[00 Conceptualizing a Project]

Space... the final frontier. Right now I am working on two projects for my Ph.D. The first is working on incorporating thermal control and radiation protection into spacesuits. Thermal control is very important in space becauase 1) its very cold out there and 2) it can get really hot when you're working hard to fight against a highly pressurized space suit! Ok, so the key point is that you need to be able to both heat and cool a spacesuit. The gloves though, in general, just need to be heated (extremities get very cold). But they're tricky, they need to maintain good mobility for all the dextrous work astronauts do. So, how can we make heated gloves that won't hinder the astronaut, will be able to fit inside a spacesuit, and will allow thermal control?

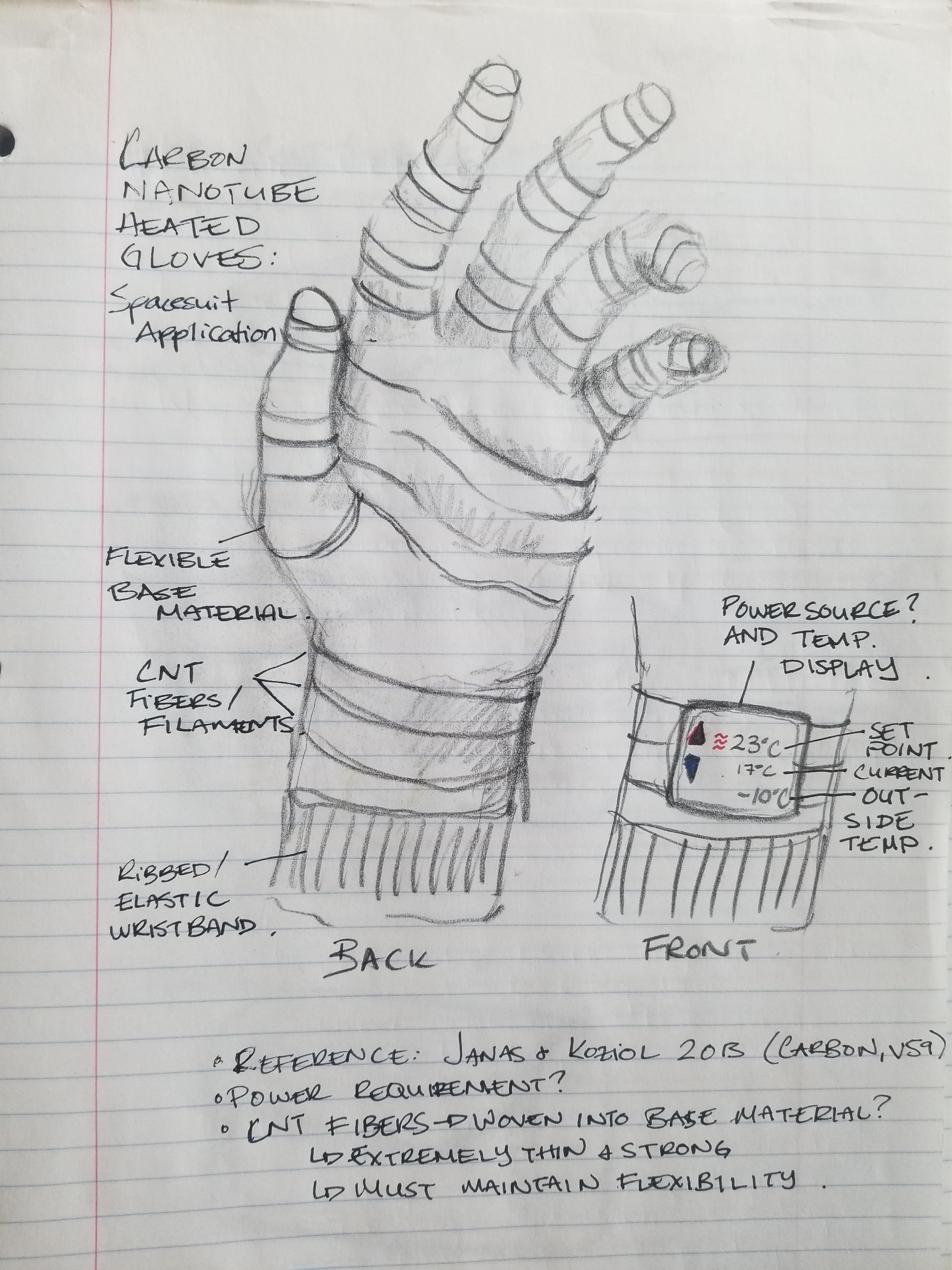

In our first lecture we learned about all of the different maker tools we'll be learning how to use. I have some experience doing CAD modeling, but only with solid parts. Modeling fabrics is a complete mystery to me. I also have no experience with electronics design. So, for my final project, I wanted to draw on these new tools to be able to design a heated glove for spacesuits. I sketched out an idea of what these might look like using some technologies I know already exist that are lightweight, strong and flexible.

The Design

I would like to design a glove with integrated carbon nanotube filaments. I will run a current through these filaments to have them act as heaters. Ideally I would like to use a specialized polyethylene fiber that would help to even out the heating over the hand. I will control the heaters using a small display that will allow the user to set the temperature. Now, in reality, this display would be on the outside of the spacesuit so the astronaut would have access to it during extravehicular activity (EVA), but for this class, let's just put it on the wrist to see if we can get this to work!

Why carbon nanotubes?

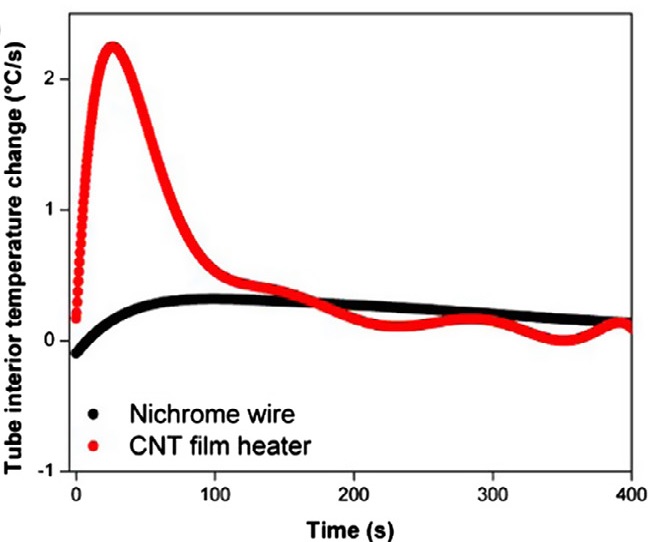

Carbon nanotube thin films are able to provide the capability of introducing active elements into fabrics with benefits over traditional metal wires or strips because of their improved mechanical properties, low density (making them a lightweight option) and better resistance to flex fatigue. Janas and Koziol (Janas and Koziol (2013)) showed that applying a DC bias voltage to CNT sheets turned them into ultra-light film heaters. They demonstrated that CNT film heaters outperformed nichrome, the most commonly used resistive material, providing the same heat capacity in 1 g of CNT film as 120 g of nichrome.

Trying out Fusion 360

All of my previous experience with CAD modelling has been using SolidWorks. Its not a bad program, but it's also not great. I wanted to take this opportunity to learn something new. I chose Fuison 360 mainly because it has a timeline feature -- it allows you to go back to any step in your design process and make changes from there. For anyone who's done any modelling, you'll know, this is a very attractive feature! Many a time have I had to scrap a design and start from scratch because I messed up something early on.

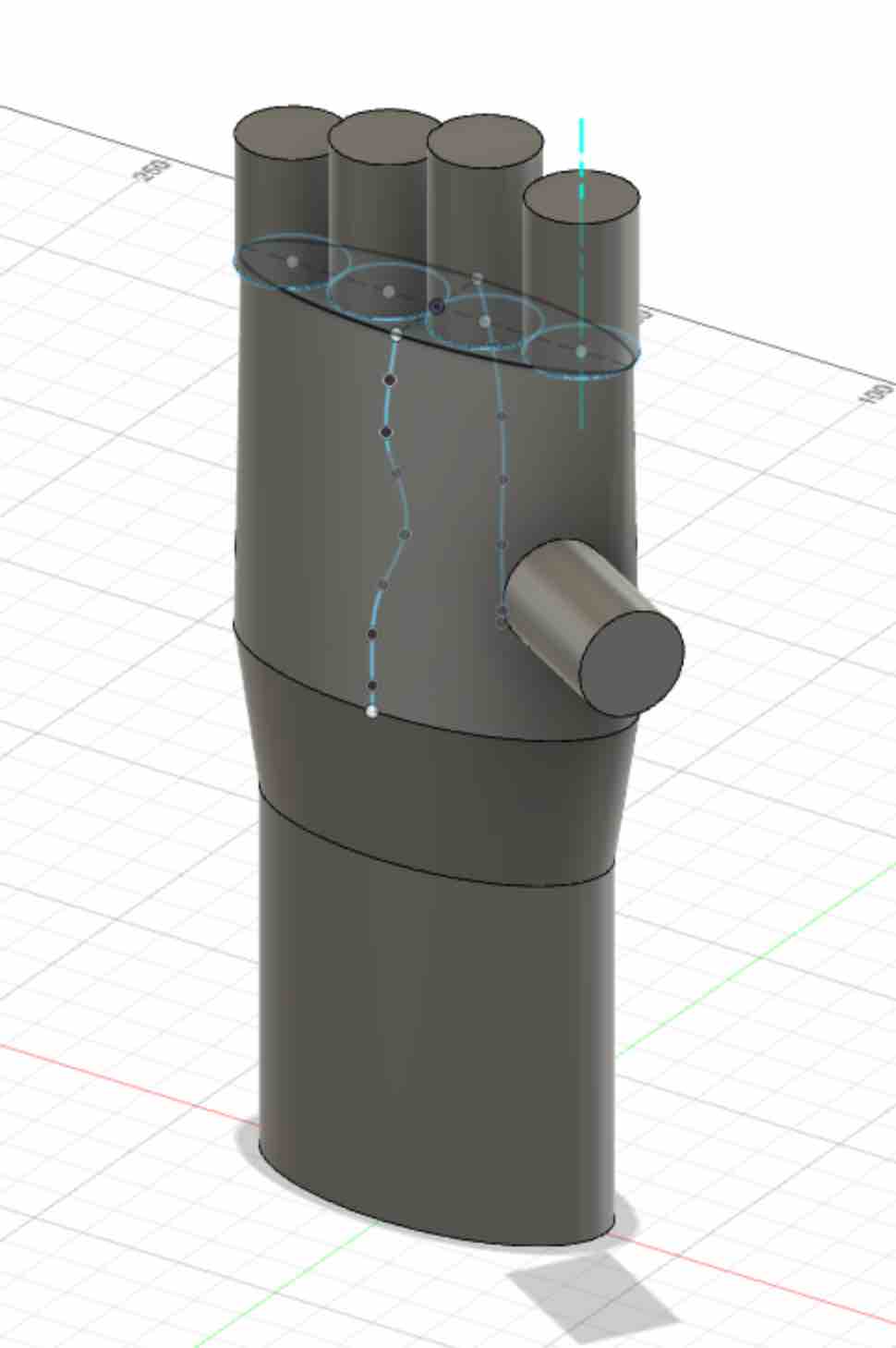

While Fusion 360 is relatively intuitive, and there are tons of youtube videos out there to get you started, it turns out making a 3D model of a hand is actually a very difficult thing. Here's where I got with my first try:

I've got a long way to go, but had to start somewhere! For the rest of my journey on designing gloves for spacesuits....check out my final project page