Week 10: Mechanical Machine Design

For this week, a group of 16 graduate students from CBA section worked on different sections of machine making such as machine design, fabrication, assembly, electronics and programming. I was a part of electronics team. We did not have a step-by-step guide. Here is the documentation of our group.

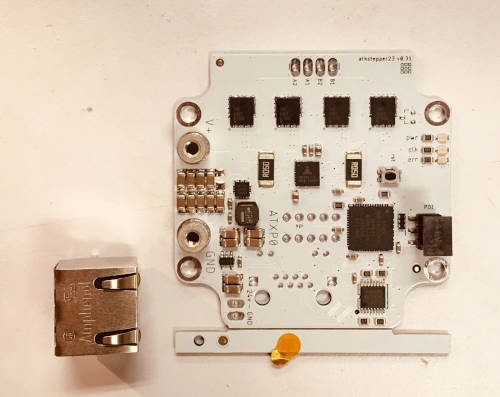

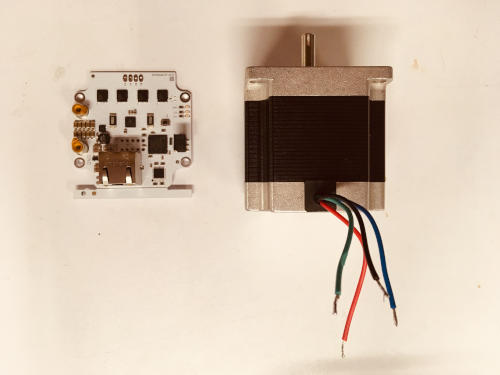

I first started working on the motor driver boards and steppers. I soldered the component and programmed the boards using atmel studio 7 as following.

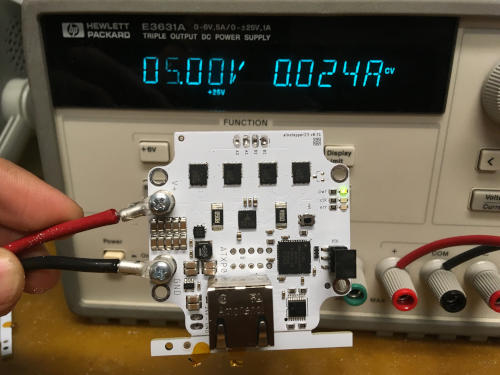

Power check to see if board is drawing any power. I made sure the green LED lights up!

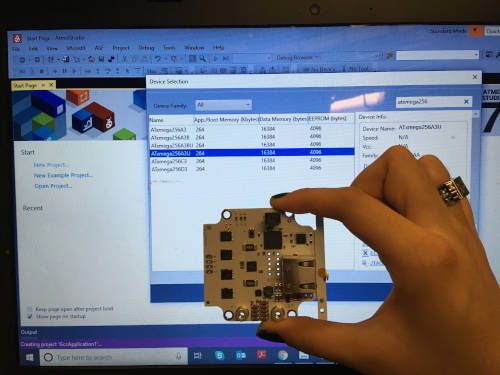

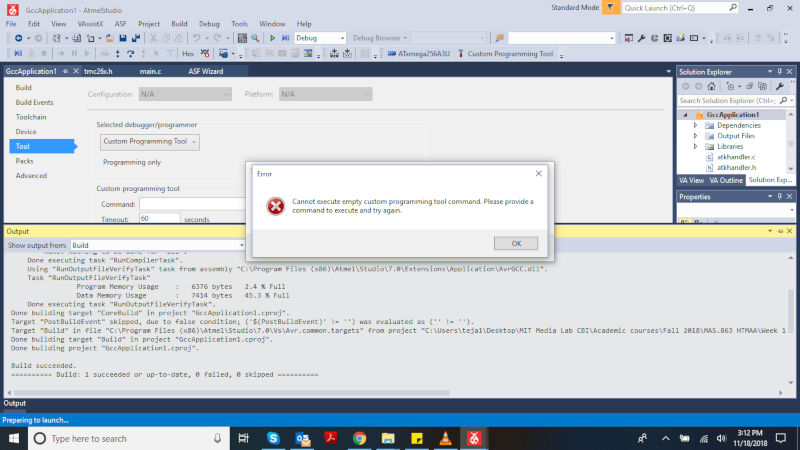

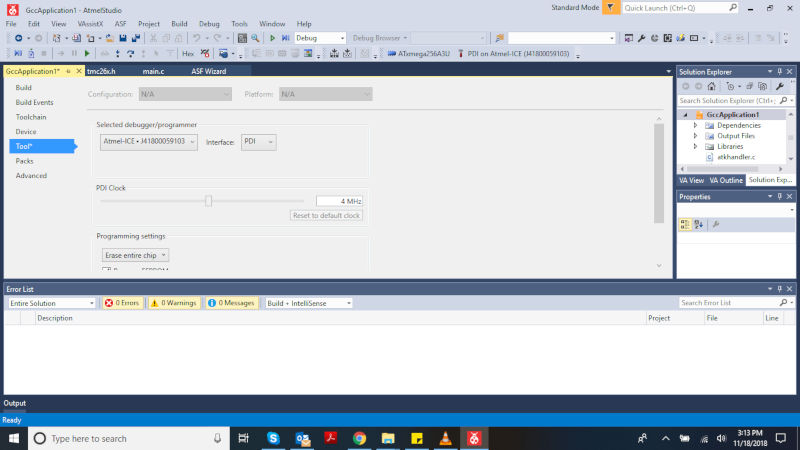

Programming using atmel studio:

Error because of wrong programmer and interface selection

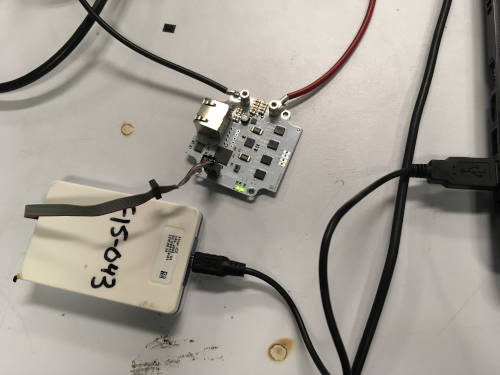

Soldering the driver boards to steppers.

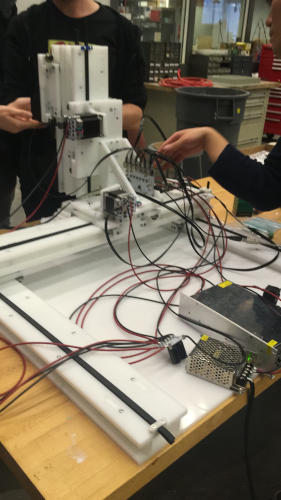

Assembling process:

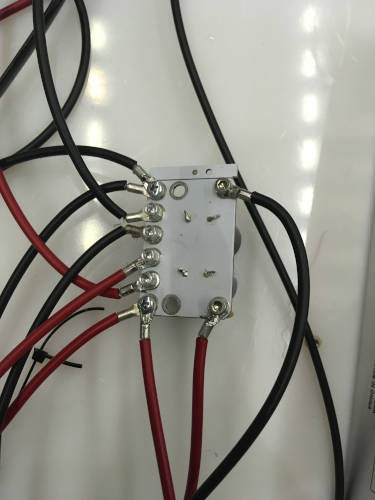

We used a capacitor board to remove fluctuations from 24V power supply. We found out that one of the connections on the capacitor board was not proper. Therefore, one of the steppers didn't work as expected.

After assembling process is done, the machine couldn't life the chocolate extruder part upwards, although it was able to lower the extruder easily. We thought that the extruder is too heavy for the steppers to lift up. We later realized that it was because of the conveyor belt. It wasn't stiff enough to move the extruder upwards. Please refer to the group's documentation on more troubleshooting cases of electronics team.

It works after the belt is set!