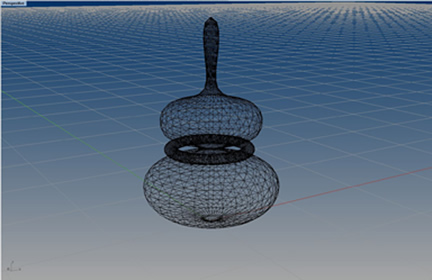

[clean Dino]We also had the option of using the ABS printer so I wanted to try a very small top with embedded

ring. A very nice advantage of using ABS Dimension is that you can have working and embedded

parts.

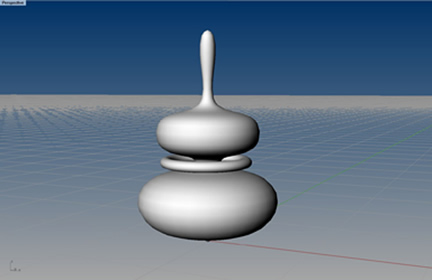

[spinning top modeled with an embedded ring]

[top.stl]

[printed top]

[SPINNING TOP]