Final Project

Throughout the weeks I was constantly working toward my final project which morphed from an electrically expanding dinny room table into a home alarm keypad!

Hi! I'm a computer scientist turned management consultant turned engineer looking to build meaningful hardware and software products. I took this class so that I could get my fabrication skills up to snuff so that I can rapidly prototype electromechanical hardware systems. I hope you find this documentation helpful as you begin your fabrication journey. I know I had a blast learning how to make things and I'm sure you will too!

You can visit the main course website from my year here.

Throughout the weeks I was constantly working toward my final project which morphed from an electrically expanding dinny room table into a home alarm keypad!

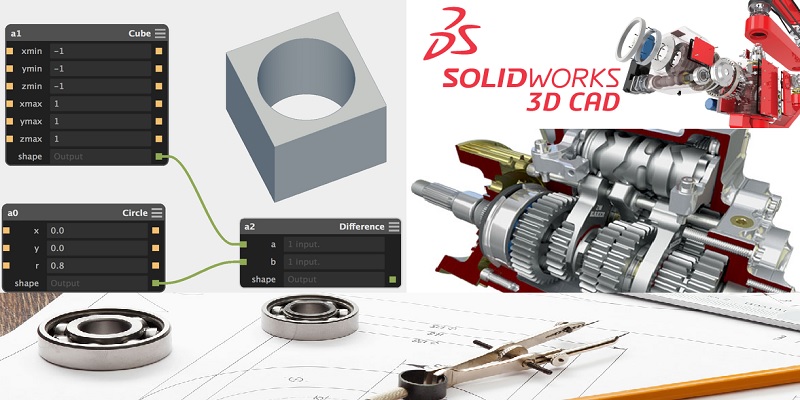

Our week 1 task was to sketch and model a final project using CAD software. I decided to tackle this week using Antimony and Solidworks.

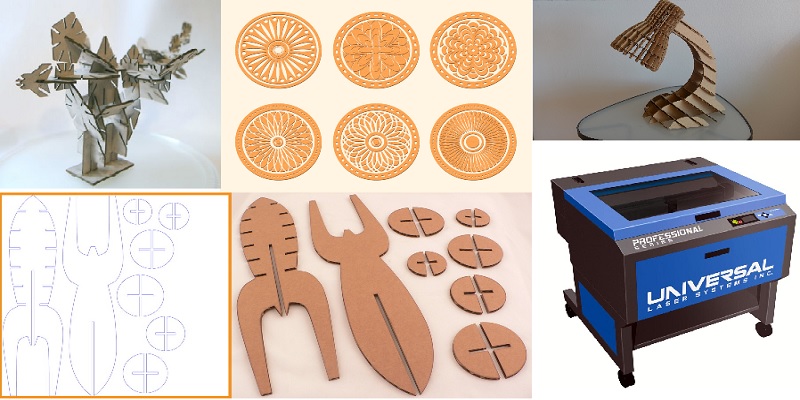

Our week 2 task was to begin to experiment with the vynil and laser cutters and to use the laser cutter and some corregated cardboard to build a press-fit construction kit. I decided to take some simple shapes and make "legos" and build something random.

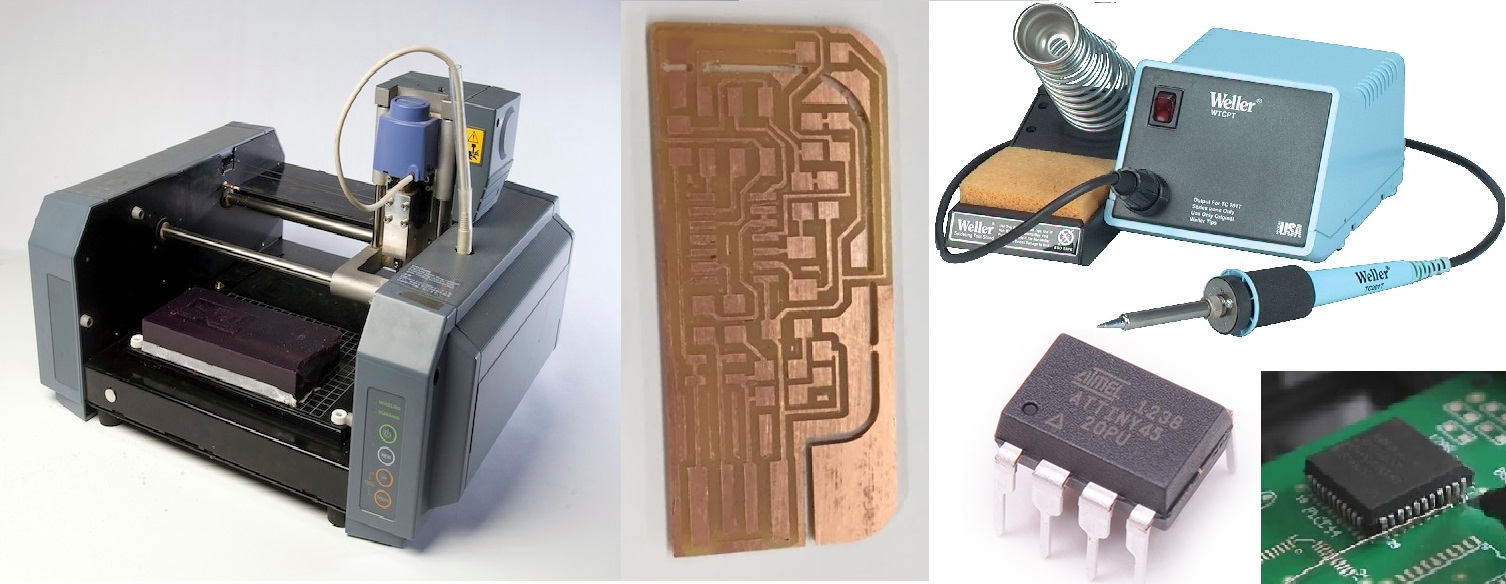

Our week 3 task was to mill the microcontroller programmer board provided to us and surface mount soder on the required componenets. I decided to make one slight modificaiton to mine and add a power indicator LED.

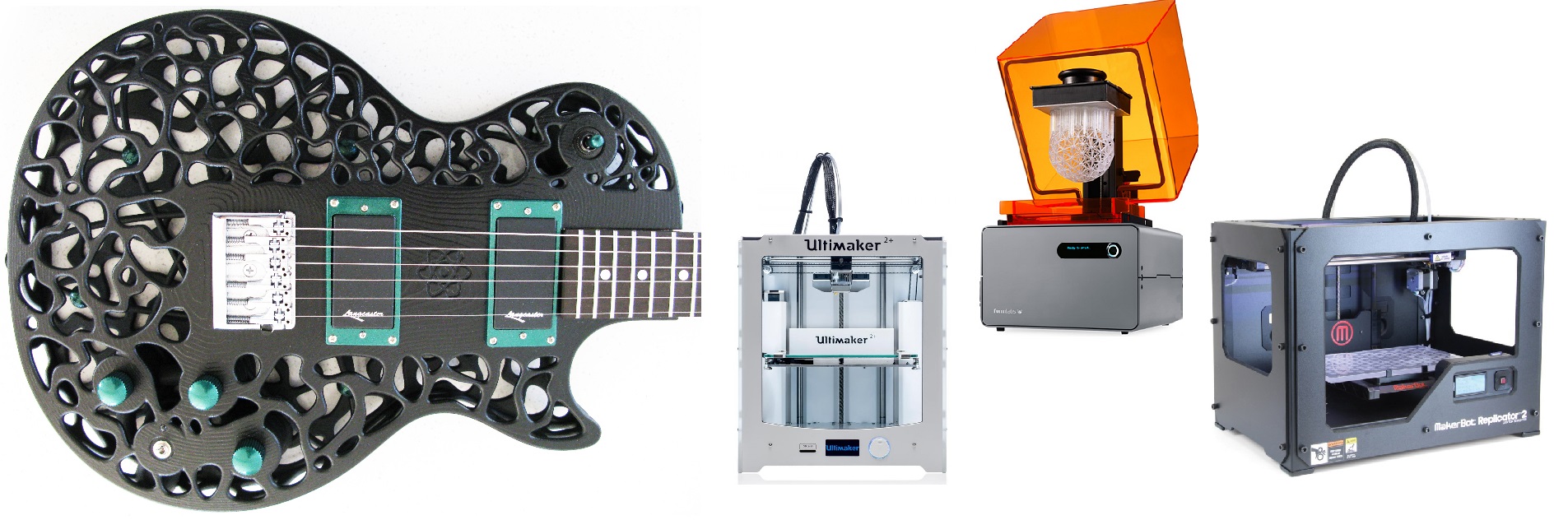

Our week 4 task was to make a design that can't be easily cut and print it on the 3D printers and to do some simple 3D scanning. I decided to make myself a new toothbrush holder.

Our week 5 task was to add at least a button and LED to the hello world board. I decided to add two LEDs and a button and then time permitting try to write code to have it count mod 4 with the button presses and the lights!

Our week 6 task was to "make something big" we were provided with a 4x8 sheet of Oriented strand board (OSB) with which to work from and I used it to prototype a puzzle piece coffee table.

Our week 7 task was to program our boards from Week 5 so I went about making the binary counter work!

Our week 8 task was to create a positive mold in machineable wax then a negative mold in oomoo and then cast our object. I decided to make a small penguin because of an inside joke with my fiance.

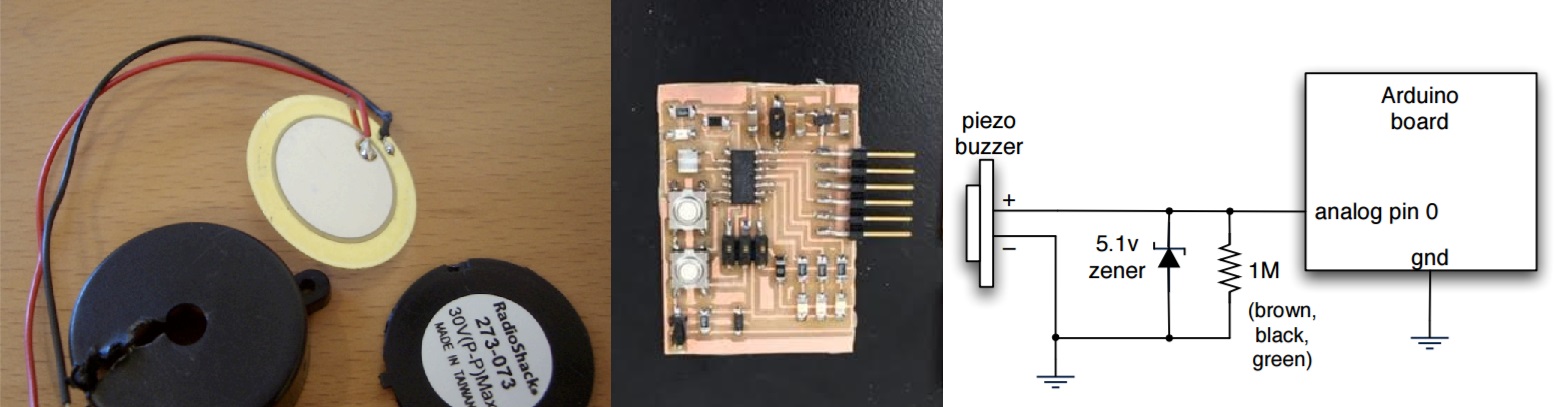

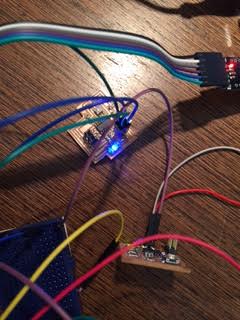

Our week 9 task was use a new input device on our boards. I decided to use the piezo as an input and keep working with buttons and LEDs.

Our week 10 taks was to make burlap composite using foam as either the core or the mold. I decided to make a tennis racket!

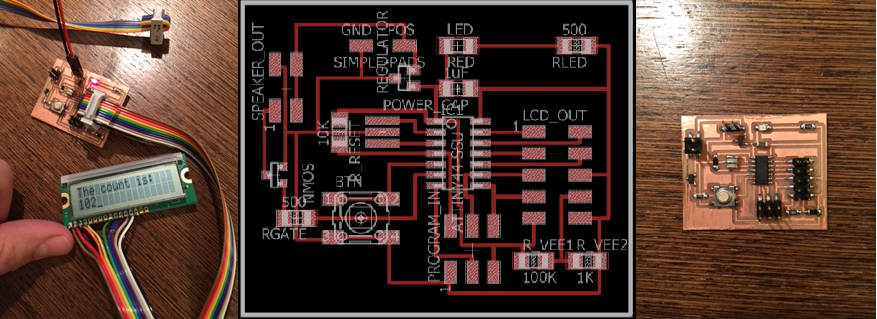

Our week 11 taks was to make a board that uses an output device. On the way to my new final project design I decided to build a board to output to an LED and to a speaker with a button as an input!

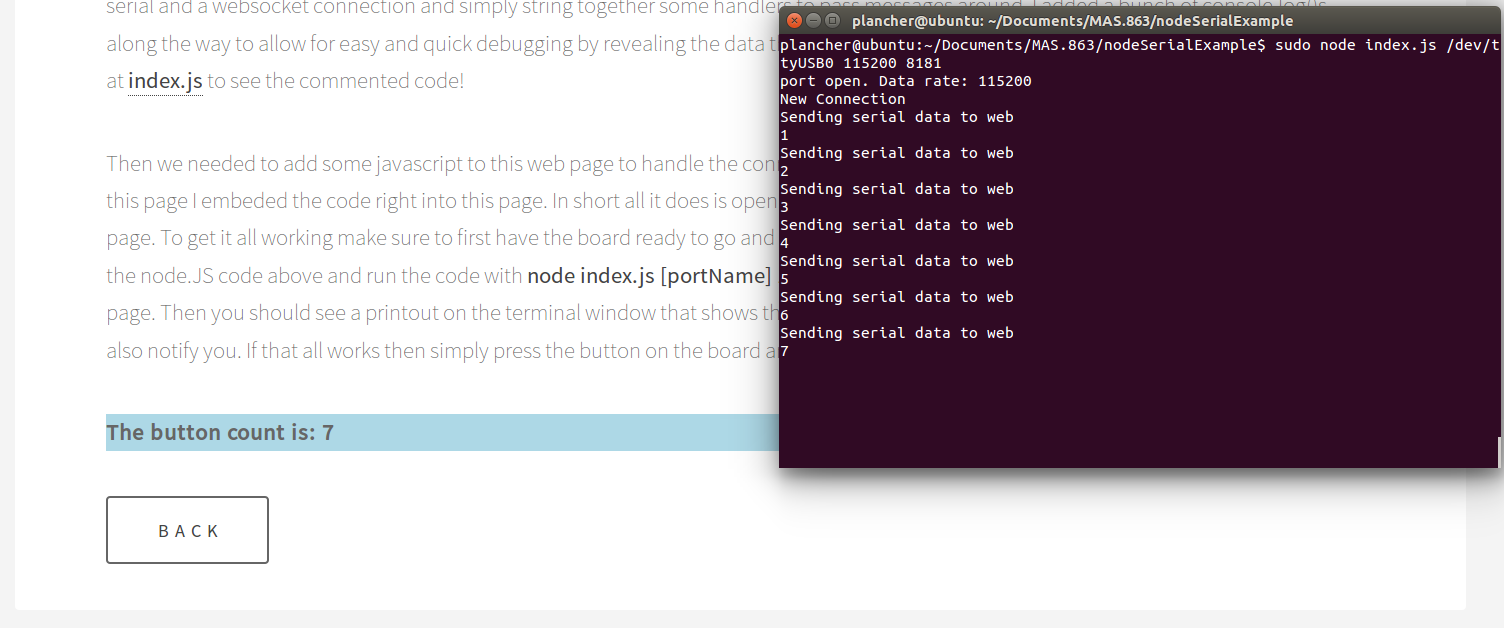

Our week 12 taks was to interface one of our input or output boards to the computer and display data. I decided to do button counts over serial to node.JS!

Our week 13 taks was to network between devices. I decided to practice for my final project and talk between Attiny44s in serial.