Week 8 Molding and Casting

Our task this week is to mkae something "big". It is a so-called "pretty crazy week" according to the TAs.

In our Architecture session, OSB boards and MasterCam is used, we went to N51 to do the machining.

Since I want to make a robotic arm for my final project, it is a good chance to start practicing the

3D modeling software from now and try to make a large "prototype".

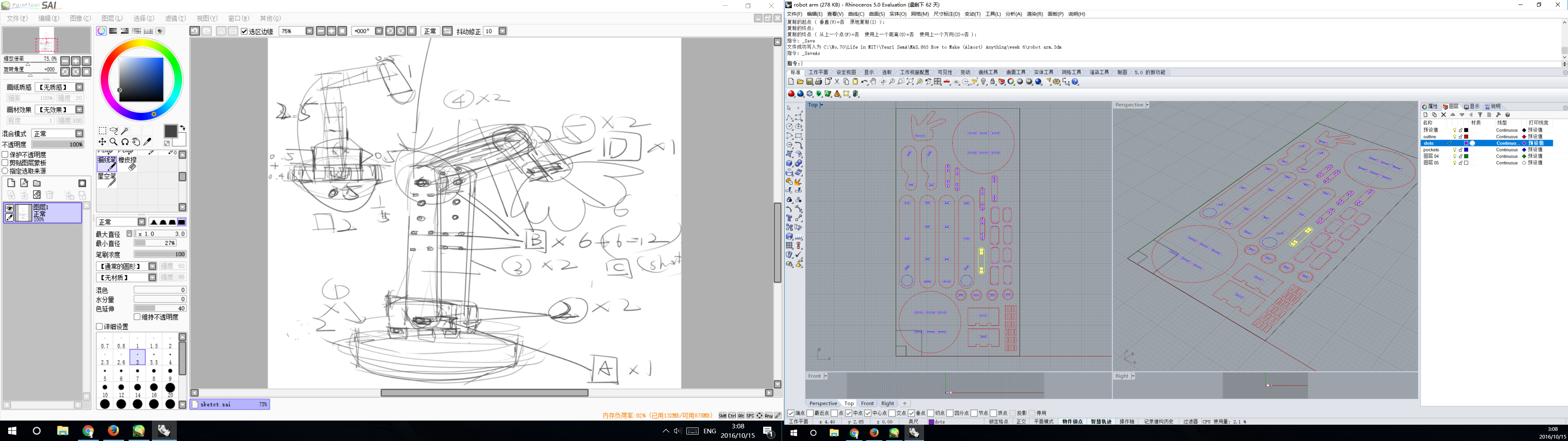

Robotic Arm Design

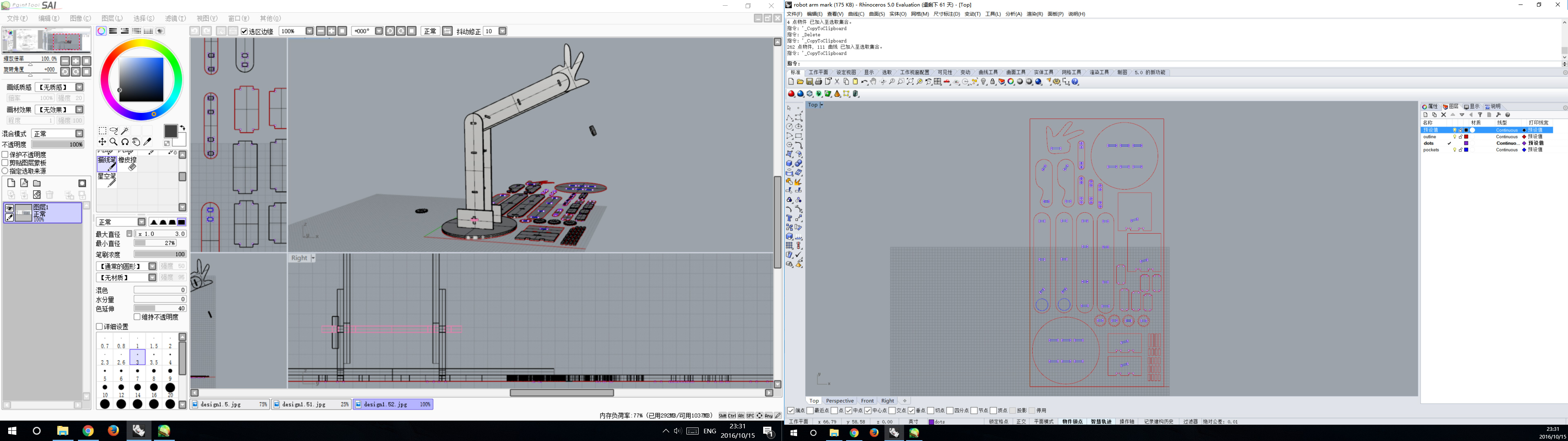

I made a basic sketch first in Easy Paint Tool SAI in order to give myself a basic idea of how this press-fit robotic arm will look like and how many parts are needed. After the sketch I started to draw cutting path in Rhino. I made the model as large as I could. It was a time consuming and tiring process. After finishing the first iteration of trace I extrude 3D solid from the 2D curves and assembled the parts to see whether there need any modifications or any part missing.

Later I thought Rhino may not be the best tool for this task, if I could do it again I may download and start to learn Solidworks or freeCad. These two are better in building things related to mechanicals, Solidworks is especially fit for designing a complicated mechanical system such as cars and robots.

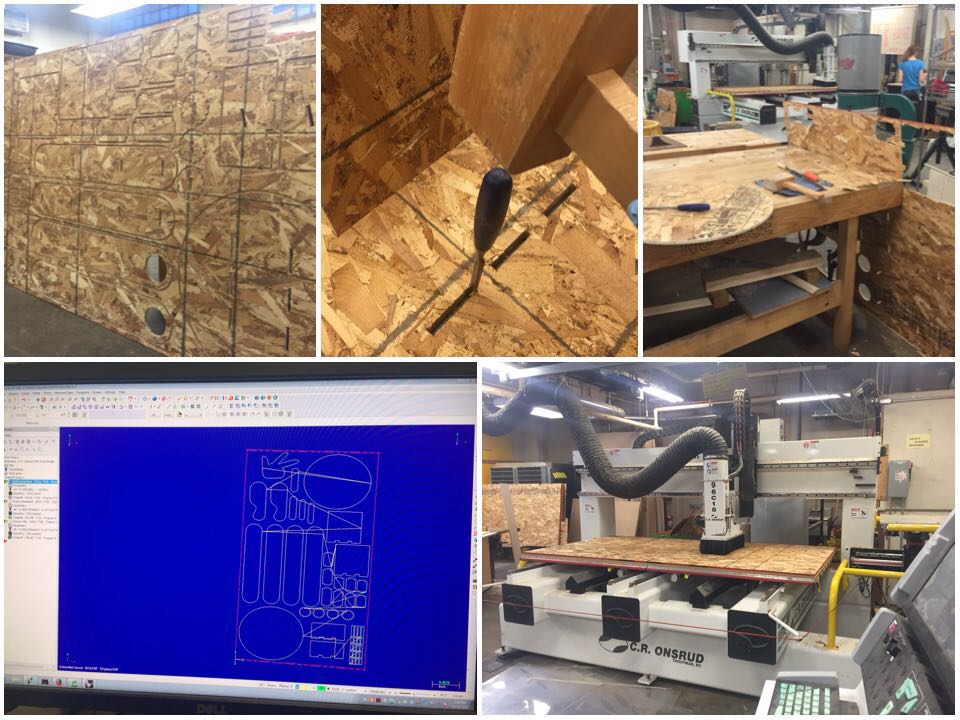

Setting up MasterCam

We export .3ds files for MasterCam. It is complex software the setting steps of which is hard to be remembered through just one short tutorial session. The toolchain is majorly concluded into 2 steps:1. Drill points at the corners, since the endmill is round and corner parts won't be cut without the holes.

2. Set offset for the tool chain and cut the board. We also need to adjust the direction of the end mill's movement since there will be a size difference based on different moving direction.

Thanks to Max and Calvin, they set up office hours during the weekend to help us setting up and check our MasterCam files before we run the machine,

in order to make sure no one is going to get trouble with this huge project.

Thanks to Max and Calvin, they set up office hours during the weekend to help us setting up and check our MasterCam files before we run the machine,

in order to make sure no one is going to get trouble with this huge project.

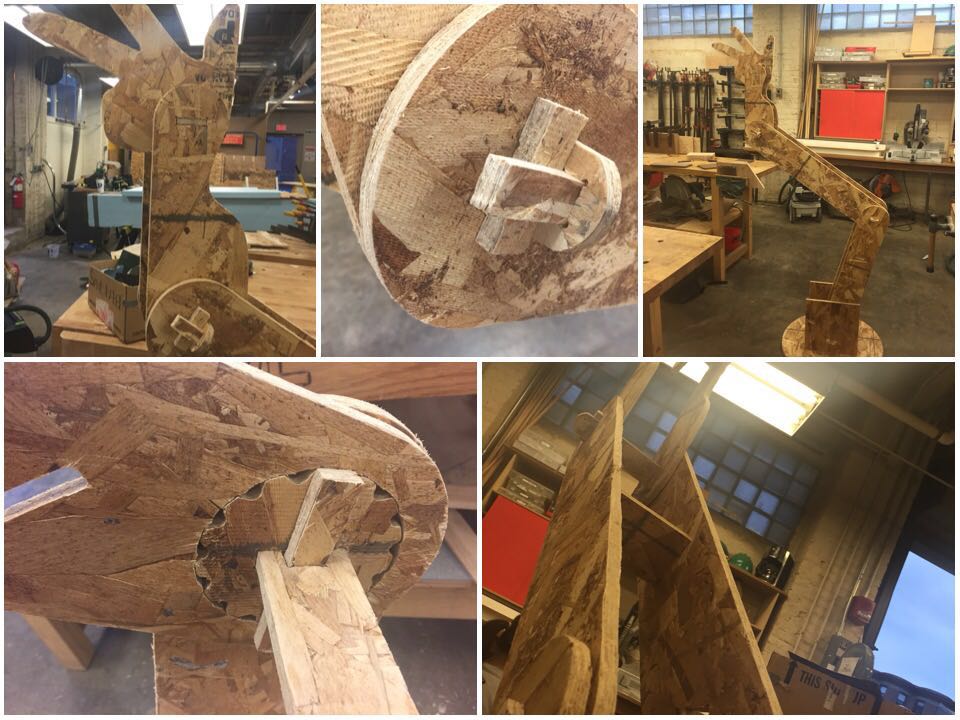

Machining and Assembling

This part does not need much technique. Just work hard and USE FORCE.

And welcome to SANDPAPER HELL.

The worst mistake I've made is not realizing the existence of sandpaper machine until I

finished 70 percent of the assembling. It made my life much easier.

The worst mistake I've made is not realizing the existence of sandpaper machine until I

finished 70 percent of the assembling. It made my life much easier. Here is the final arm, it is taller than me! Wow!

Here is the final arm, it is taller than me! Wow!