final project

DEFENSIVE HOOD

Concept

As an architect, I think a lot about how people will interact with the things we design but I've never worked at the immeadiate scale of the body. So my only criteria for my final project is that it be specific to the body - either something that is worn by the body or interfaces with the body specifically. I don’t really have experience in fashion design but figured: I also don’t really have experience in programming or electronics design either so why not?

Meejin Yoon's Defense Dress

Meejin Yoon's Defense Dress

Behnaz Farahi "Caress of the Gaze"

Behnaz Farahi "Caress of the Gaze"

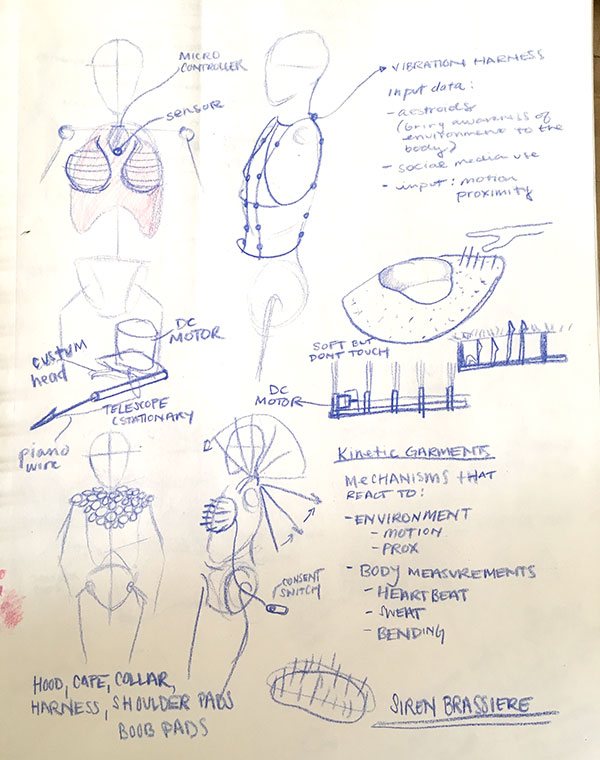

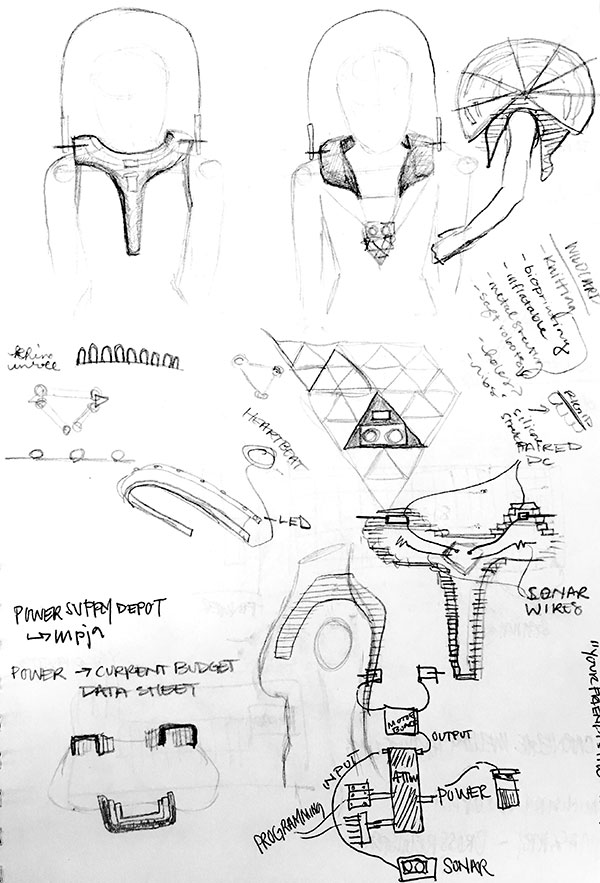

My precedents were projects like Meejin Yoon's Defense Dress and Behnaz Farahi's Caress of the Gaze. The final shape came from a long line of design iterations: I originally thought to make a collar because it required little tailoring. Then I figured shoulder pads took about the same amount of tailoring but even less material. Since by this point, I decided to create a garment that moves when it senses someone nearby. Around this time, there was an ongoing trial in Ireland that infuriated me because it implied that what women wear implies consent about being touched that basically implied the old argument that women are “asking for it” when they wear certain items. Rather than internally screaming, I decided to move the shoulder pads to the breasts – creating a Siren Brassiere, that looks soft but you’ll regret touching.

Design

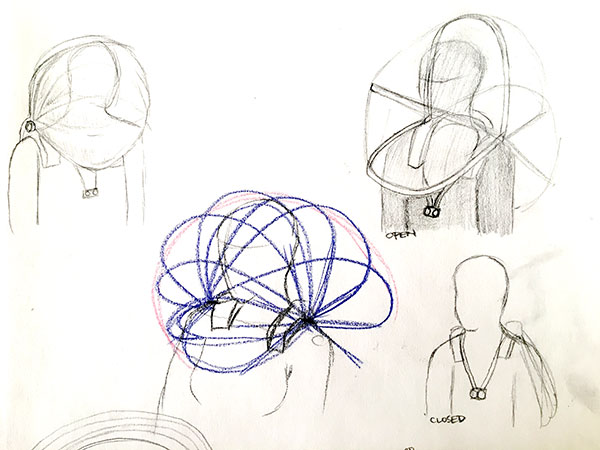

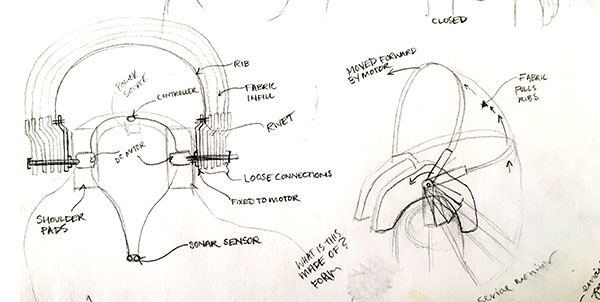

I finally decided to make some kind of privacy hood similar to projects like Meejin Yoon’s Defensible Dress. While I was researching I found a project by Li Zheng that was doing exactly what I wanted to do. I referenced her project frequently as I tried to design a structure for this thing.

Electronics

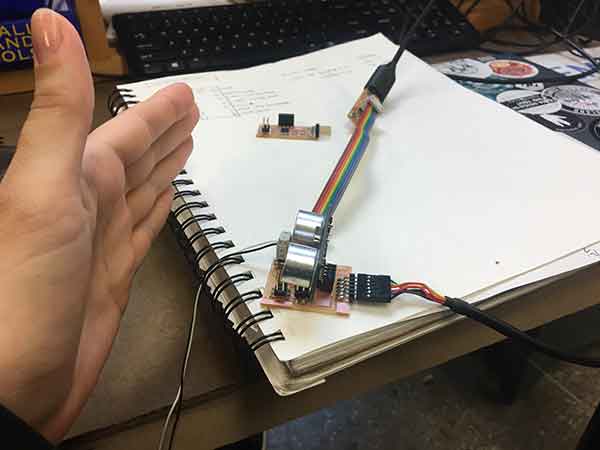

I tried to keep the electronics in my projects simple but they still gave me a lot of trouble. I worked my way through every type of motor (which I have backlogged in Week 09) before finding one that worked for me. Originally I thought to use two DC motors (I can’t even remember why at this point) but killed that for two reasons: 1. I couldn’t figure out how to talk to both motors simultaneously and I didn’t want one motor to be slightly off and 2. I needed to find a motor that could move to a certain a certain location and back. I was choosing between a stepper and servo.

My original design used a stepper motor which I used because it had a higher torque rating than a servo and I was very afraid of the hood being too heavy and breaking the motor. I got the stepper motor working fine but because I didn't know how to map it to the Sonar. With a servo motor I would remap a range so that when the Sonar is between (0, 45) then the servo motor would be in a position between (0, 180) like this:

#include

int sensorpin = 0;

int servoPin = 11;

int pos = 0;

void setup()

{

Serial.begin(9600);

servo.attach(11);

}

void loop()

{

Serial.print("Cell = ");

Serial.println(analogRead(photocellPin)); // the raw analog reading

pos = analogRead(photocellPin);

pos = constrain (pos, 350, 800);

int servoPos = map(pos, 350, 800, 255, 0);

int servoDegree = map(servoPos, 255, 0, 0, 179);

servo.write(servoDegree);

Serial.print("Servo Degree = ");

Serial.println(servoDegree);

delay(50);

} But this code didn't work for reasons I'll go into later. Essentially I realized: Stepper motors work differently. They only know a number of steps to take but aren't aware of their position. Furthermore, I wasn't sure how to write something so that the motor would know when something was moving closer rather than further away. I made a last second decision to switch to servo motos because I’ve previously used potentiometers to remap servos with four lines of code. But that, of course, requires the Servo Library to work. Which is didn’t. Because nothing works the first time. Bust more on that later.

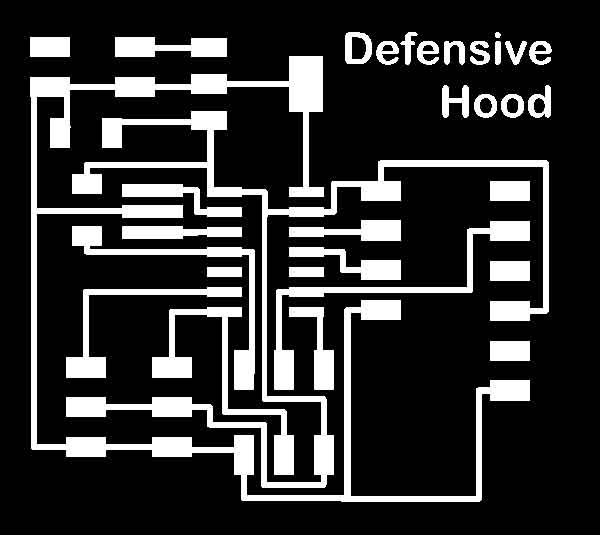

Board Design

My board was a combination of the hello.Servo boards and hello.Sonar board – I kept the FTDI connection on there because even though I wouldn’t need it for the final, I wanted to be able to use the serial connection to trouble shoot. When I had planned to use my stepper motor, I needed a 9V battery because the H Bridge could only work between 8V-40V. I decided to still use the 9V battery as a power source. The battery I bought came with a case with an on/off switch. I probably could have made a case but in this case I didn’t (pun intended).

Integration

![]()

Final Thoughts

What does it do?

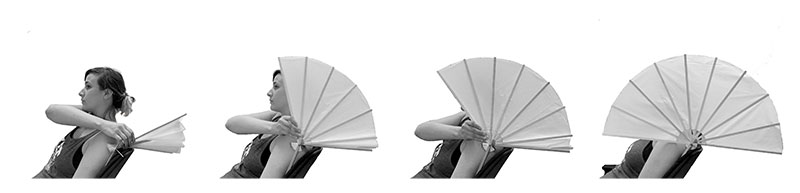

Defensible Hood senses if objects are nearby and pops open a hood to cover the face of the wearing, preventing eye contact. (While the project currently does both of these actions, they are unfortunately uncorrelated at this time)

What did you design?

I designed a board that would read a sonar sensor and move a servo motor. I then integrated it into two “shoulder pads” which were connected to a fan-like mechanism which was covered in fabric.

Materials Used:

Masonite

Acrylic

Polycarbonate

Ripstop Nylon

Acrylic Rod

Milled Copper board

Connection Wires

ATTiny 84

Sonar Sensor

Servo Motor

9V battery

Battery Holder with Switch

Resistor

Capacitor

Pin Connections

Methods Used:

Lasercutting

Sewing

PCB Milling

Soldering

Arduino IDE