Goal#

Mill Neil's design of the D11C Serial Programmer

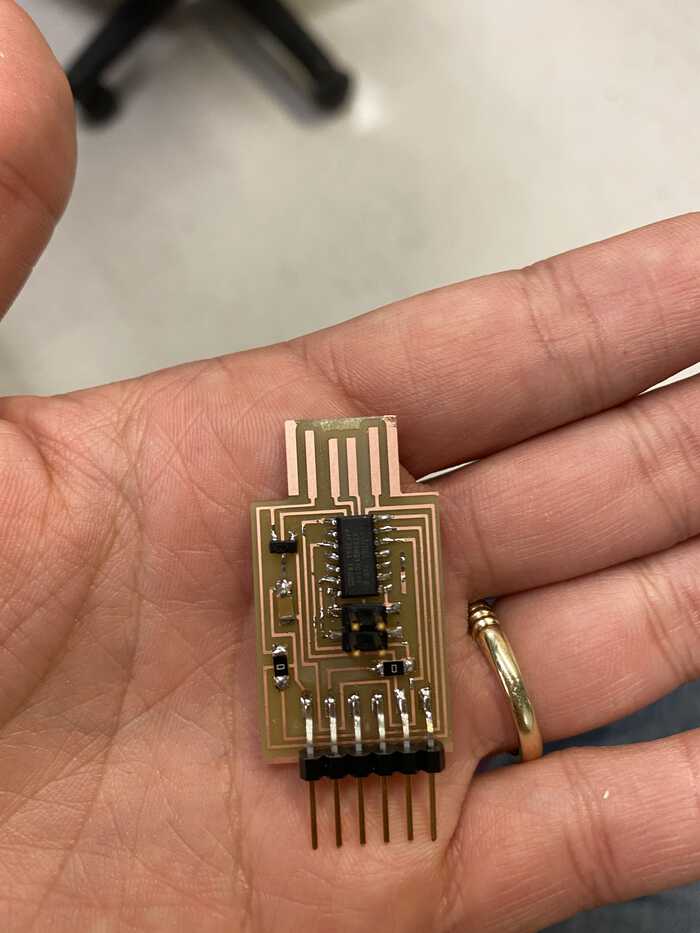

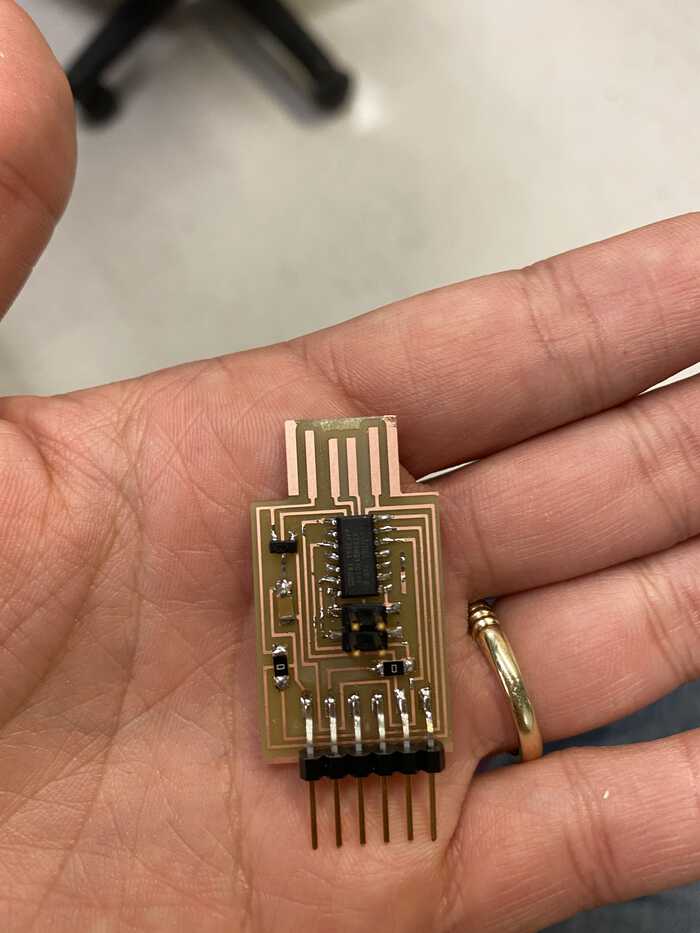

Result:#

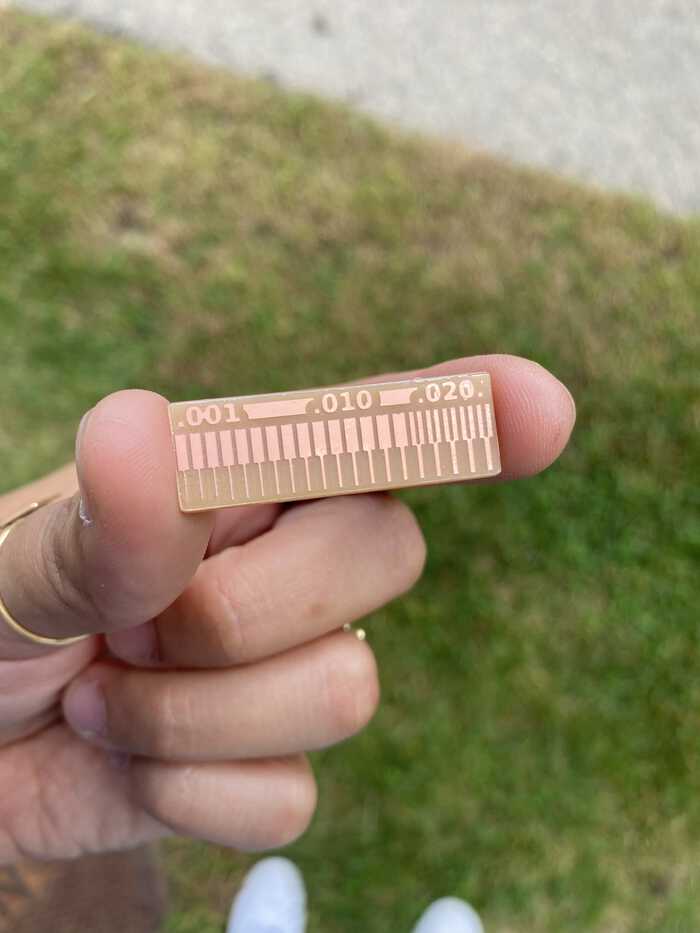

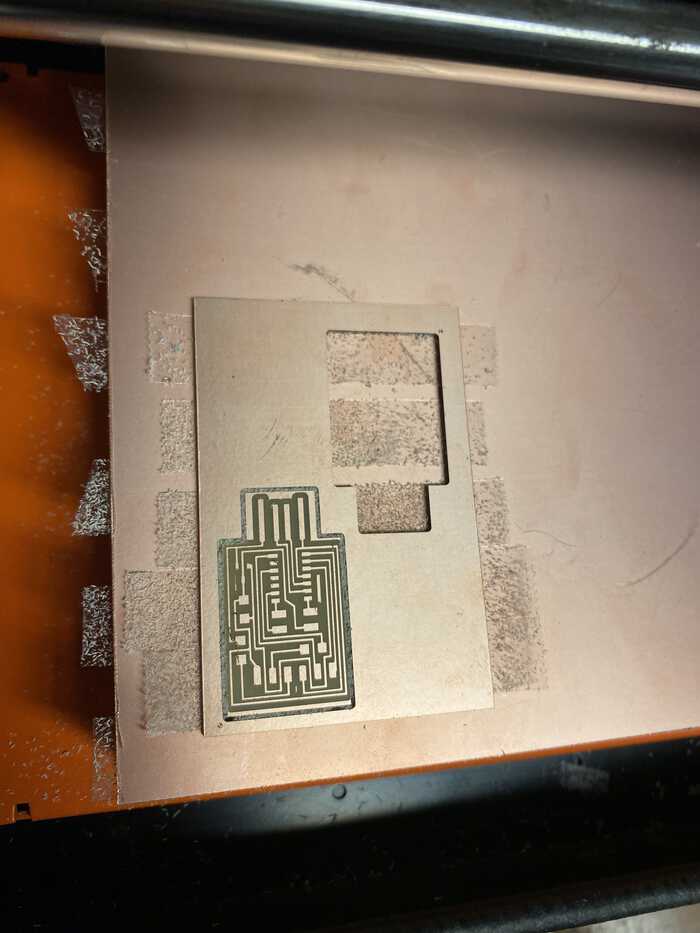

I was glad to have a more straightforward project this week. It started with testing how thin the traces and the spaces between the traces could be with the 1/64 endmill. I was surprised that the whole thing basically came out clean! But I don't think I can rely on always getting such clean tiny traces.

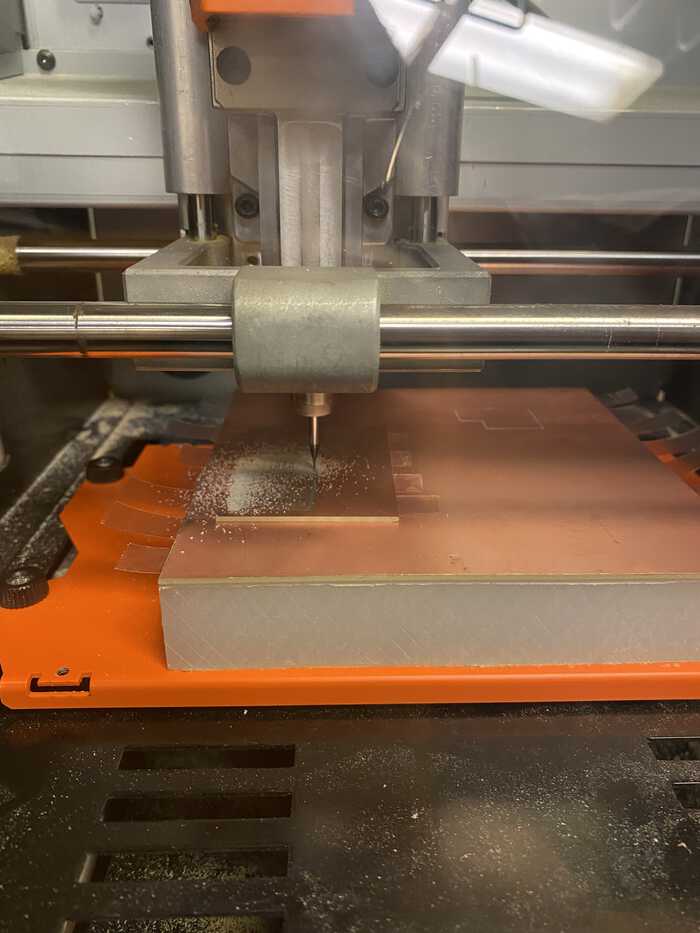

I came into the lab on Sunday feeling confident in my ability to mill the board. It all went smoothly EXCEPT... I forgot to switch from milling traces to milling outlines during cutting phase 🤦. And I didn't notice until I had already pried the board off. I did try to manually realign my board and try again but I was off by 1 mm and it cut off one of the traces.

Joanne had a meeting coming up soon so we tried to combine two images of the traces and interiors so we could mill two boards at the same time. It almost worked but we couldn't figure out how to export from Inkscape with 1000 DPI without changing the image dimensions. But regardless, it seemed there was something wrong with the bed so the first board we tried to mill didn't work. Only the bottom 10% of it was milled.

I came back on Monday morning and thankfully this time everything worked perfectly! I even was able to mill an extra board on the same small FR1.

When I sat down to solder and saw just how tiny the components were, I thought "I don't know how I'm going to be able to do this. I can barely see the pieces!". I also have quite unsteady hands, poor focus, and I'm clumsy. So I really thought I was not going to be able to solder. Zach was an immense help, bless his heart for running the soldering workshops.

The final result is decent! My joinst are shiny, some smoother than others, and I left a bit of mess. But I think it'll work!