HOW TO MAKE (ALMOST) ANYTHING

Lily Gabaree

Composites

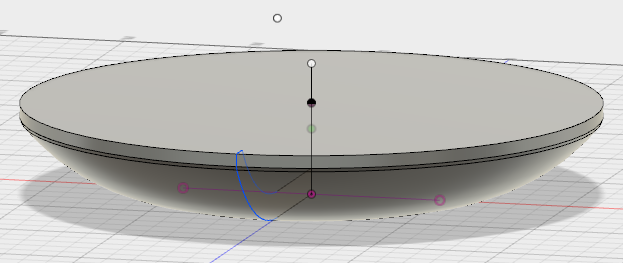

My final project requires a vessel/bowl of some sort, so I’ve decided to try making bowls this week. It seems like burlap is pretty tricky to work with, and that complex geometries don’t always come out too well, so I’m keeping the design really simple. I realized that I really only need one side of the bowl milled out, so I made the whole thing into a closed shape and exported it from Fusion as an STL file.

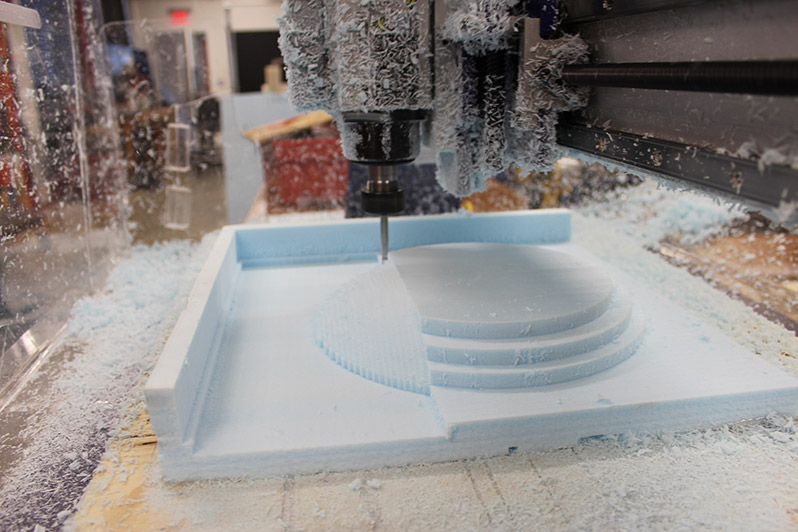

I imported the file into VCarve, identified my material size and thickness (13 inches square, and 2 inches thick), and created a roughing toolpath, along with two finishing toolpaths (one offset, and one raster), just to see what the simulated results would be. I decided to stick with the roughing toolcut, followed by the raster finishing cut. To prep the foam, I cut out a 13x13 inch piece from a sheet with a knife, and then hot glued it to the bed of the Desktop ShopBot. I’m using a ¼ upcut bit.

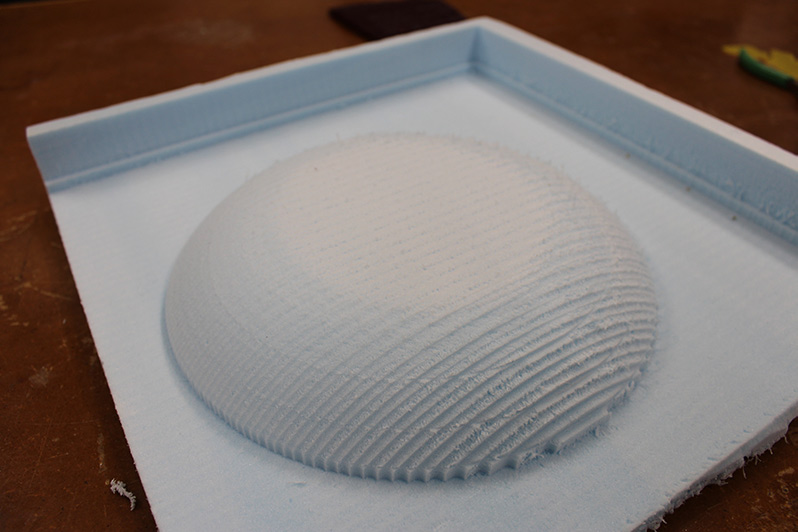

The mold came out well - in retrospect, maybe I should have milled an even larger area, so I could make bowls with more extended brims.

Once I had my mold, I applied the following layers: two layers of plastic wrap release; one layer of resin-soaked burlap; one “bleeder” (plastic wrap with holes); two layers of foam “breather”; and another layer of plastic wrap to hold it all together.

Then I sealed it in a bag, and Rob showed me how to vacuum-pack the mold. I left it to dry for 24 hours.

When it was cured, I trimmed the edges down with scissors. I think it turned out pretty well! One of the nice things about the burlap is the loose weave seems to have allowed it to stretch into the shape; there aren’t really any creases or folds. I like the single layer of burlap - it looks pretty and clean - but the loose weave also means that there are a few places where the seal isn’t watertight, so this won’t work as the vessel in my project. For now it is coming in handy as a storage container for some of my final project parts.

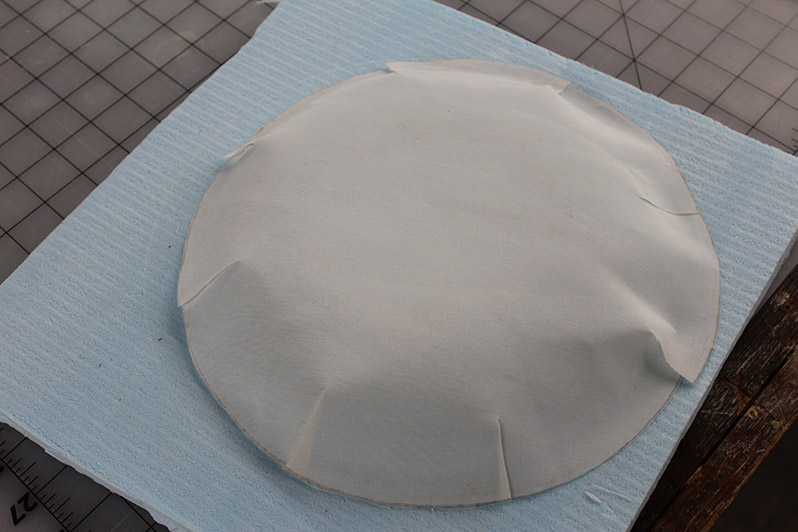

I was feeling encouraged, so I decided to try to make a watertight - but still thin - bowl with a tighter weave (cotton). The cotton isn’t as forgiving as the burlap, so I cut some darts in the piece to allow the fabric to sit without creasing.

At this point, I was having a hard time finding a not-leaky bag in the Harvard shop. I thought I’d managed to get one - it held tight initially - but when I came back the next day the bag was really loose, so the shape hadn’t been held well.

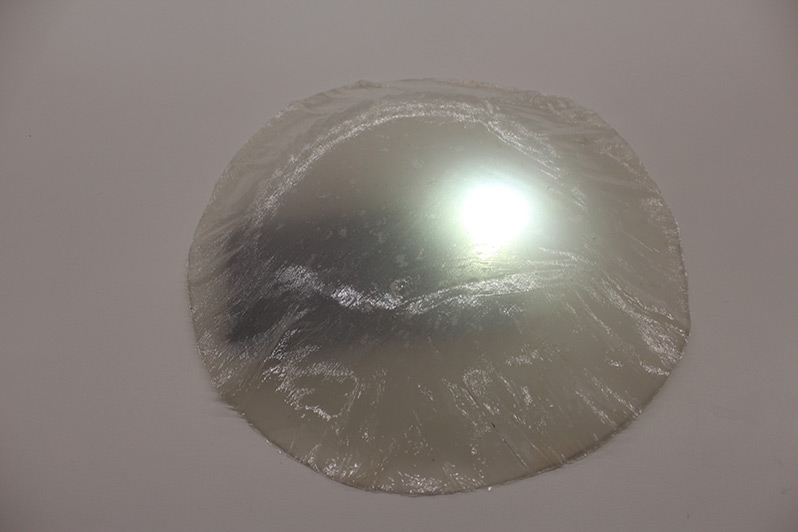

Despite this, the bowl is still an ok receptacle; I like the pellucid look. This fabric might be nice to use in a lamp project.

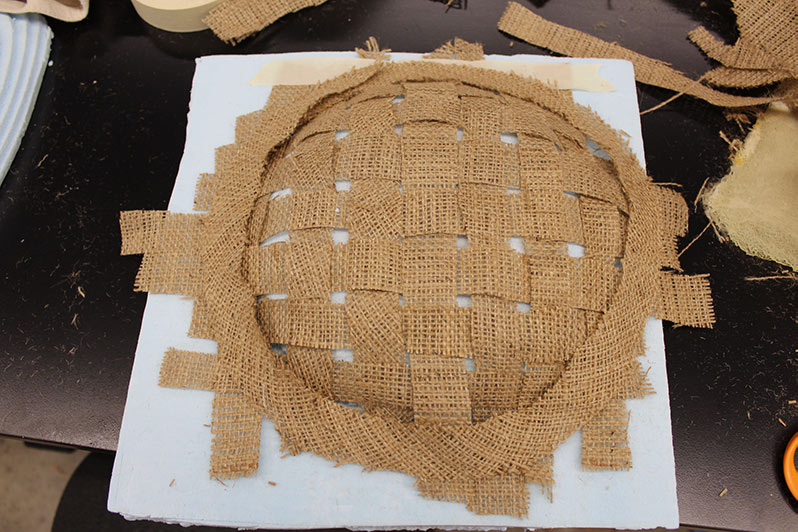

Finally, I wanted to try making something that would be more like a basket, and wove strips of burlap over the mold. I used a different bag, and vacuumed it super tight, and it STILL leaked, so when I came back the shape was not as exact as I’d prefer.