| |

|

| |

|

|

|

|

|

|

|

|

|

|

|

| |

HOW TO MAKE (ALMOST) ANYTHING MAS.863.12 |

|

|

|

|

|

PROJECTS |

ABOUT |

CONTACT |

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

| |

| |

|

|

|

|

|

|

|

|

|

| |

|

|

| |

|

|

| |

|

|

|

|

| PRESS-FIT CONSTRUCTION KIT - week2 |

|

|

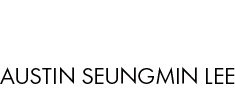

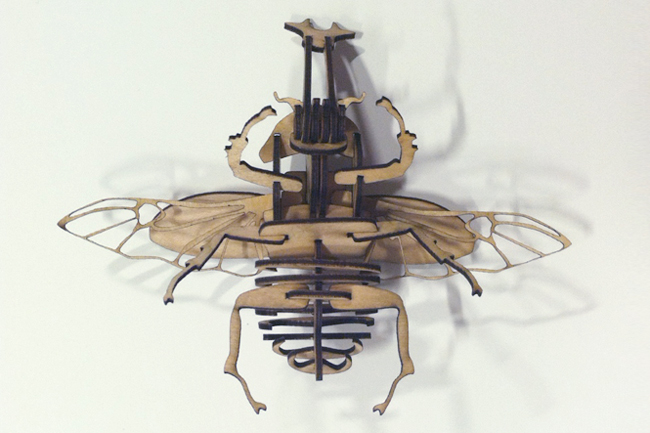

| This week we learned computer-controlled cutting. The goal was to design and create a press-fit construction kit using either laser cutter or vinyl cutter. Initially, my idea was to create a construction kit with the form factor of many different kinds of insects' body parts. The design of the construction kit would allow builders to create hybrid insects, biomorphic architectural models, and visually explore biologically inspired compositions. My first step was to study the structure of an insect. Inspired by woodcraft construction models, I decided to create a custom beetle model using the laser cutter. |

|

|

| |

|

|

|

|

| |

|

|

|

|

|

|

| |

|

|

|

|

| Design Process |

|

|

| For my model, I chose Northeast Asia's rhinoceros beetle. First, I sketched a rough design based on photo images. Later, I created vector illustrations that would be imported to Mac V5 Rhino Work in Progress for OS X Lion(10.7) or later (currently, the Rhino OS X is free for user testing purpose). After extruding the curves, I virtually constructed my custom model and refined the design. Using boolean tool I was able to generate marks on the joining parts. I extracted the curves and brought it to my original illustration file for the final clean-up before the laser cutting. |

| |

|

|

|

|

| |

|

|

|

|

|

|

| |

|

|

|

|

| Result |

|

| After several attempts, I was able to get the size of the joint gaps correctly. One trick that helped was to have a different layer for the curves that created the gaps. In Adobe illustrator, I basically created small rectangles for the joining parts so that I could instantly change the stroke size to get different thickness. The following image is the finished version of the custom insect construction kit. After getting feedback from a friend from previous How To Make class, I thought it would be interesting to use these parts to build a custom cardboard furniture. (HR Giger's aesthetics + Frank O. Gehry's cardboard furniture) Maybe I will try it out later this semester if I find time. By the way, if you want to build this model, I can share you my final png image that you can use for your own laser cutting. Click Here to download the construction-kit. Enjoy! |

|

| |

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

FINAL PROJECT PROPOSAL.

My ideas for the final project- week1

|

|

PRESS-FIT CONSTRUCTION KIT.

Learn how to make something using vinyl cutter and laser cutter - week2

|

|

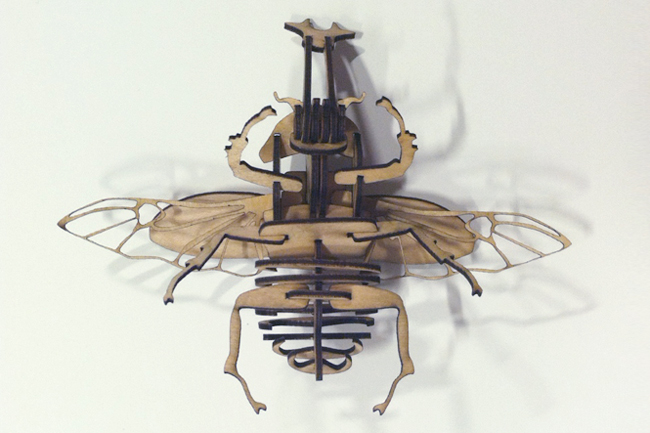

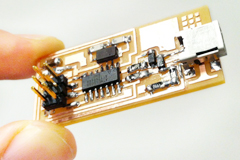

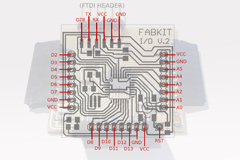

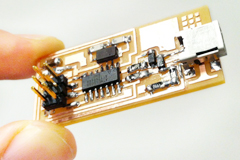

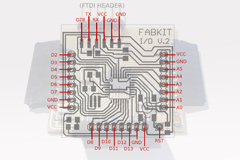

FAB ISP (IN-SYSTEM PROGRAMMER)

Learn how to make a custom PCB - week3 |

| |

|

|

|

|

3D SCANNING AND PRINTING.

Learn how to make 3D printed model - week4 |

|

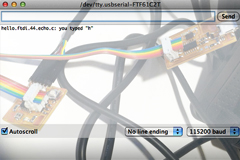

ELECTRONICS DESIGN.

Learn how to redraw the echo hello-world board - week5 |

|

MOLDING AND CASTING.

Learn how to design a 3D mold, machine it, and cast parts from it - week6 |

| |

|

|

|

|

EMBEDDED PROGRAMMING.

Learn how to program a custom board to do something - week7 |

|

MAKE SOMETHING BIG.

Learn how to make SOMETHING BIG through computer-controlled machining- week8 |

|

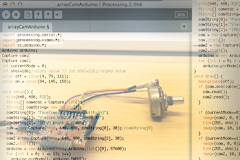

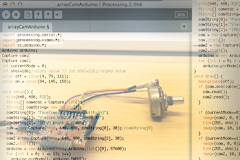

INPUT DEVICES.

Learn how to add sensor to a microcontroller board and read it - week9 |

| |

|

|

|

|

COMPOSITES.

Learn how to assemble a 3D mold, and lay up a fiber composite part in it - week10 |

|

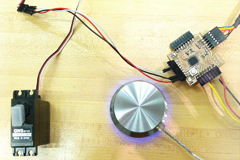

OUTPUT DEVICES.

Learn how to add an output device to a microcontroller board and program it to do something - week11 |

|

INTERFACE AND APPLICATION PROGRAMMING.

Learn how to write an application that interfaces with an input &/or output device - week12 |

| |

|

|

|

|

NETWORKING AND COMMUNICATIONS.

Learn how to build a wired &/or wireless network with at least two nodes - week13 |

|

MECHANICAL/MACHINE DESIGN.

Learn how to design or modify a machine and automate the machine - week14 |

|

FINAL PROJECT.

My final project for How To Make (almost) Anything - week15, 16 |

| |

|

|

|

|

MAS.863

Learn about the How To Make (almost) Anything course at MIT |

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

| |

|

Copyright © 2012 by AUSTIN S. LEE |

|

|

| |

|

|

|

|

| |

|

| |

|

|

|