Goal#

Make a press-fit construction using the laser cutter, make anything using the vinyl cutter.

Results#

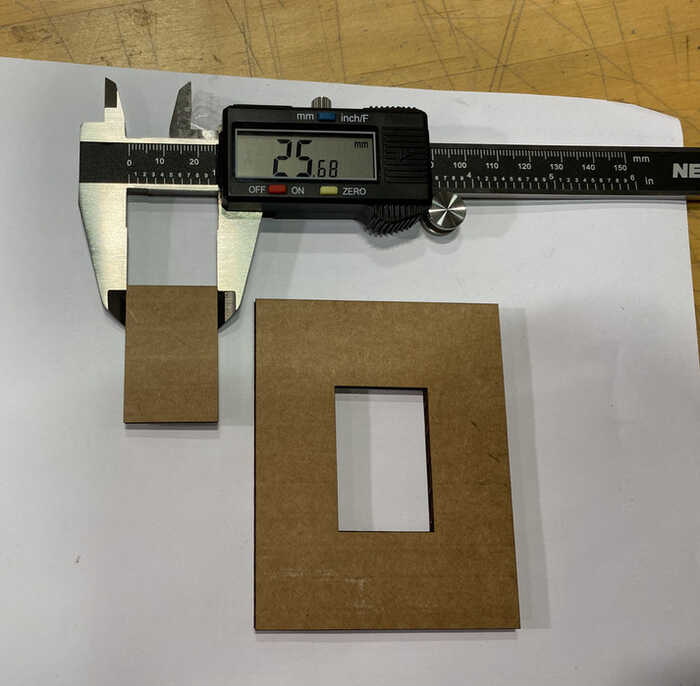

This project started by measuring the laser cutter's kerf with my training group. I had the idea to cut a rectangle with a smaller rectangle inside it. Then, we could measure the gap in the larger rectangle, measure the smaller rectange in the same dimenions, subtract those dimensions, and divide by 2 to get the kerf.

I wanted to make something that I would be proud to display in my home. I looked around on pinterest until I found this style of press-fit lampshades and decided that's what I would make.

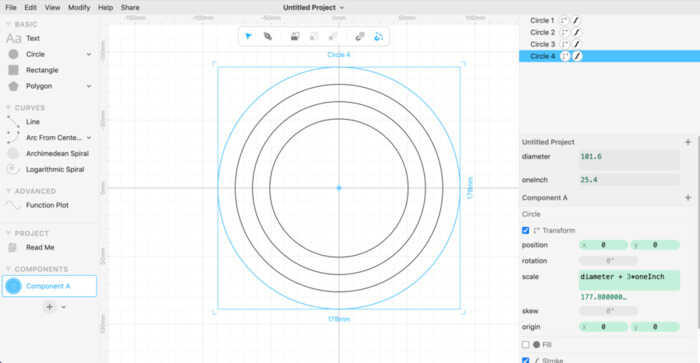

I also decided I would use Cuttle because it's designed for use with laser and vinyl cutters, seemed simple yet powerful, and is made by old acquaintances I wanted an opportunity to reconnect with. I started making these concentric circles almost absent-mindedly since I hadn't settled on a design yet and that's when I got the idea for my design.

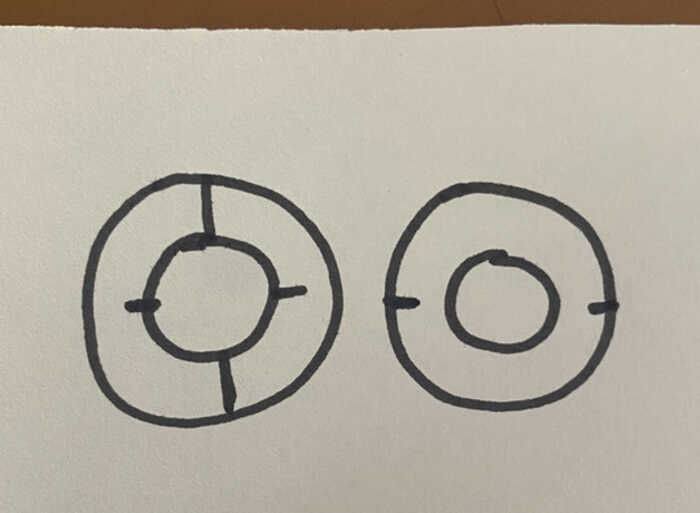

I decided to make a sphere whose structure would be various vertical and horizontal planes. I wanted to test my intuition that as long as I placed the slots at the same heights, I could make the vertical and horizontal circles have the same diameters and it would all fit together. So I made a small paper prototype. In hindsight, this prototype was too far removed from my actual design idea. If I had made it a little more robust by making it bigger and adding more slots, I would have caught my second design mistake earlier.

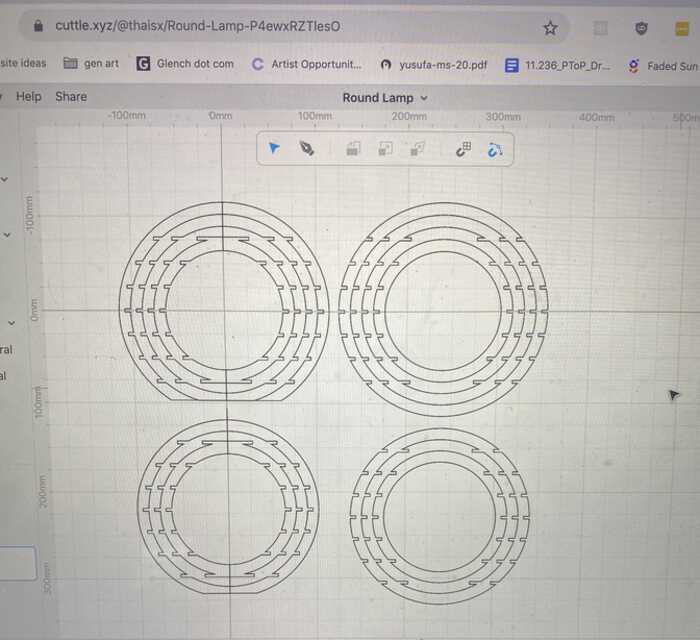

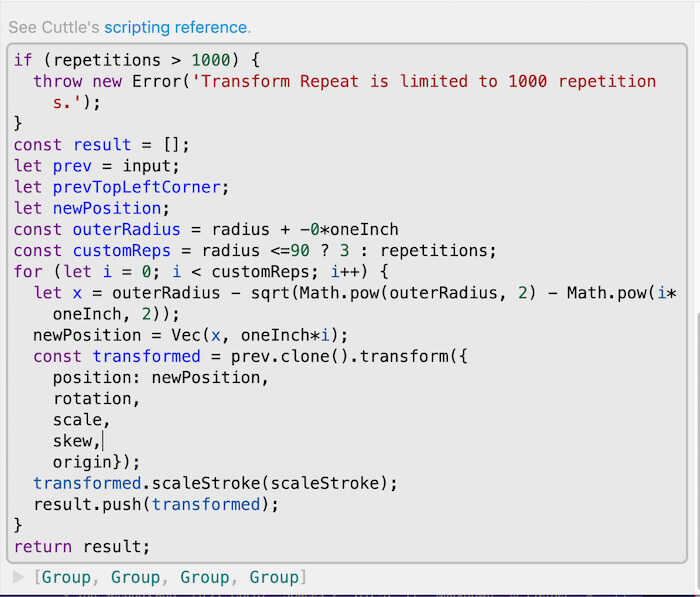

So I got to designing my lampshade in Cuttle. At first, I manually placed all the slots on one quadrant of each ring, then used Mirror Modifiers to complete the slots on the ring. This took a lot of time however so by my third design iteration I wrote a custom modifier in Javascript to place the slots. This is one of the things I really liked about Cuttle because Javascript is familiar to me.

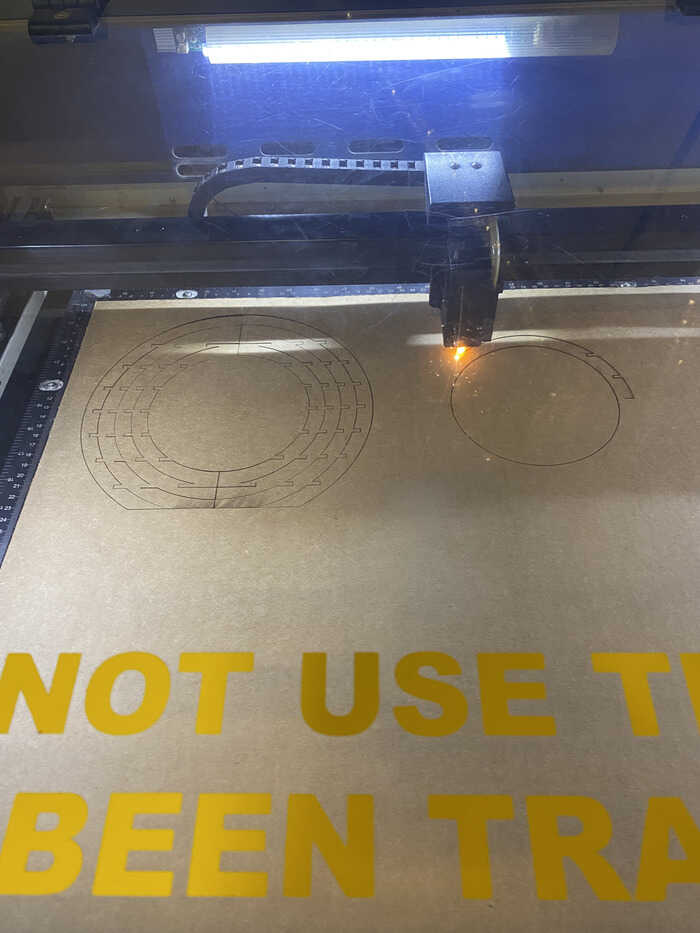

When I finished my design and showed up for my laser cutting slot, I asked the person before me what number they used for their cardboard thickness because I kept getting between 4 - 4.3 mm depending on where I measured my board. They said 4.1 and that's what I put into my program. HUGE MISTAKE!!! For my first print, the slots didn't fit at all... So I edited my cardboard parameter and also decided to print some test slots on the sheet I would be using before cutting the whole thing.

After confirming that 4.2 mm was a better fit than 4.3 mm, I changed the parameter in my design and sent it off to the laser cutter.

Assembling seemed to be going well until I got to the horizontal rings other than the middle one. They were too short! Something about my ring diameter intuition had been off.

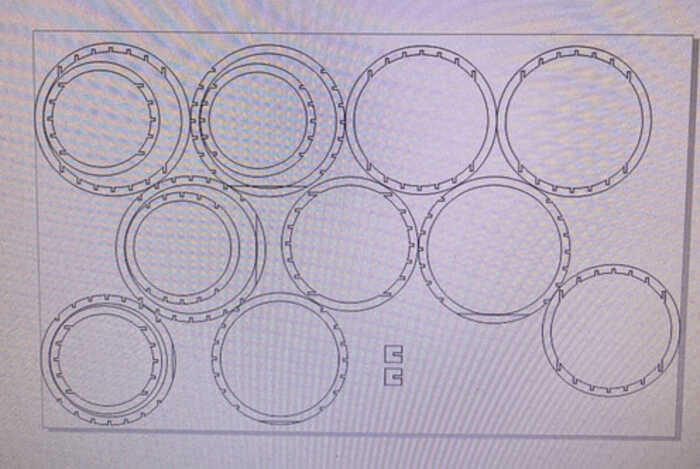

After playing with my failed prototype a bit and doing some back-of-the-napkin math, I realized that my mistake was making the circles concentric. I had thought this was a good idea to save cardboard, but what I ended up doing was changing the diameters linearly instead of according to the arc on the sphere. After calculating what my chord lengths should actually be, I redid my design (and this is when I parametrized the slot placement). I ended up using Deepnest to place my rings and was pleased that it all still fit on one sheet.

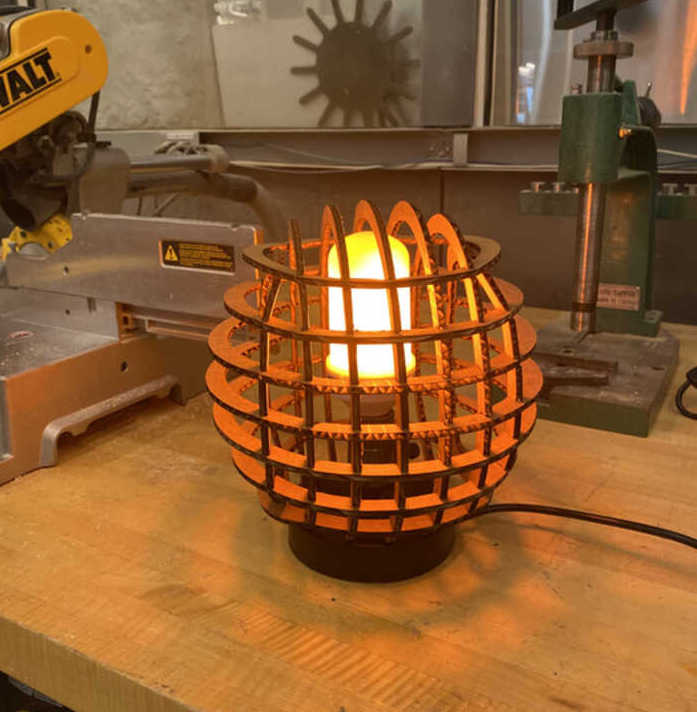

Finally, third time's the charm:

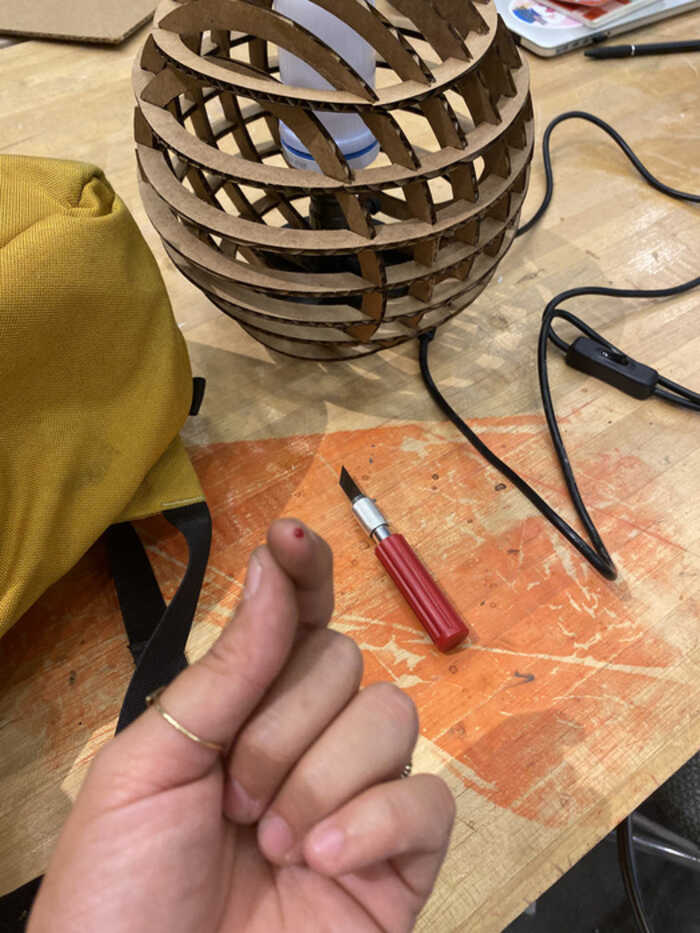

I still made a small mistake which was that after changing my ring diameters, I did not check whether the smallest circles now needed slots (and they did, but barely). You can see that the smallest circles are a bit bent. I tried to fix it with an exacto knife because I didn't want to hog the laser cutter but that quickly went sideways and I decided I was done.

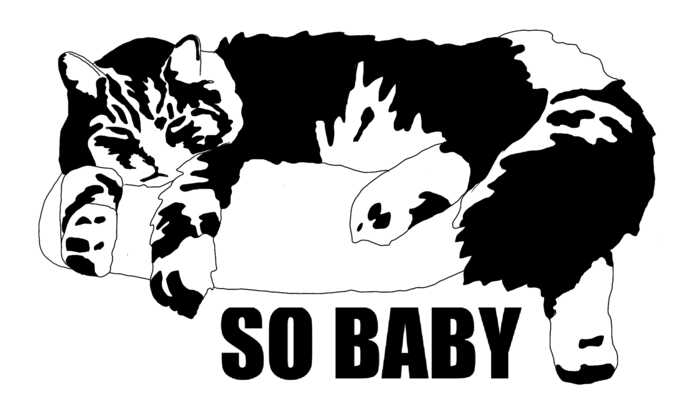

As for my vinyl cutting project, I wanted to make a gift for my partner who loves their cat echo.

I took that photo of him and traced it over in Procreate.

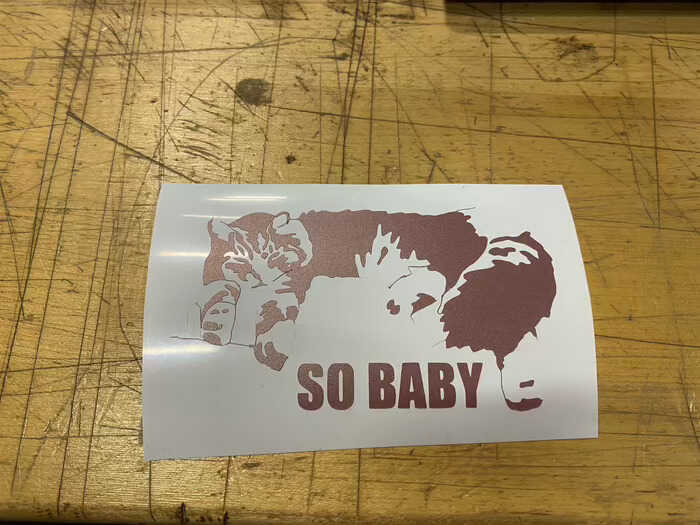

And here was my sticker result:

Definitely made some lines way too thin, or maybe they would've worked if I'd made it a bigger sticker.